सारांश:

उच्च कठोरता शीयर ब्लेड औद्योगिक कटिंग अनुप्रयोगों में असाधारण स्थायित्व, सटीकता और परिचालन दक्षता प्रदान करें। यह लेख लाभ, सामान्य उपयोग और सही ब्लेड चुनने के लिए युक्तियों का पता लगाता है, जिससे व्यवसायों को कटिंग प्रक्रियाओं को अनुकूलित करने और ब्लेड के जीवन को बढ़ाने के लिए सूचित विकल्प बनाने में मदद मिलती है।

1. परिचय: औद्योगिक कटाई में उच्च कठोरता का महत्व

जिन उद्योगों में सटीक कटाई की आवश्यकता होती है, वहां स्थायित्व और दक्षता आवश्यक है। उच्च कठोरता वाले कतरनी ब्लेड तीक्ष्णता और दीर्घायु बनाए रखते हुए कठिन सामग्रियों को संभालने की उनकी क्षमता के लिए खड़े हैं। इस प्रकार के ब्लेड को विशेष रूप से पहनने का विरोध करने और मांग वाले कटिंग वातावरण में भी शीर्ष प्रदर्शन बनाए रखने के लिए इंजीनियर किया जाता है। उच्च कठोरता के साथ, ये ब्लेड डाउनटाइम को कम करते हैं और लंबे समय तक चलने वाले, विश्वसनीय प्रदर्शन प्रदान करते हैं।

सही ब्लेड का चयन आपकी उत्पादकता और लागत दक्षता को महत्वपूर्ण रूप से प्रभावित कर सकता है। उच्च कठोरता वाले ब्लेड धातु निर्माण, प्लास्टिक, रीसाइक्लिंग और अन्य जैसे उद्योगों के लिए आदर्श हैं। इन ब्लेड के अनुप्रयोगों और लाभों को समझने से आपको यह तय करने में मदद मिल सकती है कि वे आपके संचालन के लिए सही हैं या नहीं।

उच्च कठोरता कैसे होती है, यह जानने के लिए पढ़ते रहें काटने वाले ब्लेड आपके व्यवसाय को अनुकूलित कर सकते हैं.

2. उच्च कठोरता क्या है? शीयर ब्लेड?

