Elegir lo mejor cuchillas industriales para cortar papel is very important. Good industrial paper cutting knives last longer and stay sharp, needing fewer replacements. Sharp knives make cleaner cuts, which saves paper and money. Whether you use a paper cutter or need a cuchilla personalizada, the right choice boosts work speed. Companies like Nanjing Metal have good options for your needs. To find the right knife and cut perfectly every time, be sure to póngase en contacto con experts.

Puntos clave

- Picking the right paper cutting knife saves time and money. Sharp blades cut better and last longer.

- Learn about knife types: guillotine knives cut thick stacks, circular knives are precise, and Cuchillas cortadoras make fast cuts.

- Check the blade material. High-speed steel and tungsten carbide are strong and work well for tough tasks.

- Take care of your knives. Clean, sharpen, and store them properly to make them last longer and work smoothly.

- Ask experts and try samples before buying. This helps you choose the best knives for your cutting needs.

Types of Industrial Paper Cutting Knives

Picking the right knife for cutting paper is important. Each knife type has a special job. Knowing how they work helps you choose the best one.

Guillotine Knives and Their Uses

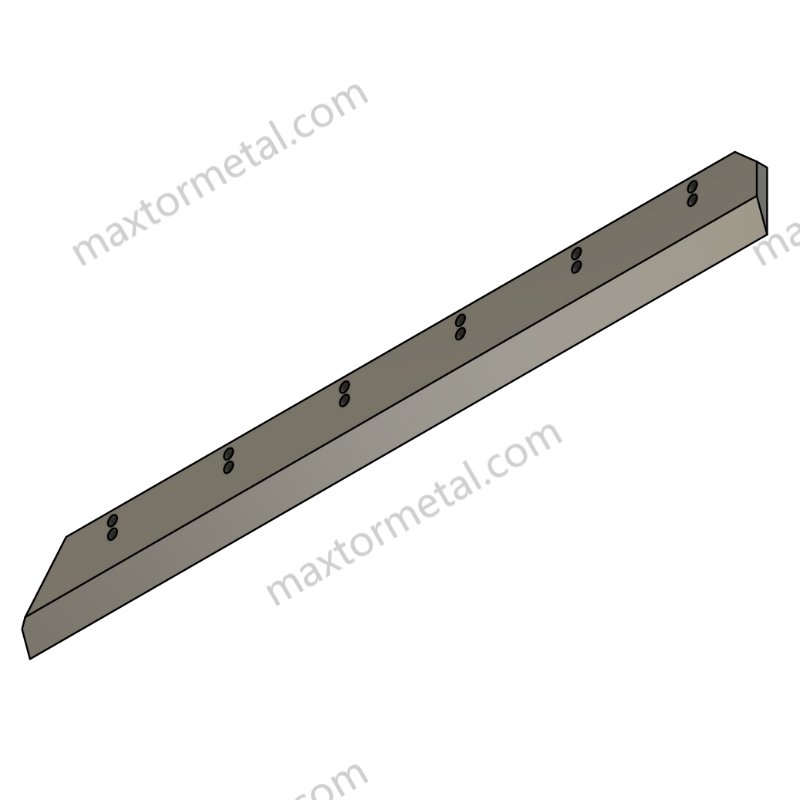

Guillotine knives are common in cutting large paper stacks. These long, straight blades make neat, straight cuts. They are great for jobs like bookbinding or packaging. Sharp guillotine knives cut cleanly, saving paper and time.

A big benefit of guillotine knives is cutting thick paper stacks at once. This makes them perfect for busy workplaces. But, they need regular care, like sharpening and aligning. For heavy-duty cutting, guillotine knives are a smart pick.

