لماذا يعد اختيار شفرة تقطيع المطاط المناسبة أمرًا مهمًا

تحسين كفاءة القطع

اختيار الحق شفرة تقطيع مطاطية يُسهّل القطع. يُمكن لتغييرات صغيرة في تصميم الشفرة أن تُحسّن الأداء بشكل ملحوظ. على سبيل المثال، زاوية حافة الشفرة مهمة جدًا. تظهر الدراسات حتى تؤثر التغييرات الصغيرة في هذه الزاوية على قوة القطع. سرعة القطع مهمة أيضًا ويمكن أن تغير مدى جودة عمل الشفرة.

تُظهر الاختبارات أن شفرة تقطيع المطاط الجيدة يمكنها قطع 15 قطعة مطاطية في الدقيقة. هذا يُسرّع الإنتاج ويُقلّل من وقت التوقف. الآلات المتطورة، مثل مازاك نيكسوس موديل 410 أ, وضّح كيف تؤثر سرعة المغزل ومعدل التغذية على سرعة القطع. كفاءة القطع العالية تعني إنجاز المزيد من العمل والحفاظ على ثبات النتائج.

الحفاظ على جودة المنتج عالية

تعتمد جودة منتجك على الشفرة التي تستخدمها. قد تُسبب الشفرات القديمة أو غير المناسبة خشونة في الحواف أو تشققات أو مشاكل أخرى. تُتلف هذه المشاكل المنتجات وتُسبب هدرًا. يُساعد العناية المنتظمة بالشفرة واستبدال الشفرات البالية في الحفاظ على نظافة الجروح. علامات مثل ضوضاء قطع عالية أو سرعة أبطأ يعني أن الشفرة قد تحتاج إلى الاستبدال.

تثبت الأمثلة الواقعية ذلك. شركة واحدة تم تحسين جودة القطع بواسطة 15% باستخدام شفرة مخصصة ذات حافة أكثر سمكًا. قامت شركة أخرى بتصنيع شفرات 25% تدوم لفترة أطول وتقلل من الغبار باستخدام شفرات دقيقة الطحن. اختيار شفرة تقطيع المطاط المناسبة يُحسّن الجودة ويُقلل النفايات.

توفير المال باستخدام الشفرة المناسبة

استخدام الشفرة المناسبة يوفر عليك المال. الشفرات عالية الجودة، مثل مركبات المصفوفة الخزفية (CMCs)، تدوم لفترة أطول وتتطلب عناية أقل. تُظهر الدراسات أن مركبات المصفوفة الخزفية وفر 15–20% المزيد من المال مع مرور الوقت، تتفوق الشفرات العادية. فهي متينة، لذا تحتاج إلى استبدال أقل ووقت تعطل أقل.

تتميز شفرات CMC أيضًا بمعدل إرجاع 62%، مقارنةً بمعدل 45% للمواد الأخرى. هذا يعني أنها أكثر ربحية على المدى الطويل. اختيار شفرات متينة يوفر المال ويجنب التكاليف الإضافية مثل الاستبدال المتكرر. شركات مثل Nanjing Metal نقدم حلول شفرات مخصصة تناسب احتياجاتك ونقدم لك أفضل قيمة. لمزيد من المعلومات، تفضل بزيارة اتصل بنا هم.

النقاط الرئيسية

- اختيار شفرة تقطيع المطاط المناسبة يُسهّل عملية القطع. تستطيع الشفرة الجيدة قطع ١٥ قطعة مطاطية في الدقيقة، مما يُسرّع العمل.

- الشفرات الجيدة تُنتج منتجات أفضل. العناية المنتظمة واستبدال الشفرات في الوقت المناسب يمنعان الجروح الخشنة والهدر.

- شفرات قوية توفر المال مع مرور الوقت. شفرات السيراميك تدوم لفترة أطول وتُخفّض تكاليف الاستبدال بنسبة 15-20%.

- اختر مواد الشفرة بناءً على نوع المطاط. يتناسب المطاط الصلب جيدًا مع كربيد التنغستن، بينما يتطلب المطاط اللين الفولاذ المقاوم للصدأ.

- تختلف أشكال الشفرات في أداء وظائفها. الشفرات المستقيمة مثالية للقطع المسطح، بينما الشفرات المستديرة مثالية للقطع السريع.

- العناية بالشفرات يجعلها تدوم لفترة أطول. نظّفها، خزّنها بشكل صحيح، وشحذها لتوفير المال.

- يمكن للشفرات المخصصة أن تقطع بشكل أفضل. تناسب الشفرات الخاصة احتياجات الصناعة، مما يجعل العمل أسرع ويهدر أقل.

- فكّر في التكلفة الإجمالية، وليس فقط في السعر. قد تكون تكلفة الشفرات الجيدة أعلى في البداية، لكنها ستوفر المال لاحقًا.

دليل اختيار الشفرة: العوامل الرئيسية التي يجب مراعاتها

التوافق المادي

مطابقة مادة الشفرة مع نوع المطاط

اختيار مادة الشفرة المناسبة أمر بالغ الأهمية. تحتاج أنواع المطاط المختلفة إلى شفرات محددة لقطع نظيف واستخدام طويل الأمد. على سبيل المثال، كربيد التنغستن الشفرات رائعة لقطع المطاط الخشن لأنها مقاومة للتآكل. وفي الوقت نفسه، الفولاذ المقاوم للصدأ تعمل الشفرات بشكل جيد مع المطاط الناعم، وتوفر قطعًا دقيقة.