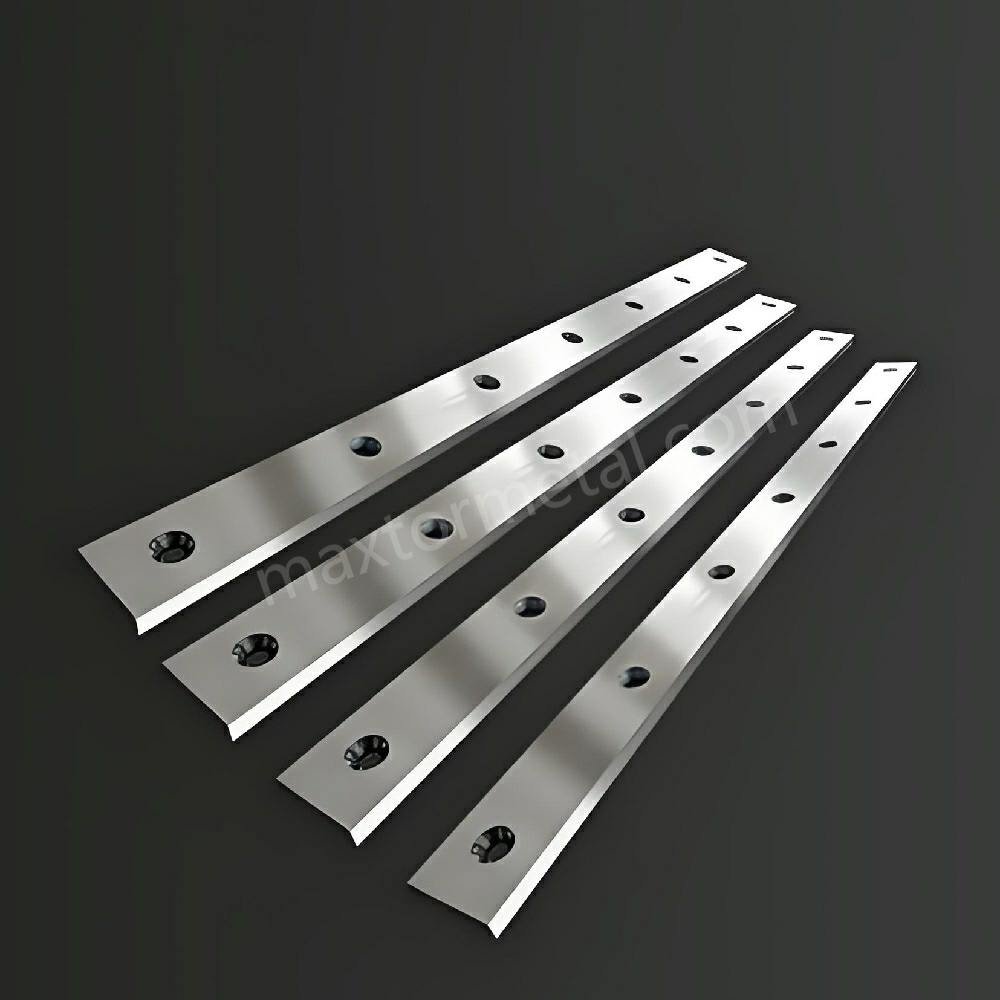

उच्च कठोरता कतरनी ब्लेड निरंतर उच्च-तनाव उपयोग के तहत एक तेज, टिकाऊ धार बनाए रखने के लिए डिज़ाइन किए गए औद्योगिक ब्लेड का एक वर्ग है। ये ब्लेड उन्नत मिश्र धातुओं जैसे कि उच्च-कार्बन स्टील, टूल स्टील या टंगस्टन कार्बाइड से बने होते हैं, जिनमें से प्रत्येक सामग्री को इसकी उच्च रॉकवेल कठोरता रेटिंग के लिए चुना जाता है, जो अक्सर 60 और 70 HRC (कठोरता रॉकवेल C) के बीच पहुँचती है। यह सख्त प्रक्रिया, जिसमें आमतौर पर गर्मी उपचार शामिल होता है, ऐसे ब्लेड बनाती है जो पहनने, विरूपण और टूटने के लिए प्रतिरोधी होते हैं, खासकर मानक औद्योगिक ब्लेड की तुलना में।

कठोरता प्रक्रिया उनके स्थायित्व के लिए महत्वपूर्ण है और इसमें कठोरता और मजबूती के बीच आदर्श संतुलन प्राप्त करने के लिए हीटिंग और शमन दोनों शामिल हैं। उच्च कठोरता शीयर ब्लेड चुनौतीपूर्ण वातावरण में तीव्र दबाव और बार-बार उपयोग को झेलने के लिए डिज़ाइन किए गए हैं, जो उन्हें उन उद्योगों में अमूल्य बनाता है जहाँ काटने की सटीकता और ब्लेड की लंबी उम्र ज़रूरी है। परीक्षणों में, उच्च कठोरता वाले ब्लेड आमतौर पर समान परिचालन स्थितियों के तहत मानक ब्लेड की तुलना में 40-50% अधिक समय तक चलते हैं, जिसका अर्थ है कम प्रतिस्थापन और कम दीर्घकालिक लागत।

संक्षेप में, ये उच्च प्रदर्शन औद्योगिक ब्लेड ऐसे अनुप्रयोगों में दीर्घायु और बेहतर पहनने के प्रतिरोध प्रदान करने के लिए अनुकूलित हैं जो साधारण ब्लेड को जल्दी से सुस्त कर देते हैं। बेहतर स्थायित्व और ताकत के साथ, उच्च कठोरता वाले कतरनी ब्लेड रखरखाव को कम करते हैं और निर्बाध उत्पादन सुनिश्चित करने में मदद करते हैं।

