Complete Guide to Press Brake Tooling for Complex Metal Profiles

You need strong tools to shape tricky metal profiles. More than 80% of metal projects use press brake tooling for complex metal profiles to achieve good and steady results. Special and custom tools help you get better accuracy and make work faster. Nanjing Metal provides press brake tooling for complex metal profiles that adhere to tough industry standards. Technology Impact […]

The True Cost of Press Brake Tooling: A Total Cost of Ownership (TCO) Analysis

The real cost of press brake tooling is more than the price you pay at first. You need to think about every cost that comes up over time. You spend money on more than just the tool. You also pay for maintenance, downtime, and resale value. Key Takeaways Total Cost of Press Brake Tooling What Is TCO? […]

Specialized Press Brake Tooling for Unique Metal Profiles

Selecting specialized press brake tooling for unique metal shapes requires careful consideration. You must match the tooling to the complexity of the shape. Additionally, you need to think about the type of material you are using. Ensure that the tooling is compatible with your machine. Consider how precise you need the work to be. More than 80% of […]

How to calculate press brake bending force and tonnage

You must know how to calculate press brake bending force and tonnage to ensure safe and effective metal bending. The formulas below are commonly used in metalworking: Formula Description P (lbs.) = 2 × b × t² × Fy/W This is the basic method to calculate press brake bending force. P (tons/foot) = 0.012 × t² × Fy/W This […]

Press Brake Tooling Guide for Beginners: Choosing the Right V-Die Opening

Choosing the right V-die opening starts with knowing your material thickness. You can refer to our press brake tooling guide for beginners to help you with this process. This guide assists in keeping your bends correct and your shop safe. Picking the right V-die lowers the chance of accidents and provides you with better results. A wider V-die helps […]

The Ultimate Guide to Press Brake Dies: Choosing the Best Material to Prevent Wear

Choosing the right press brake dies material is very important. It helps stop wear and gives better results. You need a strong material for repeated bending. It should not lose accuracy. Studies show high-strength steel makes dies last much longer. Dies can last 30% to 50% longer with this steel. Special alloys help dies last even longer. They can […]

Air Bending vs. Bottoming: Choosing the Right Press Brake Tooling for Your Project

Imagine you have to pick between air bending vs. bottoming for your metal project. This choice can change your costs, your speed, and how exact your parts are. Look at the table below to see how each method affects your work: Criteria Air Bending Bottom Bending Tooling Costs Lower tooling costs More money spent on tooling Precision […]

European vs. American Style Press Brake Tooling: Which is Right for Your Shop?

Choosing between European vs. American style press brake tooling depends on what your shop needs. You should think about how accurate you need to be, how fast you want to set up, if the tools will fit your machines, and how much money you want to spend. In metal fabrication, these factors influence how you work and […]

Choosing the Best Press Brake Tooling for Stainless Steel

Choosing the best Press Brake Tooling for Stainless Steel helps you work better. You get more accurate bends. Your tools last longer. You spend less money making things. You need exact tools because stainless steel bends in a special way. It does not bend like other metals. Special tooling can help you save time and money: Key […]

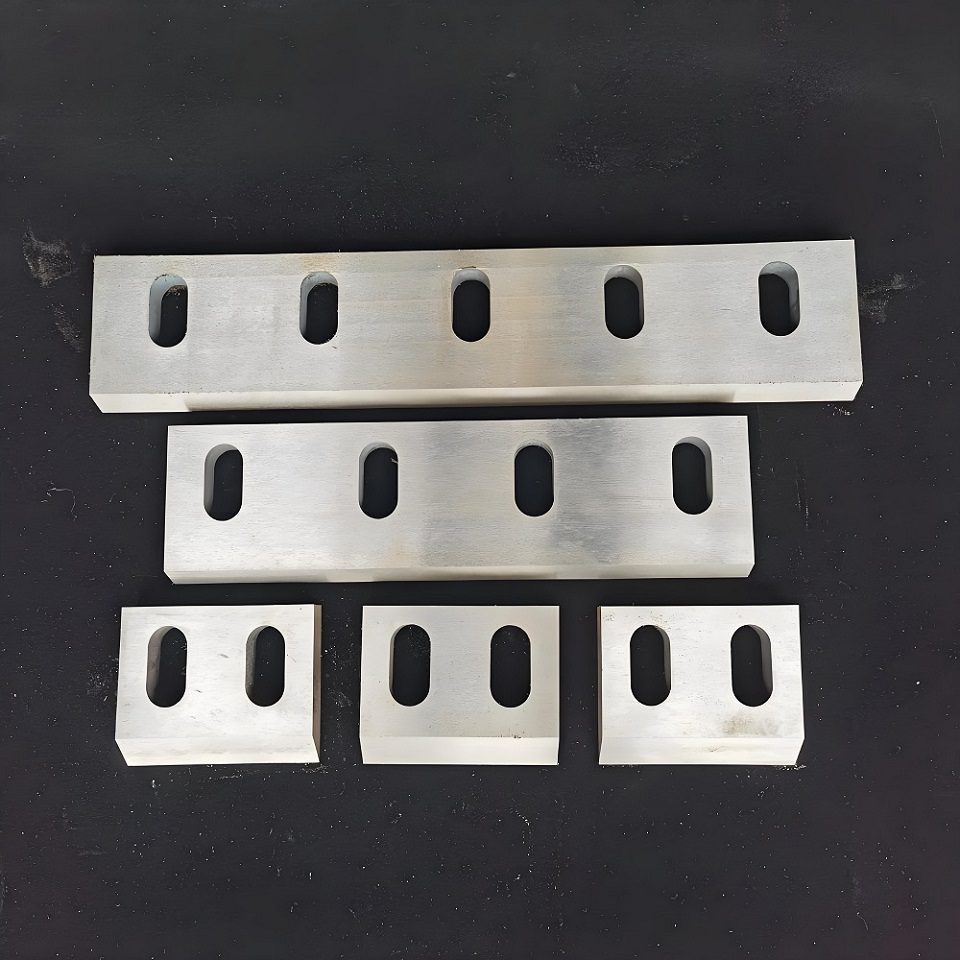

Why Your Plastic Shredder is Not Working: Common Blade Issues & Troubleshooting

Your plastic crushing machine might stop working or produce uneven flakes, often due to issues with plastic crusher blade wear. Troubleshooting plastic crusher blade wear is essential because worn or broken blades cause frequent machine shutdowns and poor cutting performance. When blades become dull or cracked, the efficiency of your machine drops significantly. Using high-quality blades made […]