فكّر في صلابة المطاط ومرونته وخشونته عند اختيار الشفرة. استخدام الشفرة المناسبة يقلل من التلف ويحافظ على ثبات الأداء. هذا أيضًا يُسهّل القطع ويطيل عمر الشفرات، مما يوفر المال على الاستبدال.

اعتبارات المطاط الصلب مقابل المطاط اللين

يحتاج المطاط الصلب إلى شفرات قوية وحادة. كربيد التنغستن وشفرات الفولاذ المُسبَك خيارات جيدة. هذه المواد تبقى حادة ولا تتشقق تحت الضغط.

المطاط الناعم يحتاج إلى لمسة لطيفة. الشفرات المصنوعة من الفولاذ المقاوم للصدأ الفولاذ عالي السرعة أو الفولاذ المقاوم للصدأ أفضل. فهو يقطع بسلاسة دون تمزيق أو ثني المطاط. اختيار الشفرة المناسبة للمطاط اللين يتجنب الأخطاء ويحافظ على جودة المنتجات.

نصيحة: اختبر الشفرات على قطعة مطاطية صغيرة أولًا. هذا يساعد على التحقق من عملها بشكل جيد ويمنع الأخطاء الكبيرة.

تصميم الشفرة ونوعها

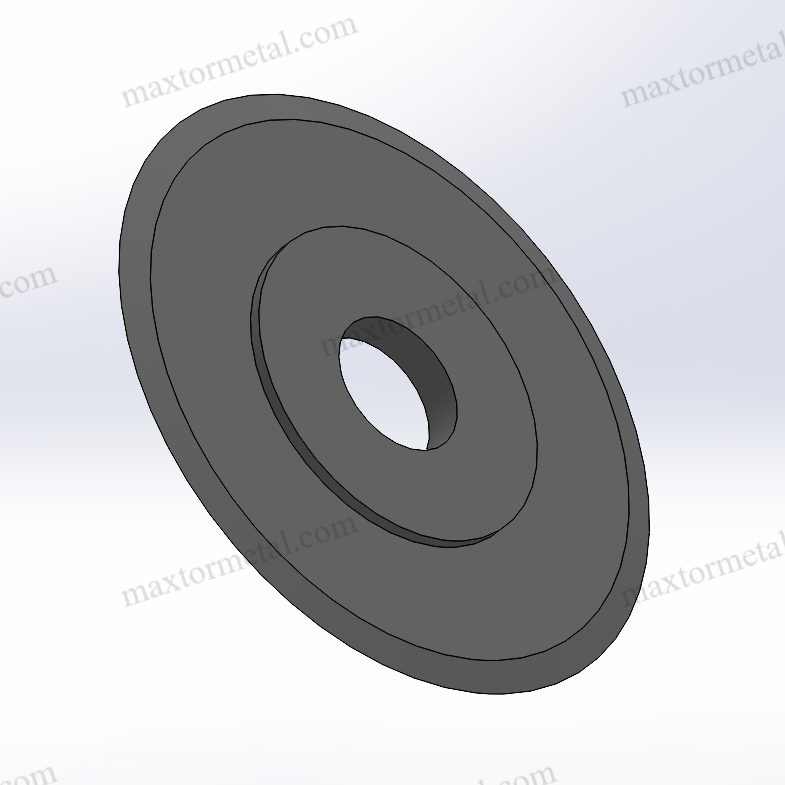

الشفرات المستقيمة: الميزات والتطبيقات

الشفرات المستقيمة بسيطة ومفيدة للعديد من المهام. فهي مثالية لقطع صفائح أو أشرطة المطاط المسطحة. تُجري هذه الشفرات قطعًا دقيقة ونظيفة، وهو أمر بالغ الأهمية للأعمال الدقيقة.

لكن الشفرات المستقيمة قد لا تعمل جيدًا مع المطاط السميك أو المطاطي. في هذه الحالات، جرّب تصميمات شفرات أخرى للحصول على نتائج أفضل.