3. उच्च कठोरता वाले कतरनी ब्लेड के मुख्य अनुप्रयोग

उच्च कठोरता काटने वाले ब्लेड अपनी लचीलापन और सटीकता के कारण कई उद्योगों में अपरिहार्य हैं। यहाँ कुछ प्राथमिक अनुप्रयोग दिए गए हैं:

- Metal निर्माणकार्बन स्टील, स्टेनलेस स्टील और एल्युमीनियम जैसी धातुओं को काटना एक कठिन काम है जिसके लिए तीक्ष्णता और मजबूती दोनों की आवश्यकता होती है। उच्च कठोरता वाले कतरनी ब्लेड लंबे समय तक उपयोग के बाद भी तेज धार बनाए रखते हुए धातु के काम के अनुप्रयोगों में उत्कृष्ट होते हैं। उद्योग के आंकड़ों के अनुसार, धातु निर्माण में उच्च कठोरता वाले ब्लेड का उपयोग करने वाली कंपनियों को उनके लंबे समय तक पहनने के कारण ब्लेड प्रतिस्थापन में 30% की कमी देखने को मिलती है।

- कागज और पैकेजिंग: कागज और पैकेजिंग उद्योगों को सख्त गुणवत्ता मानकों को पूरा करने के लिए सटीक और सुसंगत कटिंग की आवश्यकता होती है। उच्च कठोरता औद्योगिक ब्लेड कागज, कार्डबोर्ड और लेमिनेटेड सामग्रियों पर साफ कट सुनिश्चित करने में मदद करते हैं, जो बड़े पैमाने पर पैकेजिंग उत्पादन के लिए विशेष रूप से महत्वपूर्ण है। अध्ययनों से पता चलता है कि इन क्षेत्रों के निर्माताओं ने उच्च कठोरता वाले ब्लेड का उपयोग करके 25% तेज़ उत्पादन चक्र हासिल किया है, जो बार-बार तेज करने की कम आवश्यकता के कारण है।

- प्लास्टिक और रबर प्रसंस्करणप्लास्टिक और रबर की सामग्री को काटना मुश्किल हो सकता है क्योंकि उनमें लचीलापन होता है और ब्लेड के किनारे घिसने लगते हैं। उच्च कठोरता शीयर ब्लेड इन सामग्रियों को सटीकता के साथ संभालने के लिए आवश्यक स्थायित्व प्रदान करते हैं, जिससे वे किनारे की तीक्ष्णता से समझौता किए बिना प्लास्टिक और रबर को ट्रिम करने, काटने और काटने के लिए उपयुक्त हो जाते हैं। औसतन, उच्च कठोरता वाले ब्लेड मानक ब्लेड की तुलना में प्लास्टिक प्रसंस्करण में 30% अधिक समय तक चलते हैं, जिससे ब्लेड के घिसने से जुड़ी लागत कम हो जाती है।

- अपशिष्ट पुनर्चक्रण: रीसाइक्लिंग प्लांट को स्क्रैप मेटल, प्लास्टिक और कागज़ को संभालने के लिए भारी-भरकम ब्लेड की ज़रूरत होती है। उच्च कठोरता गिलोटिन ब्लेड या चॉपर ब्लेड इन कार्यों में आवश्यक हैं, क्योंकि वे डाउनटाइम को कम करते हैं और निरंतर कटिंग के माध्यम से अपनी धार बनाए रखते हुए समग्र उत्पादन को बढ़ाते हैं। रीसाइक्लिंग सुविधाओं की रिपोर्ट है कि उच्च कठोरता वाले ब्लेड का उपयोग करने से उन्हें प्रतिदिन 20% अधिक सामग्री को संसाधित करने की अनुमति मिली है, जिससे अधिक कुशल अपशिष्ट प्रबंधन में योगदान मिला है।

इनमें से प्रत्येक अनुप्रयोग यह दर्शाता है कि उच्च कठोरता शीयर ब्लेड न केवल उत्पादकता में वृद्धि होती है, बल्कि मांग वाले वातावरण में विश्वसनीय प्रदर्शन भी मिलता है। उच्च कठोरता वाले ब्लेड पर स्विच करने वाले उद्योगों को आम तौर पर कम परिचालन लागत और उच्च काटने की सटीकता का अनुभव होता है, जिसके परिणामस्वरूप बेहतर गुणवत्ता वाला उत्पाद मिलता है।

