Daily maintenance tips for paper perforating blades including cleaning, lubrication, sanding, and blade tip protection rules

You can keep paper perforating blades working well with daily care. Clean, lubricate, sand, and protect each blade every day. This helps stop damage and keeps cuts neat. A recent survey showed plants with regular care had less downtime. They also saved more money. You can make your paper perforating blades last longer. Key Takeaways Importance of […]

Plastic film perforating blades optimization: speed, pressure, and tooth profile matching

Optimizing speed, pressure, and tooth profile helps plastic film perforating blades cut better. You get better cutting quality, more efficiency, and lower costs. You will notice changes when you use advanced technology and good blade materials. Here is an example: Metric Before Optimization After Optimization Blade changes per day 3 times Once every 2 days Misaligned pouches […]

Why packaging perforating knives are widely used in the packaging industry

Packaging perforating knives are very important in packaging. They help make packaging fast and accurate. These special blades add easy-open parts, let air move, and help products split cleanly. Manufacturers use packaging perforating knives in many ways: Key Takeaways How Packaging Perforating Knives Work Mechanism Packaging perforating knives work by pressing or rolling their sharp edge on […]

Perforating blade knives uneven perforation and inconsistent line length troubleshooting and optimization

If you see uneven perforation or lines that are not the same length, it can change your finished product a lot. Every step needs to be exact, especially when you use perforating blade knives or a micro-perforating machine. Research shows that companies using exact micro-perforating blades have fewer mistakes and work faster. When micro-perforating is steady, you get holes […]

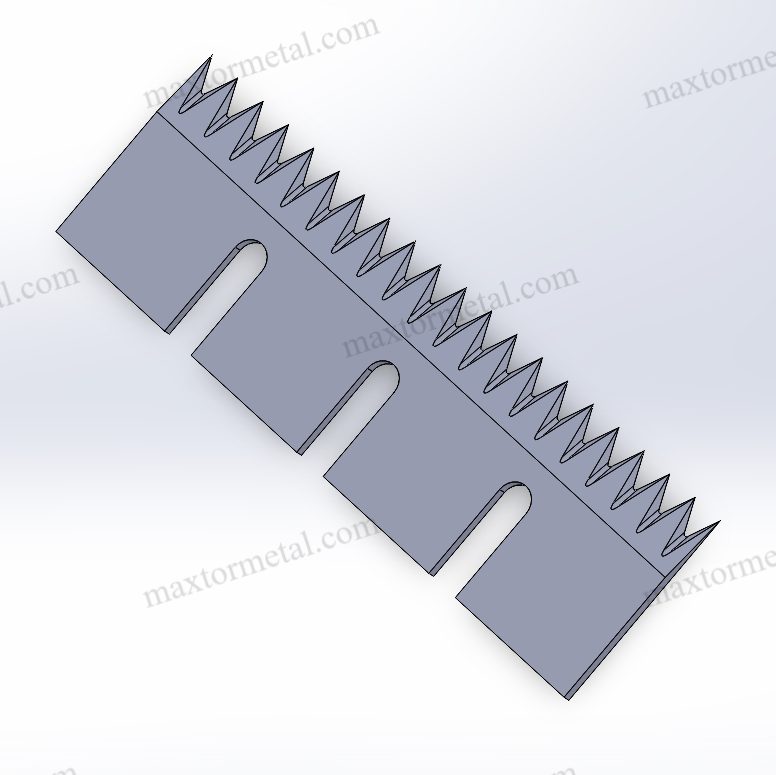

Practical Perforation Blade Installation, Machine Adjustment, and Sharpening Techniques to Improve Production Line Stability

You may see uneven perforations and lots of stops in your production line. Using a good perforation blade helps a lot. These blades make your work faster and your products better. The table below shows how much better your process can get with the right blade. Benefit Category Statistical Impact Production Efficiency Increases production line efficiency by 12-15% […]

