Are you sure your press brake tooling fits your needs? If you ask good questions before buying, you can save money and avoid costly mistakes. When you choose مصنعي الأدوات المخصصة you receive expert assistance and solutions tailored specifically for you. Use this checklist to help you make informed decisions. Consider quality, compatibility, safety, and value for your shop. Think about what will benefit your shop for the long term.

النقاط الرئيسية

- Know what your workpiece needs. Check its size and material. This helps you pick the right tooling. Make sure the tooling fits your press brake machine. This stops expensive problems and delays. Pick tooling shapes that match your bending jobs. This keeps your work neat and correct. Check how much force your press brake can handle. This keeps your tooling and machine safe from harm. Buy tooling made from strong materials like alloy steel. This makes them last longer and saves money on new ones. Think about how much you will use the tooling. If you use it a lot, get stronger tooling. If not, you can choose more flexible ones. Look at the price and the quality. Good tooling may cost more at first but saves money later. Make sure your supplier helps with care and support. This keeps your tooling working well and safe to use.

Top 10 Things To Consider

Workpiece Requirements

Dimensions

Before you buy custom press brake tooling, know your workpiece size. The length, width, and thickness of your metal sheets matter. These measurements help you pick the right tooling for your job. If your parts are big or need exact sizes, you must get tooling that fits those needs. This helps you avoid mistakes and saves material.

نوع المادة

The kind of metal you bend is important. Some metals, like stainless steel or aluminum, need special tooling. Harder metals can wear out your tools faster, so you need strong alloys. Look at this table to see how different things affect your choice:

| عامل | وصف |

|---|---|

| Material abrasiveness | Harder tools are needed for rougher materials |

| حجم الإنتاج | Making more parts means you should use better materials |

| Bend complexity | Sharp bends need stronger alloys |

If you make lots of parts, better tooling is worth it. For small jobs, you can use regular tooling. Do you need special shapes or dies? Custom tooling lets you make unique bends and profiles. You can also check شفرات مخصصة for special jobs.

Tip: Always match your tooling to your workpiece size. This keeps your bends right and your work easy.

توافق الأدوات

Machine Specs

Your press brake machine has its own details. Check the tonnage, bed length, and ram type before buying new tooling. Not all tooling works with every machine. If you skip this step, you might have delays and spend more money. Here’s what could happen:

| تأثير | وصف |

|---|---|

| Increased Costs | New tooling can cost as much as your machine if it does not fit. |

| Production Delays | Wrong tooling can slow down your work a lot. |

Press brakes use certain punches and dies for bending. If your tooling does not fit, you lose options and slow down your work.

ملاءمة التطبيق

Think about what your shop does every day. Does your tooling work for your daily jobs? If you use different metals or shapes, you need flexible tooling. Make sure your tooling matches your bending needs and goals. Older machines may need more care, which can cost more and cause downtime.

Note: Always check your machine and job needs before buying new tooling. This is one of the top 10 things to think about for smooth work.

Tooling Geometry

تصميم

The way your tooling is made changes every bend. The punch and die shape, die opening, and punch radius all matter. Small V-die openings make tight bends. Big openings give you wider bends. If you want sharp angles, you need strong alloys and exact shapes.

احتياجات الانحناء

Your bending power depends on the right tooling shape. If your tooling gets worn out or crooked, your bends will not be right. Pick tooling that matches your metal’s thickness and type. This helps you avoid marks or cracks on your parts. Here is a quick checklist:

- Check die opening and punch radius for your bend.

- Look at your tooling for wear and straightness.

- Match tooling to your metal’s thickness and hardness.

If you need special shapes or tools that do many jobs, custom designs can help. You can find more choices for special bends at شفرات مخصصة.

Reminder: The right tooling shape keeps your bends the same and correct. This is important for your shop’s bending power.

سعة الحمولة

Load Handling

You need to know how much force your press brake can handle. Tonnage is the amount of pressure your machine uses to bend metal. If you pick tooling that cannot handle your machine’s tonnage, you risk damaging your tools or your press brake. Always check the maximum load your tooling can take. If you work with thick or tough metals, you need stronger tooling.

Here are some quick tips for load handling:

- Check your machine’s tonnage rating before you buy new tooling.

- Match your tooling’s load capacity to your heaviest job.

- Ask your supplier for advice if you are unsure.

Tip: Using the right tonnage capacity keeps your shop safe and your tooling in good shape.

جودة المواد

خليط معدني

The type of steel in your tooling matters a lot. Alloy steel is a popular choice for custom press brake tooling. It gives you better hardness and durability than regular carbon steel. This means your tools last longer and keep their shape.

| Alloy Steel Type | مزايا |

|---|---|

| خليط معدني | Better hardness and durability than carbon steel |

If you want your tooling to stand up to tough jobs, choose alloy steel. It helps you get clean bends and reduces wear.