Circular Knives for Detailed Cuts

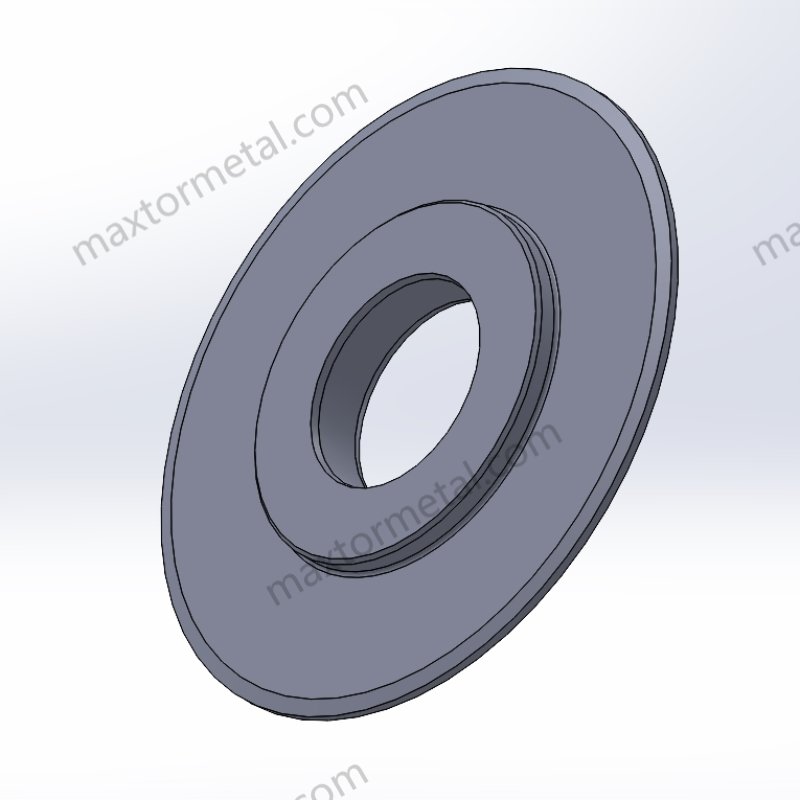

cuchillos circulares are great for cutting with precision. These round blades spin while cutting, making smooth, exact cuts. They work well for cutting shapes or patterns. Industries like printing often use them for detailed tasks.

These knives can cut many paper types, from thin to thick. They prevent tearing and leave clean edges. If you need detailed cuts, circular knives are a good choice. Always check they fit your cutting tools for the best results.

Slitter Knives for Fast Cutting

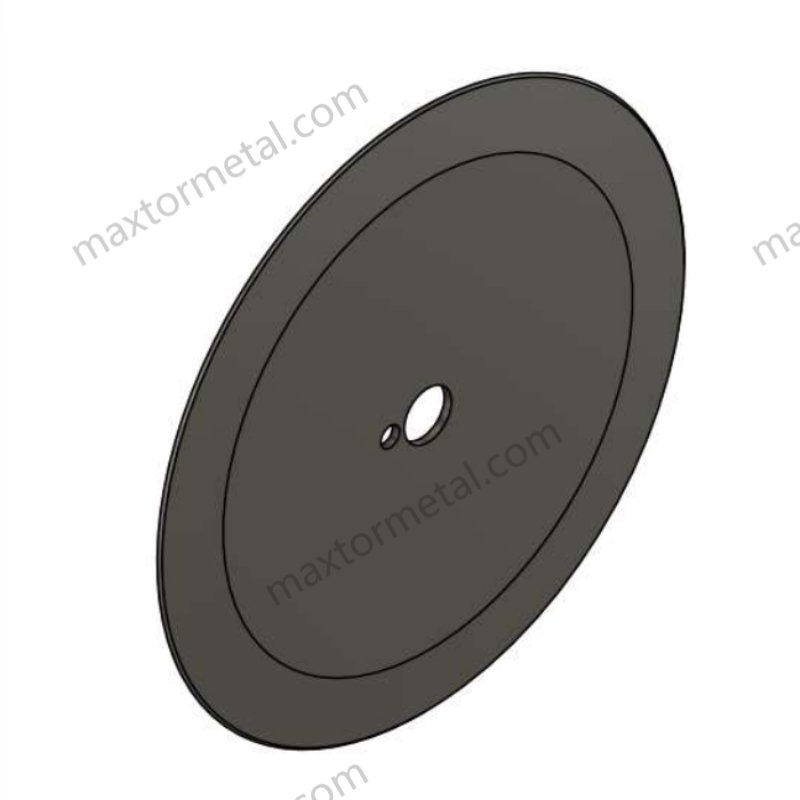

Slitter knives are best for quick cutting jobs. They cut paper into thin strips quickly and accurately. Industries like paper making and packaging use them a lot.

