| Otros nombres | Cuchilla de corte dentada para máquina envasadora, cuchilla dentada para máquina envasadora, cuchilla dentada para máquina envasadora, cuchilla dentada para envasado, cuchilla dentada para envasado, cuchilla dentada para máquina envasadora |

|---|---|

| Lugar de origen | Porcelana |

| Solicitud | El plastico, Papel, Tablero, Película, Papel de aluminio, Etiquetas, Embalaje, Corrugado, Revistas, Libros |

| Material | Acero carbono |

| Número de modelo | GP-SC |

| Servicio OEM | Disponible |

| Términos de pago | LC, T/T, Western Union |

| Paquete | Caja de cartón, En cajas de madera. |

| El tiempo de entrega | 7-20 días |

Compartir a:

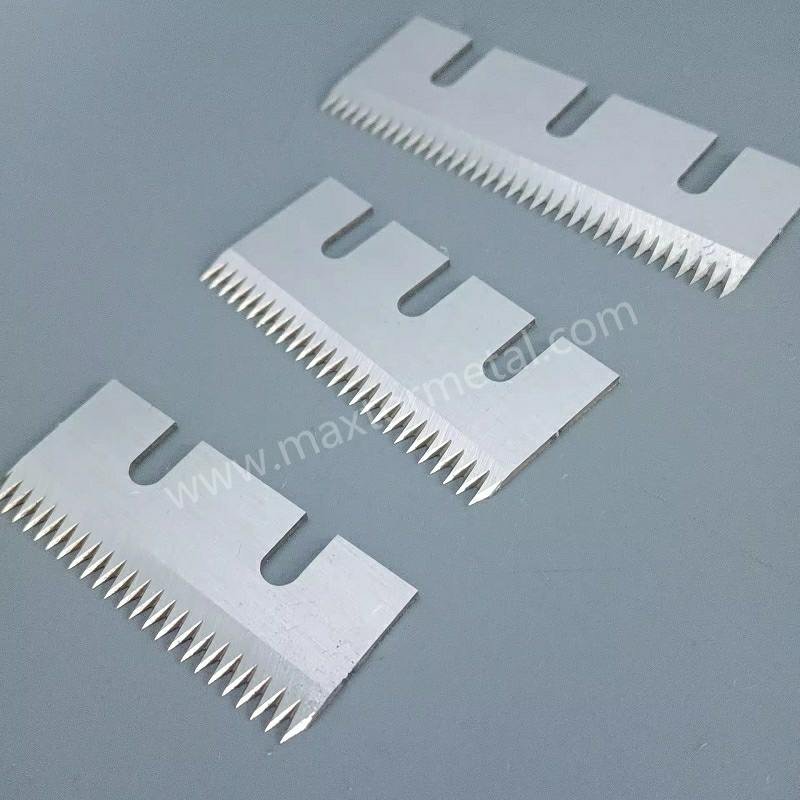

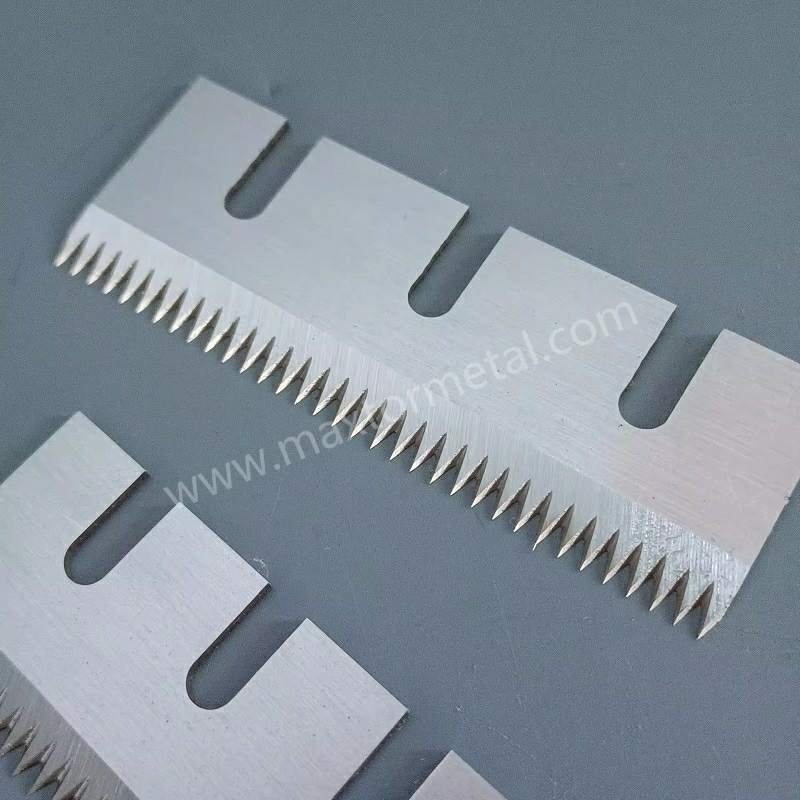

A serrated packing knife blade, also known as a toothed packing knife blade, is a type of cutting tool specifically designed for use in packaging processes where a saw-like cutting action is beneficial. The serrated edge, characterized by a series of teeth along the blade, allows for efficient cutting through various packaging materials, including cardboard, foam, plastic films, strapping bands, and tapes. The term “serrated packing knife blade” highlights its toothed cutting edge and its application in the packaging industry.

