You want each slitting job to have neat, sharp edges. سكاكين خط الشق and spacers work as a team. The right material and blade shape help your knives work better. You need to set the space between blades carefully. When you set it up right, you work faster and can use machines to keep the slitting process smooth.

النقاط الرئيسية

- Slitting line knives cut big metal coils into strips. The strips have smooth edges and the right size.

- Picking the best blade material is important. Tungsten carbide or high-speed steel lasts longer and cuts better.

- Taking care of blades helps them work well. Clean and check them often to make them up to 40% better.

- Spacers help keep the space between knives the same. This makes all the strips the same size.

- If you set up spacers wrong, small mistakes add up. This can make strip sizes very different. Always check your measurements.

- Putting knives and spacers in the right place stops rough edges and bad cuts. This makes the product better.

- Using machines in slitting lines makes setup faster. It also lowers mistakes and keeps workers safe.

- Look at your setup checklist often. Update it to keep things working well and stop problems with slitting.

Slitting Line Knives: Role & Features

Cutting Function in Slitting

Slitting line knives cut big coils of metal into thin strips. First, you put a master coil on the uncoiler. The metal moves through blades set to the right width. Each blade is in the right spot for the strip size you want. These knives cut metal with great accuracy. You get smooth edges and clean cuts. After cutting, you roll up the strips into smaller coils. These coils are ready for the next step.

- Slitting line knives help you keep sizes exact.

- The blades make sure the edges are neat.

- You can keep tight limits, so your product is better.

- The knives cut many metals well, so you work faster.

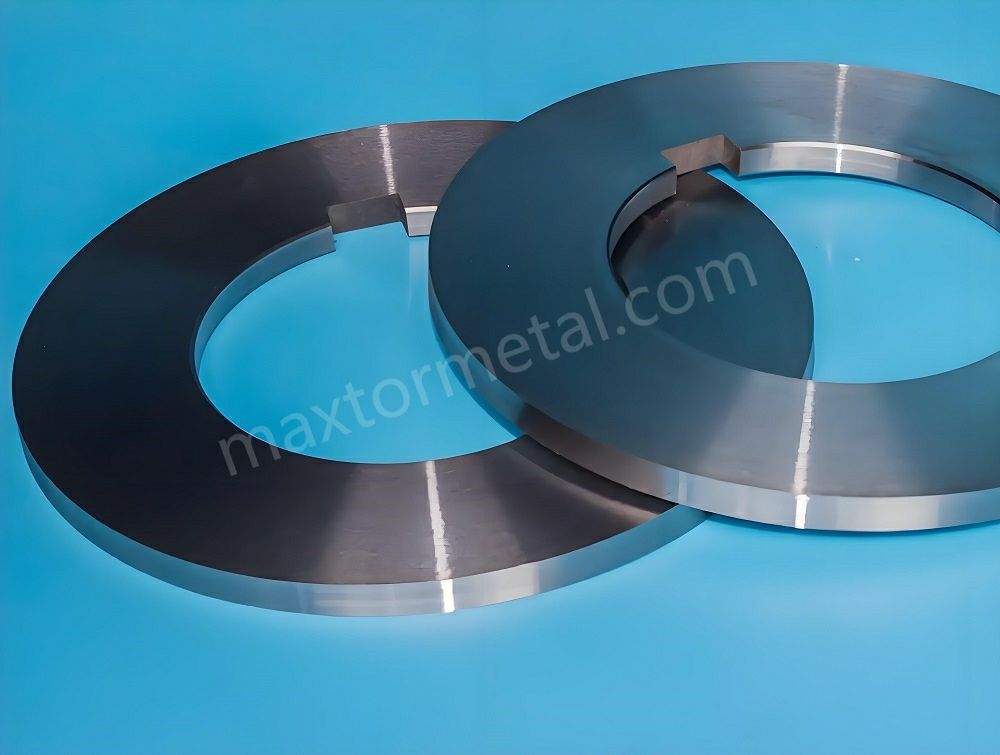

Knife Material & Geometry

The blade’s material and shape matter for edge quality and how long it lasts. You must pick the right blade for your job. Nanjing Metal Industrial’s Roller Shearing Blades are strong slitting line knives. You can also look at شفرات مخصصة if you need something special.

