You need good saw blades for your work. Good blades help you cut well and last longer. When you check कार्बाइड ब्ले드 की गुणवत्ता, look at how it looks and some key details. Some coatings like TiAlN can make the blade last twice as long. Using the right cutting speed, depth, and feed rate helps your blade stay sharp. Picking the right saw blade makes it last and work better. नानजिंग Metal औद्योगिक has blades that fit what you need.

चाबी छीनना

- Look at carbide blades to find chips or cracks before using them.

- Good carbide tips work longer and cut better, so pick blades with good tips.

- Check if the blade is thick and flat to make sure it fits your machine and cuts straight.

- A smooth blade surface helps lower friction and wear, so the blade lasts longer.

- Match the blade’s tooth count and angles to the material for the best cutting.

- Sharpen blades often to keep them cutting well and make them last longer.

- Check what the blade is made of and its grade to see if it fits your cutting needs.

- Buy blades from trusted sellers to avoid fake blades that do not work well.

Visual Inspection for Carbide Blade Quality

When you want to judge carbide blade quality, start with a careful visual inspection. This step helps you spot problems before you use the blade. You can use simple tools like a magnifier or even a microscope for a closer look. Here is how you can check each important part of the blade.

Carbide Tip Grade and Integrity

Carbide teeth are the most important part of your saw blade. The grade of the carbide tip affects how long the blade lasts and how well it cuts. High-grade carbide teeth stay sharp longer and handle heat better. They also cut many types of materials with ease. However, they can be brittle and need careful handling.

| लाभ | नुकसान |

|---|---|

| Extreme hardness and heat resistance | Brittle with sensitive impact tolerances |

| Maintains sharp cutting edge | Higher per piece cost |

| Long working life if undamaged | Requires advanced bonding technology |

| Universal material cut capability | Difficult to sharpen thus replace tips |

Detecting Chips and Cracks

Look closely at each carbide tooth. Chips and cracks can lower carbide blade quality. Even small chips can cause the blade to fail early. Use a magnifier to check the edges and corners of the carbide teeth. If you see any cracks or missing pieces, do not use the blade. Damaged carbide teeth can break off during cutting and ruin your work.

Microscopic and Magnifier Checks

You can use a magnifier or a microscope to find tiny defects. Sometimes, cracks or chips are too small to see with your eyes. Hold the blade under good light and check each tooth. Move the blade slowly so you do not miss any spots. This careful check helps you catch problems early. If you need custom blades for special jobs, you can find more options on the कस्टम ब्लेड पृष्ठ.

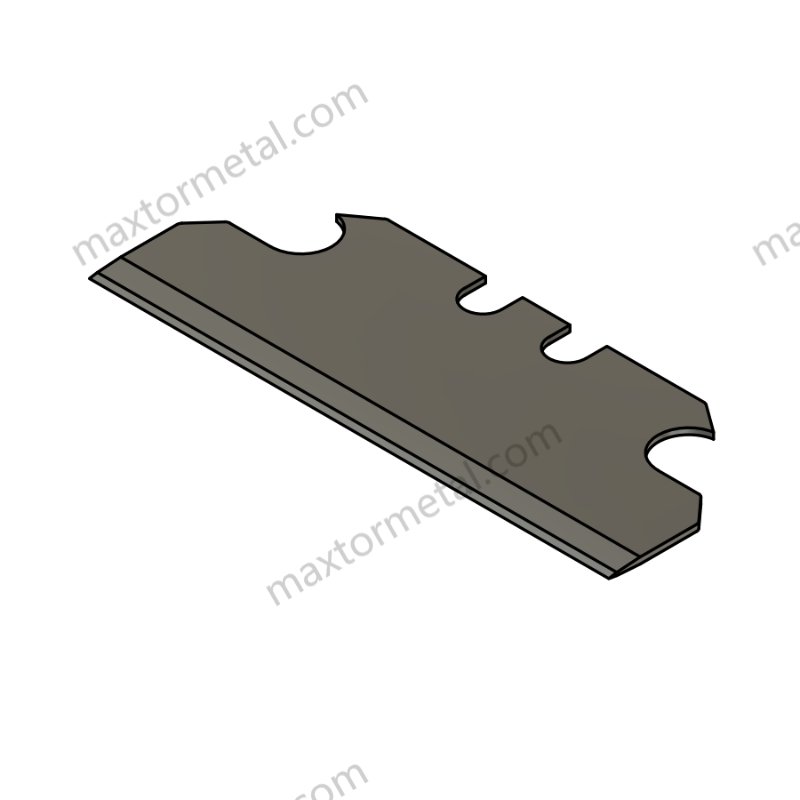

Tooth Shape and Consistency

Carbide teeth come in different shapes. The shape and arrangement of the teeth affect how the blade cuts and how long it lasts. Flat-topped teeth give you straight cuts, while hooked teeth help you cut faster. The right tooth shape depends on the material you want to cut.

Uniformity and Wear

Check that all carbide teeth look the same. Uniform teeth help you get smooth and accurate cuts. If some teeth look worn or different from others, the blade may not cut well. Uneven teeth can cause rough edges and make the blade wear out faster. The design and shape of the teeth also affect how much heat the blade makes and how fast it cuts. More teeth can give you a smoother finish, but fewer teeth can cut faster.