Slitter knives are strong and handle nonstop work. They cut big paper rolls into smaller pieces, perfect for busy production lines. Regular checks and care keep them working well for a long time.

Specialty Knives for Unique Paper Cutting Needs

Specialty knives are made for special paper cutting tasks. These blades make tricky jobs easier and faster. They are built for tasks that regular knives cannot do. If you cut detailed designs or unusual paper, these knives are ideal.

Types of Specialty Knives

Specialty knives come in different types for specific tasks. Here are some examples:

- Cuchillas de perforación: These blades make dotted lines for easy tearing. They are great for coupons, tickets, or forms.

- Scoring Knives: These knives make shallow cuts to fold paper neatly. They are useful for packaging and crafts.

- Die-Cutting Knives: These blades cut shapes and patterns. They are perfect for greeting cards and decorative items.

Benefits of Specialty Knives

Specialty knives are precise and flexible. They handle detailed cuts and special finishes. For example, perforation knives save time by avoiding manual tearing. Scoring knives make clean folds without ripping the paper. Die-cutting knives create unique designs that look amazing.

Choosing the Right Specialty Knife

Pick a specialty knife based on your needs. Think about the paper type and the result you want. For neat folds, use scoring knives. For creative projects, die-cutting knives work best.

Custom blades can also be made for specific jobs. Manufacturers offer unique designs and materials. Ask experts to help you find the right blade for your work.

Maintenance Tips for Specialty Knives

Taking care of specialty knives makes them last longer. Clean them often to avoid buildup and keep cuts smooth. Sharpen the blades to keep them precise. Store them in a safe, dry spot to prevent damage.

Consejo: Follow the manufacturer’s care instructions. This keeps your knives working well for a long time.

Key Features of Industrial Cutter Blades

Material and Composition for Durability

The material of industrial cutter blades is very important. Strong blades are often made from high-speed steel knives o carburo de tungsteno. These materials make the blades last longer, even with heavy use. For instance, high-speed steel knives resist wear and stay sharp during big cutting jobs. Tungsten carbide blades are harder and great for cutting tough paper.

Always check what the blade is made of before buying. Strong blades cut better and need fewer replacements. This saves time and money over time. If you need blades for hard jobs, focus on the material first.

Sharpness and Cutting Edge Quality

Sharp blades are key for clean, smooth cuts. Dull blades can tear paper, wasting time and materials. Good-quality blades stay sharp longer and cut better.

Look for blades with a precision-ground edge. These blades cut paper smoothly and accurately. Sharpen them often to keep them working well. Sharp blades also protect your machine by reducing strain.

Blade Design and Machine Compatibility

The blade’s design must fit your cutting machine. Always check the size and mounting style to ensure it works. Using the wrong blade can harm the machine or cause bad cuts.

Some blades are made for special tasks, like slitting or perforating. Others can work with many machines. Check the manufacturer’s guide to pick the right blade. A good match improves cutting and keeps your machine running smoothly.

Consejo: Test a new blade on your machine before using it fully.

Wear Resistance and Longevity

When picking industrial cutter blades, think about how long they last. Blades with good wear resistancestay sharp longer. This means fewer stops and better cutting results.

The blade material affects wear resistance. Carburo de tungsteno y high-speed steel knives are strong and last longer. These materials handle tough jobs without wearing out quickly. Spending more on good materials saves money over time.