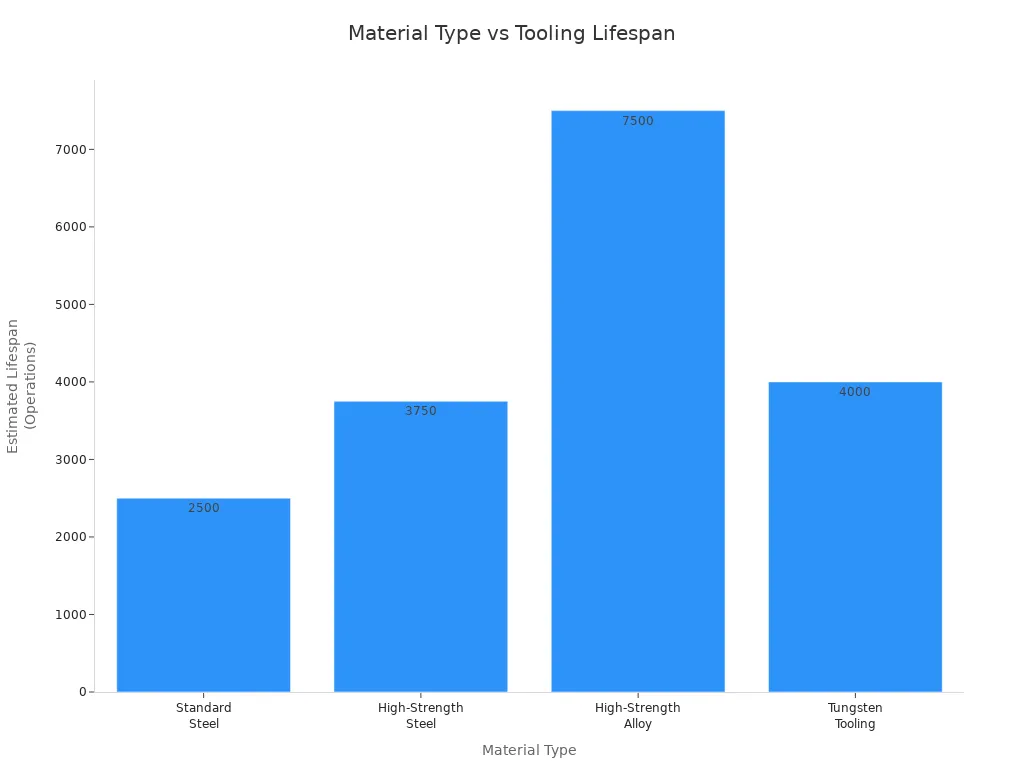

متانة

Material quality affects how long your tooling lasts. High-strength steel and tungsten tooling can last much longer than standard steel. You spend less time and money on replacements and repairs. Take a look at this table to see how different materials compare:

| نوع المادة | مقارنة العمر الافتراضي |

|---|---|

| القوة العالية تدوم | Lasts 30% to 50% longer than standard steel tooling |

| Tungsten Tooling | Lasts over 60% longer than standard tooling |

| الفولاذ القياسي | Typically withstands 2,000 to 3,000 bending operations |

| High-Strength Alloy | Endures 5,000 to 10,000 operations |

Note: Better material quality means less downtime and fewer repairs. You get more value from your custom press brake tooling.

حجم الإنتاج

High/Low Volume

Think about how many parts you need to make. If you run a high-volume shop, you need tooling that can handle lots of work without wearing out. Durable materials like high-speed steel or carbide are best for these jobs. They keep working even after thousands of bends.

If you only make a few parts or work on prototypes, you can use more flexible and cost-effective tooling. These tools let you change setups quickly and save money on smaller runs.

Here’s a quick checklist for production volume:

- Choose tough materials for high-volume jobs.

- Pick adaptable tooling for low-volume or prototype work.

- Plan for fast changeovers if you switch jobs often.

Reminder: Your production volume helps you decide which tooling design and material fit your shop best.

Cost vs. Quality

التسعير

When you look at custom press brake tooling, you might see the price first. High-quality tooling costs more at the beginning. Low-quality tooling looks cheaper, but it can cost more later. You want the best value for your money, not just the lowest price.

Here’s a table that shows how price and value compare for different tooling qualities:

| Tooling Quality | التكلفة الأولية | فوائد |

|---|---|---|

| High-Quality | أعلى | Better performance, lasts longer, saves money later |

| Low-Quality | أدنى | Might cost more over time because of problems |

If you pick high-quality tooling, it lasts longer and works better. You spend less on repairs and replacements. Low-quality tooling might save money now, but you could pay more for fixing and downtime.

Tip: Think about the total cost, not just the price. The right tooling gives you more value in the long run.

طول العمر

You want your tooling to last a long time. Longevity means your tools keep working without breaking or wearing out. High-quality tooling is stronger and lasts longer. You get more bends and fewer problems. This saves you money and keeps your shop running.