Grinding Quality

Look at the grinding marks on the carbide teeth. Good grinding means the teeth have smooth, even surfaces. Poor grinding can leave rough spots or uneven edges. These flaws can lower cutting performance and reduce the life of the blade. Well-ground carbide teeth help you get clean, even cuts every time.

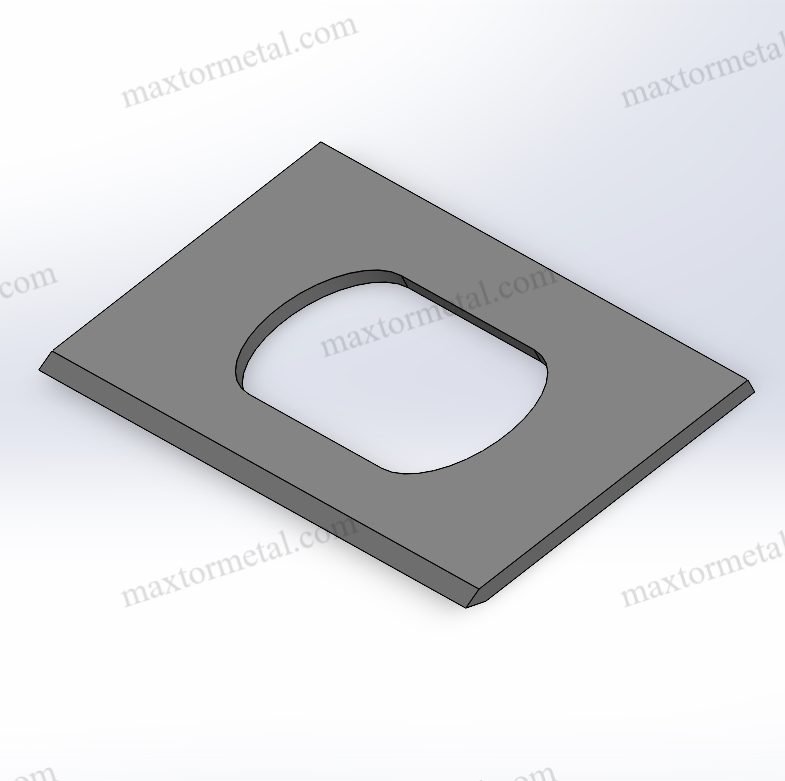

Blade Thickness and Flatness

The thickness and flatness of the blade body are key parts of carbide blade quality. If the blade is too thick or too thin, it may not fit your machine. If it is not flat, it will not cut straight.

| सहनशीलता प्रकार | विनिर्देश |

|---|---|

| मोटाई | +/- 0.001″ |

| समतलता | Max TIR |

Warping and Bending

Hold the blade up and look along its edge. A good blade should look flat with no bends or warps. Warped blades can cause the cut to wander and make your work less accurate. Flat blades cut smoothly and last longer. If you see any bending, do not use the blade.

- Cutting accuracy: Flat blades give you straight, even cuts.

- Cutting efficiency: Flat blades move through material with less force.

- Blade life: Flat blades wear evenly and last longer.

- Chip evacuation: Flat blades help chips move away from the cut, so the blade does not clog.

किनारे की सीधापन

Check the edge of the blade for straightness. You can use a straightedge tool for this. The edge should not have any waves or dips. A straight edge helps you get clean, accurate cuts and keeps the blade running smoothly.

By following these steps, you can judge carbide blade quality before you start your work. Careful inspection helps you avoid problems and choose the best blade for your needs.

Surface Finish and Coating

The surface finish and coating of a carbide blade tell you a lot about its quality. When you check a blade, you should look at how the surface looks and feels. A good finish helps the blade last longer and cut better.

Color and Luster

You can judge carbide blade quality by looking at the color and shine of the blade. A high-quality blade often has a bright, even color. The surface should look smooth and reflect light well. If you see dull spots or uneven colors, the blade may not have the best finish.

A smooth surface finish does more than just look good. It helps the blade resist wear and reduces friction during cutting. This means the blade will last longer and work better, especially when you need precise cuts.

Here is a table that shows how surface finish values relate to different uses:

| Surface Finish (Ra µm) | अनुप्रयोग उदाहरण |

|---|---|

| 0.01 – 0.05 | Seal rings, medical tools (mirror polish) |

| 0.05 – 0.2 | Valve seats, precision molds |

| 0.2 – 0.8 | Cutting inserts, drilling tips |

बख्शीश: A smoother finish (lower Ra value) means less friction and better wear resistance. This helps your carbide blade stay sharp and last longer.

You should also check for these qualities:

- Smoothness helps the blade resist wear and tear.

- Less friction means the blade does not heat up as much.

- A shiny, even surface shows good manufacturing.

Coating Adhesion

The coating on a carbide blade protects it from wear and helps it cut better. You should check if the coating sticks well to the blade. If the coating peels or flakes, the blade will not last as long.

Different coatings give different results. For example, a multilayer TiN/AlTiN coating gives the best durability for carbide blades. Thicker coatings can make the blade last longer, but only if they stick well. If the coating does not bond to the blade, it can come off during use.

When you inspect a blade, look for these signs:

- The coating should cover the blade evenly with no peeling or bubbles.

- The color should be uniform across the blade.