Taking care of blades helps them last. Clean them often and sharpen them when needed. Check blades for dull edges or chips. Fixing problems early keeps them working well.

The type of paper also matters. Thick or rough paper wears blades faster. Use blades made for hard cutting jobs. They last longer and work better.

Consejo: Follow the maker’s care instructions. This keeps blades sharp and working for a long time.

By focusing on wear resistance, you save time and money. It helps cutting jobs stay smooth and efficient.

Matching Industrial Paper Cutting Knives to Your Needs

Assessing Industry Requirements

Understanding Specific Applications

When picking industrial cutter blades, I first think about the job. Different industries need different blades. For example, packaging companies cut thick paper, while printing needs sharp blades for thin paper. Knowing the task helps me choose better.

I also look at the final product. If I need perforated forms or fancy designs, I use specialty blades like perforation or die-cutting knives. By focusing on the job, I pick the right blade every time.

Identifying Cutting Tasks

Figuring out the cutting task is very important. I ask questions like, “Am I cutting big paper rolls or small sheets?” or “Do I need smooth edges or detailed shapes?” These answers help me decide.

For fast jobs, slitter knives are great. They cut quickly and stay accurate. Guillotine knives are best for cutting thick paper stacks. By knowing the task, I save time and pick the right blade.

Analyzing Paper Types

Evaluating Thickness and Weight

Paper thickness and weight matter a lot when choosing blades. Thick paper needs strong blades, like tungsten carbide, for clean cuts. Thin paper, like tissue, needs sharp blades to avoid tearing.

I always check the paper’s thickness and weight first. This stops problems like dull cuts or rough edges. Circular knives are good for thin paper, while guillotine knives handle heavy stacks well.

Considering Paper Composition

The type of paper changes how blades work. Coated paper, like in magazines, needs blades that resist wear. Uncoated paper, like cardboard, needs tough blades for rough surfaces.

I also check for glue or ink in the paper. These can make blades dull faster. Using high-speed steel or tungsten carbide blades keeps them sharp longer, even with tricky paper.

Determining Cutting Volume

Estimating Daily Production Needs

Knowing how much cutting I do daily helps me pick blades. For high-volume work, I choose durable, fast blades. Slitter knives are great for nonstop cutting, while guillotine knives work for batch jobs.

For smaller tasks, I focus on accuracy. Circular or specialty blades are perfect for detailed work. Matching the blade to the workload keeps things running smoothly.

Planning for Future Growth

Thinking about future needs is smart when buying blades. If I expect more work later, I get long-lasting, strong blades.

I also check if the blades fit new machines. Versatile blades save money because they work with upgrades. Planning ahead helps me make better choices for cutting tools.

Ensuring Compatibility

Matching Knives to Equipment

I always check if the blades fit my machine. Each machine needs specific blade sizes and shapes. Using the wrong blade can cause bad cuts or damage. I read the machine’s manual to find the right blade type.

Sometimes, I ask the machine maker for advice. They often suggest blades that work well. Before starting big jobs, I test the blade on the machine. This makes sure everything works properly.

Verifying Manufacturer Specifications

Before buying blades, I read the manufacturer’s details carefully. These include the blade’s material, size, and purpose. I compare this with my machine’s needs to avoid mistakes.

I also look for certifications or quality marks. Trusted makers follow industry rules, which means better blades. If I have questions, I contact the maker for answers. This helps me pick the right blade.

Seeking Expert Guidance

Consulting Industry Professionals

When I’m unsure about blades, I ask experts for help. They know a lot and can guide me to the best choice. Experts explain which blades work for certain tasks or materials.

I meet professionals at trade shows or events to learn more. These are great places to see new tools and ideas. Online groups also help me learn from others. This keeps me informed and confident in my choices.

Utilizing Manufacturer Resources

Manufacturers share helpful information about their blades. They offer guides, videos, and customer support to explain their products. I use these tools to learn more.

Some makers give personal advice. I tell them about my cutting needs, and they suggest blades that fit. This saves time and ensures I get good-quality blades.