4. उच्च कठोरता वाले कतरनी ब्लेड के मुख्य लाभ

उच्च कठोरता शीयर ब्लेड औद्योगिक परिचालनों को कई मूल्यवान लाभ प्रदान करते हैं:

- बढ़ी हुई स्थायित्वमानक ब्लेड की तुलना में, उच्च कठोरता वाले कतरनी ब्लेड कहीं अधिक घिसाव प्रतिरोधी होते हैं, परीक्षणों से पता चलता है कि वे उच्च-तनाव वाले अनुप्रयोगों में दोगुने समय तक चलते हैं। इसका मतलब है कि कम ब्लेड परिवर्तन और बिना किसी रुकावट के लंबे समय तक उत्पादन चलता है, जो विशेष रूप से उच्च-मात्रा वाले विनिर्माण के लिए फायदेमंद है।

- बेहतरीन कटिंग परिशुद्धता: अपनी तेज धार को बनाए रखने की क्षमता के साथ, ये ब्लेड विभिन्न सामग्रियों पर साफ, सटीक कट प्रदान करते हैं। उदाहरण के लिए, इलेक्ट्रॉनिक्स या फाइन पैकेजिंग जैसे उद्योगों को मिलीमीटर तक की सटीकता की आवश्यकता होती है, वे पाते हैं कि उच्च कठोरता वाले ब्लेड कट की गुणवत्ता में काफी सुधार करते हैं। इससे उत्पाद की बर्बादी कम होती है और लगातार गुणवत्ता सुनिश्चित होती है।

- दक्षता और उत्पादकता में वृद्धि: उच्च कठोरता काटने वाले ब्लेड ब्लेड समायोजन या प्रतिस्थापन की आवश्यकता के बिना मशीनों को लंबे समय तक संचालित करने की अनुमति देता है। उच्च-आउटपुट सुविधाओं के लिए, इससे 20-30% तक की उत्पादकता में वृद्धि होती है, जैसा कि औद्योगिक सुविधाओं द्वारा रिपोर्ट किया गया है जिन्होंने इन प्रकार के ब्लेडों में बदलाव किया है। रखरखाव की कम आवश्यकता भी अधिक परिचालन दक्षता में योगदान देती है।

- रखरखाव लागत में कमी: उच्च कठोरता वाले ब्लेड की लंबी उम्र और लचीलापन सीधे रखरखाव लागत को कम करता है। कम प्रतिस्थापन और कम बार-बार तेज करने का मतलब है कि सुविधाएं संसाधनों को अधिक कुशलता से आवंटित कर सकती हैं। भारी उपयोग वाले वातावरण में, अध्ययनों का अनुमान है कि उच्च कठोरता वाले ब्लेड वार्षिक रखरखाव लागत को 40% तक कम कर सकते हैं, जिससे वे कई उद्योगों के लिए लागत प्रभावी समाधान बन जाते हैं।

ये लाभ दर्शाते हैं कि उच्च कठोरता शीयर ब्लेड यह एक ऐसा निवेश है जो समय के साथ अपने आप में लाभदायक होता है, विशेष रूप से ऐसे स्थानों में जहां ब्लेड का स्थायित्व, सटीकता और दक्षता महत्वपूर्ण होती है।

5. सही उच्च कठोरता वाले शियर ब्लेड का चयन कैसे करें

सही उच्च कठोरता का चयन शियर ब्लेड्स इसमें कई कारकों पर सावधानीपूर्वक विचार करना शामिल है:

- सामग्री संगततासभी ब्लेड हर सामग्री पर समान रूप से अच्छा प्रदर्शन नहीं करते हैं। उदाहरण के लिए, उच्च कार्बन स्टील ब्लेड धातुओं को काटने के लिए आदर्श हो सकते हैं, जबकि टंगस्टन कार्बाइड ब्लेड फाइबरग्लास जैसी अत्यधिक घर्षण सामग्री को काटने में उत्कृष्ट हैं। ब्लेड की सामग्री को काटे जाने वाली विशिष्ट सामग्रियों से मेल खाना ब्लेड के जीवन और कट की गुणवत्ता को अधिकतम करने के लिए आवश्यक है।

