माइक्रो-छिद्रण ब्लेड make tiny holes or cuts in things. They are important in advanced material processing. These blades help companies work faster and make better products. मैक्सटर Metal is a top company with many perforating blades for packaging and other uses. The blades are accurate and dependable. Many industries use perforating blades every day and see good results. Perforating blades make tear lines that help materials come apart easily. Makers use these blades to work faster and get the same results each time.

चाबी छीनना

- Micro-perforating blades make small, exact holes. These holes help materials tear easily. They also make products better.

- Blades have different shapes and use strong materials like tungsten carbide. This helps blades last longer. It also helps them cut better for many uses.

- Blades with more teeth and special patterns cut smoothly. They can lower waste by up to 30%.

- People use these blades in packaging, paper, textiles, and electronics. The blades help make products safer, fresher, and easier to use.

- Checking blades often and making custom designs keeps them sharp and reliable. This makes sure blades fit each customer’s specific needs.

Micro-Perforating Blades Overview

परिभाषा और कार्य

Micro-perforating blades are special tools. They make tiny holes or cuts in materials. These blades help companies add tear lines or air holes to products. Perforating blades come in many shapes and sizes. Each type has a different job in material processing.

The main parts of these blades are the blade, a seat, and a clamp. These parts keep the blade steady and accurate when cutting. Makers can change or remove blades for different jobs. The material, like stainless steel or tungsten carbide, changes how long the blade lasts and how well it cuts.

| Functional Mechanism | Explanation |

|---|---|

| ब्लेड निर्माण | Blades can be changed or adjusted for clean cuts. This helps with special jobs. |

| ब्लेड सीटें | The seat holds the blade tight. This keeps cuts straight and steady. |

| क्लैम्पिंग तंत्र | Strong clamps stop the blade from moving. This keeps the holes even. |

| कस्टम छिद्रण | Different blade shapes make different hole patterns for many uses. |

| सामग्री की गुणवत्ता | Strong materials like stainless steel or tungsten carbide help blades last longer and cut better. |

Perforating blades work in many machines. Manual tools are good for small or careful jobs. Semi-automated machines mix hand work and speed. Fully automated machines do big jobs fast and well.

| Tool Type | Mechanism | Impact on Functionality |

|---|---|---|

| Manual Tools | People use these by hand for small or careful work. | They give good control but are slow for big jobs. |

| Semi-Automated Machines | These need some hand work and some machine work. | They are faster than hand tools but still need people. |

| Fully Automated Machines | These work by themselves with no help. | They are very fast and make the same cuts every time. |

Micro-perforating blades are not the same as regular perforating blades:

- Regular blades have one sharp side and need another knife to work. This can make rough or broken edges.

- Micro-perforating blades have two sharp sides and tiny teeth. They do not need another knife.

- Micro-perforating blades make smooth, flat cuts. These cuts go through printers and other machines easily.

- Micro-perforations are very small and can have up to 72 teeth in one inch. This lets them work in-line without extra steps.

- Micro-perforating blades break less and do not hurt machines. They also work faster and make better products.

Note: How well blades work depends on the material and care. High-carbon steel is good for light jobs. Tungsten carbide is better for hard jobs. Special coatings like DLC or ceramic help blades last longer. Sharpening blades often keeps them working well and saves material.

Importance in Precision Processing

Precision is important in making things today. Perforating blades help companies get exact results. Micro-perforating blades are used in packaging, paper, and textiles. These blades make easy-tear lines in food packages without hurting the film. Even cuts can lower waste by up to 30%. This means less material is thrown away.

Blade coatings like Titanium Nitride and Diamond-Like Carbon help blades last up to 40% longer. This keeps cuts even and machines running longer. Good blades can stop machines from breaking down by 18%. This makes work faster and products better.

Micro-perforating blades use smart designs for tough jobs. In food packaging, they make tiny holes for air. The holes are so small they do not weaken the package. In electronics, these blades make clean edges for soft materials.

- Micro-perforating blades make cuts you can barely see. These cuts help sheets move through printers and copiers.

- Blades with lots of teeth make small, even holes. This is good for things that need air flow or easy tearing.

- Using perforating blades means less waste, better-looking products, and smoother machines.