If you buy tooling made with strong materials and smart design, you get more value. Your tools stay accurate, and you avoid mistakes. You also lower the chance of tool failure during big jobs.

Note: Longevity helps you get the most from your investment. Durable tooling keeps your production going and your costs low.

Maintenance & Support

تنظيف

Keeping your custom press brake tooling clean is important. Dirt and metal flakes can build up after each bend. If you do not clean your tools, they will not work as well. You should check your tools often and clean them to keep them working.

Here are some common cleaning tips:

- Wipe off metal flakes and dirt after each job.

- Store tools the right way to stop damage.

- Wear gloves when handling tools.

Cleaning your tools helps protect your investment and makes them last longer.

Technical Help

You need good support from your tooling supplier. Technical help makes it easier to fix problems and keep your shop running. Many manufacturers offer services like checking, calibration, and alignment. They also help with oiling and maintenance.

Here’s what you can expect from a good support team:

- Regular checks to find wear and stop problems.

- Oiling moving parts to stop rust and friction.

- Calibration and alignment checks for accuracy.

- Advice on when to replace tools and spot wear.

If you have questions or need help, ask your supplier. Good support helps you keep your tools working right and get more value.

Reminder: Maintenance and support help your tools last longer and stop costly downtime.

مهلة

تصنيع

Lead time is important when you order custom press brake tooling. How long it takes depends on your design and material. If you need special shapes or strong alloys, it may take longer. Ask your supplier how long your order will take.

Plan ahead so you do not run out of tooling. Fast manufacturing helps you keep your shop moving and meet deadlines.

توصيل

After your tooling is made, you need it delivered on time. Good delivery means you get your tools when you need them. Some suppliers ship fast, but others take longer. Check delivery options before you order.

If you have tight deadlines, pick a supplier with quick and reliable delivery. This helps you avoid delays and keep your work on track.

Tip: Always ask about how long making and shipping will take. Good planning helps you get the most value from your custom press brake tooling.

Future Adaptability

Modifications

You want your custom press brake tooling to keep up with changes in your shop. Sometimes, your projects grow or your needs shift. If your tooling can handle upgrades, you save time and money. You do not need to buy new tools every time your work changes.

Let’s look at some features that make modifications easy:

| ميزة | وصف |

|---|---|

| Extra hydraulic ports | You can add new parts or functions later. |

| Over-engineered frames | Your tooling can handle bigger jobs in the future. |

| Software upgrade paths | You can update your system as technology improves. |

If you choose tooling with these features, you get more flexibility. You can add new dies, change punch shapes, or boost your machine’s power. You do not have to worry about outgrowing your equipment.

Tip: Ask your supplier if your tooling can be upgraded or changed. This helps you plan for new projects and keeps your shop ready for anything.

براعه

Versatility means your tooling works for many jobs. You do not want to buy new tools for every project. If your tooling bends different metals, shapes, and sizes, you save money and space.

Here are some ways to get more versatility from your custom press brake tooling:

- Pick multi-purpose dies that work for several bending tasks.

- Choose punches that fit different thicknesses and materials.

- Look for designs that let you swap parts quickly.

When your tooling is versatile, you can take on new jobs without delay. You can switch from thin aluminum to thick steel with ease. This keeps your shop busy and your customers happy.

Note: Versatile tooling helps you handle more projects and adapt to changes. You get better durability and more value from your investment.

Custom Press Brake Tool Selection

Application Needs

Industry Requirements

Every industry has its own needs for press brake tools. Car shops often bend thick steel. Aerospace companies need very exact bends with light metals. Construction jobs use tools for big sheets and strong bends. You must pick tools that fit your industry.

وهنا بعض الأمور التي يجب التفكير فيها:

- Material type and thickness: Your tool must work with your metal.

- Machine tonnage: Make sure your tool can take the force.

- Tooling material: Choose hard steel for long life or soft for savings.

- Type of metal: Know if you use carbon steel, aluminum, or another alloy.

- Gauge and length: These help you pick the right size and strength.

- Tensile strength: Check your metal’s strength to stop tool damage.

Tip: When you know your industry’s needs, you can pick a tool that gives you good bends every time.

Workpiece Specifications

Your workpiece details are just as important as your industry. Look at thickness, material, and how exact you need to be before picking a tool. Thin aluminum needs tools with more grip so it does not slip. Strong steels need tough tools and careful control to stop breaking.

See this table to learn how thickness changes your tool choice:

| Material Thickness Range | نوع الأداة | وصف |

|---|---|---|

| Up to 1/8 inch (3 mm) | Lighter-duty tools | Good for air bending or coining. |

| 1/8 to 1/2 inch (3-12 mm) | Standard V-die tools | Used for air or bottom bending. |

| Over 1/2 inch (12 mm) | Heavy-duty tools | Needs special ways for extra strength. |

Pick a tool that matches your workpiece’s thickness and metal. This helps you get the right bends and keeps them the same.

