The fish processing industry plays a pivotal role in meeting the global demand for seafood, an essential source of protein for millions. With the seafood market valued at over $160 billion in 2022 and projected to grow significantly in the coming years, efficient fish processing methods have become critical to ensuring quality, sustainability, and profitability. Whether you’re a small-scale processor or a large industrial player, understanding the role of fish processing industrial knives in achieving operational excellence is key to success.

The Basics of Fish Processing

What Is Fish Processing?

Fish processing involves a series of steps aimed at transforming freshly caught or farmed fish into high-quality products ready for consumption or further value addition. These steps include cleaning, gutting, filleting, freezing, and packaging, all designed to preserve freshness, maintain nutritional value, and enhance the product’s appeal to both consumers and distributors.

For instance, global consumption of processed fish products, including fillets, canned fish, and frozen items, is on the rise, with demand driven by convenience and an increased focus on protein-rich diets. By ensuring optimal processing techniques, producers can tap into this growing market and minimize waste, a critical factor considering the average processing yield of fish is 50-70%, depending on the species.

Impact on the Supply Chain

Efficient fish processing underpins the entire seafood supply chain, impacting quality, sustainability, and marketability. For example:

- Consistent Quality: Proper handling and processing ensure uniformity in taste, texture, and appearance, essential for meeting consumer expectations.

- Waste Reduction: High-efficiency equipment, such as precision industrial knives, minimizes waste during filleting and portioning.

- Extended Shelf Life: Techniques like vacuum sealing and rapid freezing preserve freshness and expand market reach, enabling products to travel globally without compromising quality.

According to the Food and Agriculture Organization (FAO), up to 35% of global fish harvests are wasted annually, largely due to inadequate processing and preservation methods. By adopting advanced tools and techniques, processors can significantly reduce this figure, bolstering supply chain efficiency.

Fish Processing Steps

Key Steps in Fish Processing

Fish processing comprises multiple precise steps, each critical to achieving high-quality end products. Here’s a closer look:

- Sorting and Classification:

- Fish are sorted by size, species, and quality immediately upon arrival.

- Sorting ensures efficient processing and prevents cross-contamination. For example, using automated systems equipped with AI sorting technology can handle up to 300 fish per minute, vastly improving productivity.

- Cleaning and Gutting:

- Includes removing scales, heads, tails, and viscera to prepare fish for further processing.

- Hygiene is critical here, as improper cleaning can introduce harmful bacteria.

- Filleting and Slicing:

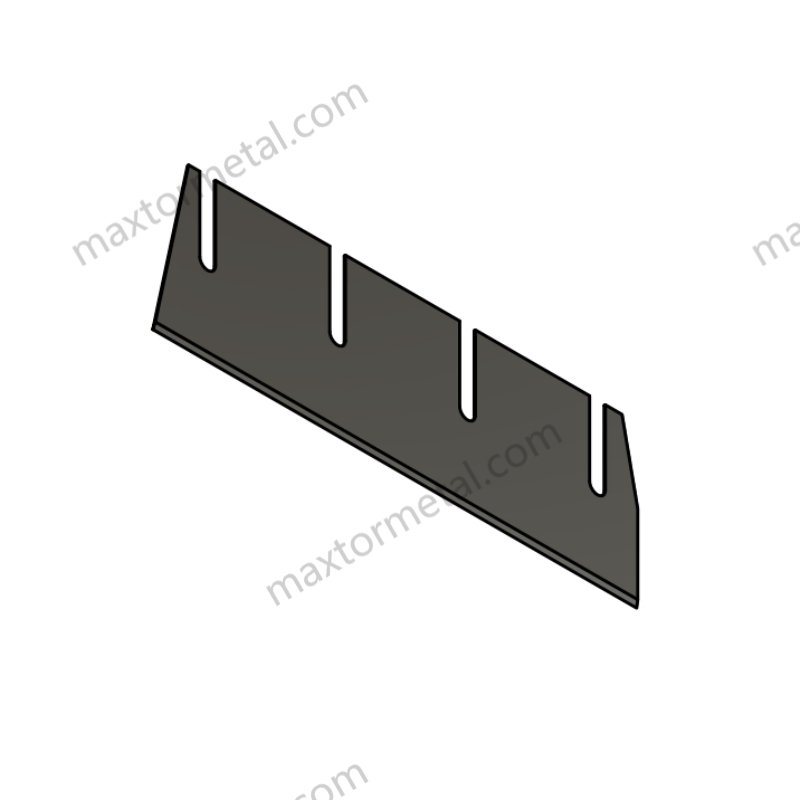

- Industrial knives play a central role, ensuring precise cuts to maximize yield. Specialized filleting blades, such as Nanjing Metal’s serrated or straight-edge knives, enhance productivity and reduce waste by achieving clean, uniform cuts.