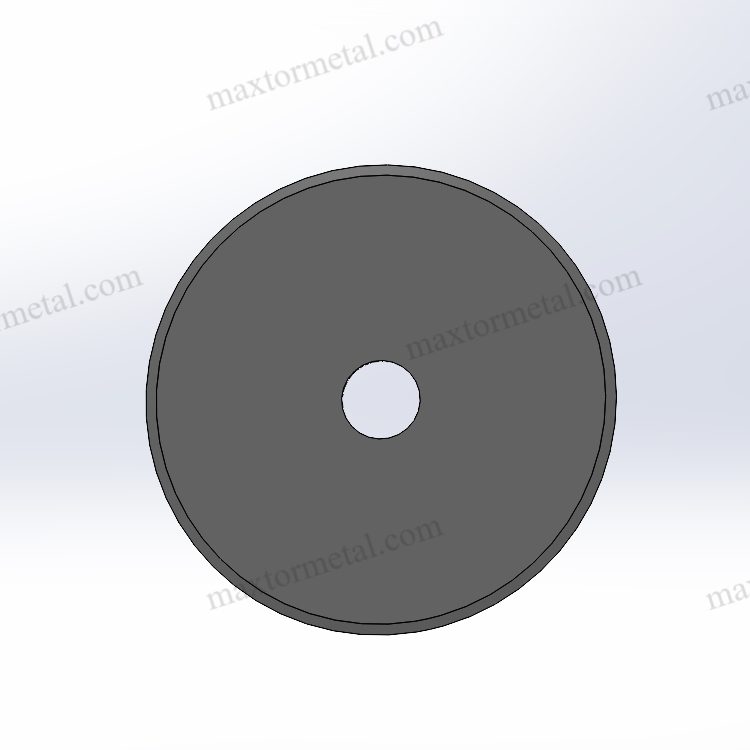

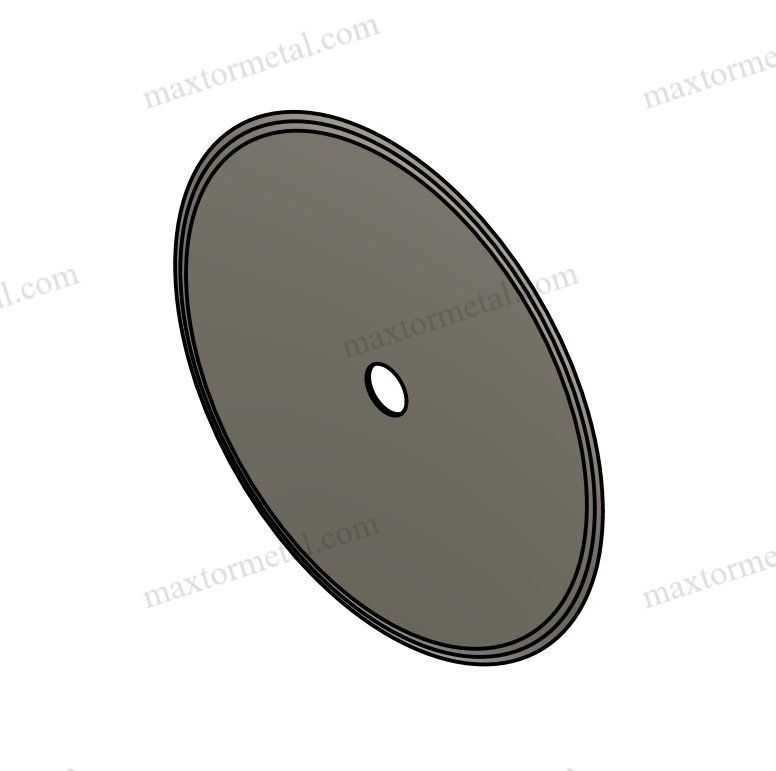

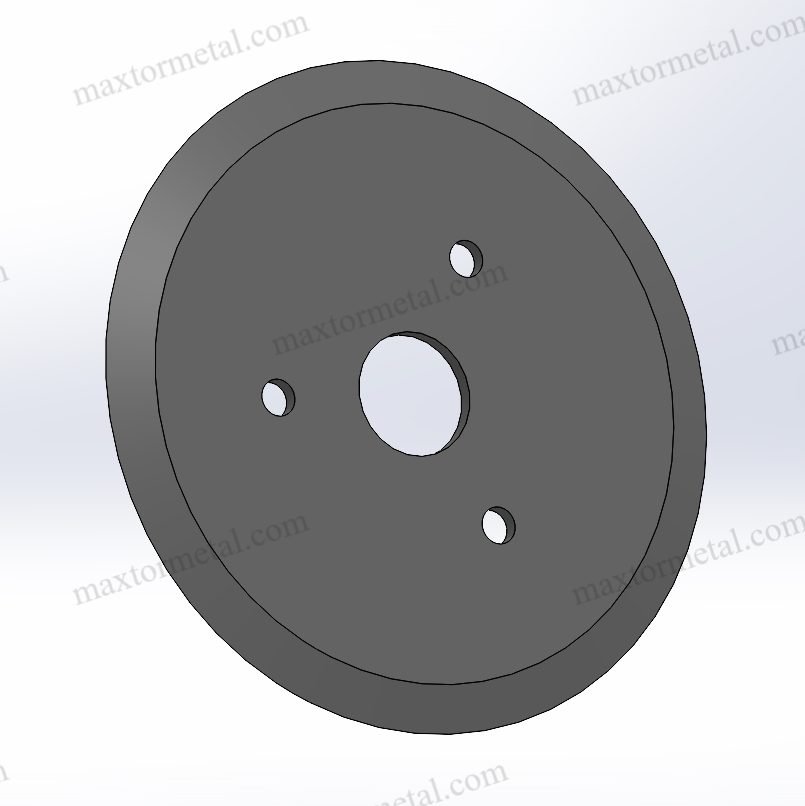

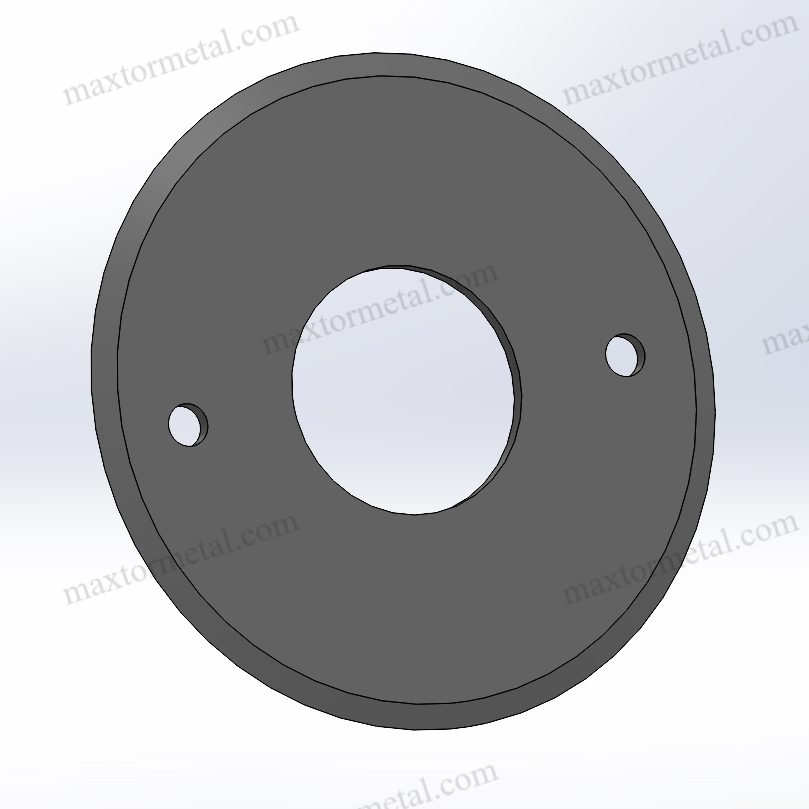

الشفرات الدائرية: الفوائد وحالات الاستخدام

تدور الشفرات الدائرية أثناء القطع، مما يقلل الاحتكاك. هذا يجعل القطع أسرع وأكثر سلاسة. وهي مثالية لقطع لفات المطاط الطويلة أو العمل على خطوط الإنتاج السريعة.

كما أن الشفرات الدائرية تُهدر مواد أقل. فقصها الدقيق يُخلّف حوافًا ناعمة، مما يجعلها مثالية للتشطيبات عالية الجودة. وغالبًا ما تستخدم صناعات مثل صناعة السيارات الشفرات الدائرية لموثوقيتها وكفاءتها.

الشفرات المسننة: تطبيقات متخصصة

تتميز الشفرات المسننة بحواف مسننة تُمسك بالمطاط أثناء القطع. وهي مناسبة للمواد الزلقة أو القابلة للتمدد. تُستخدم هذه الشفرات غالبًا في التغليف حيثما يلزم قطع أنيق.

مع ذلك، تحتاج الشفرات المسننة إلى عناية أكبر. اشحذها باستمرار لضمان عملها بكفاءة.

| سمة التصميم | كيف يؤثر ذلك على أداء القطع |

|---|---|

| شكل الشفرة | تصميم الحافة وتغيير زاوية سرعة القطع والدقة. |

| يؤدي ضبط هذه العناصر إلى تحسين الدقة والسرعة. | |

| اختيار المواد | كربيد التنغستن يقاوم التآكل أثناء المهام الصعبة. |

| الفولاذ المقاوم للصدأ هو الأفضل للحصول على قطع أنيقة ودقيقة. | |