- If you see spots where the coating is missing, the blade may wear out quickly.

टिप्पणी: Good coating adhesion means the blade will resist wear and keep its edge longer. Poor adhesion can lead to early blade failure.

You should always check both the surface finish and the coating when you judge carbide blade quality. These features help you pick a blade that will give you clean cuts and last through many jobs.

Geometric Measurement and Saw Blade Quality

You need to measure your saw blade carefully. This helps you get good results and keeps you safe. Measuring the blade makes sure it meets quality standards. If you measure right, you avoid problems when cutting.

Measuring Thickness and Flatness

Micrometers and Gauges

Special tools help you check thickness and flatness. Micrometers show you the exact thickness. Flatness gauges tell you if the blade is even. Height gauges are good for checking flatness too. They help the blade touch other surfaces fully. This matters a lot in car factories. Every part must fit just right.

Here are some tools you can use:

- Dial indicators find flatness and runout.

- Surface plates give a flat spot for checking blades.

- Height gauges measure how tall parts are.

- Gauge blocks check other tools for accuracy.

- Optical comparators show the blade’s outline on a screen.

- Autocollimators measure flatness and small angles very well.

Tip: Always use tools that are calibrated. Calibrated tools give you correct measurements. Calibration that follows world standards is best.

Tolerance Ranges

Check if your blade’s thickness and flatness are in the right range. Small changes in thickness can change how the blade cuts. If the blade is too thick or thin, it might not fit your machine. It could also break while you use it. Flatness is just as important. A blade that is not flat can make rough cuts. It can also put more stress on the blade. This can make the blade fail faster.

| उपकरण का प्रकार | Recommended Model | प्रमुख विशेषताऐं |

|---|---|---|

| डायल संकेतक | Federal Dial Indicator | Sensitive readings, works well in shops |

| Surface Plates | Starrett Granite Surface Plate | Very flat, does not rust or bend |

| Height Gauges | Mahr Digimar 816 CL | Digital display, smooth movement, strong base |

| Gauge Blocks | Mitutoyo Grade AS-1 Steel Set | Very flat and shiny, comes with a certificate |

| Optical Comparators | Mitutoyo Profile Projector | Shows part outline on a screen |

| Autocollimators | Taylor Hobson Autocollimator | Measures flatness well, easy to use |

Always check these measurements before you use your blade. This helps you keep your carbide blade working well. It also helps you avoid cutting problems.

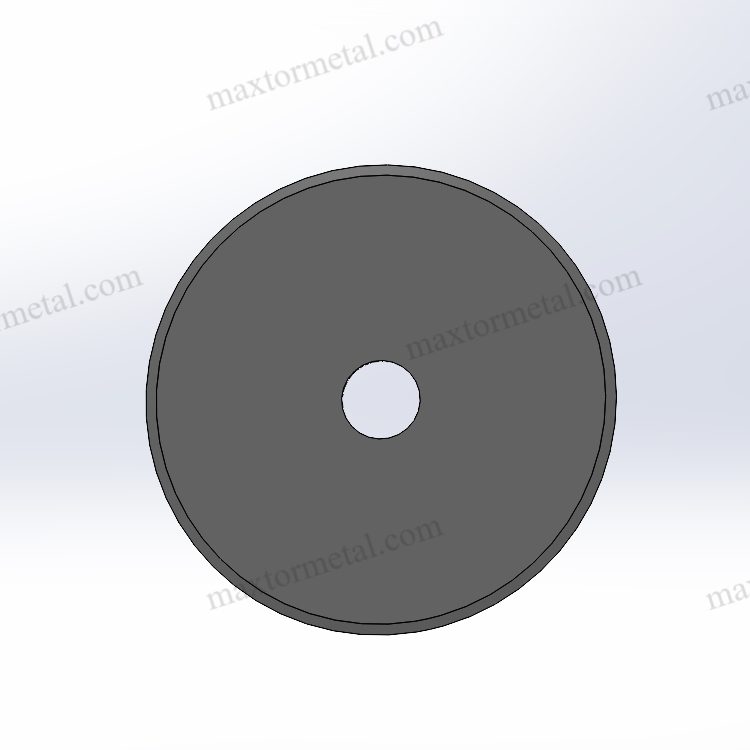

Bore Size and Concentricity

मशीन अनुकूलता

The bore size must match your machine. The bore is the hole in the middle of the blade. If the bore size is wrong, the blade will not fit. It might wobble when you use it. Makers set strict rules for bore size. This keeps you safe and helps the blade work well.

| Diameter Range (mm) | Tolerance (mm) | Tolerance (inch) |

|---|---|---|

| 3 ≤ 6 | 0 / -0.008 | 0 / -0.00024 |

| 6 ≤ 10 | 0 / -0.009 | 0 / -0.00031 |

| 10 ≤ 18 | 0 / -0.011 | 0 / -0.00035 |

| 18 ≤ 30 | 0 / -0.013 | 0 / -0.00043 |

| 30 ≤ 50 | 0 / -0.016 | 0 / -0.00051 |

Always check the bore size before you put the blade in. This helps your machine work well and stops damage.

Vibration Prevention

Concentricity means the bore and blade are centered. Good concentricity helps the blade spin smoothly. This lowers vibration. Less vibration means better cuts and longer blade life. Some blades have tensioning rings or laser-cut slots. These features help keep the blade steady. Balancing systems also help the blade last longer.