Note: The right tool material makes your work better and your tool last longer. Different metals act in their own way under pressure, so always know your metal.

بيئة الإنتاج

Your shop’s setup affects your tool choice. If you make lots of parts, you need strong tools for many uses. If you use robots, you want tools that fit machines or change fast. Small shops or test runs need tools that are easy to swap.

Ask yourself these questions:

- Do you need to switch tools fast for new jobs?

- Is your shop run by people or robots?

- How many parts do you make each day?

When your tool fits your shop, you get better bends and keep your work moving.

Shape Options

Standard Tooling Shapes

There are many shapes for press brake tools. Each shape does a different job and fits certain bends. Here is a table with common shapes and what they do:

| Tooling Shape | وصف | التطبيق النموذجي |

|---|---|---|

| لكمة قياسية | Thick body, narrow tip | Bending short flanges |

| لكمة الزاوية الحادة | Sharp tip | Making small angle bends |

| Narrow Punch | Same length | Closing square or box shapes |

| Sash Punch | Angled tip | Making door jambs |

| لكمة رقبة البجعة | U shape, avoids hitting other parts | U bends |

| Joggle Punch | Thin shape | S-shape bends |

| Radius Top Punch | Rounded tip | Making round corners |

| Single V Die | V-shaped hole | Most bending jobs |

| Two-Way Self-Centering V Die | Two V holes | Many bend angles without new tools |

| Multi V Die | Many V cuts | Change bend angles or thickness |

| Corrugating Dies | Wavy pattern | Special surface needs |

Most jobs use these shapes, but sometimes you need something special.

Custom Profiles

Custom profiles help you make special bends and meet exact needs. If you need a hard bend or a shape normal tools can’t do, custom tools are best. You can make a tool for your part, metal, and how close you need to be.

Custom profiles help you:

- Get very close bends for planes or electronics.

- Make special shapes for furniture or appliances.

- Fix problems that normal tools can’t solve.

Note: Custom profiles give you more choices and help you do jobs others can’t.

Multi-purpose Tooling

Multi-purpose tools let you do more jobs with one tool. You save space and money. If you use many metals or thicknesses, these tools make switching fast and easy.

Some things you may want:

- Dies you can change for different thicknesses.

- Punches that work with many metals.

- Designs that let you swap parts quickly.

Multi-purpose tools help you take on more jobs and handle new work. You get more ways to bend and keep your shop running well.

خدمات OEM/ODM

OEM (Original Equipment Manufacturer) Services

OEM services let you make a press brake tool from your own design. You choose every part, like shape and metal. This gives you lots of choices and makes sure your tool fits your needs. OEM suppliers like Nanjing Metal have good supply chains and save money, but you need a strong team.

Benefits of OEM services:

- You control your tool’s features.

- You get custom tools for special jobs.

- You save money with good factories.

Tip: Pick OEM if you want to keep your ideas safe and need a tool made just for you.

ODM (Original Design Manufacturer) Services

ODM services give you ready-made tools for your shop. You do not have to design the tool yourself. ODM companies do the design and make the tool, which is good if you do not have a design team. You pay less and get your tool faster, but you cannot change it much.

Advantages of ODM services:

- Fast delivery for normal jobs.

- Lower costs to make the tool.

- Good for shops without design teams.

Note: ODM is best when you need a tool fast and do not need special features.

Choosing the Right Service

You must pick OEM or ODM based on your job. Here is a table to help you choose:

| معايير | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Internal Capabilities | Needs strong design and engineering | Handles design and production |

| Level of Product Customization | High, based on your designs | Lower, uses pre-existing designs |

| Intellectual Property Rights | You keep design rights | Manufacturer usually owns rights |

Pick OEM if you want full control and special features. Pick ODM if you want a fast answer and do not mind normal tools. You can ask Nanjing Metal for help to find what is best for your shop.

Tip: Think about your team, your job’s needs, and how exact you need to be before you choose.

Tooling Compatibility with Hydraulic Press Brake

When you pick custom press brake tooling, check if it fits your machine. Not all press brakes work the same way. Some use hydraulic power, and others use mechanical systems. The right fit gives you better results and fewer problems later.

نوع الماكينة

Hydraulic Press Brake Compatibility

Hydraulic press brakes are popular because they are precise and flexible. You can bend many metals and different thicknesses with them. These machines use oil pressure to move the ram. This gives you smooth and controlled motion. You can change the force and speed for each job. This helps you get the same bend every time, which is good for repeat work.

Always check the specs when you purchasing a hydraulic press brake. Look at the tonnage, bed length, and back gauge system. The back gauge system helps you put your metal in the right spot. Make sure your custom press brake tooling fits the clamping system. It should also work with the control system. The control system lets you set up jobs and save programs.

Tip: Ask your supplier if the tooling is made for hydraulic models. This saves you time and helps you avoid mistakes.