| توازن القوة والحدة بين السبائك والفولاذ عالي السرعة. |

المتانة وطول العمر

أهمية طلاء الشفرات

طلاءات الشفرات تطيل عمرها. تُقلل الطلاءات مثل نيتريد التيتانيوم أو الكربون الشبيه بالماس الاحتكاك وتحمي الشفرات من التآكل. كما تُحافظ هذه الطلاءات على حدتها لفترة طويلة، مما يُحسّن أداء القطع.

قد تكون الشفرات المطلية أعلى سعرًا في البداية، لكنها توفر المال مع مرور الوقت. فهي تدوم لفترة أطول وتحتاج إلى استبدال أقل، مما يوفر الوقت والجهد.

العوامل المؤثرة على مقاومة التآكل

تؤثر عوامل كثيرة على عمر الشفرة. المادة، وشكل الحافة، وكيفية استخدامها، كلها عوامل مهمة. على سبيل المثال، كربيد التنغستن الشفرات متينة للغاية ومناسبة لقطع المطاط الخشن.

من المهم أيضًا الحفاظ على زاوية الشفرة الصحيحة أثناء القطع. فالزاوية الجيدة تُخفف الضغط على الشفرة وتُطيل عمرها. بالتركيز على هذه التفاصيل، يمكنك تحسين أداء شفراتك وإطالة عمرها.

ملحوظة: افحص شفراتك باستمرار واعتني بها. ابحث عن أي حواف باهتة أو قطع غير متساوية، وأصلح المشاكل بسرعة.

فعالية التكلفة

موازنة الاستثمار الأولي مع القيمة طويلة الأجل

عند اختيار شفرات تقطيع المطاط، قد تبدو الشفرات الرخيصة أفضل. لكن التركيز على الأسعار المنخفضة فقط قد يكلفك أكثر لاحقًا. الشفرات عالية الجودة تكلف أكثر في البداية، لكنها توفر المال مع مرور الوقت.