- Skin Removal:

- Skinning can be done manually or with specialized de-skinning machines. Automated systems equipped with high-performance blades reduce time and labor costs, processing up to 60 fillets per minute.

- Washing and Handling:

- Washing removes residues, blood, and contaminants. Using ozone-treated water is increasingly popular for its ability to sanitize fish while extending shelf life without chemicals.

Manual vs. Automated Processing

Manual Processing:

- Advantages:

- Greater control over delicate species or unique cuts.

- Flexible and cost-effective for small operations.

- Disadvantages:

- Labor-intensive and time-consuming.

- Higher risk of inconsistent quality.

Automated Processing:

- Advantages:

- Superior speed and consistency.

- Reduces labor costs and improves workplace safety.

- For instance, state-of-the-art filleting machines can handle 200 fish per minute with precision.

- Disadvantages:

- High upfront costs.

- Limited flexibility for custom cuts or smaller batches.

Small vs. Large Processing Facilities

- Small Facilities:

- Typically use manual methods or semi-automated equipment.

- Focus on niche markets or artisanal products.

- Relatively low investment costs but limited scalability.

- Large Facilities:

- Fully automated production lines capable of processing thousands of fish per day.

- Integration of robotics and AI systems improves throughput and quality control.

- Require significant capital investment but offer high scalability and efficiency.

Quality and Safety Control

Unique Challenges in Fish Processing

Fish are among the most perishable food items due to their high water content (65-80%), low connective tissue, and rich protein composition, which makes them an ideal substrate for microbial growth. Spoilage can set in within 12-24 hours at ambient temperatures if proper handling measures are not taken. The enzymatic activity and microbial proliferation in fish can lead to the production of harmful compounds such as histamine, which poses serious health risks if consumed.

Furthermore, maintaining quality during processing requires stringent control over environmental conditions and consistent use of high-quality equipment, such as food-grade industrial knives, to avoid cross-contamination.

Key Quality Control Measures

1. Temperature Control

Temperature is the single most critical factor in preventing fish spoilage. The optimal temperature range for fish processing and storage is 0°C to 4°C, with freezing temperatures as low as -18°C recommended for long-term storage. Research by the FAO shows that maintaining fish at sub-zero temperatures can reduce spoilage rates by 50-70%, thereby significantly extending shelf life.

- Rapid Chilling: Ice slurry or brine chilling systems are commonly used for immediate post-catch cooling.

- Blast Freezing: Advanced systems that rapidly freeze fish at -35°C retain moisture, color, and texture better than traditional freezing methods.

2. Humidity Management

Humidity levels during processing and storage should ideally range between 75-85%. Low humidity causes dehydration and weight loss in fish, while high humidity encourages microbial growth. Automated humidity control systems integrated into processing lines help maintain these optimal levels, ensuring product quality.

3. Oxygen Control

Excess oxygen promotes oxidation of lipids in fish, leading to rancidity. Using vacuum packaging or modified atmosphere packaging (MAP) with gases like nitrogen and carbon dioxide can significantly reduce oxidative spoilage. Studies show that MAP can extend the shelf life of processed fish by 2-3 times, making it a popular choice for retail products.

Microbial Growth Control

Fish processing environments are highly susceptible to microbial contamination due to water, organic matter, and processing residues. Key strategies include:

- Sanitation Protocols: Regular cleaning and sterilization of knives, cutting boards, and processing equipment. Advanced industrial knives with non-stick coatings and antimicrobial properties (e.g., silver ion-infused coatings) help minimize contamination risks.

- Hygienic Design of Equipment: Tools such as seamless stainless-steel knives reduce the risk of bacterial buildup in cracks or joints.

- Monitoring: Routine microbial testing, including swabs and cultures, ensures compliance with safety standards such as HACCP (Hazard Analysis and Critical Control Points).

For instance, data from the European Food Safety Authority (EFSA) shows that adopting robust hygiene practices can reduce Listeria monocytogenes contamination in processing plants by 30-50%.

Waste Management in Fish Processing

Types of Waste

Fish processing generates significant quantities of by-products, including:

- Solid Waste: Heads, tails, fins, scales, and bones.

- Liquid Waste: Blood and wastewater from cleaning processes.

- Organic Residues: Viscera and other internal organs.

Globally, the seafood industry generates approximately 20 million tons of by-products annually, equivalent to 30% of total production, according to the FAO.