Mechanical Press Brake Compatibility

Mechanical press brakes use a flywheel and clutch to move the ram. These machines are simple and easy to take care of. They work well for basic jobs and cost less than hydraulic ones. But you get less control over the bending process. The force and speed stay the same every time, so you have less flexibility.

If you use a mechanical press brake, check if your tooling matches the machine’s specs. Some custom press brake tooling may not fit older machines. Some may not work with all materials. You also need to check the back gauge system. Make sure the tooling lines up with your setup.

Key Differences and Examples

Let’s see how hydraulic and mechanical press brakes are different. This table shows the main differences for custom press brake tooling:

| ميزة | Hydraulic Press Brake | Mechanical Press Brake |

|---|---|---|

| دقة | Higher precision for tricky bends | Less precision and control |

| Control | Better control with settings | Simple to use but less control |

| يكلف | Usually costs more | تكاليف أقل |

| Complexity | More complex to use | Easier to use and fix |

| Compatibility with Tooling | Works with many thicknesses and materials | Has limits on precision and power |

If you want to bend many types of metal, a hydraulic press brake is better. You get more choices for custom press brake tooling. You can do harder jobs. Mechanical press brakes are good for simple jobs where you do not need much control.

Mounting Style

Quick-Change Mounting

Quick-change mounting lets you swap tooling fast. You do not need special tools or lots of time. This is good if you do many jobs or change setups often. You unlock the clamp, slide out the old tool, and put in the new one. The control system can help you line up the tooling.

Quick-change mounting gives you:

- Faster tool changes

- Less downtime

- Easier use for new workers

If you want to work faster, quick-change mounting is a smart pick.

Bolt-On Mounting

Bolt-on mounting uses bolts or screws to hold the tooling. This gives you a strong and safe hold. You may need a wrench or other tools to change the dies and punches. Bolt-on mounting is good for heavy jobs or when you do not change tooling often.

Bolt-on mounting gives you:

- Very secure fit

- Handles heavy force and big tooling

- Good for long jobs

If you run the same job all day, bolt-on mounting keeps your tooling steady.

Pros and Cons of Each Mounting Style

Here’s a quick look at the good and bad parts of each mounting style:

| Mounting Style | الايجابيات | سلبيات |

|---|---|---|

| Quick-Change | Fast swaps, less downtime, easy to use | May cost more, less safe for heavy jobs |

| Bolt-On | Very secure, handles heavy loads | Slower changes, needs tools |

Note: Think about your shop’s needs before you pick a mounting style. If you switch jobs a lot, quick-change saves time. If you do big jobs with heavy tooling, bolt-on is safer.

Compatibility Tips

You want your custom press brake tooling to fit your machine and work style. Here are some tips to help you check:

- Look at your machine’s specs before you buy new tooling.

- Check the clamping system and make sure the tooling fits.

- Ask about the back gauge system and how it lines up.

- Make sure the control system works with the new tooling.

- Talk to your supplier about upgrades you might need later.

Tip: Always plan ahead when buying a hydraulic press brake or new tooling. The right fit gives you better results and less downtime.

Evaluating Custom Tooling Manufacturers

Picking the right custom tooling manufacturers is very important. If you choose the wrong one, your project might fail. You need a company you can trust to do a good job. Let’s see what you should think about when you compare companies.

سمعة

Always check if the custom tooling manufacturers have a good reputation. A good reputation means they make quality tools you can count on. Here are some things you should look for:

- They know how to work with your materials.

- They understand different bending jobs.

- Their tooling fits your press brake machine.

- They offer many tooling choices.

- Their tools last long and are easy to care for.

- They are known for being experts in the field.

- They help customers and answer questions.

- They deliver fast and have spare parts ready.

Ask other shops what they think about the company. Read reviews and see what people say. If a manufacturer has a good reputation, you will have fewer problems later.

Tip: A trusted manufacturer helps your shop work better and gives you less to worry about.

مراقبة الجودة

Quality control is what makes some custom tooling manufacturers better than others. You want your tools to work well every time you use them. The best companies check every tool before sending it out.

Here’s how some top manufacturers check their tools:

| الشركة المصنعة | Quality Control Process |

|---|---|

| LVD | Uses smart tools to watch for wear and fix problems before they happen. |

Some companies, like Wilson Tool, care about quality and service. Others, like Mecon Industries, make many types of tooling for different jobs, from light to heavy work.

You should ask how your manufacturer checks their tools. Do they test for strength and accuracy? Do they look at every tool? Good quality control means you will have fewer mistakes and less time fixing things.

Note: Good quality control saves you money and keeps your shop working well.

دعم العملاء

Good customer support is very helpful. You want custom tooling manufacturers who answer your questions quickly. Shops like it when they get help fast and not just when they buy, but after too.

Look for companies that give you:

- Fast answers when you ask something

- Help with setting up and fixing problems

- A promise to fix things if you are not happy

Some manufacturers even promise you will be 100% happy. This shows they care about your shop and their products.