Tungsten Carbide vs. High-Speed Steel

Blades are often made from tungsten carbide or high-speed steel. Each one has its own good points. The table below shows how they are different:

| مادة | مزايا | سلبيات | التطبيقات المناسبة |

|---|---|---|---|

| الفولاذ عالي الكربون | High hardness, excellent wear resistance | Increased brittleness, prone to rust | Cutting paper and films |

| الفولاذ المقاوم للصدأ | Excellent corrosion resistance, easy to process | تكلفة أعلى | Cutting corrosive materials, packaging |

| أداة الصلب | صلابة استثنائية ومقاومة للتآكل | Costly, difficult to process | Cutting metal sheets, thick materials |

| كربيد التنغستن | Extremely high wear resistance, long life | Brittleness, expensive | Cutting hard materials like steel, copper |

Tungsten carbide blades last a long time and do not wear out fast. This means you do not have to change them as much. High-speed steel blades are strong and good for tough jobs. But you may need to sharpen them more often.

Edge Sharpness & Surface Finish

Blade shape changes how good your cut edge looks. You should think about these things:

- The angle or bevel of the edge changes sharpness and how hard it is to cut. Sharper angles cut better but wear out faster.

- Tooth shape and pitch change how fast you cut and how much metal you remove. More teeth make smoother cuts but can get hot.

- Blade material changes how hard and tough the blade is. This matters for different metals.

- Blade width changes how much force you need and how much metal you waste. Thin blades need less force but can bend.

You get better cuts and smoother edges when you match the blade shape to your job.

Maintenance & Longevity

You can use your slitting line knives longer if you take care of them. Good care stops problems and keeps your work good. If you follow the right steps, blades can work حتى 40% أحسن.

نصيحة: Clean your blades and the area around them often. Take away dust, dirt, and sticky stuff so the blades stay sharp.

Here is a table of important maintenance jobs:

| مهمة الصيانة | وصف |

|---|---|

| Inspect blade sharpness | Look for dull spots, chips, or uneven wear. Replace or sharpen if needed. |

| Clean cutting areas | Take away dust, dirt, and sticky stuff from blades and coils. |

| Check bearings and belts | Look for worn parts and check belt tightness. Change or tighten as needed. |

You should clean, check, and adjust your blades often. These steps help your blades last longer and keep your machines working well. Good maintenance also keeps your products the same, stops delays, and makes your workplace safer.

Spacers in Slitting: Precision & Tolerance

Spacer Function & Slit Width

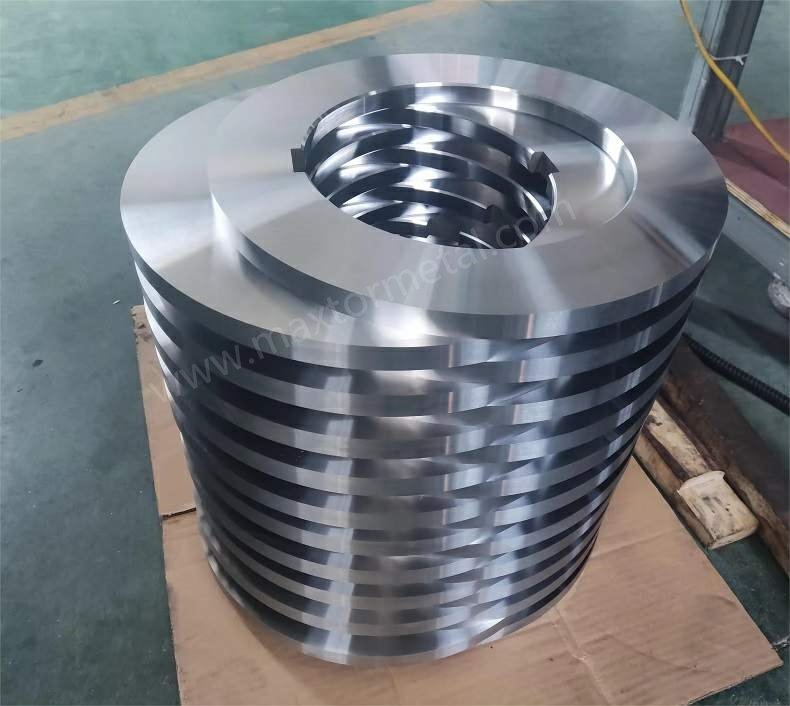

Spacers help set the space between each knife. This space decides how wide each strip will be. If you want many strips, you must place knives carefully. Spacers keep every strip the same size. They hold the knives steady, even when the machine is fast.

