You might think سعر أدوات مكبس الفرامل is most important. Press brake tooling price can change your budget in many ways. If you only look at press brake tooling price, you might miss hidden costs. These hidden costs can hurt your financial plans. Press brake tooling price can look cheap, but low quality can cause problems. You might need repairs or have downtime. You should use cost-benefit analysis to help your choices. Press brake tooling price is just one part. Financial managers need to check the value too. Nanjing Metal’s press brake tooling shows how results get better when you look at more than price.

النقاط الرئيسية

- The price of press brake tooling is only one cost. You should also think about maintenance and energy bills.

- Hidden costs can grow fast. Downtime, repairs, and slow work can hurt your budget a lot.

- Good tooling makes better products. High-quality tools lower mistakes and waste.

- Use cost-benefit analysis to help you decide. Look at all costs and benefits to get the best deal.

- Supplier reliability is important. Pick suppliers with a good name and strong support to stop future problems.

- Buying strong tooling is a smart choice. Tough materials last longer and need fewer replacements.

- Regular maintenance helps your tooling last longer. Taking care of tools saves money and keeps work going well.

- Always think about the long-term value of tooling. Cheap tools may cost more later because of repairs and slowdowns.

Press Brake Tooling Price: More Than Meets the Eye

Upfront Cost vs. Total Cost

When you see a low price for press brake tooling, it may look like a good deal. But the first price is just one part of what you will pay. Over time, you will spend more than just the first cost. You should think about the total cost of owning the tooling. This means you pay at the start and also during the tooling’s life.

Here is a table to show how upfront cost and total cost are different:

| Cost Component | وصف |

|---|---|

| Initial Purchase Price | The base cost of the machine and any standard features included. |

| Optional Features | Additional costs for upgrades like advanced controls and safety features. |

| تكاليف التشغيل | Ongoing costs for tooling, consumables, and maintenance. |

| إجمالي تكلفة الملكية | Comprehensive assessment of all costs over the machine’s lifespan. |

If you only look at the price tag, you might not see how much you will spend later. You could pay more for things like maintenance, upgrades, and running the machine. The total cost can end up being much higher than you first thought.

Hidden Expenses

Some costs are not easy to see when you buy new tooling. These hidden costs can show up in your daily work. They can add up quickly and hurt your budget.

- Operator pay can go up if your tooling slows down work.

- You may need to buy more consumables like hydraulic fluid and extra tooling.

- If your tooling is not efficient, energy bills can rise.

- Downtime can be expensive because you pay workers even when machines stop.

Note: Downtime costs are not just about lost products. You still pay your team when nothing is made, so you lose money.

Other hidden costs are:

- Time lost from machines not working and doing jobs by hand again.

- You can lose chances to finish jobs on time or keep customers happy.

- More scrap and rejected parts mean higher quality costs.

- Extra costs come from worn dies and machines losing accuracy.

You need to look past the first price to find these hidden costs.

Impact on Manufacturing Quality

The tooling you use changes how well you make parts every day. Good tooling helps you make better parts and have fewer mistakes. Bad tooling can cause more errors and waste.

- Precision dies can cut bending mistakes by almost 35%. This means you make fewer errors and have better control.

- Using precision tooling helps you meet tough industry rules. You get good parts and fewer rejections.

- Custom tools can lower the number of bad parts by up to 25%. This saves money and keeps your customers pleased.

If you pick tooling just because it is cheap, you could hurt your product quality. Good tooling helps you make high-quality products and keeps your work running smoothly.

Cost-Benefit Analysis for Tooling Decisions

What Is Cost-Benefit Analysis?

التعريف والغرض

Cost-benefit analysis helps you make smart choices in manufacturing. You use it to compare all the costs and benefits of each option. You do not just look at price. You also think about the value you get over time. This process shows if your tooling investment is worth it. You want the benefits to be bigger than the costs. This method helps you see if a choice is good for your business.

Key Elements Considered (Costs and Benefits)

A good cost-benefit analysis checks many things. You need to look at both costs and benefits. Here is a table to help you see the main parts:

| عنصر | وصف |

|---|---|

| Costs | Direct, indirect, intangible, and opportunity cost linked to the project. |

| فوائد | Tangible and intangible benefits you can measure or describe. |

| Timeframes | The period over which you measure costs and benefits. |

| Discount Rates | The rate you use to figure out the present value of future costs and benefits. |

You must count every cost, like the first price, maintenance, and what you lose by picking one thing over another. You also need to look at every benefit, such as better quality, higher performance, and saving money.