Remember: Good support helps your shop keep working and lets you get the most out of your tooling.

Safety and Certifications

When you buy custom press brake tooling, you want your shop to be safe. You also need to follow rules made by important groups. Safety and certifications help stop accidents and keep your team safe.

Compliance

You must check if your tooling meets safety standards. These rules come from groups that know how to keep shops safe. If your tooling follows these rules, you can trust it to work well. It will help protect your team.

Here’s a table that shows the main certifications you should look for:

| Certification Body | وصف |

|---|---|

| Fabricators & Manufacturers Association (FMA) | Offers programs with training so operators learn skills and know how to use press brakes safely and well. |

| National Institute for Metalworking Skills (NIMS) | Gives certifications for metalworking, including press brake use, to show operators can set up machines and check quality. |

| OSHA | Makes strict safety rules for press brake operators, and says you must train workers and check equipment often. |

| ANSI | ANSI B11.3-2012 is a rule that says press brakes must meet safety and work standards. |

Ask your supplier if their custom press brake tooling meets these certifications. This helps you avoid problems during checks and keeps your shop working well.

Tip: Certified tooling means you can trust your tools and keep your team safe.

ميزات السلامة

You want your custom press brake tooling to have good safety features. These features help protect you and your team while you work. They also make your job easier and help stop injuries.

Here’s a table with some important safety features to look for:

| ميزة السلامة | وصف |

|---|---|

| Ergonomic Designs | Made to lower strain and make operators more comfortable. |

| Protective Coatings | Coatings make tools last longer and help stop cuts from sharp edges. |

| Intuitive Operation Interfaces | Easy-to-use controls help stop mistakes when using the machine. |

You should also look for these extra safety features:

- Guards or devices that stop you from touching the die space by mistake.

- Pullbacks, gates, and fences that keep your hands away from moving parts.

- Training and inspection steps that help everyone follow safety rules.

If your tooling has these safety features, you can work with confidence. You will worry less about accidents and get your work done right.

Note: Good safety features help you avoid injuries and keep your shop running without problems.

Maintenance and Changeover

Upkeep

Taking care of your custom press brake tooling keeps your shop running smoothly. If you want your tools to last longer and work better, you need a good maintenance routine. Here are some best practices you can follow:

- Regular Inspection and Cleaning

Check your tools every day. Look for cracks, chips, or signs of wear. Wipe off dust and metal shavings after each use. Clean tools work better and last longer. - التخزين والتداول السليم

Store your custom press brake tooling in a safe place. Use racks or cases made for tooling. Train your team to handle tools carefully. Dropping or bumping tools can cause damage. - Calibration and Alignment

Schedule regular checks for calibration and alignment. If your tools are not lined up right, your bends will be off. Use gauges or measuring tools to keep everything precise. - Employee Training and Safety

Teach your team how to use and care for custom press brake tooling. Good training helps prevent accidents and tool damage. Safety always comes first. - Monitoring Tool Wear and Replacement

Watch for signs of wear. Some tools have wear indicators to help you know when to replace them. Make a schedule for checking and replacing old tools.

Tip: A little time spent on upkeep saves you money and trouble later. Well-maintained tools give you better results and fewer headaches.

Tool Change

Changing custom press brake tooling is a big part of your daily work. Every time you switch tools, you stop production for a while. Even in advanced shops, tool changeover can slow things down and create bottlenecks.

Tooling changeover usually takes about 6% of the total time for each bending job. That may not sound like much, but it adds up fast if you do many jobs each day. Long setup times can hurt your productivity and make it harder to meet deadlines.

You can make tool changes faster by:

- Organizing your tools so you can find them quickly.

- Using quick-change systems if your press brake supports them.

- Training your team to follow a simple, step-by-step process.

- Keeping your work area clean and free of clutter.

Some shops now use automatic tool-changing systems. These systems help reduce setup times, especially when you have lots of changeovers in a single shift. If you want to boost efficiency, look for ways to speed up your tool changes.

Note: Fast and safe tool changes keep your production moving. The right process helps you get more out of your custom press brake tooling every day.

Cost and Warranty

عندما تنظر إلى أدوات مكابح الضغط المخصصة, you want to know what you are paying for and what protection you get. Let’s break down the cost and warranty so you can make a smart choice.

هيكل التسعير

Custom press brake tooling prices can look confusing at first. You might see a big range between different suppliers. Why does this happen? Several things affect the price:

- جودة المواد: Stronger alloys and special coatings cost more, but they last longer.

- Tool Complexity: Simple shapes cost less. Custom profiles or multi-purpose tools cost more because they take more time to make.

- Size and Weight: Bigger and heavier tools use more material, so they cost more.

- حجم الإنتاج: If you order more tools at once, you might get a better price per piece.

- Finishing and Tolerance: Tighter tolerances and smooth finishes add to the price.