In wrap shear slitting, spacers help set the female knives in the right spot. The web wraps around these knives and sits on a shaft with knives and spacers. The material is pulled tight and fully supported. This stops the web from moving or sagging. With good support and tension, the web stays in place. This gives you even slit widths and tight tolerance.

Using the right spacers gives you smooth, even edges. You waste less material and get better quality.

Tolerance Stack-Up Effects

You need to watch for small mistakes when setting up. Each spacer has a size, and tiny errors can add up. This is called tolerance stack-up. If you do not check, your strips may be too wide or too narrow.

Cumulative Error Impact

One small spacer mistake may not seem big. But many small errors can add together. This can change the total width of your strips. You might see uneven edges or strips that do not fit. Always measure and check your spacers before starting. This helps you keep things accurate and avoid problems.

Spacer Materials & Efficiency

You can pick from different spacer materials. Each type has its own good points. The right one helps you keep things precise and makes your line work better.

- Picking the right metal slitting spacers is important for accuracy.

- Good materials stop wear and lower friction.

- Keeping even gaps between parts helps your line run well.

Steel, Nylon, Composite Options

Here is a table to compare spacer materials:

| مادة | ملكيات | Effects on Efficiency and Wear |

|---|---|---|

| Phenolic | Composite, fiber reinforced material. Hard and long wearing. Resistant to heat and debris. | Lasts long and does not wear out fast because it is hard and resists heat and dirt. |

| Nylon | Homogeneous plastic material. Softer and less likely to scratch processed material. | Is gentle on materials and does not scratch, but may wear out faster if it gets hot. |

| فُولاَذ | High precision and wear resistance. Resistant to acid and alkali. | Keeps strips the right size and lasts longer in tough jobs. |

Metal spacers, also called knife pads, must be very exact and tough. You want them to last long and keep your strips the right size. When you choose the best material, you get better results and less machine downtime.

Knives & Spacers: System Interaction

Setup Sequence & Tooling Logic

You must follow steps when setting up your slitting line. The order you put knives and spacers in matters a lot. First, check each knife and spacer for damage or wear. Put the knives on the shaft for the strip widths you want. Use spacers to set the gap between each knife. This helps you control slit width and keeps strips even.

Artus Slitter Knives and Spacers show how careful making gives sharp edges and perfect spots. Smart engineering lets you change tools fast, sometimes up to 14 times in one shift. Robots can move parts with less travel, so setup takes less time. Multiple Picking means you grab more parts at once, making setup faster.

Tip: Always check where each knife and spacer is before you start. This helps you avoid mistakes and keeps your line working well.

Alignment & Parallelism

You need to keep knives and spacers lined up and flat for perfect edges. If knives are not flat or parallel, the gap changes. This can cause burrs and uneven strips. High flatness and parallelism keep the shear clearance the same during slitting. When everything is lined up, you get clean cuts and better strips.

Good blade position helps product quality and machine life. If things are not lined up, you get burrs and strip width changes. You can fix alignment problems in different ways:

- Two-Step Method: Use sensors across each flex plane of the spacer to fix big misalignments.

- Single-Shot Method: Put sensors at the ends of each spacer for small misalignments.

Note: If you see burrs or uneven edges, check knife and spacer alignment first.

Tension control is important for keeping things lined up. You need the right tension on the coil as it moves. If tension is wrong, the material can shift and cuts will be bad. Good tension control keeps knives and spacers in place and makes slitting more reliable.

Common Setup Errors

Many setup mistakes can hurt edge quality and slow down your work. You need to watch for these problems and fix them fast.

| خطأ في المحاذاة | Impact on Edge Quality |

|---|---|

| Misaligned guide rollers | Makes cuts uneven and causes wrinkles in the material. |

| Misaligned winding shafts | Causes uneven material flow and hurts cut quality. |

| Improper knife settings | Gives poor cuts and uneven edges. |

Other common mistakes are:

- Incorrect Knife Alignment: Knives not lined up make uneven cuts.

- Incorrect Knife Penetration Depth: Not deep enough means incomplete cuts. Too deep bends the material.

- Incorrect Blade Pressure: Too much or too little pressure changes the product.

