شفرات التثقيب المخصصة نساعدك على رسم خطوط أنيقة وسهلة التمزيق. استخدم شفرات مخصصة لتلبية احتياجاتك في مجال التغليف والمنسوجات. كما أنها تُستخدم في صناعات أخرى.

النقاط الرئيسية

- شفرات التثقيب المخصصة تساعدك على قطع الأشياء بدقة أكبر. تدوم لفترة أطول ولا تحتاج إلى استبدالها كثيرًا. هذا يوفر لك المال والوقت.

- اختيار مادة الشفرة وشكل الحافة المناسبين يضمن لك قطعًا أنقى. ستقلل النفايات وينجز عملك بشكل أسرع. هذا مفيد في مصانع التعبئة والتغليف والمنسوجات والأغذية.

- شفرات مخصصة تناسب أجهزتك تمامًا. لا تحتاج إلى تغييرها كثيرًا، مما يوفر عليك وقتًا في إصلاحها.

- Nanjing Metal نصنع شفرات مخصصة عالية الجودة. نتحقق من الجودة بعناية. نوصل بسرعة ونسمح لك بطلب الكمية التي تحتاجها. شفراتنا تناسب أعمال القطع الخاصة بك.

- من المهم اختيار شركة شفرات جيدة ذات خبرة واسعة. يجب أن توفر خيارات مخصصة وفحوصات جودة دقيقة. هذا يساعدك على الحصول على منتجات أفضل ويضمن سير العمل بسلاسة في مصنعك.