إليك الطريقة:

- متانةالشفرات القوية، مثل كربيد التنغستن أو السيراميك، تدوم لفترة أطول. فهي تبقى حادة وتحتاج إلى استبدال أقل، مما يوفر المال.

- أداءشفرات جيدة تقطع أسرع وأكثر سلاسة. هذا يقلل من هدر المواد ويوفر الوقت أثناء الإنتاج.

- تكاليف الصيانةالشفرات عالية الجودة تتطلب عناية أقل. لن تستغرق وقتًا طويلاً في إصلاحها أو شحذها، مما يُسهّل العمل.

نصيحة:اعتبر شراء الشفرات خيارًا ذكيًا. إنفاق المزيد الآن قد يوفر عليك الكثير لاحقًا.

على سبيل المثال، استخدمت إحدى الشركات شفرات مطلية وخفضت تكاليف الاستبدال بمقدار 30% خلال عام. كانت التكلفة الأولية تستحق العناء، مما يثبت أن الجودة تؤتي ثمارها.

تجنب التكاليف الخفية للشفرات الرديئة

قد تبدو الشفرات الرخيصة صفقةً رائعة، لكن لها تكاليف خفية. هذه التكاليف الإضافية قد تؤثر سلبًا على ميزانيتك مع مرور الوقت.

فيما يلي المشاكل الشائعة المتعلقة بالشفرات ذات الجودة المنخفضة:

- الاستبدالات المتكررةالشفرات الرخيصة تبلى بسرعة. ستحتاج لشراء شفرات جديدة باستمرار، مما يتراكم.

- جودة القطع رديئة:الشفرات السيئة تُحدث قطعًا خشنة أو تُتلف المواد. هذا يُهدر الموارد ويُنتج منتجات غير صالحة للاستخدام.

- زيادة وقت التوقف:الشفرات الباهتة تُبطئ العمل. التوقف عن استبدالها أو إصلاحها يُهدر الوقت ويُقلل الإنتاجية.

- تكاليف الصيانة الأعلى:تحتاج الشفرات الرخيصة إلى مزيد من الإصلاحات والشحذ، مما يزيد من التكاليف.

| مشكلة | كيف يكلفك ذلك | اختيار أفضل |

|---|---|---|

| الاستبدالات المتكررة | أنفق المزيد على شراء شفرات جديدة | استخدم مواد تدوم طويلاً |

| جودة القطع رديئة | المواد النفايات والمنتجات المرفوضة | اختر شفرات مصنوعة بدقة |

| زيادة وقت التوقف | ضياع الوقت وتباطؤ الإنتاج | اختر شفرات متينة وطويلة العمر |

| احتياجات صيانة أعلى | ادفع المزيد مقابل الإصلاحات والعمالة | احصل على شفرات ذات طلاءات قوية |

ملحوظة:قد توفر الشفرات الرخيصة المال الآن، ولكنها ستكلف أكثر لاحقًا.

باستخدام شفرات عالية الجودة، تتجنب هذه المشاكل. ستوفر المال، وتقلل الهدر، وتعمل بكفاءة أكبر. فكّر دائمًا في التكلفة الإجمالية، وليس فقط في السعر.

توصيات خاصة بالصناعة لشفرات تقطيع المطاط

صناعة السيارات والإطارات

قطع المطاط للإطارات والأختام

صناعة الإطارات تحتاج شفرات قوية وحادةتستخدم الإطارات مواد متينة كالمطاط الصناعي ومركبات الفولاذ. وتحتاج هذه المواد إلى شفرات حادة وذات قطع جيد.

آلات التقطيع الخاصة مهمة لقطع مواد الإطارات. فهي مصممة للتعامل مع هذه المواد الصلبة. إذا أصبحت الشفرات باهتة، فإنها تعمل بشكل أبطأ وتتآكل بشكل أسرع. تقول الشركات إن آلات التقطيع الجيدة تدوم طويلًا. 25 سنة بعناية. هذا يُظهر كيف تُوفّر الشفرات عالية الجودة المال مع مرور الوقت.

نصيحة:تحقق من الشفرات وشحذها بشكل متكرر للحفاظ على عملها بشكل جيد.

احتياجات القطع عالية الدقة

تحتاج الإطارات إلى قطع دقيق للغاية لتجنب العيوب. قد يؤدي القطع غير المتساوي إلى إتلاف الأختام وتقليل جودة الإطارات. تُعد الشفرات الدائرية مثالية للقطع السلس والدقيق. فحركتها الدورانية تجعل القطع أسهل وأنظف.

تستخدم شركات السيارات شفرات دقيقة التجليخ لتلبية معايير صارمة. تُنتج هذه الشفرات قطعًا دقيقة، مما يُعزز السلامة والأداء. اختيار تصميم الشفرة المناسب يُقلل الهدر ويُحسّن الدقة.

صناعة التعبئة والتغليف

تقطيع المطاط للتغليف الواقي

يساعد تقطيع المطاط على صنع الأختام والحشيات اللازمة للتغليف. تتطلب هذه القطع قطعًا دقيقةً لتناسبها بشكل صحيح. الشفرات المستقيمة مناسبة لقطع صفائح المطاط المسطحة.