- Unwind Shaft Issues: If the roll moves, slack forms and slitting suffers.

- Edge Guide Limitations: If the edge guide cannot fix the cone shape, you get misalignment and bad edges.

Tension control helps you avoid many mistakes. With the right tension, material stays in place and knives and spacers work together for perfect edges. Always check tension control before starting a new job. This helps you find problems early and keeps slitting efficient.

Tip: Make a checklist for setup. Include knife alignment, spacer placement, tension control, and guide roller position. Use this list every time you set up your slitting line.

You can get better results by focusing on setup steps, alignment, parallelism, and tension control. These steps help you get clean edges and make your slitting process work better.

Optimizing Slitting Efficiency

Selecting Knives & Spacers

You can make slitting work better by picking the right knives and spacers. First, check how hard the anvil is. The anvil costs more to replace than the blade. So, you should match your blade material to what you need. Some common choices are 52-100 steel and M2 steel. The best blade depends on how long you want it to last and what you will cut.

When you pick knives and spacers, remember these things:

- Make sure the blade fits your slitting line.

- Use spacers with normal bore sizes for fast changes.

- Find suppliers who give bulk deals and quick shipping.

- Pick products with a warranty of at least 12 months.

- Get technical help and guides for installing.

- For food or medical jobs, use safe, non-toxic materials.

- Choose anti-slip and vibration-proof features for safer, fast work.

Think about saving money in the long run. Blades that last longer and need less fixing save you money.

Knives and spacers together change how well and how neatly you cut. The table below shows how different choices affect your results:

| نقطة الدليل | وصف |

|---|---|

| Precision of Slitter Spacers | Ground spacers help you get the strip width and knife spot right. |

| Matched Components | Full sets keep knives and strips lined up for neat cuts. |

| Separator Discs Function | Strong separator discs guide strips and protect edges at high speeds. |

| تباين المواد | Different materials fit many coils, making them stronger and last longer. |

| OEM Replacement | Custom sets can make cuts more exact and improve results. |

Installation & Alignment Tips

Good installation and lining up make slitting work better. Follow these steps for the best results:

- Clean the top dish slitter knives. Wipe off any oil before you start.

- Put the upper knife on the lower knife. Make sure they match up.

- Use spacers to hold the upper knife in place.

- Change the knife bed height by hand. Set the cutting depth between 0.5 and 1 mm.

- If only one end touches, move the shaft behind the frame.

- Always put the machine in tool-change mode before you work.

- Keep your hands away from the knife bed and do not move fast.

The gap between the band and blade should be 4 to 6 mm (0.16″ to 0.24″). This gap helps you cut right and keeps the force even.

Check for good alignment and that everything is flat. If you use matched spacers and separator discs, knives and strips stay in line. This setup means less guessing and gives you neat, even edges every time.

Take care of your tools often. Clean your knives and spacers a lot. Look for dull spots or uneven wear. Replace or sharpen blades when needed. These habits keep your slitting line working well and stop delays.

Automation & Safety

Automation makes slitting faster and easier. Automated loading lets you move coils and strips with less work. You can use automated loading to set up faster and keep your line moving. Automated systems also help keep knives and spacers in the right place, which makes things safer and more exact.

Here is a table showing how automation features help with speed and safety:

| ميزة | فائدة |

|---|---|

| Servo-driven knives | Clean, exact cuts with fewer mistakes |

| Laser-guided positioning | Cuts are more exact and need less fixing |

| Automatic tension control | Keeps material tight and makes work safer |

| Touch-screen interfaces | Easy to use and fewer errors |

| Programmable recipes | Fast changes and better speed |

| Real-time diagnostics | Quick fixes and safer work |

Automated loading and systems work together to keep your line fast. You can use automated loading to lift heavy coils, which helps stop injuries. Automated systems also keep things steady, even when working fast.

Safety is most important with automation. Always wear safety glasses, gloves, and steel-toe boots. Check your machines for loose parts or leaks. Keep your work area clean and load materials the right way. Use guard rails and know how to stop the machine fast if needed. Train your team often and update safety rules when you get new ideas.

Tip: Check your setup and care routines often. Automation and regular cleaning help you get the best from your slitting line.

If you want to learn about advanced automation or custom tools, you can read more about Nanjing Metal Industrial and their modern slitting line solutions.