Serrated packing knife blades are versatile tools used in a wide range of packaging operations:

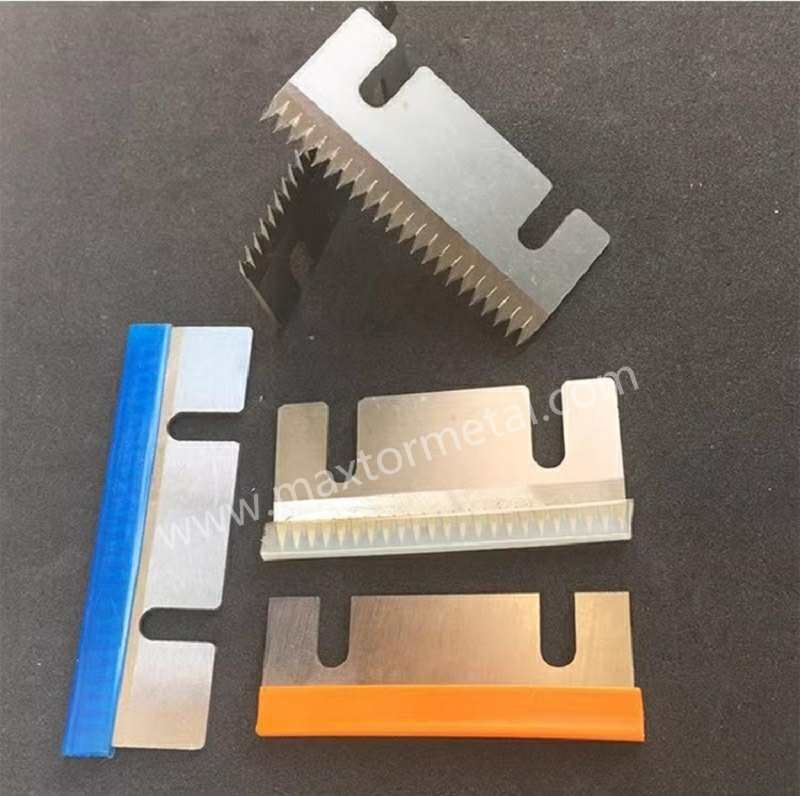

The materials used for serrated packing knife blades need to be durable, corrosion-resistant (especially if exposed to moisture or adhesives), and capable of maintaining a sharp serrated edge. Common materials include:

The blades are typically hardened and tempered to achieve the optimal balance of hardness and toughness for the serrated teeth. The serrations themselves are precisely formed and sharpened to maximize cutting efficiency and longevity.

Serrated packing knife blades come in various shapes and serration patterns to suit different cutting tasks:

The working principle of a serrated packing knife blade relies on the concentrated pressure applied by the sharp tips of the serrations. These teeth grip the material and create multiple points of initial penetration, allowing the user to cut through with a sawing motion. The valleys between the teeth help to pull the material across the blade, enhancing the cutting action, especially on fibrous or uneven surfaces. The specific shape and sharpness of the serrations are optimized for the types of packaging materials the blade is intended to cut.

Bienvenido a ¡preguntar!

Si no encuentras la cuchilla de tijera que buscas, también podemos personalizarla, consulta nuestra "Cuchillas personalizadas" ¡Para aprender cómo!

Fácil de disfrutar de la comodidad de importar, desde el transporte hasta el despacho de aduana, manejamos todo el proceso, usted solo necesita pagar el IVA y esperar a que la mercancía llegue a la empresa.

Hemos visto sus hojas utilizadas en innumerables aplicaciones y estamos listos para manejar cualquier proyecto que se nos presente, brindando precisión, durabilidad y precios competitivos inigualables.

Ya sea que nos proporcione dibujos, bocetos o muestras, podemos diseñar y fabricar para usted. También tenemos la capacidad de ayudarlo a modificar diseños y especificaciones existentes para mejorar casi cualquier aplicación de herramientas industriales. Comuníquese con nuestro equipo de ventas especializado para analizar sus requisitos específicos.

Se realizan una serie de pruebas e inspecciones para controlar la calidad, incluida la inspección del primer artículo, la inspección del material entrante y los materiales certificados, la inspección de calidad en proceso y la inspección de calidad final.

Ya sea que sea un importador, distribuidor, mayorista o usuario final, lo invitamos a unirse a nosotros con un MOQ mínimo, sin problemas para realizar consultas y más libertad para comprar.

Conviértete en su monitor exclusivo, transmisión regular de cada nodo importante en la línea de producción, sin importar cuán lejos esté, ¡el progreso del producto lo más lejos posible para captar!

Nanjing Metal Industrial CO., Limitado

Parque industrial Mingjue, Lishui, Nanjing, Jiangsu, China

Manténgase al día con nuestras últimas noticias.