Companies pick perforating blades because they work well and can do many jobs. These blades help many industries, like packaging and textiles. Maxtor Metal sells many kinds of perforating blades for different needs. Their blades help customers get great results and high-quality products.

Perforating Blades Types and Materials

Blade Shapes and Configurations

Perforating blades have many shapes. Each shape is good for a different job. The main types are straight blades, rotary blades, toothed blades, and circular blades.

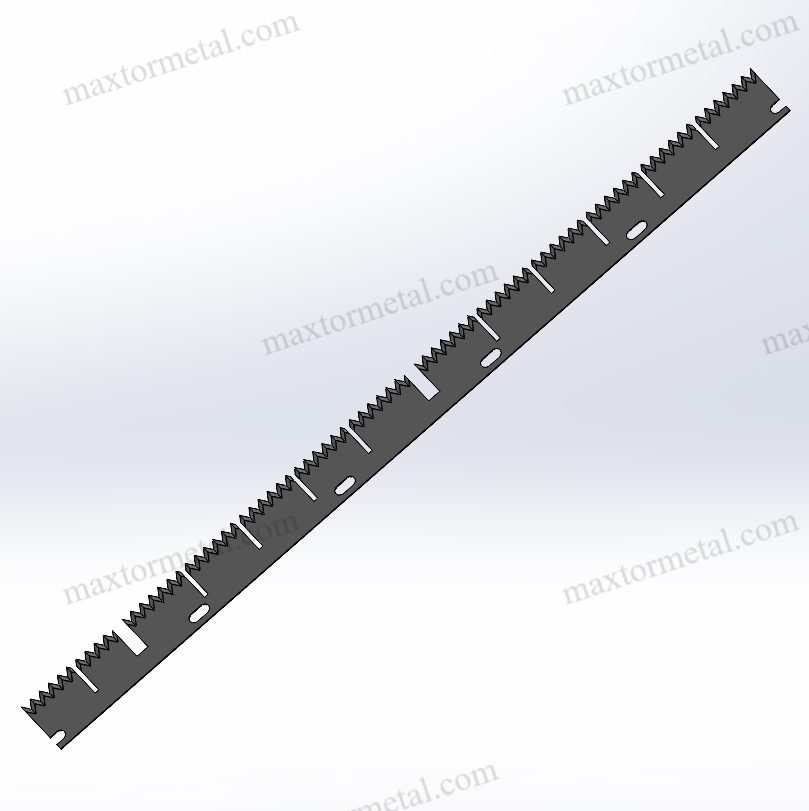

सीधे ब्लेड

Straight blades have a flat edge. They come in many sizes. These blades cut in straight lines. Companies use them for packaging film and paper rolls. They also use them for non-woven fabric. Straight blades make smooth cuts across the whole material.