Troubleshooting Edge Quality

When you use a slitting line, you want every strip to have clean, straight edges. Sometimes, you might see problems like burrs, camber, or edge wave. You can fix these problems if you know what to look for and how to change your setup.

Identifying Defects

You might see different edge problems while slitting. Each problem has its own cause and way to check for it. The table below helps you spot common issues:

| Edge Defect | وصف | Identification Method |

|---|---|---|

| Slit Edge | Small bits of web material stick out from the slit edge. | Use a cotton ball or swab to check for chips or if the blade is not lined up. |

| Flared Edge | The outside edge is bigger than the roll body. | Look for sharp cutting edges and keep a log to track problems. |

| Cracked Edge | The edge of the web breaks or tears. | Watch for trim flutter and check if the knife overlap and speed are right. |

| Fuzzy Edge | The edge has torn fibers instead of a clean cut. | Check if the knife is sharp, press harder, and see if there is too much overlap or not enough contact. |

Burrs, Camber, Edge Wave

- Burrs look like rough, raised metal on the slit edge. You can feel them with your finger or see them under a light.

- Camber means the strip curves instead of staying straight. You see this when the strip does not lay flat.

- Edge wave shows as wavy or uneven edges. The strip may wrinkle or not coil smoothly.

Tip: Always check the first few strips after you set up. Early checks help you find problems before you run the whole coil.

Diagnosing Knife & Spacer Issues

Many edge problems come from your slitting line knives or spacers. Use the table below to match causes with fixes:

| سبب | حل |

|---|---|

| Dull or damaged knife | Replace or sharpen the knife. |

| Dirty knife | Clean the knife and add a little 20W oil. |

| Knife timed early | Retime the knife using your machine’s guide. |

| Knife action sluggish | Check the bearing and pivot end; add oil if needed. |

| Obstruction in film slot | Remove anything blocking the slot. |

| Elevator incorrectly positioned | Check slot alignment with a straight edge and fix it. |

| Paper clamp roll out of time | Adjust the cam for more lift to the clamp roll. |

| Elevator paper clamp not working | Clean the clamp and slot; check if the shaft turns. |

| Paper clamp rolls dirty | Wipe off any build-up with a damp cloth. |

If you see burrs, check if your slitting line knives are sharp and set at the right gap. If you see camber or crooked cuts, look at the pressure on your knives and the shape of your spacers. Worn or uneven spacers can make strips wander or curve.

Note: Always check both knives and spacers when you see edge problems. Many problems come from both parts working together.

Solutions & Adjustments

You can fix most edge problems by making careful changes. The table below shows common problems, causes, and what you can do:

| نوع المشكلة | الأسباب المحتملة | حلول |

|---|---|---|

| Burrs on Slit Edges | Blade dullness, wrong gap, blade not lined up | Sharpen or replace dull blades, fix knife gap, make sure blades are lined up right |

| Camber and Crooked Cuts | Uneven knife pressure, worn spacers, bad material | Make knife pressure even, use good spacers, check coil before slitting |

| Excessive Edge Wave or Wrinkling | Uneven tension, wrong recoiling settings | Fix tension, use tension pads or brakes, check strip width is right |

| Knife Breakage or Premature Wear | Too much cutting pressure, wrong blade hardness | Lower cutting pressure, pick the right blade, make sure coil feeds right |

| Slit Strip Width Variations | Knife stack not lined up, material thickness changes | Line up knife stacks, use strong blades, check coil thickness is the same |

You can also follow these steps to get better edges:

- Set up your slitting line knives with care. Make sure every blade is sharp and in the right spot.

- Keep tension even across the strip. Uneven tension causes edge waves and wrinkling.

- Use high-precision spacers. Bad spacers cause camber and width changes.

- Check your material before slitting. Look for problems in the master coil.

- Clean all parts often. Dirt and build-up can make knives slip or cut badly.

Preventing edge problems starts with good habits. Check your master coil, set up your knives and spacers carefully, and keep your tools clean. These steps help you get perfect edges every time.

If you still see problems after these changes, talk to a slitting line expert. You might need to check your machine alignment or try different knife materials for your job.

Copper Coil Slitting Line Applications

Steel Service Centers & Automotive

Copper coil slitting lines are used in steel service centers and the automotive industry. These places need copper strips that are the right size and quality. Copper coil slitting lines help make strips that fit these needs. This means car parts work well and last longer.