نظرة عامة على شفرات التثقيب المخصصة

ما هي الشفرات المثقبة

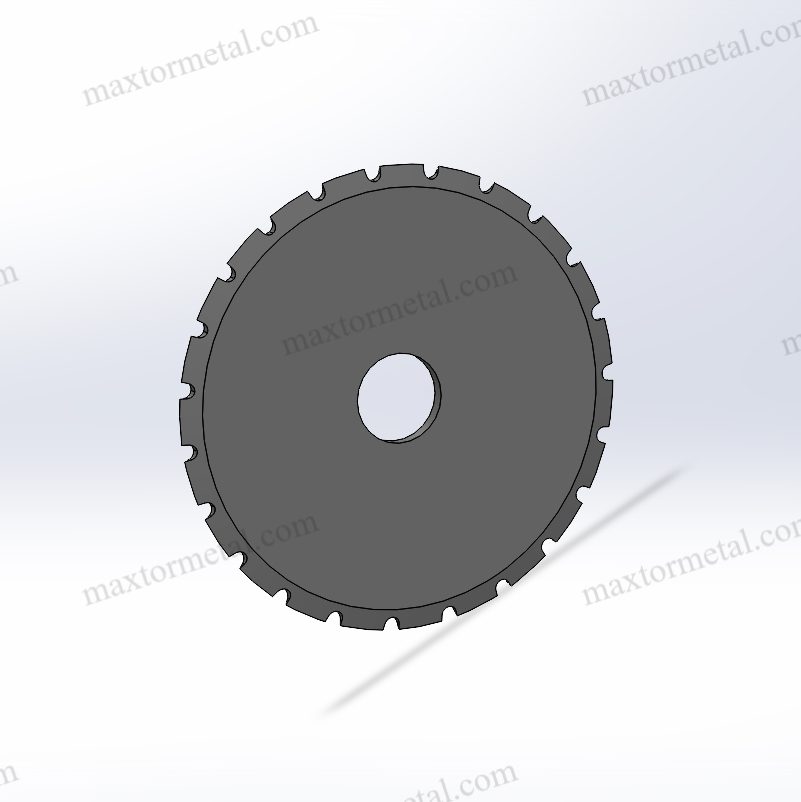

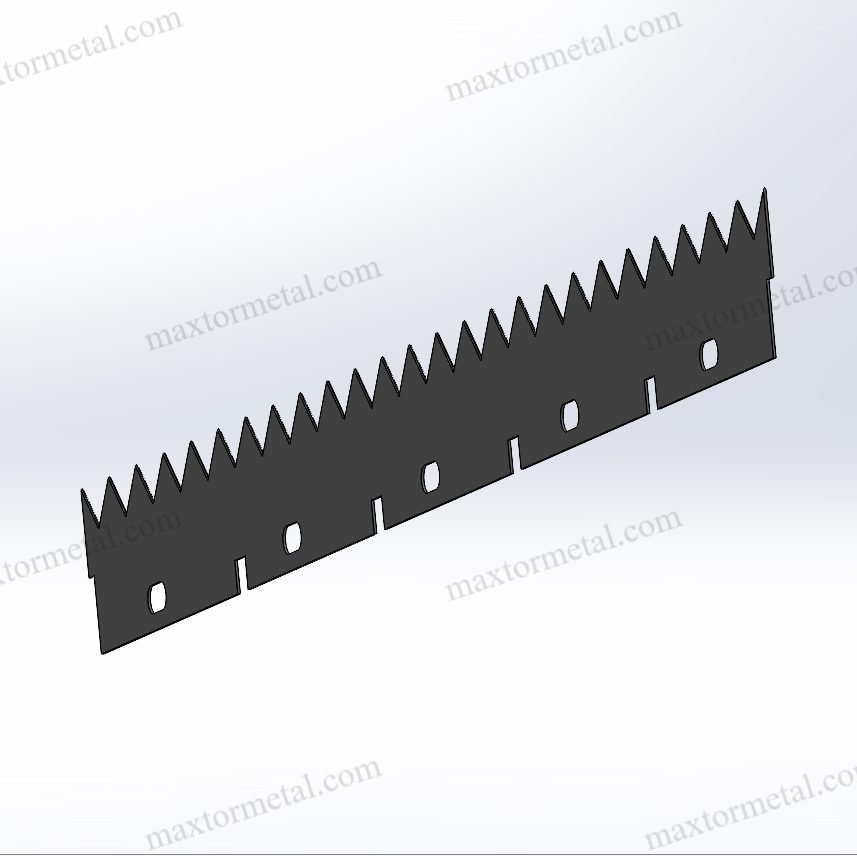

شفرات التثقيب تُحدث قطعًا أو ثقوبًا صغيرة في الأشياء. تُساعدك هذه الشفرات على تمزيق مواد التغليف والورق والمنسوجات بسهولة. يمكنك الاختيار من بين أشكال وأحجام مُتعددة. بعض الشفرات تقطع خطوطًا مستقيمة، بينما تُحدث شفرات التثقيب الدوارة قطعًا دائرية ومتواصلة. يُغير شكل الأسنان وشكل الشفرة آلية عملها. عليك اختيار الشفرة المُناسبة للمادة والماكينة، فهذا يُساعدك على الحصول على أفضل النتائج.

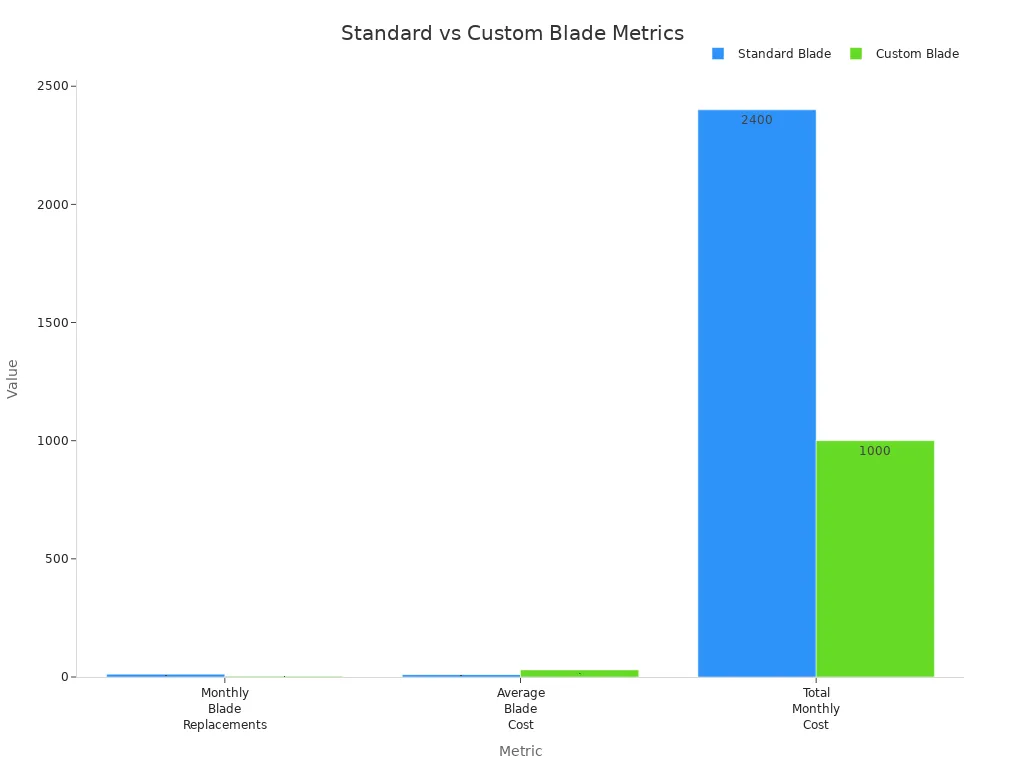

شفرات التثقيب المُخصصة تُمكّنك من التحكم في عملية القطع بشكل أفضل. يُمكنك إرسال رسومات أو صور لمطابقة شفرتك مع ماكينتك. تُناسب الشفرات المُخصصة ماكيناتك وموادك الخاصة، كما أنها تدوم لفترة أطول وأقل عرضة للكسر من الشفرات العادية، كما أنها أقل حاجة للتثبيت. يُمكنك تغيير تصميمها لتحسين أدائها. يُوضح الجدول أدناه مُقارنة بين الشفرات المُخصصة والشفرات القياسية:

| متري | شفرة قياسية | شفرة مخصصة |

|---|---|---|

| استبدال الشفرة شهريًا | 12 | 3 |

| متوسط تكلفة الشفرة | $10 | $30 |

| التكلفة الشهرية الإجمالية | ~$2,400 | ~$1,000 |

كما ترى، الشفرات المُخصصة تُوفر المال وتُقلل الحاجة إلى استبدالها. كما أنها تُساعدك على القطع بشكل أفضل وأسرع.