Application in Press Brake Tooling Selection

When you pick press brake tooling, cost-benefit analysis helps you see everything. You do not just choose the cheapest tool. You look at how the tooling changes your work, product quality, and long-term value. For example, you might compare standard tooling with custom blades. You can read more about custom blades هنا. This way, you can weigh better performance and longer tool life against the costs. You also think about what you miss if you pick a lower-quality tool.

Why Analysis Matters in Manufacturing

Avoiding Short-Term Thinking

It is easy to focus only on the lowest price. This can cause bigger costs later. Cost-benefit analysis helps you avoid this mistake. You look at the value over the whole life of the tooling. A better investment now can save you money and problems later.

Identifying Hidden Costs and Long-Term Value

Cost-benefit analysis helps you find hidden costs that are not in the price tag. You might have extra costs from downtime, repairs, or bad performance. You also see the long-term value of better tooling. Good tooling can lower waste, make better products, and help your factory work better. You get more from your investment when you look at everything.

Enhancing Decision-Making for Procurement Managers

You need a clear way to make good choices. Cost-benefit analysis lets you compare options fairly. You can show your team and leaders why you picked something. This process helps you check how suppliers do and find missed chances. You build trust by showing the value of your choices with real numbers.

Tip: Cost-benefit analysis makes your choices clear and fair. You can explain your decisions with facts, not just opinions.

Steps for Effective Analysis

Identify All Relevant Costs (Upfront, Maintenance, Downtime)

You must find every cost linked to your tooling. Here are some ways to do this:

- Regular checks and maintenance can make your tooling last 15% to 25% longer.

- Cleaning the surface cuts wear by 10% to 15%.

- Lubrication lowers wear by 20%.

- Preventive maintenance stops big repairs before they start.

- Regular checks catch problems early and save money.

- Watching how well things work helps you see where you lose value.

You also need to think about costs from lost accuracy, more energy use, and big repairs. Preventive care costs less than fixing big problems after a breakdown.

Evaluate Tangible and Intangible Benefits (Quality, Service, Reliability)

You should look at both types of benefits. Tangible benefits are easy to measure, like saving money or making more products. Intangible benefits are harder to count but still matter. These include happier workers, satisfied customers, and a good reputation for quality. You can use surveys and interviews to learn about these soft benefits.

Compare Tooling Options Using a Structured Framework

You need a clear way to compare your choices. Here is a simple process:

- Look at the first costs of tooling options.

- Check benefits like working faster and making less waste.

- Think about long-term costs for cheaper tooling.

- Compare how precise and steady each tooling option is.

This process helps you see which tooling gives you the best value.