Eco-Friendly Waste Handling

Composting Organic Waste

Composting converts fish waste into nutrient-rich fertilizers. Pilot studies in aquaculture hubs like Norway have shown that composting reduces waste disposal costs by 40% while producing high-quality organic compost for agricultural use.

By-Product Conversion

By-products can be transformed into high-value materials through methods such as:

- Rendering: Converts fish waste into fish meal and fish oil, used extensively in animal feed and aquaculture.

- Hydrolysis: Produces bioactive peptides with applications in pharmaceuticals and food additives.

- Fermentation: Utilized to extract enzymes and collagen for cosmetic and industrial uses.

Adding Value to Waste

Omega-3 Supplements

Fish oil extracted from by-products is a key source of omega-3 fatty acids, essential for heart health and brain function. The global omega-3 market is projected to reach $7.8 billion by 2027, driven by rising health awareness.

Gelatin and Collagen

Scales and skins are excellent sources of gelatin and collagen, which have growing demand in the food, pharmaceutical, and beauty industries. For example:

- Gelatin Market Growth: Valued at $3.2 billion in 2021, it is expected to grow at a 6.8% CAGR by 2030.

- Collagen Applications: Used in anti-aging cosmetics, dietary supplements, and medical treatments like wound healing.

Fish-Based Biofuels

Technological advancements allow for the conversion of fish waste into biodiesel, providing an eco-friendly energy source. A case study in Chile showed that processing plant waste could generate enough biodiesel to power 20% of local fishing fleets, significantly reducing environmental impact.

End Products of Fish Processing

Types of Products

Processed fish products are tailored to meet diverse consumer preferences and market demands. Below are the major categories:

- Fillets:

- Fillets are boneless, skinless portions that maximize convenience for consumers. They are widely used in restaurants, retail, and meal kits.

- Precision industrial knives are crucial for producing uniform fillets, reducing waste by up to 15% compared to manual methods, according to research from the Norwegian Institute of Seafood Science.

- Fillets are available in fresh, frozen, or vacuum-packed formats to suit global distribution needs.

- Steaks:

- Steaks are thicker cuts of fish, typically cross-sections that include the backbone, making them ideal for grilling or frying.

- Large-scale production of fish steaks often utilizes advanced band saws with replaceable industrial blades that can handle 200 kg/hour, enabling high-volume operations.

- Whole Fish:

- Whole fish are processed minimally and frozen or refrigerated to preserve their natural state.

- Demand for whole fish is particularly high in regions with cultural preferences for intact fish, such as Asia, where whole fish consumption accounts for 70% of seafood sales.

Storage Options

- Freezing:

- Freezing remains the most effective method for extending the shelf life of fish products. Techniques such as blast freezing (at temperatures as low as -35°C) lock in freshness, reducing spoilage rates by 90%.

- Innovations like cryogenic freezing use liquid nitrogen to minimize ice crystal formation, preserving texture and nutritional value. This is particularly beneficial for premium products like sashimi-grade fillets.

- Canning:

- Canned fish products, such as tuna and sardines, are highly valued for their long shelf life (up to 5 years) and convenient storage.

- Retort processing, which sterilizes fish at 121°C for 15 minutes, ensures microbial safety while retaining flavor and texture.

- According to the Seafood Export Association, the global canned fish market was valued at $8.4 billion in 2021, with steady growth fueled by consumer demand for ready-to-eat meals.

- Refrigeration:

- Refrigerated products are preferred for short-term storage, maintaining fish at 0-4°C to retain freshness.

- This storage method is most suitable for high-turnover products like fresh fillets, which are typically consumed within 5-7 days.

Packaging Types for Fish Products

Common Packaging Methods

- Vacuum-Sealed Bags:

- Vacuum sealing removes air from the package, reducing oxidation and microbial growth, extending shelf life by 2-3 times compared to traditional methods.

- Studies by the Food Packaging Forum have shown that vacuum-sealed fish products retain 98% of their freshness after 30 days when stored at 0°C.

- IQF (Individually Quick Frozen):

- This method involves freezing each piece of fish separately, ensuring they do not clump together during storage.IQF technology is especially effective for portioned products like fillets and shrimp, enabling processors to cater to bulk buyers and retail consumers.

- According to the Global Cold Chain Alliance, IQF products constitute 25% of the frozen seafood market due to their convenience and quality preservation.

- Cans and Tins:

- Ideal for long-term storage, cans protect fish from light, air, and moisture, ensuring extended shelf life without refrigeration.

- The use of BPA-free coatings in modern canning ensures safety while maintaining product appeal for health-conscious consumers.