When to Sharpen vs Replace a Slotter Machine Blade – A Practical Decision Guide

You have a simple rule for your slotter machine blade. Sharpen it if you see it is dull or making rough cuts. Replace it if you see cracks, chips, or a lot of wear. Taking care of your blade keeps your workspace safe. It also saves you money. Look at the table below to see how […]

Corrugated slotter knives: Common problems, cause analysis, and solutions

Corrugated slotter knives are very important in packaging. But workers often face problems that stop production. Finding out why these problems happen helps companies save money on repairs and avoid stopping work. Key Takeaways Troubleshooting Common Issues Misalignment Symptoms When slotting knives are not lined up right, workers see problems. Causes Many things can make corrugated […]

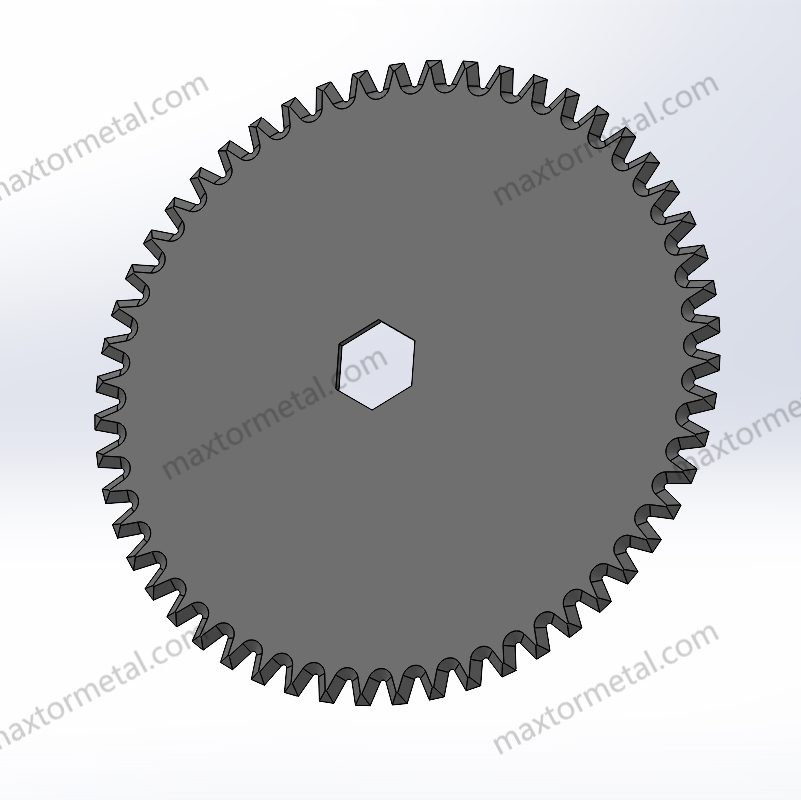

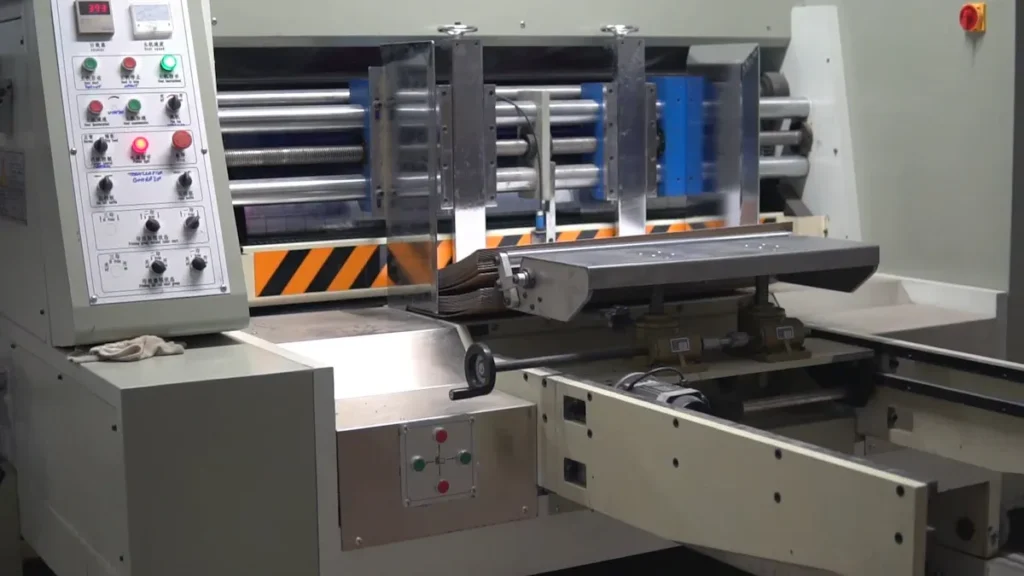

Slotter blade manufacturer application scenarios and equipment compatibility with common slotter machine brands and models