Here’s a quick table to help you compare:

| عامل | Low Cost Option | High Cost Option |

|---|---|---|

| مادة | Standard steel | Alloy or hardened steel |

| تصميم | Standard shapes | Custom profiles |

| مقدار | Small batch | Large batch |

| ينهي | أساسي | Precision/special |

Tip: Always ask for a detailed quote. This helps you see what you are paying for and spot any hidden fees.

You should also think about the total cost of ownership. Cheaper tooling might save you money now, but it can wear out faster. You might spend more on replacements and downtime. High-quality custom press brake tooling can save you money in the long run.

Warranty Terms

A good warranty gives you peace of mind. You want to know that your investment in custom press brake tooling is protected. Warranties can be different from one supplier to another, so always read the details.

Look for these things in a warranty:

- Coverage Period: How long does the warranty last? Some last six months, others a year or more.

- What’s Covered: Does the warranty cover only defects, or does it also cover wear and tear?

- Exclusions: Some warranties do not cover damage from misuse or accidents.

- Replacement or Repair: Will the supplier fix the tool, send a new one, or give you a refund?

- يدعم: Can you get help fast if you have a problem?

Here’s a checklist to use when you review a warranty:

- Check the length of coverage.

- Ask what types of problems are included.

- Find out how to make a claim.

- See if you get free repairs or replacements.

- Make sure you know who to contact for help.

Note: A strong warranty shows that the supplier stands behind their custom press brake tooling. It also means you can trust the quality and get help if something goes wrong.

When you compare costs and warranties, you get a clear picture of value. You can choose custom press brake tooling that fits your budget and keeps your shop running smoothly.

Lead Time and Delivery

Production Schedule

When you order custom press brake tooling, you want to know how long it will take to make. The production schedule tells you when your tooling will be ready. You should ask your supplier about their process. Some shops finish simple tools in a few days. Custom designs or special materials can take weeks.

Here are some things that affect the production schedule:

- Tool complexity: Simple shapes get made faster. Custom profiles need more time.

- Material availability: If the supplier has the right steel, production starts sooner.

- Order volume: Large orders may take longer to complete.

- Factory workload: Busy factories might need extra days.

You can ask for a timeline before you place your order. Suppliers often give you a schedule with key dates. This helps you plan your jobs and avoid delays.

Tip: Always check the production schedule before you order custom press brake tooling. This keeps your shop running smoothly.

Shipping

After your custom press brake tooling is ready, you need it delivered to your shop. Shipping is the last step before you start bending metal. You should look at shipping options and costs. Fast shipping helps you meet deadlines. Reliable delivery means your tools arrive in good shape.

Here’s a table to help you compare shipping choices:

| Shipping Method | سرعة | يكلف | Tracking | الأفضل لـ |

|---|---|---|---|---|

| Standard Freight | 5-10 days | أدنى | نعم | Large or heavy tooling |

| Express Courier | 2-4 days | أعلى | نعم | Urgent orders |

| Air Freight | 1-3 days | أعلى | نعم | International delivery |

You should ask your supplier for tracking numbers. This lets you see where your tooling is at any time. If you have a tight deadline, pick express or air freight. For big orders, standard freight saves money.

🚚 Note: Good shipping keeps your custom press brake tooling safe and on time. Always check delivery dates and tracking before you order.

You can also ask about insurance. Insurance protects your tooling during transit. If something happens, you get help fast.

When you plan for production and shipping, you avoid surprises. You get your custom press brake tooling when you need it. Your shop stays busy, and your customers stay happy.

Tool Life and Performance

متانة

When you buy custom press brake tooling, you want it to last. You need tools that can handle tough jobs day after day. If your tooling wears out fast, you spend more time and money replacing it. You should look for tooling made from strong materials like alloy steel. These materials resist bending, cracking, and breaking.

Here are some things that help your tooling last longer:

- Choose the right material for your workpieces.

- Clean and inspect your tools often.

- Store your tooling in a safe place.

- Use the correct tonnage for each job.

If you follow these steps, you get more bends from each tool. You also keep your shop running without delays. Good durability means you can trust your tooling to perform well, even with heavy use.

Tip: Ask your supplier about the expected lifespan of their custom press brake tooling. This helps you plan for future jobs and avoid surprises.

Real-World Data

You might wonder how long custom press brake tooling really lasts. Shops often track the number of bends before a tool needs replacement. Some tools handle thousands of bends. Others last even longer with proper care.

Check out this table to see how different materials perform:

| Tooling Material | Average Bends Before Replacement | أفضل حالة استخدام |

|---|---|---|

| الفولاذ القياسي | 2,000 – 3,000 | Light jobs |

| خليط معدني | 5,000 – 10,000 | Heavy-duty work |

| Carbide Inserts | 10,000+ | إنتاج بكميات كبيرة |

You can also ask other shops about their experience. Many operators say that regular cleaning and careful handling make a big difference. If you keep records, you know when to order new tooling before problems start.