Impact of Packaging on Consumer Appeal

Packaging plays a vital role in influencing purchase decisions. Key factors include:

- Design and Branding:

- Attractive designs with clear labeling appeal to modern consumers who value transparency. Certifications like MSC (Marine Stewardship Council) or organic labels build trust and highlight sustainability.

- In a survey conducted by Seafood Source, 60% of consumers stated they preferred brands with eco-friendly packaging.

- Material Sustainability:

- Packaging made from biodegradable materials or recycled plastics is increasingly preferred by environmentally conscious consumers.

- Research by Euromonitor International shows that sustainable packaging can boost brand loyalty by up to 20% in key markets such as the EU and North America.

- Functional Features:

- Features like resealable vacuum bags or portion-controlled packaging enhance convenience, catering to busy households and reducing food waste.

- Innovations in intelligent packaging, such as freshness indicators, further enhance consumer confidence and reduce spoilage.

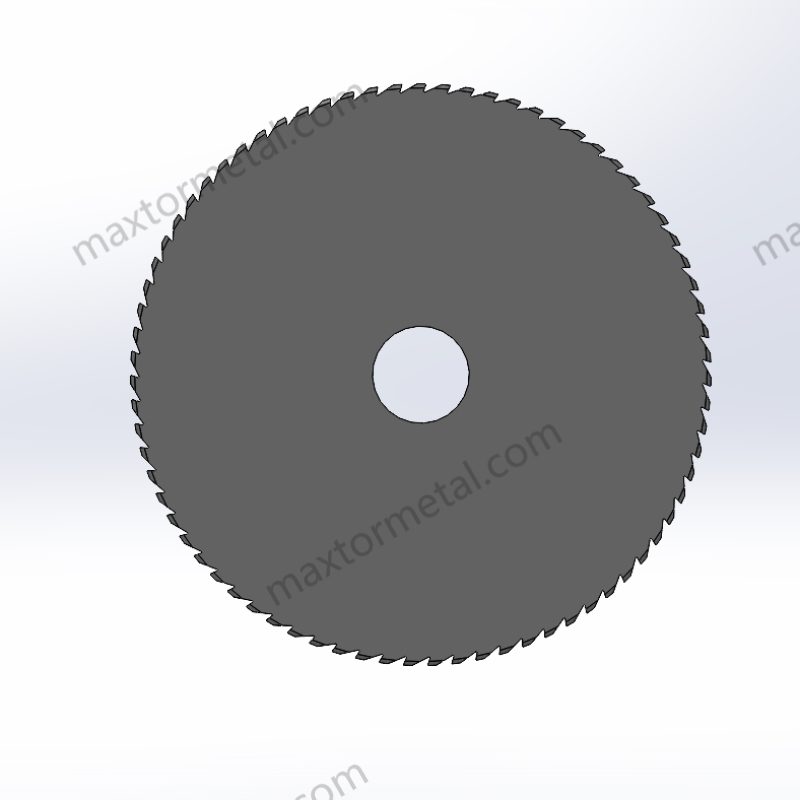

Equipment and Fish Processing Industrial Knife

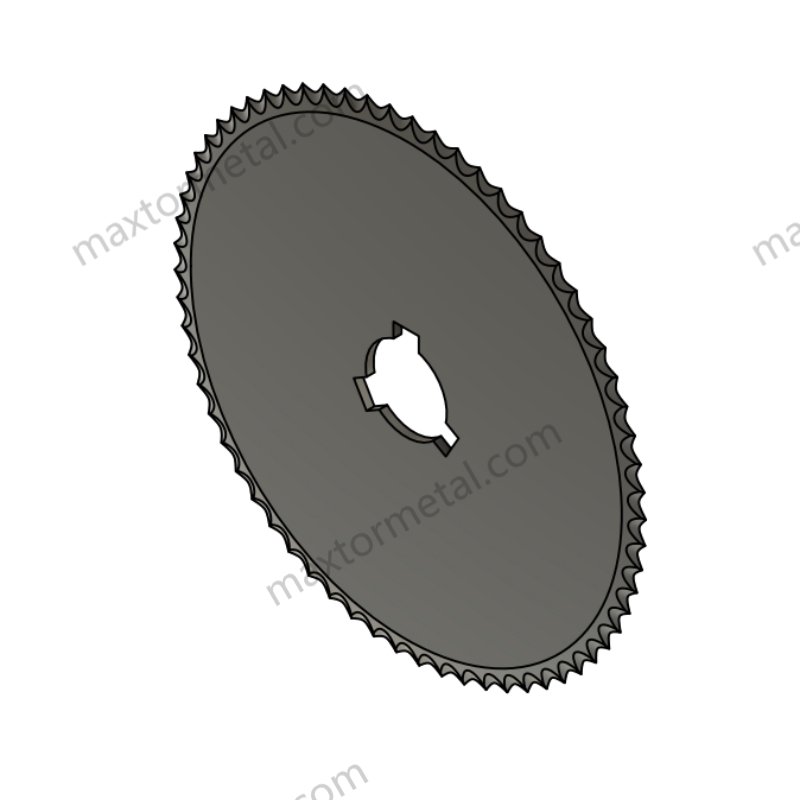

Role of Industrial Knives

Industrial knives are at the heart of fish processing, performing critical functions at every stage. Their precision, durability, and adaptability directly impact product quality, processing efficiency, and overall yield.

Why Choose Nanjing Metal Blades?

- Durability: Our knives are crafted from premium materials, ensuring long service life.

- Customization: Tailored blades designed to meet specific processing needs.

- Precision Cutting: Achieve flawless results, reducing waste and enhancing yield.

Importance of Custom Knife Solutions

Custom knives enable processors to address unique challenges, such as handling different fish species or achieving precise cuts.

Emerging Technologies and Trends

Innovations in Fish Processing

- Automation:

- Robotic systems equipped with AI-powered vision technology now perform tasks such as sorting, filleting, and portioning with unparalleled accuracy.

- For instance, automated sorting lines can handle 20-30 tons of fishper hour, reducing human error and improving speed.

- Combined with high-performance industrial knives, these systems ensure consistent quality and optimize processing efficiency.

- Smart Equipment:

- IoT-enabled machinery tracks parameters such as blade sharpness, cutting force, and temperature in real-time, alerting operators to maintenance needs before failures occur.

- Smart systems also integrate with supply chain software, enabling traceability from catch to consumer. A recent study by Seafood Source showed that 78% of consumers value traceability when purchasing seafood, driving demand for such innovations.

- Precision Automation:

- Laser-guided cutting technology ensures precise weight-based portioning, reducing giveaway and enhancing profitability.