- A tensioning ring keeps the blade steady.

- Good concentricity lowers vibration and helps you cut better.

- Laser-cut slots make less vibration and noise.

- Balancing systems help the blade last longer and work better.

Note: Always look for tensioning features. Test the blade for vibration before you start.

Measuring your blade is very important. Using the right tools and checking all measurements helps your carbide blade cut well and last longer.

Material Validation for Carbide Blades

You should check the material of cemented carbide saw blades before using them. This helps you know if the blade will last and cut well. You can do some easy tests to make sure you have a good carbide blade.

Confirming Carbide Grade

Cemented carbide saw blades come in different grades. Each grade has its own hardness and use. Always check the grade before you buy or use a blade.

कठोरता परीक्षण

Hardness shows how well a blade can resist wearing out. You can use a hardness tester to find the number. Most cemented carbide saw blades have hardness between 1290 and 1910 HV30. A higher number means the blade is harder. Hard blades last longer and make cleaner cuts, but they can break more easily.

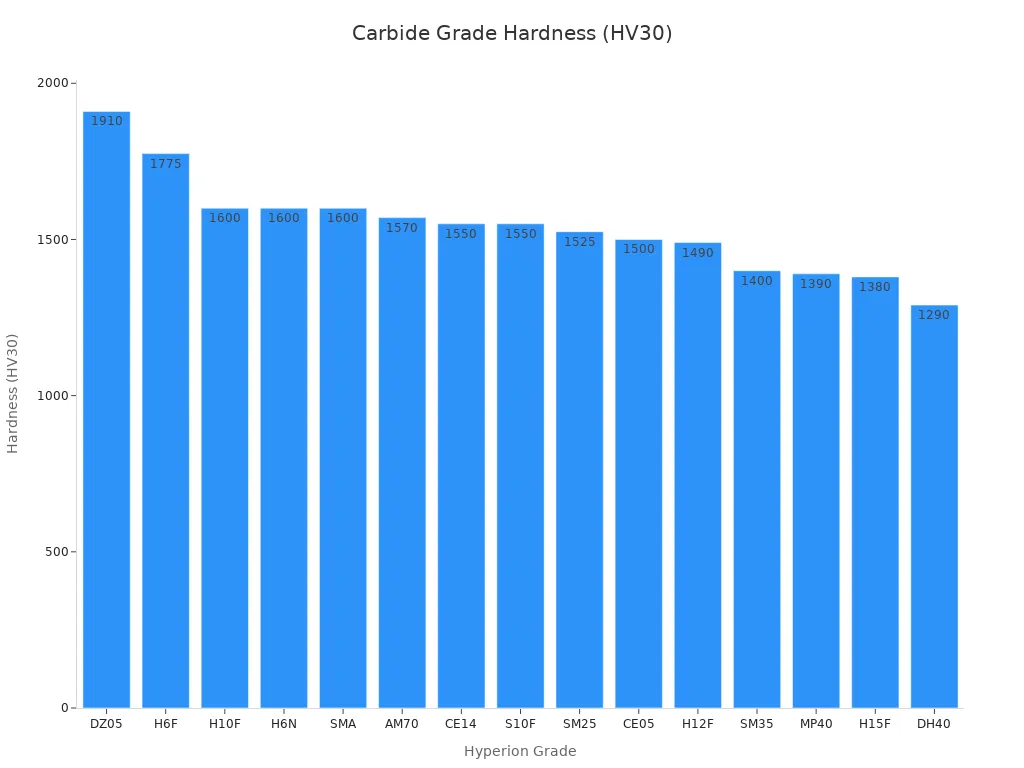

Here is a table that lists common carbide grades and their hardness:

| Hyperion Grade | Hardness (HV30) | विशिष्ट अनुप्रयोग |

|---|---|---|

| DZ05 | 1910 | Nonferrous, clean cutting |

| AM70 | 1570 | INCONEL®, Duplex stainless steel |

| H6F | 1775 | Nonferrous, clean cutting |

| H10F | 1600 | General purpose cutting |

| H12F | 1490 | General purpose cutting |

| H15F | 1380 | General purpose cutting |

| CE05 | 1500 | Ferrous, continuous cutting |

| CE14 | 1550 | Ferrous, impact cutting |

| S10F | 1550 | Cast iron cutting |

| H6N | 1600 | Ferrous, high impact cutting |

| DH40 | 1290 | Ferrous, continuous / impact cutting |

| SM25 | 1525 | Ferrous, continuous / impact cutting |

| SMA | 1600 | Ferrous, continuous / impact cutting |

| SM35 | 1400 | Ferrous, continuous / impact cutting |

| MP40 | 1390 | Ferrous, continuous / impact cutting |

You can also see how hardness is different in this chart:

Tip: Pick the right hardness for your job. Harder blades are best for clean cuts in soft materials. Softer blades are better for tough jobs and hard materials.

Density Checks

Density tells you how strong and tough the blade is. You can measure density with a scale and by checking the blade’s size. Blades with high density last longer and do not wear out fast. Blades with low density can wear out quickly.

- High density helps the blade drill better and last longer.

- More cutting parts mean better work in soft materials.