Here are some quick tips from real users:

- Track the number of bends for each tool.

- Replace tooling before it causes bad bends.

- Share your results with your team.

If you use these tips, you get better results and save money. Your custom press brake tooling works harder and lasts longer.

🚀 Note: Real-world data helps you make smart choices. You can compare your results with others and improve your shop’s performance.

References and Case Studies

شهادات العملاء

You might want to know what other shops think about custom press brake tooling. Real stories from users can help you feel sure about your choice. Here are some things people who use custom press brake tooling every day have said:

“We started using custom press brake tooling for our car parts. We were surprised by the results. Our bends got more accurate, and we wasted less metal.”

— Shop Manager, Midwest Auto Fabrication

“Our old tooling broke down quickly. After talking to a supplier, we got custom press brake tooling made from alloy steel. Now, each tool lasts longer, and we have less downtime.”

— Production Lead, Sheet Metal Works

“We needed a special die for a hard project. The custom press brake tooling fit our machine just right. The supplier also helped us set up and train our team.”

— Operations Supervisor, Precision Metalcraft

These stories show that shops in many fields trust custom press brake tooling to fix real problems. They talk about better accuracy, longer tool life, and helpful support from suppliers.

خبرة الصناعة

Custom press brake tooling is used in many industries. You might work with cars, planes, buildings, or even furniture. Each industry needs something different, but all want tools they can trust.

Here are some examples:

- Automotive: You need to bend thick steel for car frames. Custom press brake tooling helps you make strong bends every time.

- Aerospace: You use thin aluminum and need very exact bends. Custom tooling gives you the precision needed for safety and quality.

- البناء: You work with big sheets and tough jobs. Custom dies help you make strong bends for beams and panels.

- تصنيع الأجهزة: You want smooth edges and perfect shapes. Custom press brake tooling helps you avoid marks and get clean finishes.

Here’s a simple table showing how different industries use custom press brake tooling:

| صناعة | حالة الاستخدام الشائعة | الفائدة الرئيسية |

|---|---|---|

| السيارات | Bending frames and panels | High strength, accuracy |

| الفضاء الجوي | Forming lightweight parts | Precision, tight tolerance |

| بناء | Shaping beams and supports | Heavy-duty performance |

| أثاث | Making custom metal parts | Unique shapes, flexibility |

Note: When you see how others use custom press brake tooling, you get ideas for your own shop. You can ask suppliers for more stories or case studies if you want to learn more.

Custom press brake tooling helps you handle tough jobs. You get tools that fit your work, your machines, and your industry. Real stories and examples show why it is smart to ask good questions before you buy.

You now know the top 10 things to check before you buy custom press brake tooling. Asking smart questions helps you avoid mistakes and keeps your shop safe. Use this checklist every time you plan a purchase. Compare different suppliers and see which one fits your needs best. If you want expert advice, reach out to a sales engineer for help with your next custom press brake tooling project.

التعليمات

What is custom press brake tooling?

Custom press brake tooling means you get tools made just for your bending jobs. These tools match your machine and your workpiece. You get better results and fewer mistakes.

How do I know if my tooling fits my press brake?

Check your press brake’s specs. Look at the clamping system, tonnage, and bed length. Ask your supplier if the custom press brake tooling matches your machine.

Why should I choose custom tooling over standard tooling?

Custom press brake tooling gives you the exact shape and size you need. You can handle special bends, unique materials, or tight tolerances. Standard tools may not fit every job.

How long does custom press brake tooling last?

Tool life depends on the material, how often you use it, and how well you care for it. Alloy steel tools can last thousands of bends with proper maintenance.

Can I use custom press brake tooling for different materials?

Yes! You can design custom press brake tooling for many metals, like steel, aluminum, or copper. Just tell your supplier what you plan to bend.

What should I do if my tooling gets damaged?

Stop using the tool right away. Clean it and check for cracks or wear. Contact your supplier for repair or replacement advice.

How do I maintain my custom press brake tooling?

Wipe your tools after each use. Store them in a safe place. Inspect them often for wear. Regular cleaning and checks help your tooling last longer.

How long does it take to get custom press brake tooling?

Lead times vary. Simple tools may take a few days. Complex designs or special materials can take weeks. Ask your supplier for a timeline before you order.

انظر أيضا

5 ملحقات أساسية لآلات ثني المعادن لتعزيز إنتاجيتك

دور أدوات تشكيل المعادن في تصنيع الصفائح المعدنية الحديثة

كيفية إصلاح عيوب الثني الشائعة باستخدام قوالب وألواح الثني المناسبة

الدليل الكامل لأدوات مكبس الفرامل للمقاطع المعدنية المعقدة

التكلفة الحقيقية لأدوات مكبس الفرامل: تحليل التكلفة الإجمالية للملكية (TCO)