تُعدّ الشفرات الدائرية خيارًا ممتازًا لقطع لفات المطاط بسرعة. وهي مثالية لخطوط الإنتاج المزدحمة. اختيار نوع الشفرة المناسب يوفر الوقت ويعزز الكفاءة.

أهمية القطع النظيفة والدقيقة

تتطلب العبوات قطعًا ناعمة ونظيفة. قد تُعيق الحواف الخشنة عمل الأختام أو الحشيات بشكل صحيح. تُناسب الشفرات المسننة المطاط المرن أو الزلق، حيث تُثبّت حوافها المسننة المطاط أثناء القطع.

الشفرات الحادة أساسية للحصول على نتائج جيدة. الشفرات الباهتة قد تُمزق المطاط وتُهدر المواد. العناية المنتظمة تحافظ على حدة الشفرات ويتجنب التكاليف الإضافية.

ملحوظةاختبر الشفرات على قطعة مطاطية صغيرة أولًا. هذا يساعد على تحديد المشاكل قبل البدء بأعمال كبيرة.

التصنيع العام

التنوع في قطع منتجات المطاط المختلفة

تحتاج المصانع إلى شفرات قادرة على قطع العديد من المواد المطاطية. تتطلب الأحزمة الناقلة والحصائر المطاطية أساليب قطع مختلفة. تُعد الشفرات الدائرية والمستقيمة شائعة الاستخدام نظرًا لتعدد مهامها.

تستخدم الشركات الكبيرة مثل جنرال إلكتريك وسيمنز أنظمة مرنةتُسهّل هذه الأنظمة العمل وتُلبّي احتياجات العملاء. كما يُساعد استخدام شفرات قابلة للتكيّف على الحفاظ على الجودة العالية وتلبية مختلف المتطلبات.

| الشركة | كيف تساعد على التنوع |

|---|---|

| جنرال إلكتريك | يستخدم أنظمة مرنة لتحسين سرعة الإنتاج. |

| سيمنز | بناء أنظمة لتلبية طلبات العملاء بسرعة. |

متطلبات الشفرة شديدة التحمل

يحتاج المطاط السميك إلى شفرات قوية. شفرات كربيد التنغستن مثالية للأعمال الشاقة، فهي تبقى حادة ولا تتآكل بسهولة.

المتانة أمرٌ بالغ الأهمية في المصانع. يجب أن تعمل الشفرات بكفاءة دون أن تتعطل. تنظيف الشفرات وشحذها يُساعد غالبًا على إطالة عمرها. الشفرات القوية تُقلل من وقت التوقف عن العمل وتُحافظ على سير العمل بسلاسة.

نصيحة:اختر الشفرات ذات الطلاءات مثل نتريد التيتانيوم للحصول على قوة إضافية وتآكل أقل.

شفرات صناعية مخصصة:حلول مصممة خصيصًا لصناعتك

مزايا الشفرات المخصصة

حل مشاكل الصناعة الفريدة

تختلف احتياجات القطع باختلاف الصناعات. غالبًا ما لا تعمل الشفرات العادية بكفاءة. يتم تصنيع الشفرات المخصصة لتناسب مهامك بدقة. على سبيل المثال، يتطلب قطع المطاط الصلب حوافًا أقوى. أما المطاط الناعم فيحتاج إلى شفرات أكثر حدة لقطع سلس دون تلف.

تُساعد الشفرات المُخصصة أيضًا على تقليل الهدر. فهي تقطع فقط ما يلزم، مما يُوفر المواد. أدوات مثل ماكينات CNC تُجري قطعًا دقيقة، مما يُحسّن الجودة ويُقلل الأخطاء. تُحل الشفرات المُخصصة مشاكل لا تستطيع الشفرات العادية معالجتها.

تحسين السرعة والكفاءة

الشفرات المُخصصة تُسهّل العمل وتزيد من كفاءته. تُظهر الدراسات أن الشركات التي تستخدم هذه الشفرات العمل بمعدل 12–15% أسرع كل عاميمكن للتصاميم الخاصة زيادة الإنتاج بمقدار ٢٠١TP٤T. هذا يعني عملاً أسرع ونتائج أفضل.

كما أن الشفرات المخصصة تقلل من وقت التوقف عن العمل. مصنع بصندوق واحد تم تقليل وقت التوقف من 14 ساعة إلى أقل من 5 ساعات باستخدام شفرات أسنان دقيقة مخصصة، وفّر هذا الوقت وحسّن سلاسة العمل. مع تأخير أقل، تساعدك الشفرات المخصصة على تحقيق أهدافك بشكل أسرع.

| نوع الدليل | تفاصيل |

|---|---|

| دراسة الحالة | نجح مصنع الصناديق في تقليص وقت التوقف من 14 ساعة إلى أقل من 5 ساعات باستخدام شفرات مخصصة. |

| يذاكر | لقد وفرت الشفرات المحسنة للشركات 28% من التكاليف على مدار عام. |

| اقتباس العميل | "لقد وفرنا يومين من وقت تشغيل الماكينة شهريًا." — مدير الصيانة، معالج البولي إيثيلين عالي الكثافة |

| نتائج | تم تخفيض تغييرات الشفرة بمقدار 50%، وتم تقليص وقت التنظيف بمقدار 35%. |

خدمات الشفرات المخصصة من نانجينغ Metal

خيارات شفرات تقطيع المطاط المخصصة

Nanjing Metal تقدم الشركة خيارات شفرات مخصصة متعددة لتلبية احتياجاتك. نصمم شفرات تناسب ماكيناتك وموادك. للمواد الصلبة كالمطاط المقوى، نصنع شفرات قوية تدوم طويلًا. للمواد اللينة، نصنع شفرات حادة لقطع نظيف.