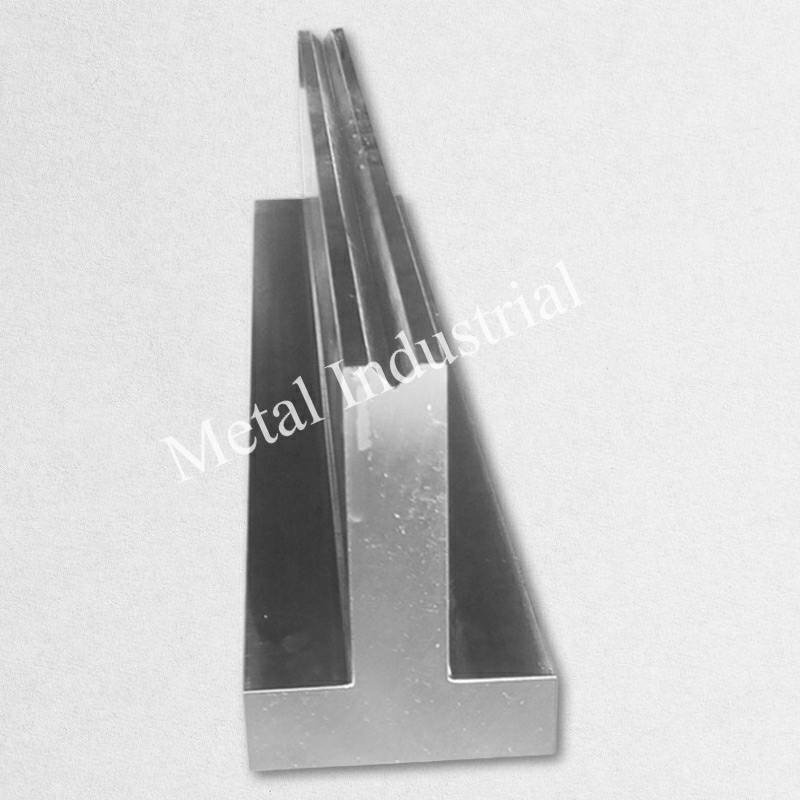

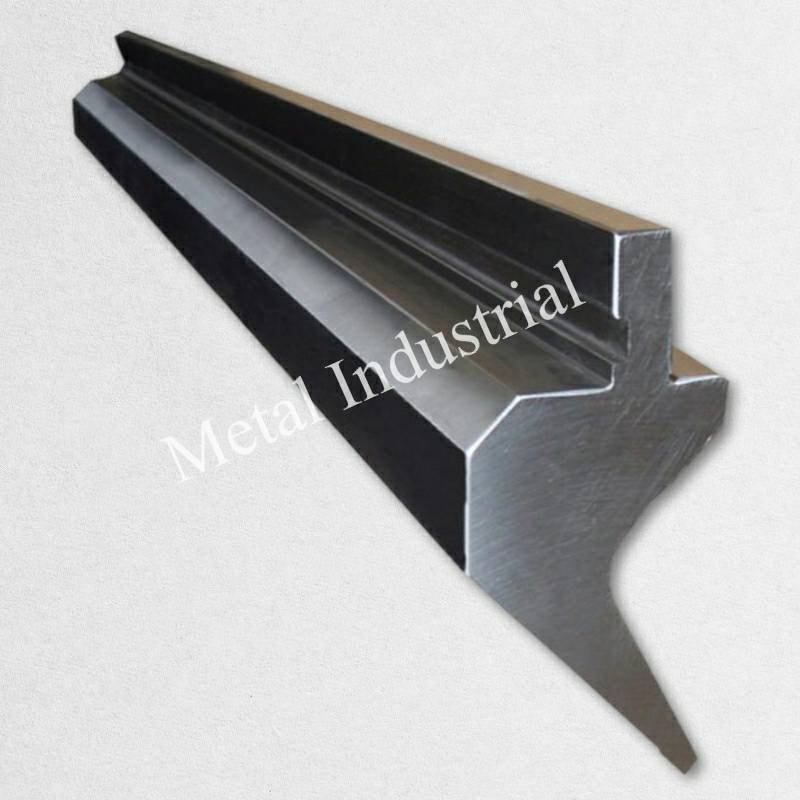

Incorporate Supplier-Specific Factors (e.g., Nanjing Metal’s Quality, Durability, and Service)

You should also look at what each supplier gives you. Nanjing Metal, for example, checks the materials in their press brake tooling. They use strong materials that last longer and need less care. This means you get more value from your money. Even if the first cost is higher, you save money over time because the tooling lasts longer and works better. Nanjing Metal also cares about quality and good service after you buy. This support helps your factory run well and adds to the value you get.

Note: Picking the right supplier can help you do better and reach your goals in manufacturing.

Key Cost Factors Beyond Price

Tooling Durability

You should not just look at the first price when picking press brake tooling. Tooling durability is very important for your business. If your tools last longer, you do not need to buy new ones often. This means you spend less money fixing or replacing them. Your business can keep working without many stops.

Using strong materials helps your tools last longer. Deep induction hardening makes tools tougher. This process helps tools fight wear and last more years. You do not have to fix broken tools as much. You can spend more time making products. Strong tools also mean less downtime, so you save money.

If you choose tools that last, you do not need to replace them a lot. Your work stays fast and smooth. You also have fewer problems with product quality. Buying tough tools helps your business and keeps costs down over time.