تتميز شفرات التثقيب بتصاميم حواف مختلفة. يمكنك اختيار حافة مربعة، أو حافة مشطوفة واحدة، أو حافة مشطوفة مزدوجة. كل تصميم يُغير طريقة قطع الشفرة ومدة عملها.

| تصميم الحافة | وصف | التأثير على أداء القطع |

|---|---|---|

| حافة مربعة | حافة مستقيمة وعمودية بدون حواف | يعطي أقصى قدر من القوة ويدوم لفترة أطول؛ جيد للمهام الصعبة؛ يقلل الحرارة والاحتكاك |

| شطبة واحدة | مشطوف على جانب واحد، والجانب الآخر مسطح | يجعل القطع أكثر دقة؛ احتكاك أقل؛ حافة أكثر حدة لقطع أسهل وأنظف |

| شطبة مزدوجة | حواف مشطوفة على كلا الجانبين لتشكل حافة على شكل حرف V | يمزج بين الحدة والقوة؛ جيد للمواد الأخف وزناً؛ من السهل الحفاظ على حدته |

اختر تصميم الحافة الذي يناسب مادتك ومهمة القطع. هذا يساعدك على الحصول على قطع أنيقة ونظيفة في كل مرة.

تطبيقات القطع الصناعية

تُعد شفرات التثقيب مهمة في العديد من الصناعات. فهي تُستخدم في صناعات التغليف، والورق، والمنسوجات، والأغذية، والتغليف الطبي، والإلكترونيات، والنفط والغاز، والبناء، والمصانع. تساعدك هذه الشفرات على صنع شرائط سهلة الفتح، وفتحات تهوية، وتصميمات جذابة. كما أنها تُسهّل استخدام المنتجات وتطيل عمرها.

فيما يلي بعض الشفرات المثقبة الشائعة وما تفعله:

- شفرات التثقيب المستقيمة: تستخدم هذه الشفرات للقطع المستقيمة في الورق والتغليف والمنسوجات.

- شفرات ثقب القطع: تتميز هذه الشفرات بأشكال أسنان خاصة، مثل المشطوف، أو المدبب، أو المائل، أو على شكل حرف V. تُستخدم لعمل أنماط مختلفة وقطع نظيفة.

- شفرات دوارة مثقبة: تدور هذه الشفرات لتكوين ثقوب طويلة ومستقيمة. تُستخدم في التغليف ولفائف الورق.

يمكنك الاختيار من بين مختلف مواد الشفرةالفولاذ عالي السرعة (HSS)، وفولاذ الأدوات، والفولاذ المقاوم للصدأ، وكربيد التنغستن، وفولاذ مسحوق المعادن، من الأنواع الشائعة. وتتغير مدة استخدام الشفرة وجودة قطعها تبعًا للمادة.

توفر لك الشفرات المثقبة العديد من الفوائد في المصانع:

| فائدة | وصف التأثير |

|---|---|

| كفاءة الإنتاج | يجعل خطوط الإنتاج تعمل بشكل أسرع بمعدل 12-15% كل عام، مما يتيح لك إنتاج المزيد. |

| تحسين الإنتاجية | يعمل على تسريع الخطوط بما يصل إلى 20%، بحيث يتم إنجاز الأمور بشكل أسرع. |

| تقليل النفايات | يقلل من نفايات التغليف بنسبة 20-30%، مما يوفر المال ويساعد الكوكب. |

| تعزيز المتانة | تدوم الشفرات 25-40% لفترة أطول مع الطلاءات الخاصة، لذلك تقضي وقتًا ومالًا أقل في استبدالها. |

تستخدم شفرات التثقيب لتمزيق العبوات بسرعة ونظافة. تجعل العبوة تبدو أفضل وأسهل في التجميع. تُضفي مزيدًا من الأمان على أغطية الزجاجات وعبوات الأدوية. تُسهّل على الناس فتح العبوات.

تُساعد الشفرات المثقبة أيضًا في صناعة المنسوجات والأقمشة. تُصنع ملابس تُتيح التهوية، وملابس رياضية، وتصاميم عصرية. كما تمنع تآكل القماش وتُحسّن جودة المنتجات. في مصانع الأغذية، تُستخدم الشفرات للتغليف الذي يحافظ على نضارة الطعام، وتقطيع العجين، وتقطيع الجبن، وصنع أختام قابلة للفصل.