- In cars, copper strips are used for wires, batteries, and connectors. Electric cars need lots of copper for their batteries and power systems.

- Copper strips help cars move electricity, control heat, and keep people safe.

- Copper strips are also found in cables, switchgear, and transformers. These parts need copper to carry electricity safely.

Copper coil slitting lines make strips fast and with little waste. This helps car makers and parts suppliers get what they need. It also helps make cars safer and more reliable.

Electrical & Appliance Sectors

Copper coil slitting lines are important for electrical and appliance companies. These companies need copper strips with special features. You have to choose the right steel or copper and set up your line the right way.

- In the electrical field, you use electrical steel. You need to save energy and work efficiently. This is important for motors and transformers.

- In appliances, copper strips help make machines quieter and better. Washing machines and fridges work better with good copper strips.

Copper coil slitting lines let you control how you make strips. You can change your line for different materials and thicknesses. This helps you make parts for many electrical and home appliances.

Construction & Heavy Engineering

Copper coil slitting lines are used in construction and heavy engineering too. These jobs need strong copper strips for buildings and machines. Working with heavy coils and thick metal can be hard.

| تحدي | حل |

|---|---|

| Knife Misalignment | Use digital setup systems and routine calibration |

| تشكيل النتوءات | Maintain sharp knives and proper clearance setup |

| Tension Imbalance | Implement closed-loop tension control systems |

| Coil Telescoping | Use edge guides and proper tensioning during recoiling |

You need to keep your copper coil slitting line working well for these tough jobs. Digital setup systems help you line up knives. Sharp knives and the right space between them stop burrs. Closed-loop tension control keeps strips flat. Edge guides help you wind coils without trouble.

Copper coil slitting lines help you make strong and accurate copper strips for big projects. You can trust your line to do a good job every time.

Tip: Using a copper coil slitting line helps you make better products and save time. You can meet strict rules and help your customers build great things.

To get perfect edges, you need to do a few things. First, set your knife settings right and keep your machines in good shape. Next, get your coils ready and make sure the tension is just right. Use automated systems to help control the process better. Check your work often and teach your team what to do.

If you take care of your machines and use a system, you get better results. New automation, like robots for tools and automatic separators, can help you work faster:

| Automation Option | فائدة |

|---|---|

| Tooling setup robot | Makes fewer mistakes and saves time |

| Hands-free coil loading | Makes work safer and faster |

| Automatic separators | Helps you get more done |

If you want help or need something special, talk to our sales engineer.

التعليمات

What are slitting line knives used for?

You use slitting line knives to cut large coils of metal into narrow strips. These knives help you get clean, straight edges and keep each strip the right size for your job.

How do spacers work with slitting line knives?

Spacers set the distance between each knife. You place spacers between knives to control the width of each strip. This helps you keep every strip the same size and improves edge quality.

How often should you replace or sharpen slitting line knives?

You should check your slitting line knives often. Replace or sharpen them when you see dull edges, chips, or uneven cuts. Regular checks help you keep your cuts clean and your line running smoothly.

What materials are best for slitting line knives?

You can choose from tungsten carbide, high-speed steel, or tool steel. Tungsten carbide lasts longer. High-speed steel works well for tough jobs. Pick the material that fits your metal and production needs.

Why do you get burrs or rough edges after slitting?

Burrs or rough edges often mean your slitting line knives are dull or not set up right. You should check knife sharpness, alignment, and the gap between knives. Fixing these problems helps you get smooth edges.

Can you use slitting line knives for different metals?

Yes, you can use slitting line knives for steel, copper, aluminum, and other metals. You need to pick the right knife material and setup for each type of metal to get the best results.

How does automation help with slitting line knives and spacers?

Automation helps you set up slitting line knives and spacers faster and more accurately. Automated systems reduce mistakes, improve safety, and let you change setups quickly for different jobs.

انظر أيضا

شفرات قص دوارة للصفائح المعدنية

ما هي شفرات القص الدوارة وكيف تعمل؟

استكشاف تطبيقات شفرات القطع Metal في التصنيع

كيفية اختيار شفرة قص الأسطوانة المناسبة لاحتياجاتك

شفرات السليتر الدوارة ما بعد البيع مقابل الأصلية (OEM): تحليل التكلفة والعائد