Material Durability and Maintenance Cost Comparison Table

The quality of the material changes how much you pay for tools. It also changes how well your business works. You should look at different materials before you buy. Some materials last longer and do not need much care. This helps you save money and keep your machines running.

Here is a table that shows how different tooling materials compare:

| نوع المادة | Durability Level | تردد الصيانة | Average Replacement Cycle | Typical Tooling Costs |

|---|---|---|---|---|

| الفولاذ الكربوني القياسي | قليل | عالي | 1-2 years | قليل |

| فولاذ الأدوات المقوى | واسطة | واسطة | 2-4 years | واسطة |

| 42CrMo Alloy Steel | عالي | قليل | 5+ years | متوسط-عالي |

Tools made from 42CrMo alloy steel last a long time. You do not need to fix or replace them often. This means you spend less on tools and your business keeps moving. Picking better materials is a smart choice for your factory.

Tip: Strong materials help you avoid surprise costs and keep your business safe.

الصيانة والاستبدال

If you do not watch tool quality, costs can go up fast. You should check your tools often and take care of them. This keeps your machines working and stops long breaks.

If your tools wear out quickly, you pay more to fix or replace them. This makes your costs higher and hurts your budget. Good tools do not need as much care. You save money and do not have to stop work as much.

Think about tooling costs when you plan your spending. Good suppliers sell tools that last and need less care. This lets you focus on your goals and worry less about surprise costs.

When you buy strong tools and take care of them, your factory works better. You spend less on tools and your business does well.

Supplier Reliability

When picking press brake tooling, you should think about supplier reliability. A reliable supplier helps you avoid trouble and keeps your factory working. You want to buy from companies with a good name and helpful support. These suppliers make sure you get the most from your tooling.

Here is a table that shows what you should check when looking at supplier reliability:

| معايير | وصف |

|---|---|

| Reputation and Industry Experience | Find out about the supplier’s history and read customer reviews. This helps you see if they do a good job. |

| Customer Service and Technical Support | Check if they give advice before you buy, deliver fast, help after you buy, and answer technical questions. |

| Total Cost and Value | Think about all the costs, not just the first price. Look at how much value you get over time. |

You should see if the supplier knows a lot about the industry. Read what other customers say about them. Good customer service and technical help are important. You want quick answers and help when you need it. Reliable suppliers help you spend less by giving strong support and good tooling.

User Testimonials

Many people talk about their experiences with reliable suppliers. These stories show how good support can help you every day.

- “Nanjing Metal’s press brake tooling helped us have less downtime and lower maintenance costs. Their support after we bought was always helpful and quick.”

- “We trust our supplier because they deliver on time and fix problems fast. Our work stays on schedule, and we save money.”

- “The technical team helped us set up our new tooling and answered all our questions. We feel sure about using their products every day.”

Good support after you buy helps you keep your tooling working well. You get help, training, and fast answers to problems. Good support means your work does not stop and you save more money over time.

Tip: Pick suppliers with strong support and a good name. You will get better results and spend less in your factory.

Manufacturing Efficiency and Tooling Choice

Production Downtime

You want your factory to work well. If machines stop, you lose time. Downtime happens when press brake tooling breaks or wears out. Every minute machines are off, you miss finishing orders. You still pay workers even if nothing is made. You could also miss customer deadlines. Good tooling helps you avoid these problems. Your production keeps moving and you waste less time. Quick tool changes and strong materials mean fewer fixes. You save money and keep your team working.

Tip: Check your tools often and take care of them. This helps you find small problems early and fix them before they stop your work.

Lead Time and Delivery

Lead time is how long it takes to get your tooling after you order. You need to know lead time because it changes your work schedule. If lead time is long, you might have delays. These delays slow your work and can upset customers. You may wait for design, buying, making, and shipping. Each step adds more time. If you do not plan for lead time, you may have trouble with jobs that need to be done fast. Your cash flow and delivery promises depend on getting tooling on time. Good suppliers help you stay on track. Fast delivery lets you start new jobs right away.

Note: Always ask your supplier about lead time before you buy. This helps you plan your work and avoid problems.