- कठोरता बनाम कठोरता: जबकि उच्च कठोरता पहनने के प्रतिरोध को बढ़ाती है, अत्यधिक कठोरता ब्लेड को भंगुर बना सकती है, जिससे छिलने या दरार पड़ने की संभावना होती है। इसलिए, कठोरता को मजबूती के साथ संतुलित करना महत्वपूर्ण है। 60-65 HRC के बीच कठोरता वाले ब्लेड आमतौर पर भारी-भरकम कामों के लिए अनुशंसित किए जाते हैं, क्योंकि यह सीमा ताकत और स्थायित्व के बीच एक अच्छा संतुलन प्रदान करती है।

- ब्लेड आयामब्लेड का आकार, माप और मोटाई काटने के उपकरण और सामग्री के साथ संरेखित होनी चाहिए। उदाहरण के लिए, मोटे ब्लेड आमतौर पर अधिक टिकाऊ होते हैं, लेकिन उन्हें अधिक बल की आवश्यकता हो सकती है, जबकि पतले ब्लेड बेहतर कट प्राप्त कर सकते हैं। उचित ब्लेड का आकार मशीन के तनाव को भी कम करता है, जो ब्लेड और उपकरण दोनों के जीवनकाल को बढ़ा सकता है।

इन कारकों पर विचार करके, कंपनियां उच्च कठोरता का चयन कर सकती हैं औद्योगिक ब्लेड जो उनकी विशिष्ट आवश्यकताओं के लिए प्रदर्शन को अनुकूलित करते हैं, तथा दैनिक कार्यों में दक्षता और लागत प्रभावशीलता सुनिश्चित करते हैं।

6. केस स्टडी: उच्च कठोरता वाले शियर ब्लेड की सफलता की कहानियाँ

एक प्रमुख धातु निर्माण कंपनी ने हाल ही में उच्च कठोरता को अपनाया गिलोटिन ब्लेड अपने संचालन के लिए। इससे पहले, उन्हें लगातार ब्लेड बदलने और सालाना $20,000 से अधिक रखरखाव लागत का सामना करना पड़ा था। उच्च कठोरता वाले ब्लेड पर स्विच करने के बाद, उन्होंने पहले वर्ष में ही ब्लेड बदलने में 45% की कमी और रखरखाव खर्च में $12,000 की कमी दर्ज की। इस बदलाव ने न केवल उनकी काटने की दक्षता में सुधार किया, बल्कि उत्पादन चक्र को सुचारू बनाने और समग्र उत्पादकता बढ़ाने में भी योगदान दिया।

एक अन्य उदाहरण में, एक अपशिष्ट पुनर्चक्रण सुविधा जो स्क्रैप धातुओं और प्लास्टिक को संसाधित करती है, ने उच्च कठोरता में अपग्रेड करने के बाद महत्वपूर्ण परिणाम देखे चॉपर ब्लेड. इस सुविधा को पहले लगातार ब्लेड बदलने और रखरखाव संबंधी समस्याओं के कारण डाउनटाइम का सामना करना पड़ता था। उच्च कठोरता वाले ब्लेड में निवेश करके, उन्होंने दैनिक प्रसंस्करण क्षमता को 20% तक बढ़ाया और रखरखाव लागत को 35% तक कम किया। इस अपग्रेड ने उन्हें कम रुकावटों और उच्च थ्रूपुट के साथ अधिक टिकाऊ रीसाइक्लिंग प्रक्रिया प्राप्त करने की भी अनुमति दी।

ये वास्तविक दुनिया की सफलता की कहानियाँ उच्च कठोरता के परिवर्तनकारी प्रभाव को दर्शाती हैं शीयर ब्लेड औद्योगिक अनुप्रयोगों में, दक्षता बढ़ाने, लागत कम करने और परिचालन स्थिरता बढ़ाने में अपना मूल्य साबित कर रहे हैं।