- These systems can achieve up to 98% accuracy, critical for meeting retailer specifications and reducing waste.

Industry Challenges and Opportunities

- Sustainability:

- The fish processing industry faces mounting pressure to adopt sustainable practices. Efficient use of industrial knives can reduce waste and maximize yield, addressing this concern.

- For example, processors incorporating advanced waste recovery systems report a 30-50% reduction in organic waste, turning by-products into valuable materials like fishmeal or biofuels.

- Eco-Friendly and Traceable Products:

- Consumer demand for eco-friendly packaging and sustainable sourcing is reshaping the industry. Smart processing equipment with integrated industrial blades is helping processors meet these expectations while reducing carbon footprints.

Focus on Sustainability, Fish Processing Industrial Knife

Fish processors are increasingly adopting renewable energy and waste management systems to align with environmental goals.

- Energy Efficiency:

- Energy-efficient processing equipment, including blade systems with low-friction coatings, reduces energy consumption by up to 15%.

- Solar-powered refrigeration units are also gaining traction in coastal processing hubs, cutting reliance on fossil fuels.

- Circular Economy Initiatives:

- Companies are exploring ways to convert fish waste into high-value products. For example, skin and scales are processed into collagen, a booming market with a projected CAGR of 6.5% through 2030.

- Carbon Footprint Reduction:

- Modern processing plants equipped with smart automation systems reduce water and energy waste, supporting net-zero goals. The FAO estimates that such initiatives could cut emissions from fish processing by 20-25% globally.

Conclusion

The fish processing industry is an ever-evolving sector driven by innovation, sustainability, and consumer demand. By investing in advanced equipment and high-quality industrial knives, such as those from Nanjing Metal, processors can enhance efficiency and product quality while reducing waste.

At Nanjing Metal, we are committed to delivering high-quality industrial knife solutions tailored to the seafood processing industry. With 18 years of expertise, our skilled design and manufacturing team specializes in producing custom knives that enhance efficiency and precision in every stage of fish processing—from de-heading to filleting and slicing. Whether you’re looking for standard tools or unique specifications, we have the perfect solution for your needs. Don’t settle for less when it comes to your processing operations.

Contact us today to explore our range of industrial knife products and request a quote. Let Nanjing Metal be your trusted partner in optimizing your seafood processing operations!

References

- Seafood Market Overview, 2022. Source: Global Seafood Alliance.

- Fish Waste Utilization. Source: FAO Fisheries.