Consistency in Results

You want every part to be the same each time. Press brake tooling helps you do this. Accurate tooling gives you the right bend and size. You control the bend and keep the metal in place. Fast tool changes help you switch jobs quickly. You spend less time setting up and more time making things. Precise tooling means less waste. You use fewer materials and save money. The table below shows how good tooling helps your work:

| نوع الدليل | وصف |

|---|---|

| Bending Accuracy | Tooling gives the right bend and size, so products are better. |

| Control of Bending Process | Tooling holds the metal in place, so bends are always the same. |

| كفاءة الإنتاج | Fast tool changes save time when switching jobs. |

| خفض التكاليف | Precise tooling means less waste and lower costs. |

When your tooling works the same way every time, you get better results. Your work stays fast and your customers get good products.

Lifecycle Cost in Press Brake Tooling

الاستثمار الأولي

Buying press brake tooling is a big choice for your business. The first cost can be high, especially for good quality tooling. You may ask if paying more is smart. Over time, you see that better tooling lasts much longer. If you store tools right and keep them oiled, they can last for many years. This long life helps you save money because you do not buy new tools often. Cheaper tooling may look good at first, but it wears out faster. You spend more on fixing and replacing it. Picking strong press brake tooling helps your business do better and have fewer problems.

Tip: Think about how long your tooling will last, not just the price you pay today.

Ongoing Operating Cost

After you buy press brake tooling, you need to keep it working well. Costs can grow if you do not plan for them. You should set money aside for regular care. This keeps your tooling in good shape and stops breakdowns. Energy use is another cost to think about. For mid-sized hydraulic press brakes, you might spend $500 to $2000 each year on energy. You also need to train your workers. Training helps your team use the tooling safely and well. Sometimes you hire new workers, which adds to your costs. If you keep up with care and training, your tooling works better and lasts longer.

- Regular maintenance costs

- Energy use, which can be $500 to $2000 each year for mid-sized hydraulic press brakes

- Employee training costs, including money for training and hiring new workers

A press brake tooling system that gets good care helps you avoid surprise costs. You keep your work running smoothly and protect your money.

End-of-Life Considerations

All press brake tooling will wear out one day. You need to think about what to do when this happens. Good tooling costs more, but it gives you the accuracy you need. Advanced ways to make tooling make it even better. Precision-ground and hardened tooling lasts much longer than cheap ones. You save money over time because you do not need to buy new tooling often.

- Good tooling costs more but is needed for making accurate parts.

- The ways used to make good tooling are advanced and cost more, showing their value.

- Buying strong, precision-ground, and hardened tooling can save you a lot of money because it lasts longer than cheap tooling.

- The higher first cost of good tooling is balanced by needing fewer replacements, so it saves money over time.

Storing your tools the right way helps them last longer. If you keep your tools in a safe, dry place, you stop damage from water and accidents. Old ways to store tools can put them at risk. Better storage keeps your tools safe and working longer.

- Storing tools the right way is important to stop damage, which can change how long they last and how well they work.

- Old storage ways can let water or damage hurt your tools, so you need better ways to keep them safe.

When you plan for the end of your tooling’s life, you make smarter choices for your business. You save money, keep your work moving, and avoid big problems.

Case Study: Cost-Benefit Analysis in Action

Comparing Tooling Options

Think about running a busy factory. You need to pick between two press brake tooling types. One costs less at first. The other costs more but is better and lasts longer. The cheaper tooling might seem like a good deal. It helps your budget right now. But you should look closer. Cheaper tooling wears out faster. You spend more fixing and replacing it. Machines stop more often. Workers wait for repairs. This slows down your work. The better tooling costs more at the start. But it lasts much longer. You do not replace it as much. Machines keep working. Your team stays busy. You save money on repairs and avoid downtime. Over time, better tooling helps you make more products with fewer mistakes.

Tip: Always check the total cost over time, not just the price today when you compare tooling.