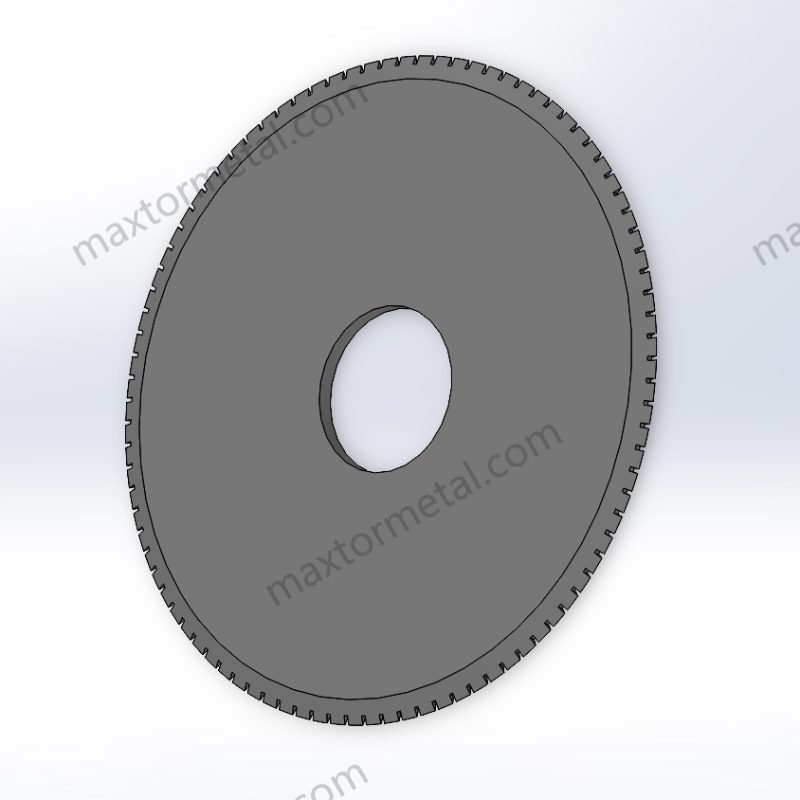

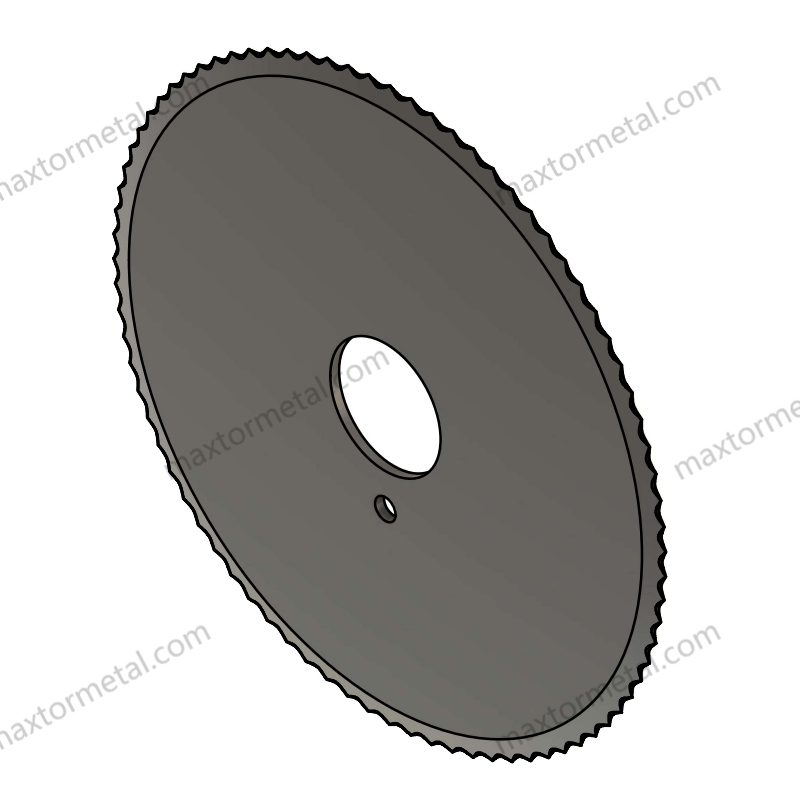

रोटरी ब्लेड

Rotary blades are round. They spin on shafts to cut fast. Rotary blades are good for high-speed cutting. Many industries use them for packaging and labels. They also use them for plastic film. Rotary blades help save material and cut better.