يمكنك أن ترى أن شفرات التثقيب المخصصة والدوارة تساعدك في حل العديد من مشاكل القطع في المصانع. ستحصل على نتائج أفضل، وعمر أطول للشفرة، وتكلفة أقل. ستُسرّع عملك وتُحسّن جودة منتجاتك.

القطع الدقيق لتلبية احتياجات الصناعة

التثقيب في التغليف والورق

يجب أن تكون دقيقًا عند استخدام الشفرات المثقبة. تُشكّل هذه الشفرات خطوطًا سهلة التمزيق في أغلفة الفقاعات البلاستيكية والأغشية. يمكنك فصل الأوراق بسرعة وتعبئة الأشياء القابلة للكسر مع تقليل الهدر. في الصناديق والكرتون، تُشكّل الشفرات المثقبة قسائم قابلة للتمزيق، وألسنة سهلة الفتح، وفتحات تهوية، وأماكن عرض. هذا يُسهّل استخدام العبوات ويحافظ على نضارتها.

يمكنك العثور على الشفرات المثقبة في العديد من أنواع التغليف:

- يتم استخدامها في أكياس القمامة وحزم الأجزاء لتسهيل فصلها.

- يتم استخدامها في معطرات الجو وأغطية الزجاجات لإخراج الروائح أو السوائل ببطء.

- تستخدمها عبوات الأدوية والأختام حتى تتمكن من معرفة ما إذا كان شخص ما قد فتحها.

أشكال شفرات خاصة، مثل الحواف المسننة أو المزخرفة، تُسهّل العمل. تُساعد على مرور الهواء في ورق الكرافت والكرتون. تُتيح لك الشفرات المثقبة الوصول إلى الأشياء بالداخل بسرعة، ومنع التلف، وتسريع عملية التعبئة.

استخدام شفرات التثقيب يمنحك صناديق قوية وحواف ناعمة. ستحصل على منتجات متشابهة، مما يُساعد الآلات على تعبئتها. القطع السلس يجعل العبوات تبدو أنيقة ويقلل من الهدر. عند استخدام القطع الدقيق، تعمل أكثر من 20% أسرع ولديه وقت تعطل أقل بمقدار 25%. في كل مرة، تقوم بإنشاء حزم أفضل وأجمل مظهرًا.

حلول القطع للمنسوجات والأغذية

تواجه مصانع المنسوجات والأغذية مشاكل خاصة. فالأقمشة الرقيقة قد تتحرك أو تتفتت، والأقمشة المطاطة قد تتغير أشكالها. يتم إصلاح هذه المشاكل بشفرات ثقب مخصصة. وتستخدم آلات ذكية وشفرات خاصة لقص طبقات متعددة وترتيب الأنماط. طاولات الفراغ والحصائر اللاصقة حافظ على ثبات القطع الصغيرة. يساعد القطع بالليزر والموجات فوق الصوتية على منع تآكل الحواف.

حافظ على سلامة وسرعة عملك باستخدام شفرات تثقيب جيدة. الشفرات الباهتة أو القديمة تُبطئك وتُكلفك المزيد من العمل. غالبًا ما يُعيق إصلاح الشفرات عملك. بتغيير الشفرات عند الحاجة، ستحافظ على سلامتك وتُبقي العمل مستمرًا.

| الميزة/الجانب | توضيح | التأثير على الكفاءة والسلامة |

|---|---|---|

| تكوين الأسنان القابل للتخصيص | يتيح لك اختيار حجم الثقب والتباعد | تمزيق أسهل، وضغط أقل على الآلة |

| مواد شفرة متينة | جعل الشفرات تدوم لفترة أطول | استخدام أطول، توقف أقل للعمل |

| تصاميم ذات قوة قطع منخفضة | تحتاج إلى طاقة أقل للقطع | قطع أكثر سلاسة، واحتمالية أقل للكسر |

| الاستخدام في التعبئة والتغليف والأغذية | مصنوعة لكل مادة | يعمل بشكل أفضل، جودة أعلى |

تستخدم شفرات مثقبة لتحسين عملية القطع في كل مصنع. تعمل بشكل أسرع وأكثر أمانًا، وتنتج منتجات أفضل باستخدام الأدوات المناسبة.

مواد وتصميم الشفرات المثقبة

مواد الشفرة والمتانة

عليك اختيار المواد المناسبة لشفراتك المثقبة. فالمادة التي تختارها تُؤثر على عمر الشفرة وجودة قطعها. هناك العديد من المواد القوية المستخدمة في هذه الشفرات:

- الفولاذ عالي السرعة (HSS) صلب ومتين. يُستخدم لقطع الورق أو البلاستيك الرقيق. شفرات الفولاذ عالي السرعة، مثل M2، حادة ولا تتآكل بسرعة.