يستخدم خبراؤنا أدوات متطورة لضمان أداء ممتاز. سواءً كنت بحاجة إلى شفرات للإنتاج السريع أو لمهام خاصة، فإن نانجينغ Metal تُخصص كل شفرة لتوفير المال وتحسين الكفاءة.

خطوات طلب شفرات مخصصة

طلب شفرات مخصصة من نانجينغ Metal سهل للغاية. ابدأ بـ التحدث مع خبرائهم حول احتياجاتك. شاركنا تفاصيل المواد والقطع والآلات التي تستخدمها. سيقترح فريقنا تصميم الشفرة الأنسب لعملك.

بعد الانتهاء من التصميم، نستخدم أدوات متطورة لتصنيع شفراتك. تُصمم كل شفرة لتناسب احتياجاتك بدقة. اختيار شفراتنا المخصصة يُحسّن الأداء، ويُقلل من وقت التوقف، ويُوفر المال.

نصيحة:الشفرات المخصصة تستحق العناء. فهي تُحسّن النتائج وتوفر المال مع مرور الوقت.

نصائح الصيانة لشفرات تقطيع المطاط

التنظيف والتخزين السليم

تنظيف الشفرات وتخزينها الاستخدام الصحيح يحافظ على أدائها الجيد. قد تُلحق الأوساخ والقطع المطاطية الضرر بالشفرة وتجعل القطع أصعب. بعد استخدام الشفرة، امسحها بقطعة قماش ناعمة وسائل تنظيف. تجنب استخدام مواد خشنة قد تخدش الشفرة.

من المهم أيضًا تخزين الشفرات بالطريقة الصحيحة. احتفظ بها في مكان جاف بدرجة حرارة ثابتة لمنع الصدأ. استخدم واقيات الشفرات عند نقلها لتجنب الشقوق الصغيرة. تشير الأبحاث إلى أن الشفرات بدون واقيات تكون أكثر عرضة للتلف. 60% أكثر عرضة للتلف.

| مهمة الصيانة | وصف | فوائد |

|---|---|---|

| استخدم واقيات الشفرة | حماية الشفرات أثناء النقل لتجنب التلف. | يجعل الشفرات تدوم حتى 40% لفترة أطول. |

| منع الصدأ | قم بتخزين الشفرات بشكل آمن وقم بوضع طبقات واقية عليها. | يساعد على بقاء الشفرات لفترة أطول بثلاث مرات. |

| تنظيف بانتظام | قم بإزالة الأوساخ والبقايا بعد كل استخدام. | يضيف 30% عمرًا أطول للشفرات. |

نصيحة:قم بتنظيف الشفرات بعد كل استخدام للحفاظ عليها حادة وعاملة بشكل جيد.

فحص التآكل والتلف

فحص الشفرات غالبًا ما يساعد على اكتشاف المشاكل مبكرًا. ابحث عن حواف باهتة، أو قطع غير متساوية، أو أصوات غريبة أثناء القطع. هذه العلامات تعني أن الشفرة قد تحتاج إلى شحذ أو استبدال.

ركّز على حافة الشفرة. تُظهر الدراسات كربيد التنغستن تفقد الشفرات حدتها مع كل ضربة، مما يقلل من كفاءة القطع. مراقبة أداء الشفرات تساعدك على حل المشاكل قبل تفاقمها.

استخدم قائمة التحقق هذه للتفتيشات:

- ابحث عن الشقوق أو الرقائق الموجودة على الشفرة.

- اختبر الحدة عن طريق قطع قطعة صغيرة من المطاط.

- استمع إلى الأصوات الغريبة أثناء القطع.

ملحوظة:تعمل الفحوصات المنتظمة على تحسين جودة القطع وتوفير المواد والوقت.

إرشادات الشحذ والاستبدال

شحذ الشفرات في الوقت المناسب يضمن أداءً ممتازًا في القطع. الشفرات الباهتة تحتاج إلى قوة أكبر، مما يؤدي إلى قطع سيئ وتلف أسرع للآلات. الشحذ المنتظم يُقلل استهلاك الطاقة بنسبة تصل إلى 30%.

إليك كيفية شحذ الشفرات:

- استخدم الأدوات المناسبة أو الخبراء للحفاظ على زاوية الشفرة صحيحة.

- لا تشحذ الشفرة كثيرًا، لأن ذلك قد يؤدي إلى إضعافها.

- قم بالتخطيط لعملية الشحذ بناءً على عدد مرات استخدامك للشفرة والمادة التي تقوم بقطعها.