- Good density helps blades last and cut well in hard things.

- Pick the right density for what you need to cut.

Note: Always check both hardness and density. These two things help you choose the right cemented carbide saw blade for your job.

Identifying Counterfeit Materials

Fake cemented carbide saw blades can look real but do not work well. You need to spot fake blades to keep your work safe.

Visual and Documentation Clues

You can use these steps to check for fake blades:

- Look at the box. Good blades have clear logos and product info. Bad printing or spelling mistakes can mean the blade is fake.

- Check for certification marks. Real blades have ISO or ANSI labels. If marks are missing or changed, be careful.

- Feel the blade. Real cemented carbide saw blades have a certain color, feel, and weight. The cutting edge should be sharp and even.

- Compare prices. If the price is much lower than normal, be careful.

- Buy from trusted sellers. Check reviews and buy from dealers you trust.

- Test the blade. Real blades last longer and cut better. Fake blades wear out fast.

- Ask the maker for help. Manufacturers can help you check if a blade is real.

Alert: Fake blades can break easily and hurt your machine. Always check before you buy.

Requesting Certificates

You can ask for papers to prove the blade is real. Makers give you documents that show how they make and test the blades. Look for these steps:

| कदम | विवरण |

|---|---|

| 1 | Ask for checks of the factory and quality systems. |

| 2 | Look at quality manuals, ISO papers, and test reports. |

| 3 | Use outside inspectors to check what the seller says. |

| 4 | Ask for samples to test before you buy. |

Tip: Certificates and checks help you trust the quality of cemented carbide saw blades. Always ask for proof before you buy.

You can use these checks to make sure your cemented carbide saw blades are real and good quality. Checking the material helps you get the best results and keeps your work safe.

Technical Parameters Affecting Saw Blade Quality

When you judge carbide blade quality, you must look at more than just the surface. The technical parameters of a saw blade play a big role in how well it works. These parameters include the angles of the blade, the number of teeth, the diameter, and the size of the carbide tips. Each one affects cutting performance, tool performance, and the final result of your work.

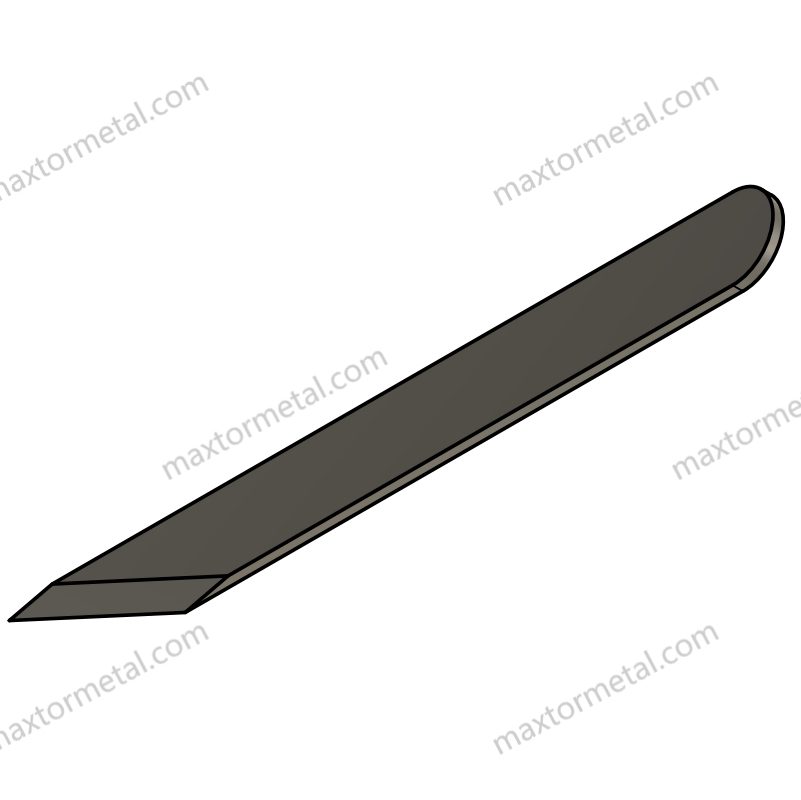

Rake, Rear, and Wedge Angles

The angles on a saw blade decide how it enters and moves through the material. You will see three main angles: rake, rear, and wedge. These angles change how the blade cuts and how long it lasts.

Cutting Performance Impact

The rake angle is the tilt of the tooth face. A positive rake angle helps the blade bite into soft materials. A negative rake angle gives more control for hard materials. The rear angle helps clear chips away from the cut. The wedge angle is the space between the tooth face and the back. This angle gives the tooth its strength.

You can see how different bevel angles affect cutting performance in this table:

| किनारे का प्रकार | बेवल कोण (°) | अनुप्रयोग | ब्लेड सामग्री | Typical Lifespan | Cutting Force Index |

|---|---|---|---|---|---|

| अल्ट्रा तेज | 10–15 | फिल्में, पन्नी, पतले वस्त्र | सिरेमिक, SS420 | 2–3 दिन | कम |

| सटीक कट | 16–25 | कागज, पैकेजिंग, नरम खाद्य पदार्थ | स्टेनलेस स्टील | 5–7 दिन | मध्यम |

| अत्यधिक टिकाऊ | 26–35 | रबर, प्लास्टिक, स्टील शीट | टंगस्टन कार्बाइड | 10–15 दिन | उच्च |

Lower blade angles, like 10° to 20°, give you more sharpness. These are best for soft materials. Higher angles, like 25° to 40°, make the blade stronger for tough jobs. You must balance sharpness and strength for the best cutting performance. If you lower the bevel angle by 5 degrees, you can make the blade 38% sharper. However, the edge will not last as long. It may lose 45% of its edge retention. You need to match the angle to your job for the best tool performance.