- فولاذ الأدوات صلب جدًا ولا يتآكل بسرعة. يُستخدم في القطع الدقيق والأعمال الشاقة في المصانع.

- الفولاذ المقاوم للصدأ لا يصدأ ولا يتآكل. يُستخدم في الأماكن التي تحتاج إلى نظافة، مثل عبوات الطعام والأدوية.

- كربيد التنغستن شديد الصلابة ويدوم طويلًا. تقطع هذه الشفرات المواد الخشنة بكفاءة عالية عند الحاجة إلى قطع كثير. تدوم الشفرات ذات الرؤوس المصنوعة من الكربيد لفترة أطول، ولا تحتاج إلى تغييرها كثيرًا.

- يُستخدم الفولاذ عالي الكربون في السكاكين المستقيمة والمستديرة والقاطعة. يُعطي حافة حادة للعديد من أعمال المصانع.

يوضح الجدول أدناه كيفية عمل كل مادة في وظائف مختلفة:

| مادة الشفرة | المتانة ومقاومة التآكل | أداء القطع والحدة | التطبيقات النموذجية |

|---|---|---|---|

| الفولاذ الكربوني | حاد، يحتاج إلى رعاية | حاد جدًا، سهل الشحذ | قطع دقيق، استخدامات عديدة |

| الفولاذ المقاوم للصدأ | لا يصدأ، سهل التنظيف | يحافظ على الحافة، وليس حادًا | الغذاء والدواء والأماكن الرطبة |

| حديدعالى السرعه | ممتاز ضد الحرارة والتآكل | يبقى حادًا ويقطع جيدًا | عمل مصنع سريع ودقيق |

| كربيد التنغستن | صعب جدًا، ويدوم لفترة أطول | يحافظ على الحافة بشكل أفضل | قطع خشنة وشديدة التحمل |

كما ترى، اختيار المادة المناسبة يُطيل عمر شفراتك ويُحسّن أداءها. فالمواد الجيدة تُجنّبك تغيير الشفرات كثيرًا، وتُنجز عملك بشكل أسرع.

ميزات التصميم المخصص

يمكنك تصميم شفرات مخصصة لتناسب احتياجات مصنعك. تتيح لك الميزات المخصصة اختيار شكل الشفرة وزاوية الحافة ونمط السن المناسب لعملك. قد تحتاج أحيانًا إلى تفاصيل دقيقة لقطع متساوٍ أو طلاء خاص لمنع التآكل والاحتكاك. تساعدك هذه الميزات على الحصول على قطع نظيفة ومطابقة منتجاتك في كل مرة.

يمكن أن تحتوي الشفرات المثقبة المخصصة على:

- أشكال الأسنان لسهولة التمزيق أو الحواف الناعمة

- سمك وعرض الشفرة لتناسب آلاتك

- الطلاءات الخاصة، مثل نتريد التيتانيوم، لتدوم لفترة أطول

- أشكال مختلفة للقطع الدوراني أو المستقيم أو الدائري

الشفرات المُخصصة تُفيدك بطرق عديدة. الشفرات ذات التفاصيل الدقيقة تُعطي كل قطع نفس النتيجة. الشفرات الحادة تتطلب قوة أقل وتُساعدك على العمل بشكل أسرع. المواد القوية مثل كربيد التنغستن تُطيل عمر الشفرات وتُحافظ على جودة القطع. كما تُقلل من الهدر وتُمنع انحشار الآلات.

إذا كنت تريد معرفة المزيد عن الشفرات المخصصة، يمكنك التحقق من صفحة الشفرات المخصصة لمزيد من الأفكار.

تساعدك الميزات المخصصة على الالتزام بقواعد الصناعة والعمل بشكل أفضل. ستحصل على شفرات تناسب ماكيناتك وعملك. هذا يساعدك على إنتاج منتجات أفضل، والعمل بشكل أسرع، وتوفير المال في مصنعك.

التخصيص ومراقبة الجودة

خدمات OEM وODM

أنت ترغب في شفرات مثقبة تُلبي احتياجاتك. تُصنّع شركة Nanjing Metal شفرات مُخصصة مع خدمات تصنيع المعدات الأصلية (OEM) وتصنيع التصميم الأصلي (ODM) الخاصة. تبدأ بإرسال الرسومات أو المخططات أو العينات. يُقيّم فريق التصميم ما تُرسله ويختار أفضل المواد. ستحصل على شفرات مصنوعة من فولاذ أدوات قوي مثل D2 أو H13 أو SKD-11. تتميز هذه الفولاذات بعمر طويل ومقاومة للتآكل.