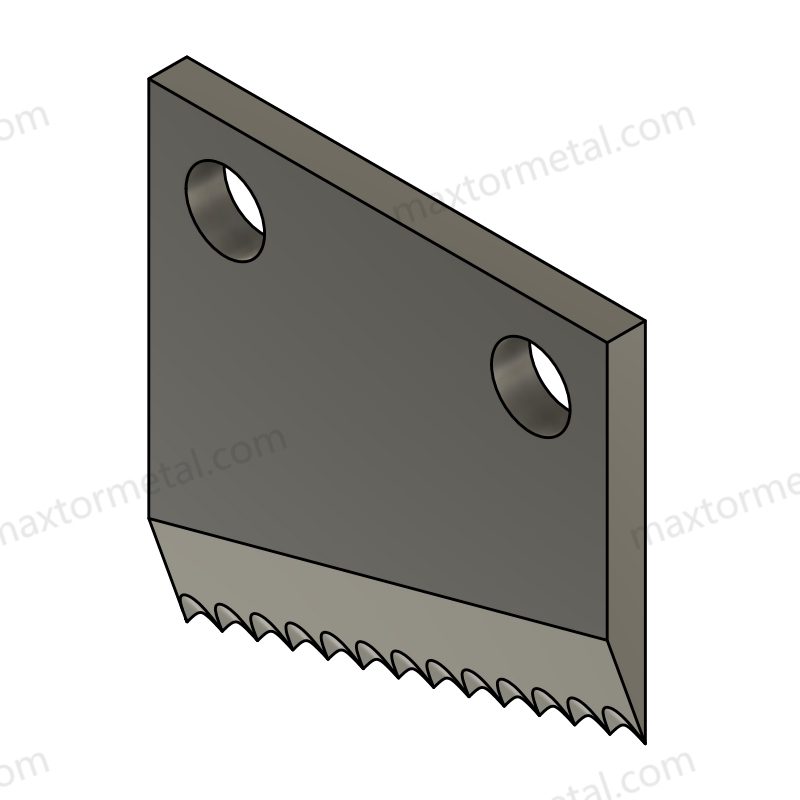

दांतेदार ब्लेड

Toothed blades have edges with teeth. The teeth can be different shapes and sizes. Toothed blades make tear lines and micro-perforations. Food packaging and easy-open bags use these blades. Hygiene products use them too. These blades make soft cuts that hold the material together.

गोलाकार ब्लेड

Circular blades are round all the way. They can be smooth or have teeth. Circular blades are used for rotary cutting. Textile and paper processing use these blades. Specialty materials use them too. Circular blades make long cuts and work fast.

Material Options for Precision Cutting

Tool steel, high-speed steel, stainless steel, and tungsten carbide are common. Tungsten carbide blades last longer than high-speed steel blades. They do not wear out fast. High-speed steel blades stay hard even when hot. Tool steel blades are very strong. Stainless steel blades do not rust and work in wet places. Each material helps blades cut well and last longer.

Precision in Micro-Perforating Blades

Design Features for Accuracy

Perforating blades need special designs to work well. Makers look at tooth count, cut-and-tie ratio, and new ways to make blades. These things help blades make clean and even lines in many materials.

High Tooth Count

A blade with lots of teeth has more cutting points. This helps the blade make tiny, even holes or cuts. More teeth mean less stress on the material. The cuts look better and smoother. Food packaging films use blades with many teeth. These blades make small holes for air. This keeps food fresh and safe.

Cut-and-Tie Ratio

The cut-and-tie ratio is the pattern of cuts and spaces. It shows how easy a material tears and how strong it stays. Makers change this ratio for each job. Hygiene product packages use a special ratio. This helps the package tear easily but stay strong. By changing the ratio, blades work well every time.

Advanced Manufacturing Techniques

Modern factories use new ways to make micro-perforating blades. Some ways are:

- Laser cutting and drilling

- सीएनसी मशीनिंग

- Photochemical machining

- Microforming

- Centerless grinding

These ways help make blades with smooth edges and tight sizes. Laser cutting makes tiny holes and cuts. CNC machines make blades very accurate. This is good for electronics and special films. Changing blade shapes and materials helps each blade fit its job.

| डिज़ाइन विशेषता | विवरण | Impact on Accuracy |

|---|---|---|

| ब्लेड सामग्री | High-Speed Steel, Tool Steel, Stainless Steel, Tungsten Carbide, Powder Metallurgy Steels | Stays sharp and strong for good cutting |

| ब्लेड ज्यामिति | Teeth shape, pitch, cut-and-tie ratio | Makes holes neat and easy to tear |

| एज डिजाइन | Lamella edges (clean cuts), bevel edges (strength) | Keeps blades sharp and tough |

| Blade Configuration | Rotary or straight blades, blade setting and movement | Makes sure cuts are straight and waste is low |

Tip: Lamella edges make clean cuts. This is important for accuracy. Bevel edges make blades stronger for hard jobs. Rounded edges are best for simple scoring.

| विशेषता | उच्च गुणवत्ता वाले ब्लेड | मानक ब्लेड |

|---|---|---|

| काटने की सटीकता | ±0.01 मिमी, न्यूनतम अपशिष्ट | ±0.03 से ±0.05 मिमी, कम सटीक |

| सहनशीलता | 300,000 तक कट | 150,000 से 200,000 कट |

Quality Control and Performance

Inspection Processes

Makers look for wear, chips, dull spots, rust, and bent blades. Checking blades often keeps them working well. Test runs check blade position, cutting depth, and pressure. Blades must be set up right to keep machines safe. Records show when blades are sharpened or fixed. Operators use guides and lists to fix problems early.