استبدال الشفرات عند الحاجة أمرٌ بالغ الأهمية. فالشفرات المهترئة قد تُسبب جروحًا سيئة، وتُهدر المواد، بل وتُلحق الضرر بالآلات. راقب جودة قطع الشفرات واستبدلها عندما لا يُجدي شحذها نفعًا.

| شهادة | وصف |

|---|---|

| الرعاية المنتظمة | يجعل الشفرات تدوم لفترة أطول وتعمل بشكل أفضل. |

| شحذ في الوقت المحدد | يحافظ على نظافة القطع ويقلل الهدر. |

| تتبع الأداء | يظهر عندما تحتاج الشفرات إلى الشحذ أو الاستبدال. |

نصيحةاحتفظ بسجلٍّ لتتبع العناية بالشفرة وأوقات شحذها. يساعدك هذا على الالتزام بالجدول الزمني وتجنب المشاكل.

من خلال اتباع هذه النصائح، ستجعل شفراتك تدوم لفترة أطول، وتقطع بشكل أفضل، وتوفر المال على الإصلاحات والاستبدالات.

اختيار الحق شفرة تقطيع مطاطية يساعدك على العمل بشكل أفضل. فهو يُحسّن عملية القطع، ويُحافظ على نظافة المنتجات، ويُوفّر المال. فكّر في أمور مثل نوع المادة، وشكل الشفرة، واحتياجاتك الخاصة. هذا يُساعدك على الحصول على قطع أدقّ وشفرات تدوم لفترة أطول. صُممت شفرات نانجينغ Metal المُخصصة لتناسب مهامك بدقة.

نصيحة احترافية:تعمل الشفرات المخصصة بشكل أسرع، وتتسبب في هدر أقل، وتوفر الوقت.

📞 هل تريد تحسين عملية القطع الخاصة بك؟ تحدث مع خبراء نانجينغ Metal اليوميمكنهم إرشادك أو مشاركة تفاصيل المنتج. دعهم يساعدونك في اختيار الشفرة الأنسب لعملك!

التعليمات

ما هي المادة الأكثر متانة لشفرات تقطيع المطاط؟

كربيد التنغستن هي المادة الأكثر متانة للشفرات. تحافظ على حدتها لفترة أطول ولا تتآكل بسهولة. هذا يجعلها مثالية لقطع المطاط الصلب والتعامل مع المهام الشاقة دون الحاجة إلى استبدالها بشكل متكرر.

كيف أعرف متى يجب استبدال الشفرة؟

تحقق من وجود حواف باهتة، أو قطع خشن، أو أصوات عالية أثناء القطع. إذا لم يُجدِ الشحذ نفعًا في حل هذه المشاكل، فقد حان الوقت لشراء شفرة جديدة. يساعدك فحص شفراتك بانتظام على اكتشاف هذه المشاكل مبكرًا.

هل يمكنني استخدام نفس الشفرة لجميع أنواع المطاط؟

لا، كل نوع من المطاط يحتاج إلى شفرات مختلفة. المطاط الصلب يعمل بشكل أفضل مع مواد قوية مثل كربيد التنغستن. يحتاج المطاط الناعم إلى شفرات أكثر لطفًا مثل الفولاذ المقاوم للصدأيساعد استخدام الشفرة الصحيحة على إبقاء القطع نظيفة ويجعل الشفرات تدوم لفترة أطول.

كم مرة يجب أن أشحذ شفراتي؟

اشحذ الشفرات حسب استخدامك لها. إذا كنت تقطع كثيرًا، اشحذها كل بضعة أسابيع. أما إذا كنت تستخدمها بشكل أقل، فقد يكفي شحذها كل بضعة أشهر. راقب جودة قطع الشفرة لتحديد وقت الحاجة للشحذ.

هل تستحق الشفرات المطلية التكلفة الإضافية؟

نعم، الشفرات المطلية استثمار جيد. الطلاءات مثل نتريد التيتانيوم تجعل الشفرات تدوم لفترة أطول وتقطع بشكل أفضل. كما أنها تقلل الاحتكاك والتآكل، مما يوفر المال على الاستبدال. الشفرات المطلية مثالية للأعمال الشاقة أو عالية الطلب.

ما هو أفضل نوع شفرة لقطع لفات المطاط؟

الشفرات الدائرية هي الخيار الأمثل لبكرات المطاط. تدور أثناء القطع، مما يقلل الاحتكاك ويضمن قطعًا سلسًا. هذه الشفرات مثالية للإنتاج السريع وتقليل هدر المواد.

كيف يمكنني تمديد عمر شفراتي؟

نظّف الشفرات بعد كل استخدام، وخزّنها في مكان جاف. استخدم واقيات الشفرات لحمايتها أثناء النقل. الصيانة الدورية، مثل الشحذ والتحقق من التلف، تُساعد على إطالة عمر الشفرات.

هل يمكن للشفرات المخصصة تحسين عملية القطع الخاصة بي؟

نعم، تُصنع الشفرات المُخصصة لتناسب احتياجاتك. فهي تُناسب المهام الخاصة بشكل أفضل وتُقلل الهدر. تُصمم شركات مثل Nanjing Metal شفرات مُخصصة لتحسين سرعة وجودة القطع.

نصيحة:تحدث إلى الخبراء قبل طلب الشفرات المخصصة للحصول على أفضل النتائج.

ردود 2