تستخدم عملية تصنيع الشفرات تقنية الطحن والمعالجة الحرارية باستخدام الحاسب الآلي. تساعد هذه الخطوات شفراتك على استيفاء معايير صارمة. ستحصل على نماذج أولية للاختبار. يتحقق الفريق من صلابة الشفرة وقوة حافتها ومدة صلاحيتها. إذا كنت ترغب في حماية إضافية، يمكنك اختيار طلاءات مثل نيتريد التيتانيوم. يساعدك المهندسون على تحسين تصميم الشفرة، وقطعها بشكل أفضل، وتقليل تكاليف الإصلاح.

إليك كيفية الحصول على شفرات مخصصة:

١. ترسل رسومات CAD أو عينات أو مواصفات. ٢. يختار الفريق المواد اللازمة لعملية القطع. ٣. يضمن الطحن والمعالجة الحرارية دقة الشفرات. ٤. يتحقق الاختبار من الصلابة والتوازن وقوة الحافة. ٥. تساعد الطلاءات على إطالة عمر الشفرات في الأعمال الشاقة. ٦. يساعد المهندسون على تحسين التصميم والأداء. ٧. يمكنك طلب شفرة واحدة أو مجموعة كاملة.

يمكنك طلب شفرة واحدة أو عدة شفرات. هذا يُفيد الشركات الصغيرة والكبيرة على حد سواء. ستتلقى تحديثات حول طلبك فور إتمامه. أنت على دراية بما يحدث ويمكنك تخطيط عملك. هذه الميزات تُساعدك على تجنب الأخطاء وتحسين أداء شفراتك.

نصيحة: الحصول على التحديثات والطلبات المرنة يساعدك على التحكم في طلبك وتخطيط عملك.

التوصيل السريع ميزة أخرى. ستحصل على شفراتك المخصصة بسرعة، مما يساعدك على العمل بشكل أسرع والثقة بالشركة. التوصيل السريع يعني ضغطًا أقل وتأخيرًا أقل. الشركات التي تقدم خدمة التوصيل السريع تجعلك ترغب بالشراء مرة أخرى.

عملية ضمان الجودة

تريد أن تكون شفراتك المثقبة عالية الجودة.

تبدأ عمليات فحص الجودة باختيار المواد الخام الجيدة. تُراقب سلسلة التوريد لمنع دخول المواد الرديئة. أثناء التصنيع، يتتبع نظام التقدم ويتحقق من الأداء. تُجرى اختبارات متقدمة للتحقق من مقاومة القطع والتآكل والصدأ. يتلقى العمال تدريبًا ويساعدون في الحفاظ على جودة عالية.

يتم فحص كل شفرة أربع مرات قبل التعبئة. يبحث الفنيون عن أي مشاكل، ويُصلحون الشفرات التالفة أو يتخلصون منها. لا نُرسل إليك إلا الشفرات المثالية. وتعتمد الشركة على خبرة تزيد عن 100 عام للحفاظ على أعلى معايير الجودة.

فيما يلي جدول يوضح فحوصات الجودة المهمة:

| مقياس مراقبة الجودة | غاية |

|---|---|

| اختبار الصلابة | تأكد من أن الشفرات لها الصلابة الصحيحة. |

| فحوصات دقة الأبعاد | تأكد من أن شفرات الفحص بالحجم المناسب، وعادة ما يكون ذلك ±0.01 مم. |

| اختبار المتانة | يختبر هذا البحث مدى عمر الشفرات في الأعمال الحقيقية. |

| الامتثال لمعايير الصناعة | يلتزم بمعايير ISO 9001 و ISO 14001 لتحقيق أعلى مستويات الجودة. |

ستحصل على هذه الفوائد من عمليات فحص الجودة:

- الشفرات تعمل بشكل جيد وتدوم طويلاً

- معالجة حرارية خاصة وتحكم في المعادن

- قطع دقيق لأعمالك

- سطح أملس لقصات نظيفة

- تشغيل قوي وسهل

ملاحظة: تساعدك فحوصات الجودة والتسليم السريع في الحصول على شفرات تثقيب جيدة عندما تحتاج إليها.

اختيار شريك شفرة التثقيب المناسب

معايير الاختيار الرئيسية

عند اختيار شركة لتصنيع شفرات التثقيب، يجب مراعاة بعض الأمور المهمة. فالشركة المناسبة تُحسّن أداء مصنعك وتضمن لك نتائج ممتازة. إليك أهم النقاط التي يجب البحث عنها:

- ضمان الجودة: اختر شركة تفحص شفراتها بدقة. هذا يضمن حصولك على شفرات تثقيب آمنة وحادة وقوية في كل مرة.

- التصنيع الدقيق: ابحث عن شريك يستخدم أدوات حديثة مثل القطع بنفث الماء، والقطع بالليزر، والطحن بالتلبيد. تساعد هذه الأدوات في صناعة شفرات تقطع بدقة متناهية.

- كميات طلب مرنة: اختر شركة تسمح لك بشراء عدد قليل من الشفرات أو الكثير، حسب احتياجاتك.