Heat treatment is important for blade quality. Hardening heats the whole blade and cools it for strength. Surface hardening makes the outside hard and the inside tough. Water, oil, or air can change how hard and tough the blade is. Tempering after cooling makes blades less brittle. These steps help blades work better and last longer.

Common Testing Equipment

Makers use many tools to check blades:

- Looking at edges for evenness and tooth shape

- Measuring size with micrometers and comparators

- Testing hardness and material type

- Trying blades on sample materials

- Using microscopes to see edges closely

- Laser tools to check size

- Hardness testers (Rockwell, Vickers)

- Machines that test cutting like real jobs

These checks help blades work well in factories. They keep machines running, lower waste, and help blades last longer.

Processing Applications and Industry Uses

Packaging, Paper, and Textiles

Perforating blades are used in many factories. These blades help companies make packaging, paper, and textiles that are easy to use and look nice.

पैकेजिंग उद्योग

Perforating blades make tear-off parts, neat seals, and clean cuts in packages. Food packs, drink labels, and shipping boxes use these blades. They help companies work faster and waste less. Some companies work up to 20% faster and throw away 20-30% less packaging. Perforating blades also make packages safer. For example, plastic bottle caps have seal rings that show if someone opened them. Snack bags and medicine packs use these blades so people can open them easily and safely. These blades also make small holes for air in fresh food packs and steam bags. Micro-perforations let steam out and keep food fresh.

- Perforating blades make lines that are easy to tear.

- Packages with micro-perforations stay strong but open fast.

- Air holes in packaging help keep food safe and fresh.

Maxtor Metal helps importers, sellers, and users with कस्टम ब्लेड. Their team helps companies pick the best blade for each job.

कागज उद्योग

Perforating blades help make tear-off sheets, tickets, calendars, cards, and invites. These blades make clean lines so things look nice. People can tear off sheets without scissors. Perforating blades also help companies make special products for different needs. The blade’s tooth shape and cut-and-tie ratio help make smooth cuts and protect machines.

- Perforating blades make checkbooks, labels, bills, and paper towels easy to use.

- Clean lines make products better and easier to use.

- Strong blade materials like solid carbide and stainless steel keep blades sharp and tough.

Textile and Non-Woven Fabrics

Perforating blades help make fabrics that breathe, sports clothes, and pretty patterns. These blades stop fabric from fraying and keep edges neat. Tough materials like tungsten carbide help blades work with fast machines and make high-quality fabric.

- Perforating blades make patterns and air holes in fabric.

- Breathable fabrics help keep clothes cool and comfy.

- Strong blades last longer and help machines run more.

Advanced Material Processing Industries

Perforating blades are important in many high-tech jobs. These blades help companies work with plastics, films, electronics, and food with great care.

Plastics and Films

| उद्योग/अनुप्रयोग | Specific Purpose/Use Case | Key Features/Benefits |

|---|---|---|

| Flexible Packaging Conversion | Making tear-resistant holes in films (PET, PP, PE) | Safe for food; works for thin and thick films; makes clean tear lines |

| Blade Material & Technology | High-grade 440C martensitic stainless steel with special coatings | Smooth finish, strong coating, food-safe PTFE layer |

| विनिर्माण प्रक्रिया | Very accurate EDM technology (Wire EDM with ±0.008mm accuracy) | No rough edges, very precise holes |

| प्रदर्शन में सुधार | Compared to regular blades | Straighter holes (±0.08mm/m vs ±0.25mm/m), blades last 3.4× longer, 62% less waste |

Perforating blades make strong holes in films like PET, PP, and PE. These blades help companies follow food safety rules. Special machines make blades with smooth edges and very small holes. Companies use blades longer and waste less material.

Electronics and Specialty Materials

| उद्योग/अनुप्रयोग | Specific Purpose/Use Case | Key Features/Benefits |

|---|---|---|

| Medical Packaging Systems | Making peelable seals with micro-perforations | Cleanroom-safe; meets ISO 11607-1; 0.5mm micro-perf |

| प्रदर्शन में सुधार | Compared to regular blades | Straighter holes (±0.08mm/m vs ±0.25mm/m), blades last 3.4× longer, 62% less waste |

Perforating blades help make peelable seals in medical packs. These blades meet strict cleanroom and safety rules. Companies use micro-perforations to make safe, easy-to-open medical packages.