Testing and Sampling

Requesting Free Samples

Before buying a lot of blades, I ask for free samples. Many makers let customers test their blades first. I use samples to check how well they work with my machine.

Testing samples stops me from wasting money on bad blades. It also shows me the blade’s quality. I suggest always trying samples before buying new blades.

Evaluating Performance in Real Scenarios

After getting samples, I test them on real cutting jobs. I use the blades with my usual machines and materials. This shows how they perform in everyday work.

I check for things like clean cuts, strength, and ease of use. If the blade works well, I buy more of them. Testing in real situations helps me choose the best blades for my needs.

Maintenance Tips for Industrial Paper Cutting Knives

Keeping Knives Sharp and Bevels Proper

I always make sure my knives stay sharp. Sharp blades cut better and protect my machines. Dull blades need more force, which wastes energy and money. Sharpening often helps knives last longer. If a knife gets too dull, I might lose up to ¼ inch of the blade to fix it. This shortens its life.

Here’s a simple sharpening schedule I follow:

| Tarea de mantenimiento | How Often to Do It |

|---|---|

| Replace regular knife | after 2,000 cuts |

| Replace high-speed knife | after 4,000 cuts |

| Replace carbide knife | after 12,000 cuts |

Following this plan saves me time and money. I also check the bevel angle. It must match the maker’s guide to avoid bad cuts or damage.

Cleaning and Storing Knives Safely

I clean my knives after every use. Paper dust, glue, or ink can make blades dull. I wipe them with a soft cloth and mild cleaner. For tough dirt, I use a gentle scrubber.

I store knives in a dry, safe place. Moisture causes rust, which weakens blades. I cover the edges to keep them safe. Good storage keeps knives sharp and prevents accidents.

Consejo: Be careful when cleaning and storing knives to stay safe.

Checking for Damage and Wear

I inspect my knives often for damage. Small chips or dull spots can ruin cuts and cost more to fix. I look for cracks or nicks and test how well the blade cuts.

If I find problems, I fix them right away. For dull blades, I sharpen them. If the damage is bad, I replace the blade. Regular checks keep my work smooth and safe.

Scheduling Professional Maintenance Services

I make sure to plan regular maintenance for my industrial paper cutting knives. Expert care keeps the blades in great shape and working well. It also stops sudden problems that could slow down work.

Why Professional Maintenance is Important

Professional maintenance does more than just cleaning and sharpening. Experts use special tools to check for hidden damage or wear. They also make sure the knives are properly aligned with the machine. This helps the blades cut better and last longer.

Consejo: Regular maintenance lowers the chance of expensive repairs or replacements.

Steps to Schedule Maintenance

Here’s how I arrange professional maintenance:

- Contact the Manufacturer or Supplier: Many blade makers offer maintenance services. I reach out to them for expert help.

- Create a Maintenance Plan: I schedule maintenance based on how often I use the blades. For heavy use, I plan it more often.

- Keep a Record: I write down all maintenance activities. This helps me know when the next service is needed.

Benefits of Professional Maintenance

Since scheduling professional maintenance, I’ve seen many benefits:

- Better Cutting: The blades cut cleaner and more precisely.

- Mayor vida útil de la hoja: Regular care stops too much wear and damage.

- Less Downtime: Maintenance prevents unexpected machine problems.

Nota: Always hire certified experts for maintenance. They know how to handle industrial blades safely and correctly.

By focusing on professional maintenance, I keep my cutting tools dependable and efficient. It’s a small cost that brings big rewards over time.

Balancing Cost and Performance in Paper Cutting

Understanding the Total Cost of Ownership

When I think about the cost of cuchillas industriales para cortar papel, I don’t just check the price. I also look at how long they last and how often they need sharpening. Downtime caused by dull blades is another factor. A cheaper knife might seem like a good deal, but if it wears out fast or harms the machine, it costs more in the end.