Real-World Manufacturing Outcomes

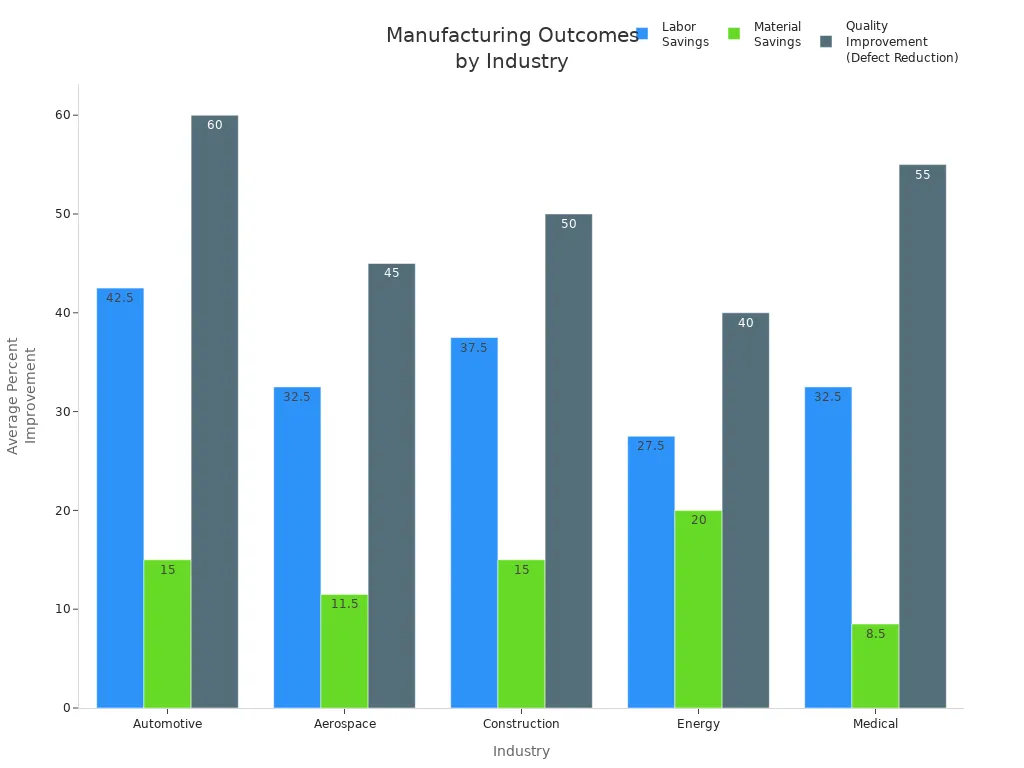

Many companies choose better press brake tooling. They see big changes in how they work. The table below shows what happens in different industries after switching:

| صناعة | Average ROI Period | وفورات العمالة | توفير المواد | تحسين الجودة |

|---|---|---|---|---|

| السيارات | 10-14 months | 35-50% | 12-18% | 60% defect reduction |

| الفضاء الجوي | 14-20 months | 25-40% | 8-15% | 45% defect reduction |

| بناء | 12-18 شهرًا | 30-45% | 10-20% | 50% defect reduction |

| Energy | 18-24 months | 20-35% | 15-25% | 40% defect reduction |

| أو الصناعة الطبية | 16-22 months | 25-40% | 5-12% | 55% defect reduction |

Companies save money on labor and materials. They also have fewer mistakes in their products. For example, car companies save up to 50% on labor and see 60% fewer defects. These changes help you make better products and keep customers happy.

When you buy quality tooling, your factory works better. You fix fewer problems and make more products. The benefits grow over time. You get a good return on your money, and your business gets stronger.

Smarter Decisions for Procurement Managers

Building a Decision Framework

Step-by-Step Decision Process

You need a clear way to make choices in manufacturing. A good plan helps you get better results and save money. Here are some steps you can use:

- Check your current process. Find problems and see what needs fixing.

- Sort your decisions. Some choices are easy to change, others are not.

- Set who can approve spending. Make rules so everyone knows their limits.

- Let your team act quickly. Give them the power to fix problems fast.

- Write down your rules. Share them and check them often.

- Use data to help you decide. Look at numbers to find new ways to improve.

Tip: A step-by-step plan helps you lower risk and get better results in your factory.

Recommended Decision-Making Tools

You can use tools to help you pick the best option. These tools make it easier to compare choices and see what works best.

- Decision matrices help you score each choice by what matters most.

- SWOT analysis lets you see good and bad points for each tooling choice.

- Cost-benefit analysis shows you what you get for your money over time.

- Dashboards with data help you watch how your factory is doing and spot ways to improve.

These tools help you make smart choices and get more from your money.