7. ब्लेड की आयु बढ़ाने के लिए रखरखाव संबंधी सुझाव

उच्च कठोरता का अधिकतम लाभ उठाने के लिए शीयर ब्लेडउचित रखरखाव बहुत ज़रूरी है। यहाँ कुछ बेहतरीन अभ्यास दिए गए हैं:

- नियमित सफाई: प्रत्येक उपयोग के बाद ब्लेड को साफ करें ताकि मलबे का निर्माण न हो, जो समय के साथ ब्लेड को सुस्त कर सकता है। धातु निर्माण के लिए, किसी भी तैलीय अवशेष को हटाने के लिए डीग्रीज़र का उपयोग करना ब्लेड को और अधिक सुरक्षित कर सकता है।

- केवल उपयुक्त सामग्री का उपयोग करेंब्लेड के डिज़ाइन मापदंडों से परे सामग्री काटने से घिसाव बढ़ सकता है और नुकसान हो सकता है। सुनिश्चित करें कि ब्लेड का उपयोग केवल संगत सामग्रियों के लिए किया जाता है ताकि इष्टतम प्रदर्शन बनाए रखा जा सके।

- नियमित निरीक्षण: घिसाव या मामूली क्षति के लिए बार-बार जाँच करने से आपको समस्याएँ बढ़ने से पहले ही उन्हें पकड़ने और उनका समाधान करने में मदद मिल सकती है। उदाहरण के लिए, उच्च-वॉल्यूम सेटिंग में साप्ताहिक रूप से ब्लेड का निरीक्षण करने से अप्रत्याशित डाउनटाइम को रोका जा सकता है और ब्लेड का जीवन बढ़ाया जा सकता है।

- समय पर पैनापन: सही अंतराल पर धार लगाने से यह सुनिश्चित होता है कि ब्लेड कुशल बने रहें और काटने के दौरान आवश्यक बल कम हो, जिससे ब्लेड और मशीनरी पर तनाव कम हो। कई कंपनियों का मानना है कि हर 3-6 महीने में ब्लेड की धार लगाने से संचालन सुचारू रूप से चलता रहता है।

इन सरल लेकिन प्रभावी रखरखाव युक्तियों का पालन करके, व्यवसाय अपनी उच्च कठोरता के जीवन और प्रदर्शन को अधिकतम कर सकते हैं काटने वाले ब्लेडयह सुनिश्चित करना कि उन्हें अपने निवेश पर सर्वोत्तम लाभ मिले।

8. निष्कर्ष: क्या उच्च कठोरता वाले शियर ब्लेड आपके लिए सही हैं?

उच्च कठोरता शीयर ब्लेड विभिन्न औद्योगिक अनुप्रयोगों के लिए अद्वितीय स्थायित्व, परिशुद्धता और लागत बचत प्रदान करते हैं। उनके लाभों, अनुप्रयोगों और चयन मानदंडों को समझकर, व्यवसाय सूचित निर्णय ले सकते हैं जो दक्षता में सुधार करते हैं और लागत में कटौती करते हैं। चाहे धातु निर्माण, पुनर्चक्रण या प्लास्टिक प्रसंस्करण में उपयोग किया जाए, ये ब्लेड उत्पादकता बढ़ाते हैं और परिचालन रुकावटों को कम करते हैं।

उच्च कठोरता वाले कतरनी ब्लेड आपके व्यवसाय को किस प्रकार लाभ पहुंचा सकते हैं, इसके बारे में अधिक जानने के लिए, हमसे संपर्क करें विशेषज्ञ मार्गदर्शन और सहायता के लिए आज ही संपर्क करें। 1टीपी1टी टीम आपकी विशिष्ट आवश्यकताओं के लिए सर्वोत्तम ब्लेड चुनने में आपकी सहायता करने के लिए यहां है, जिससे यह सुनिश्चित हो सके कि आप अपनी उत्पादन प्रक्रियाओं में परिचालन दक्षता और गुणवत्ता के उच्चतम स्तर को प्राप्त करें।

5 प्रतिक्रियाएं