Knives made from strong materials like acero con alto contenido de carbono o acero de alta velocidad save money over time. They stay sharp longer and handle tough jobs without breaking. Special coatings like Teflon or titanium nitride make cutting smoother by reducing friction. These features may cost more upfront, but they lower maintenance costs and improve performance in the long run.

Choosing Reliable Brands and Suppliers

I always pick trusted brands and suppliers for my knives. Reliable companies focus on making high-quality products that last. Their knives stay sharp longer, which means cleaner cuts and less wasted paper.

The material of the blade is very important. Blades made from acero de alta velocidad o carburo de tungsteno are stronger and stay sharp longer. Some brands add special coatings to make cutting easier. The design of the blade, like its thickness and angle, also affects how well it works. By choosing good suppliers, I get knives that meet my cutting needs.

Avoiding Common Costly Mistakes

I’ve learned to avoid mistakes that waste money. One big mistake is using the wrong knife for the job. If the blade doesn’t match the paper type or workload, it won’t work well and will need replacing often. Another mistake is skipping maintenance. Dull or damaged blades slow down work and can harm the machine.

Buying cheap, low-quality knives is also a bad idea. They wear out quickly and need replacing more often. Spending more on high-quality knives saves money and improves efficiency over time.

Consejo: Talk to experts or manufacturers to find the best knives for your needs.

Investing in Long-Term Value and Efficiency

When buying paper cutting knives, I think long-term. Good-quality knives may cost more, but they last longer. This means fewer replacements and less money spent on repairs. Durable knives also prevent work delays.

I also care about working efficiently. A sharp knife cuts better and wastes less paper. For example, a guillotine knife slices thick paper stacks neatly. Specialty knives, like scoring or perforation blades, make tricky tasks easier and faster.

To get the best value, I pick strong materials like tungsten carbide or high-speed steel. These materials handle tough jobs without wearing out quickly. Some blades have coatings that reduce friction, making them last even longer.

I also plan for future needs. I choose knives that fit different machines or handle more work. This way, I don’t need to buy new tools later. I ask manufacturers for advice to pick the right blades. Their tips help me make smart choices.

By focusing on quality and efficiency, I save money and improve my work. It’s a smart investment for better results and smoother processes.

Elegir lo correcto cuchillas industriales para cortar papel really helps your work. Knowing the knife types, their features, and how to care for them makes tools last longer. This also saves time and makes cutting jobs easier.

Consejo: Think about what you need before buying. Check the paper type, how much you cut, and if the knife fits your machine.

Ask trusted suppliers or experts for advice. Many companies give free samples to try before buying. Look into good brands now and see how better knives can improve your work!

Preguntas frecuentes

1. How can I pick the best knife material?

Think about the paper type and how much you cut. Carburo de tungsteno is great for tough jobs. Acero de alta velocidad works well for regular cutting. If unsure, ask the maker or try sample blades to see how they perform.

2. How often should I sharpen my cutting knives?

How often you sharpen depends on the blade and use. Here’s a guide:

- Regular blades: After 2,000 cuts

- Acero de alta velocidad: After 4,000 cuts

- Carburo de tungsteno: After 12,000 cutsConsejo: Check blades often to stop them from getting dull.

3. Can one knife work for all paper types?

No, not always. Thin paper needs sharp blades to avoid tearing. Thick or coated paper needs strong blades like carburo de tungsteno. Using the wrong blade can ruin the paper and the knife.

4. What if my blade doesn’t fit my machine?

Check your machine’s size and the blade’s measurements. If they don’t match, ask the supplier for help or order a custom blade. Wrong blades can damage your machine.

5. Are specialty knives worth buying?

Yes, if you do special tasks like perforating or die-cutting. Specialty knives save time and make cuts more accurate. For example, perforation knives make tearable lines, and die-cutting knives create fancy shapes. They’re useful for industries like printing or packaging.

Nota: Pick specialty knives based on what you need exactly.

Ver también

Consejos esenciales para seleccionar la cuchilla peletizadora adecuada