Engaging Stakeholders

Effective Communication Strategies

You need to talk with many people when buying press brake tooling. Good talking helps everyone know the goals and money plans. Here are ways to keep everyone working together:

| الاستراتيجية | وصف |

|---|---|

| Keep an open mind | Listen to others and look for new ideas. |

| Ask questions at the right time | Talk during meetings and ask questions when needed. |

| Provide clear communication channels | Make it easy for people to share ideas and feedback. |

| Continuous education and training | Teach your team about new things in manufacturing. |

| Listen first, prescribe later | Hear what others say before giving advice. |

| Understand the business first | Learn what your team needs and how your choices affect their work. |

Note: Talking openly builds trust and helps you make better choices.

Common Challenges and Solutions

You might have problems getting everyone to agree. Here are some common problems and ways to fix them:

| تحدي | حل |

|---|---|

| Inaccurate data | Use better systems to get the right facts. |

| Lack of internal communication | Use tools to help your team talk and share news. |

| Failure to adopt technology | Train your team to use new tools and systems. |

You can fix these problems by using good tools and keeping everyone updated. This helps you get better results and save money.

التحسين المستمر

Collecting Feedback

You need feedback to make your process better. Here are some ways to get feedback and improve your work:

- Use common shut heights in tooling. This makes bending faster and setup shorter.

- Try offline programming and bend simulations. You can check your tools before starting a job.

- Use CAM software for CNC programming. This helps you pick the best tools and get early feedback.

Callout: Feedback helps you find problems early and make better choices.

Optimizing the Procurement Process

You can make buying tooling better by using feedback and new ideas. Here are some steps to help you:

- Do regular reviews and surveys after buying tooling.

- Compare your results with other companies to see what you can do better.

- Train your team often so they know the newest trends.

- Use feedback loops to keep making your process better and save more money.

When you always try to improve, you control costs and get better results. Your factory gets stronger and works better.

When you pick press brake tooling, do not just look at price. You should also think about quality and how long the tooling lasts. It is important to check if the supplier is reliable. Use a list or a step-by-step plan to compare all the costs and benefits. This helps you make a smart choice for your business.

Want better results in your factory? اتصل بمهندس المبيعات لدينا to get help with press brake tooling.

التعليمات

What factors affect press brake tooling price?

Many things can change press brake tooling price. Material quality, tool size, and design complexity all play a role. Custom features and special coatings can also increase the cost. Always check what you need before you buy.

How does tooling quality impact my total cost?

High-quality tooling lasts longer and needs less maintenance. You spend less on repairs and replacements. This lowers your total cost over time. Good tooling also helps you make better products with fewer mistakes.

Why should I look beyond the lowest press brake tooling price?

A low press brake tooling price may seem good at first. Cheap tools can wear out fast or cause more downtime. You might pay more later for repairs, lost time, and poor product quality.

How often should I replace press brake tooling?

Replacement depends on how much you use the tooling and the material quality. Stronger materials like 42CrMo alloy steel last longer. Regular checks help you know when to replace your tools.

What are hidden costs in press brake tooling?

Hidden costs include downtime, extra maintenance, and lost production. Poor tooling can also lead to more scrap and rejected parts. These costs add up and can hurt your budget.

How can I compare different press brake tooling options?

You can use a table or decision matrix. List each option’s price, durability, and maintenance needs. Compare the total cost and benefits. This helps you choose the best value for your factory.

Does supplier support matter when buying press brake tooling?

Yes, supplier support helps you solve problems quickly. Good support means less downtime and better results. You get help with setup, training, and technical questions.

Can better tooling improve my manufacturing efficiency?

Yes! Better tooling reduces setup time and errors. You make more parts in less time. Your team works faster, and you keep customers happy.

انظر أيضا

5 ملحقات أساسية لآلات ثني المعادن لتعزيز إنتاجيتك

دور أدوات تشكيل المعادن في تصنيع الصفائح المعدنية الحديثة

كيفية إصلاح عيوب الثني الشائعة باستخدام قوالب وألواح الثني المناسبة

الدليل الكامل لأدوات مكبس الفرامل للمقاطع المعدنية المعقدة

التكلفة الحقيقية لأدوات مكبس الفرامل: تحليل التكلفة الإجمالية للملكية (TCO)