- القدرة على التخزين: تأكد من أن الشركة تحتفظ بكمية كافية من الشفرات جاهزة حتى تتمكن من الحصول عليها بسرعة.

- استجابة سريعة لما بعد البيع: أنت بحاجة إلى شركة تساعدك بسرعة إذا واجهت أي مشاكل مع شفراتك.

- التخصيص: يجب على شركتكم صنع شفرات خاصة تناسب عملكم تحديداً.

- العينات المجانية: يتيح لك الحصول على عينات مجانية اختبار الشفرة وإيجاد أفضل شفرة لعملك.

- مجموعة واسعة من المواد: اختر شريكًا لديه العديد من مواد الشفرات المختلفة لجميع أنواع الأعمال.

- مجموعة واسعة من أنواع الشفرات: أنت تريد شركة تقدم العديد من أشكال الشفرات لتلبية احتياجات القطع المختلفة.

- تصميم الحافة الاحترافي: الحافة المناسبة، مثل الحافة المستقيمة أو المسننة أو المشطوفة، تساعدك على القطع بشكل أفضل.

- الطلاءات: تعمل الطلاءات الخاصة مثل نتريد التيتانيوم أو التفلون على إطالة عمر الشفرات وتحسين أدائها. ١٢. الخبرة الصناعية: الشركات ذات الخبرة الواسعة تعرف كيف تحل مشاكل القطع لديك.

إذا اخترت شركة تمتلك هذه الميزات، فستحصل على شفرات تثقيب قوية وموثوقة ومصممة خصيصًا لأي مهمة لديك.

مزايا نانجينغ Metal

ستحصل على العديد من المزايا عند اختيارك شفرات التثقيب من شركة نانجينغ Metal. فالشركة حاصلة على شهادة ISO 9001:2015، مما يضمن لك جودة عالية لشفراتها.

يمكنك طلب شفرات مصممة خصيصًا لأي مهمة لديك. يساعدك الفريق في اختيار مادة الشفرة المناسبة، وشكل الحافة، والطلاء الذي يلبي احتياجاتك.

تشتهر شركة Nanjing Metal بسرعة التوصيل، حيث تتيح لك طلب أي كمية، وتزويدك بتحديثات فورية أثناء تجهيز طلبك. ستحصل على مساعدة سريعة وإجابات واضحة من البداية إلى النهاية.

إنهم على دراية تامة باحتياجات المصانع في مجال التثقيب. يمكنك الوثوق بجودتهم، ودقة عملهم، وشفراتهم المصممة خصيصًا لمساعدة مصنعك على العمل بكفاءة وإنتاج منتجات عالية الجودة.

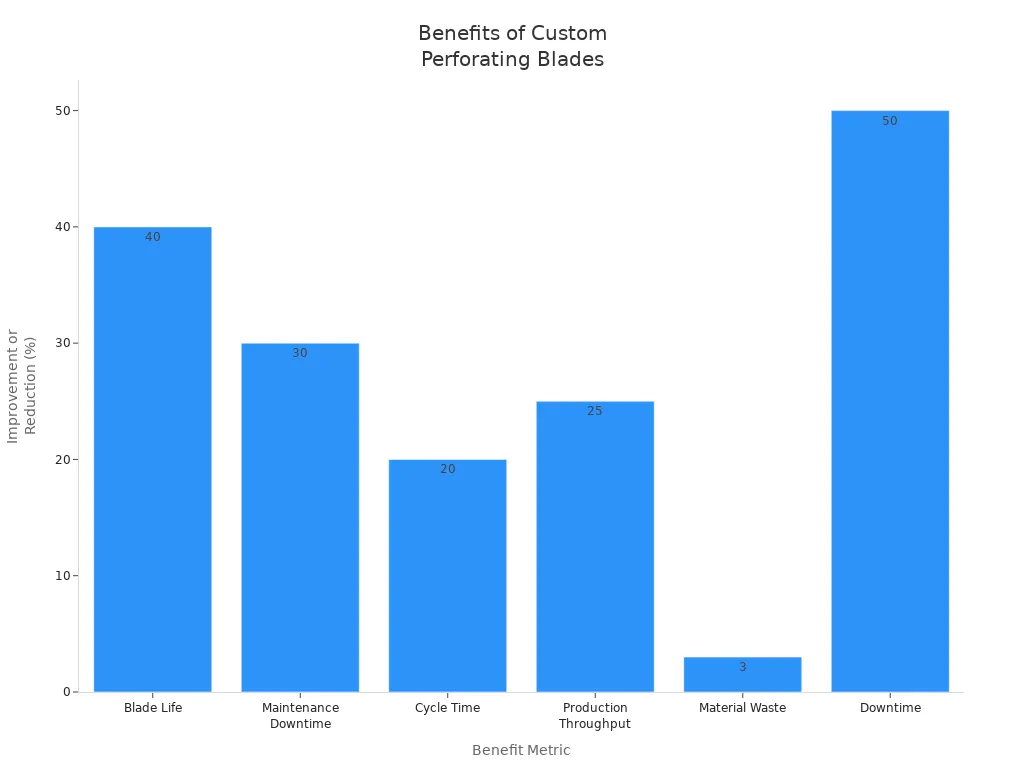

ستحصل على فوائد واضحة عند استخدام شفرات التثقيب المصممة خصيصًا. تدوم هذه الشفرات لفترة أطول، مما يقلل من توقف آلاتك. يمكنك إنتاج المزيد من المنتجات في وقت أقل. يوضح الجدول أدناه كيف تُسهم هذه التغييرات في تحسين عملك:

| مقياس الفائدة | نطاق التحسن / النسبة المئوية | التأثير القابل للقياس / الفائدة المالية |

|---|---|---|

| بليد لايف | زيادة تصل إلى 40% | عمر تشغيلي أطول، مما يقلل من تكاليف الاستبدال |

| توقف الصيانة | تخفيض 30% | وقت تعطل أقل لتغيير الشفرات |

| وقت الدورة | تخفيض 20% | يُمكّن من إنتاج 15000 وحدة إضافية شهرياً |

| معدل الإنتاج | زيادة 15-25% | حجم إنتاج أعلى |

| نفايات المواد | تم تخفيضه من 5% إلى 2% | يوفر ما يقارب 150,000 دولار سنوياً |

| وقت التوقف | تخفيض 50% | ينتج عن ذلك مكاسب إنتاجية سنوية قدرها $80,000 |

اختيار المواد المناسبة وتصنيع شفراتك حسب الطلب يوفر المال. ستحصل على هذه المزايا:

- تستخدم مواد أقل وتهدر مواد أقل.

- الأجزاء متشابهة، لذا فإن الإصلاح أسهل.

- يمكنك ترقية الأجزاء عند الحاجة.

- توفر المزيد من المال مع مرور الوقت.

ستلاحظ هذه المزايا في كل خطوة من عملك. تساعدك الشفرات المصممة خصيصًا على القطع بشكل أفضل وتدوم لفترة أطول. إذا كنت ترغب في شفرات قوية وعالية الجودة، فإن نانجينغ Metal هي خيارك الأمثل.

هل تريد تحسين عملك؟ تواصل مع مهندس المبيعات للحصول على المساعدة في العثور على الشفرات المناسبة لعملك.

التعليمات

ما هي المواد التي يمكن استخدامها لصنع شفرات التثقيب المخصصة؟

يمكنك اختيار فولاذ الأدوات، أو الفولاذ عالي السرعة، أو الفولاذ المقاوم للصدأ، أو كربيد التنجستن. لكل نوع منها مزاياه الخاصة من حيث المتانة والحدة. يعتمد اختيار المادة الأنسب على نوع القطعة التي تقطعها وطبيعة عملك.

كيف يمكنني طلب شفرة مخصصة من شركة نانجينغ Metal؟

ترسل رسمك أو عينة أو تفاصيل حول الشفرة التي تريدها. يقوم الفريق بدراسة احتياجاتك ويقترح أفضل تصميم. ستتلقى تحديثات أثناء تصنيع شفرتك. يمكنك شراء شفرة واحدة أو مجموعة منها دفعة واحدة.

كم من الوقت يستغرق استلام شفراتي المصممة خصيصًا؟

تصل معظم الطلبات خلال 7 إلى 20 يومًا. يوفر لك موقع Nanjing Metal تحديثات فورية حول طلبك أثناء تجهيزه. الشحن السريع يُمكّنك من مواصلة عملك دون توقف.

هل يمكنك الحصول على شفرات لأنماط تثقيب مختلفة؟

نعم، يمكنك طلب شفرات بأشكال وأنماط أسنان مختلفة. سيساعدك فريق التصميم في اختيار الشفرات المناسبة لعملك. ستحصل على شفرات تتناسب مع آلتك والمواد التي تستخدمها.

ما هي فحوصات الجودة التي تخضع لها شفرات نانجينغ Metal؟

تُفحص كل شفرة أربع مرات قبل شحنها. يختبر الفريق صلابة الشفرة وقوتها وحجمها المناسب. ولا تُرسل إليك إلا الشفرات التي تجتاز جميع الاختبارات. هذا يضمن حصولك على شفرات عالية الأداء في كل مرة.

انظر أيضا

تحسين شفرات تثقيب الأفلام البلاستيكية: مطابقة السرعة، الضغط، وشكل الأسنان

لماذا تُستخدم سكاكين التثقيب للتغليف على نطاق واسع في صناعة التغليف

استكشاف أخطاء شفرات التثقيب وحل مشاكل التثقيب غير المتساوي وطول الخط غير المتسق وتحسينها

تقنيات عملية لتركيب شفرة التثقيب، تعديل الآلة، وشحذها لتحسين استقرار خط الإنتاج