आवेदन मिलान

You should always match the blade angles to the material you want to cut. For example, use a sharp angle for thin films or foils. Use a stronger angle for rubber or steel sheets. This helps you get the best cutting performance and tool performance. If you need a special angle for a unique job, you can order a कस्टम ब्लेड with the right parameters.

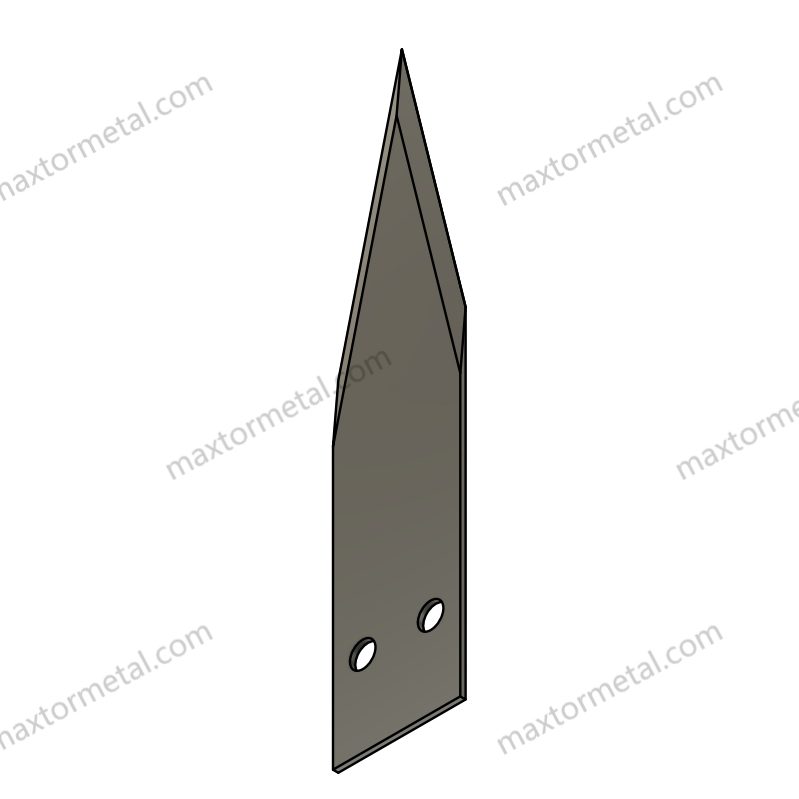

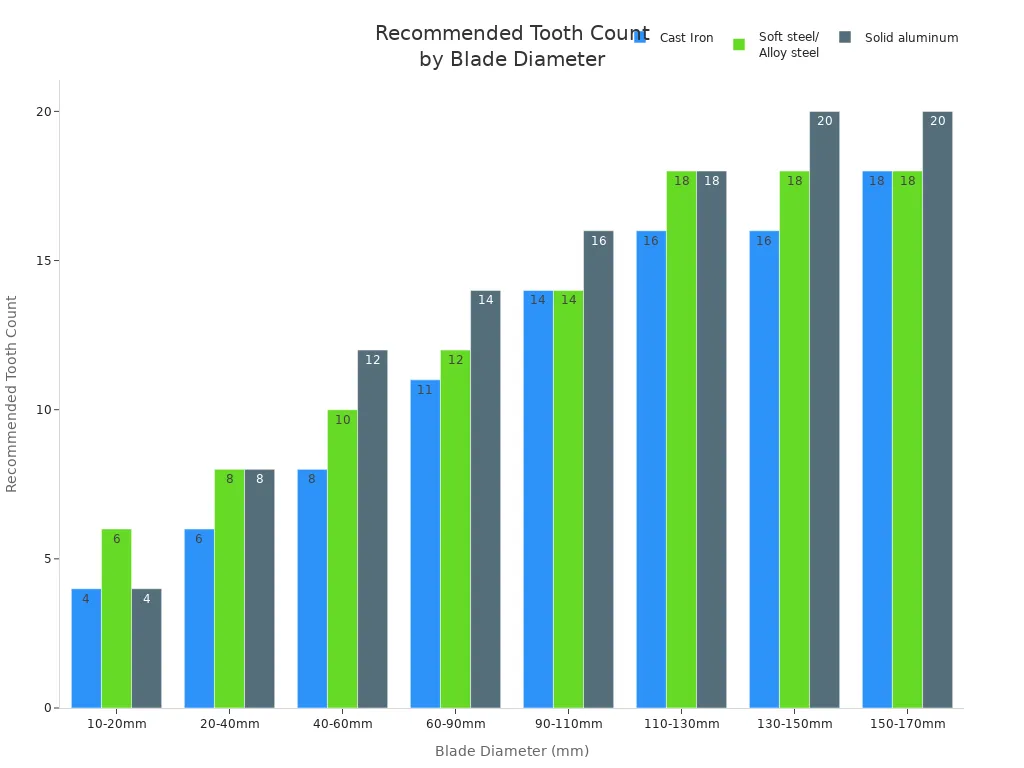

Tooth Count and Blade Diameter

The number of teeth and the diameter of the blade change how the blade works. These parameters affect how fast you can cut and how smooth the finish will be.