Selecting the right slotter blade means knowing what each machine needs. A trusted slotter blade manufacturer like Nanjing Metal has over 20 years of experience. They make custom corrugated slotter knives and solutions for every need. The blade and slotter machine must work well together for good quality and smooth work. The main slotter blade material types used around […]

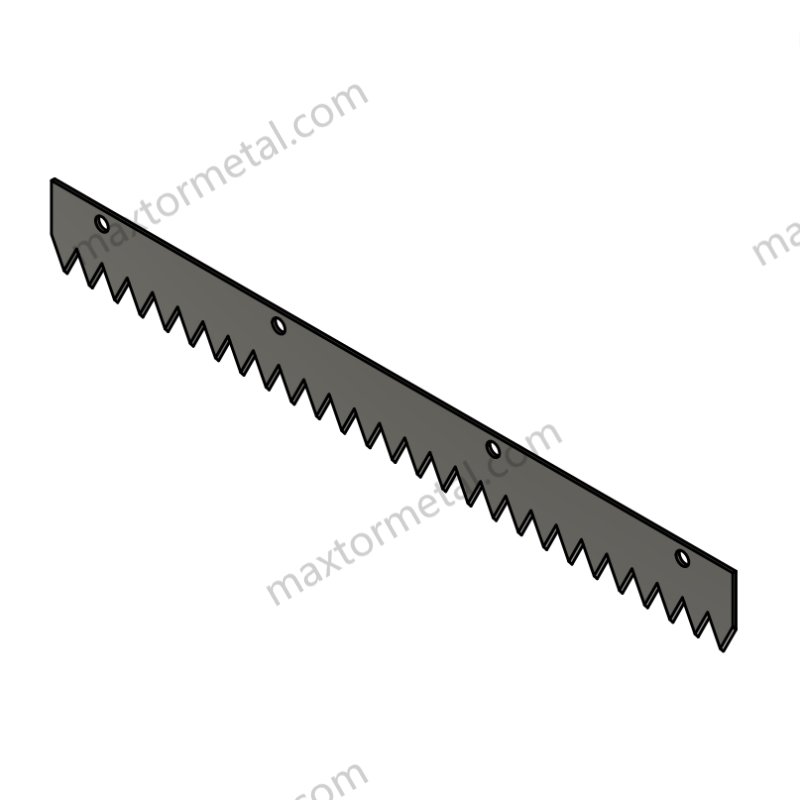

Corrugated Knife Design and Its Effects on Manufacturing Output

Corrugated knife design has a big effect on how much packaging companies can make. Good cutting tools help make better cuts, work faster, and save money. The table below shows important numbers that explain how new cutting tools help: Metric Description Impact Overall Equipment Effectiveness (OEE) Measured over 12 shifts for an auto corrugation machine, with values ranging […]

What You Need to Know About Corrugated Carton Slotter Blade Types and Their Applications

Corrugated carton slotter blades are the main tools for cutting and shaping cardboard in packaging. The type and material of these blades are very important for how well they work and how good the boxes look. Nanjing Metal is a trusted company that makes corrugated carton slotter blades. They have been doing this for twenty years. They give […]