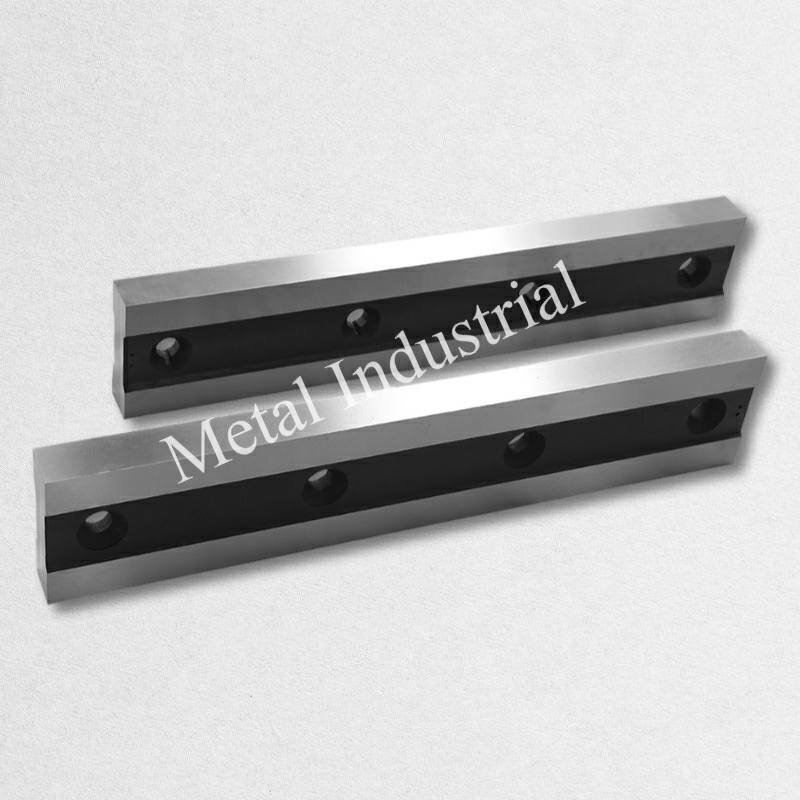

Can shear blades be sharpened again?

You bet! Most shear blades can be sharpened multiple times since they’re made of hardened tool steel.

So, how do we go about resharpening them? Here’s the step-by-step process:

1. First things first

Check the condition of the blades. How dull are they? Any cracks?

2. Sharpen the first surface

Get a grinding machine and touch it gently to the flat surface of the blades. This creates sparks, showing it’s working. If the blade’s temperature goes above 40-50°C while sharpening, take a break and let it cool down. Heat messes with the accuracy, you see.

3. Give it a once-over

Inspect the blades’ edge for any damage that’s still lurking.

4. Give it a wash

Clean off the grinding dust so the blades sit right for the next grind.

5. Sharpen the second surface

Repeat the grinding process to sharpen the second side.

6. Double-check

Make sure there’s no damage left on the edges.

7. Time to turn

Now, we’ll sharpen the actual cutting edge of the shearing blades.

8. Another check

Take a look at how beat up one of the blades’ edges is. Then, bring two blades together for better sharpening. The worn blades can get rusty, so sharpening also helps remove the rust.

9. Sharpen those edges

Grind both blades simultaneously to get those edges nice and sharp.

10. Keep an eye out

Check if the edges are sharp enough.

11. Rotate the blades

Flip the blades for their fourth and final time.

12. The final inspection

Double-check the sharpness once more.

13. Clean up

Blow off any residue from cooling and grinding dust.Now that the sharpening process is done, it’s time to take out the blades and give them a closer look.

14. Take a good look

Check if the blades are parallel and demagnetize them. Pack them up to send to the customer.

15. Protect and pack

Cover the blades with oil and greaseproof papers to prevent corrosion. Place them in a sturdy wooden box for a safe journey. They’re all set to be sent back to the customer.

One Response

I want to visit that exhibition to buy some hardware equipments