खाद्य उद्योग

Micro-perforating blades make tiny holes in plastic films, usually 50–200 microns wide. These holes let water vapor and gases move through the package. For example, laser micro-perforation can raise water vapor movement from 11 g/m2/day to 60 g/m2/day with 4000 holes/m2. This helps food stay fresh longer. Perforating blades also help make stretch films that breathe. These films let air and moisture out but keep water and dust out. The process uses machines to make tiny holes. The holes get bigger when the film stretches, letting more air in and keeping food fresh.

Tip: Micro-perforating blades help companies make packaging that keeps food fresh and safe. Breathable films stop mold and spoilage.

Benefits for Importers, Distributors, and End-Users

Perforating blades give many benefits to industry partners. Maxtor Metal uses advanced CAD/CAM to design special blades. Their team gives advice on blade materials and engineering. Careful making and checking make sure blades work well every time.

- Custom blades fit each customer’s needs.

- Testing helps improve blade designs before making many.

- Production can be small or large to fit orders.

- Good prices keep blades affordable and accurate.

- ODM and OEM options let clients send drawings or samples for special blades.

- Easy buying with low minimum orders.

- Simple import service handles shipping and customs.

- Real-time updates let partners see how orders are going.

Maxtor Metal helps importers, sellers, and users with service and support. Their team gives 24/7 help and detailed guides. Working together helps make better blades for everyone.

Micro-perforating and perforating blades are very important in making materials. These blades help companies make better packaging by adding small holes and tear lines. Micro-perforating blades help fans make less noise and help films cool things better. Math models show that perforating blades help control air and keep things fresh. Companies use these blades because they are accurate and checked for quality. The table below shows how precision, versatility, and quality control make perforating blades special:

| कारक | फ़ायदा |

|---|---|

| शुद्धता | Makes neat, high-quality cuts every time |

| बहुमुखी प्रतिभा | Works for many kinds of packaging and products |

| गुणवत्ता नियंत्रण | Strong blades last longer and work well without stopping |

People in the industry can follow these steps to pick the right perforating blades: 1. Choose the blade material that fits the work area. 2. Pick a blade design that matches the way you cut and the material. 3. Change the tooth shape to get the best holes. 4. Make sure the blade does not wear out or rust. 5. Ask experts for help with custom blades and testing.

Maxtor Metal makes custom perforating blades and gives expert help for packaging and other jobs. Their team helps customers choose the best blades for every need.

सामान्य प्रश्न

What are micro-perforating blades used for?

Micro-perforating blades make tiny holes or cuts in things. Companies use them for packaging, paper, textiles, and films. These blades add tear lines, air holes, or easy-open spots. They help products work better and last longer.

How do companies choose the right blades for their needs?

Companies think about what material they need to cut. They look at blade shape and what job needs to be done. They pick blades with the right number of teeth and edge style. The blade material is important too.

Why do blades need regular inspection and testing?

Checking blades often keeps them sharp and safe to use. Testing finds dull spots, chips, or rust on the blades. Companies use microscopes and hardness testers to check them. Good blades help machines work well and waste less material.

Tip: Always follow the maker’s care guide for blades. This helps blades last longer and cut better.

Can blades be customized for special jobs?

Yes, Maxtor Metal makes custom blades for different jobs. Customers can pick blade shapes, sizes, and materials. Custom blades fit special machines or make special cuts. This helps companies get the best results for their products.

What materials are best for making strong blades?

Tool steel, high-speed steel, stainless steel, and tungsten carbide are good choices. Tungsten carbide blades last longer and do not wear out fast. Stainless steel blades do not rust. Each material helps blades work well for different jobs.

| ब्लेड सामग्री | Main Benefit |

|---|---|

| औजारों का स्टील | मजबूत और कठोर |

| उच्च गति स्टील | Stays hard when hot |

| स्टेनलेस स्टील | No rust |

| टंगस्टन कार्बाइड | Very durable |

यह भी देखें

छिद्रण ब्लेड और उनके व्यावहारिक अनुप्रयोगों को समझना

पैकेजिंग में छिद्रण चाकू का व्यापक रूप से उपयोग क्यों किया जाता है

छेदने वाले ब्लेड चाकू में असमान छेद और असंगत रेखा की लंबाई का निवारण और अनुकूलन