Material-Specific Recommendations

You must pick the right tooth count and blade diameter for the material you want to cut. Here is a table that shows the best tooth counts for different materials and blade sizes:

| Material to cut | 10-20mm | 20-40mm | 40-60mm | 60-90mm | 90-110mm | 110-130mm | 130-150mm | 150-170mm |

|---|---|---|---|---|---|---|---|---|

| Cast Iron | 4 | 6 | 8 | 11 | 14 | 16 | 16 | 18 |

| Soft steel/ Alloy steel | 6 | 8 | 10 | 12 | 14 | 18 | 18 | 18 |

| Solid aluminum | 4 | 8 | 12 | 14 | 16 | 18 | 20 | 20 |

You can also see the recommended tooth counts in this chart:

For most jobs:

- Coarse tooth blades (2-3 TPI) work best for thick wood or fast cuts.

- Fine-toothed blades (18-32 TPI) are better for thin metals and plastics.

- For plywood, use 4 TPI for fast cuts or 14 TPI for a smooth finish.

Effect on Finish and Efficiency

Tooth count changes the finish and speed of your cut. More teeth give you a smoother finish but slow down the cutting. Fewer teeth let you cut faster, but the finish will be rougher. If you want a fine finish, pick a blade with more teeth. If you need speed, use a blade with fewer teeth. This balance helps you get the best tool performance for your job.

Carbide Tip Size and Sharpening

The size of the carbide tip and how often you sharpen it also affect performance and cost.

दीर्घायु और प्रदर्शन

Larger carbide tips last longer. They can handle more sharpening cycles. This means you can use the blade for more jobs before you need a new one. Keeping your blade sharp is important for tool performance and cutting performance. A sharp blade makes more cuts and keeps your work smooth. If you keep your blades sharp, you can get up to 500,000 cuts from a high-speed steel blade. If you do not sharpen them, you may only get 300,000 cuts. Dull blades can lower your productivity by 15%. Regular sharpening keeps your carbide blade quality high and your work efficient.

लागत पर विचार

Sharpening your blades often saves money. You spend less on new blades and lose less time changing them. Regular maintenance means less downtime and more work done. If you use blades with larger carbide tips, you can sharpen them more times. This lowers your long-term costs.

Tip: Always check the technical parameters before you buy a blade. The right angles, tooth count, diameter, and carbide tip size help you get the best performance, quality, and value from your saw blade.

Surface Finish Evaluation for Proper Saw Blade Selection

Inspecting PVD and Mirror Finishes

When you check a carbide blade, you should look closely at the surface finish. Two common finishes are PVD (Physical Vapor Deposition) and mirror polish. These finishes do more than make the blade look good. They help the blade work better and last longer.

Color Consistency

You can spot a high-quality finish by looking at the color. A good PVD or mirror finish shows even color across the whole blade. The surface should not have dark spots, streaks, or faded areas. If you see a smooth, shiny, and uniform color, you know the blade has a strong protective layer.

A smooth surface finish gives you many benefits:

- It reduces friction, so the blade moves through material faster and uses less energy.

- It helps the blade resist wear by spreading out the stress evenly.

- It keeps moisture and chemicals from getting into tiny cracks, which helps stop rust and corrosion.

If the color looks uneven, the coating may not protect the blade well. This can lead to faster wear and lower cutting quality.

Detecting Peeling or Discoloration

You should always check for peeling or discoloration on the blade surface. Peeling means the coating did not stick well. Discoloration can show that the blade got too hot or the coating is wearing off.

Look for these signs:

- Flakes or chips coming off the surface.

- Spots where the metal looks different from the rest of the blade.

- Areas that look dull or faded compared to the rest.

If you see any of these problems, the blade may not last long. A good finish should stay smooth and even, even after many uses.

Tip: Run your finger gently over the blade. A quality finish feels smooth and even. If you feel rough spots or bumps, the coating may be coming off.

Comparing Surface Quality

You can learn a lot about a blade by comparing its surface quality. Premium blades and budget blades often look different when you check them closely.

Premium vs. Budget Blades

Premium blades usually have a flawless surface. The finish looks bright and even. You will not see scratches, pits, or rough spots. The coating covers the blade fully and sticks well. These blades last longer and cut better because the surface protects the metal inside.

Budget blades may have a dull or patchy finish. You might see small holes, cracks, or uneven color. The coating may not cover the whole blade. These flaws can make the blade wear out faster and cut less smoothly.

यहाँ एक तालिका दी गई है जो दर्शाती है common defects you might find in lower-quality blades:

| Defect Type | विवरण |

|---|---|

| Internal Cracks | Cracks inside the blade can make it weak and cause it to break during use. |

| Pinhole Voids | Tiny holes in the surface show poor material mixing and can lead to weak spots. |

| Cobalt Clusters | Clumps of cobalt without carbide make the blade less strong, especially if you cut tough materials. |

| Binder Lakes | Pools of binder material can weaken the blade and lower its cutting ability. |

| Eta Phase | A special form of carbide that makes the blade harder but also more likely to break. |

Signs of Poor Manufacturing

You can spot poor manufacturing by looking for certain signs on the blade surface:

- Rough or uneven finish.

- Visible cracks or pinholes.

- Areas where the coating is missing or peeling.

- Clusters or spots that look different from the rest of the blade.

A rough surface increases friction. This makes cutting slower and less smooth. It also causes the blade to wear out faster. Moisture can get into cracks and holes, leading to rust and weakening the blade.

Note: Always choose a blade with a smooth, even finish. This helps your saw blade cut better, last longer, and stay safe during use.

By checking the surface finish carefully, you can pick the right blade for your job. A good finish means better performance, more safety, and less money spent on replacements.

Inspection Tips and Application Considerations

Step-by-Step Checklist

Visual, Geometric, and Material Checks

You can follow a simple checklist to judge the quality of your saw blade. This helps you avoid mistakes and choose the right tool for your job.

- Look at the blade under good light. Check for chips, cracks, or missing pieces.

- Use a magnifier to spot tiny defects on the carbide tips.

- Measure the thickness and flatness with a micrometer or gauge.

- Check the bore size to make sure it fits your machine.

- Test the hardness and density if you can. This tells you about the blade’s strength.

- Inspect the surface finish and coating for smoothness and even color.

- Ask for certificates or documents from the supplier.

Tip: You can print this checklist and use it every time you inspect a new blade.

Recording Results

You should write down your inspection results. This helps you track which blades work best. You can use a simple table like this:

| Blade ID | Visual Check | Geometric Check | Material Check | नोट्स |

|---|---|---|---|---|

| 001 | OK | OK | OK | No defects |

| 002 | Chip found | OK | OK | Replace soon |

Keeping records helps you spot patterns and improve your cutting process.

Avoiding Common Pitfalls

Overlooking Micro-Defects

Many people miss small cracks or chips. These micro-defects can cause the blade to break during cutting. Always use a magnifier and check each tooth. Small problems can lead to big failures.

Relying on Price Alone

Some buyers choose blades based only on price. Low-cost blades may not meet your needs. You should check all parameters, not just the price tag. Quality saves money in the long run.

Industry-Specific Needs

Packaging and Cardboard

If you work with packaging or cardboard, you need a blade with a sharp edge and smooth finish. This helps you get clean cuts without tearing the material.

FPCB and Electronics

For FPCB and electronics, choose a blade with high precision and fine teeth. This prevents damage to delicate parts.

Textiles and Chemical Fiber

Cutting textiles or chemical fiber needs a blade with a special coating. This reduces friction and keeps the edge sharp.

Food Slicing

Food slicing requires a blade made from safe materials. The surface should be smooth and easy to clean.

Metal Slitting

When you cut metal, pick a blade with strong carbide tips and the right tooth count. This helps you get a smooth cut and long blade life.

Note: Always match the blade to your material and job. The right choice improves safety and performance, whether you are cutting wood or metal.

You can check carbide blade quality by looking and measuring. Doing both helps you find problems and pick the right blade. Clean blades are easier and faster to check. This saves you time and money. Good quality blades cut better and last longer. For blades you can trust, try Nanjing Metal Industrial’s saw blades. If you need help, you can हमसे संपर्क करें सलाह के लिए।

सामान्य प्रश्न

What is the best way to check for cracks in a carbide blade?

You should use a magnifier or microscope. Good lighting helps you see small cracks or chips. Always check each tooth and the blade edge before using it.

How often should I sharpen my carbide blade?

You should sharpen your blade when you notice rough cuts or more effort is needed. Regular sharpening keeps your blade working well and extends its life.

Why does blade flatness matter?

Flatness helps your blade cut straight and smooth. A warped blade can cause uneven cuts and may damage your material. Always check flatness before using your saw blade.

Can I use the same blade for all materials?

No. You should match the blade type, tooth count, and coating to the material you want to cut. Using the wrong blade can cause poor results and faster wear.

How do I know if a blade is counterfeit?

Check for clear logos, proper documentation, and certification marks. Buy from trusted sellers. If the price is much lower than normal, be careful.

What does a good surface finish look like?

A good finish looks smooth, shiny, and even. There should be no rough spots, peeling, or discoloration. A quality finish helps the blade last longer.

Why is carbide better than steel for cutting?

Carbide stays sharp longer and resists wear better than steel. You get more cuts and less downtime. Carbide blades work well for tough jobs and hard materials.

यह भी देखें

टंगस्टन चाकू: क्या यह उपयोगी है? इसके फायदे, नुकसान और उद्योग में इसके अनुप्रयोग

टंगस्टन कार्बाइड चाकू को कैसे तेज और रखरखाव करें

Why Tungsten Carbide Knives Chip — Common Failure Modes & How to Avoid Them

औद्योगिक ब्लेड के लिए टंगस्टन कार्बाइड बनाम स्टील: प्रदर्शन, टूट-फूट और लागत

टंगस्टन कार्बाइड बनाम हाई-स्पीड स्टील (HSS): आपकी कटिंग आवश्यकताओं के लिए कौन सा सही है?