You use कॉइल स्लिटिंग ब्ले드 to help your steel service center work well. Premium blades help you have less downtime and cut more steel. Strong materials like tungsten carbide and high-speed steel give you steady, exact cuts. Custom options from brands like Nanjing Metal Industrial help you meet specific needs for your work.

Being efficient and exact in cutting helps you work faster and get good results.

चाबी छीनना

- Premium coil slitting blades last longer. They need fewer changes. This helps steel processing go faster and smoother.

- Using strong materials like tungsten carbide makes cleaner cuts. It also makes less scrap. This saves money and helps you work better.

- Regular maintenance is important. You should check and clean blades often. This makes blades last longer and keeps cuts sharp.

- Automated systems help change and line up blades. This makes work faster. Machines can run longer with fewer stops.

- Picking the right blade for your coil thickness is important. You also need to match the blade to the material type. This helps you cut better.

- Using tight tolerances in cutting gives better results. It also means you do not have to fix mistakes as much.

- Watching the total cost of blades helps you see their value. Premium blades can save money over time.

- Training your team on safety is very important. They should know how to handle blades the right way. This stops accidents and keeps work going well.

Coil Slitting Blades and Their Impact

Role in Steel Service Centers

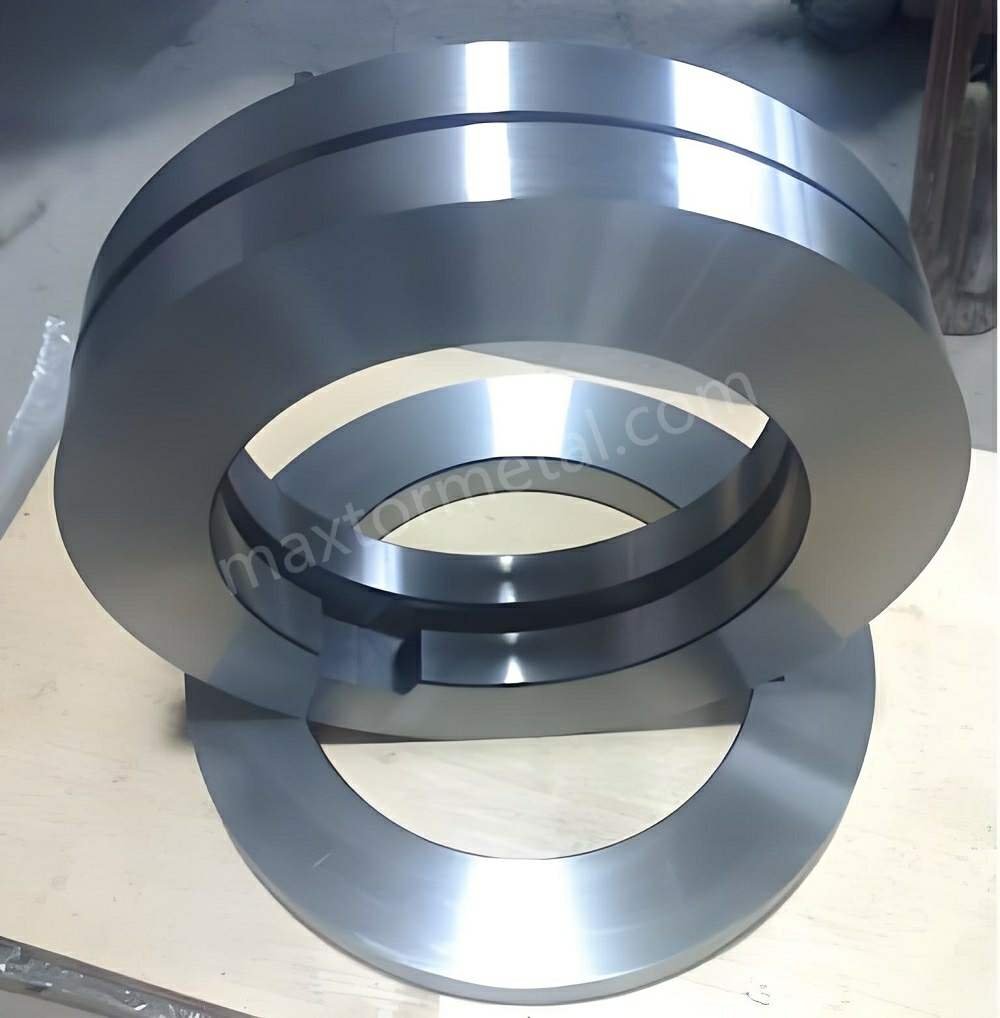

You need coil slitting blades to keep your steel service center working well. These blades cut big coils of steel into smaller strips. You use these strips for many jobs in factories. Picking the right coil slitting blades helps you work better and waste less. Good blades, like Roller Shearing Blades from Nanjing Metal Industrial, give you clean and exact cuts. When your cuts are exact, you fix fewer mistakes and make more good products.

Studies show that what your blades are made of and how you care for them matter a lot. The table below shows how different things can change how well you work:

| कारक | दक्षता पर प्रभाव |

|---|---|

| ब्लेड सामग्री | Carbide-tipped blades cut better and make less scrap. |

| रखरखाव प्रथाएँ | Taking care of blades keeps cuts clean and products good. |

| Blade Selection | Picking the right blade for coil thickness helps you cut better. |

Common Slitting Challenges

You have some problems when using coil slitting blades every day. These problems can slow you down and cost more money if you do not fix them fast. Some common problems are:

- Wasting material and slowing down production

- Damaged equipment and bad quality

- Problems with edge quality

- Camber in slit strips

- Knife wear and fixing blades

- Trouble moving material

You might also see:

- Bad edge quality makes later jobs harder

- Camber and twist in strips cause problems in making things

- Telescoping or cross winding makes handling tough

- Knives breaking or wearing out too soon stops work

- Strip widths that are not the same make scrap

Burrs on edges, camber, crooked cuts, and wavy edges often happen when blades are dull or set up wrong. These problems show why you should check your blades often and pick the right ones for your job.

Blade Quality and Productivity

Blade quality is very important for how much you can make. If you use good coil slitting blades, your cuts are cleaner and you do not need to change blades as much. This means you stop less and make more. You should check and change your blades often to keep cuts good. Having good rules for quality helps you work better.

Here are some tips:

- Cutting steel exactly helps you waste less and make more.

- Taking care of blades, like keeping them sharp and straight, helps you work well.

- Use good slitting blades to get clean cuts and change blades less.

- Set the right speed and tension to work fast and keep quality.

If you need special blades, look at custom blades to help you do even better. By picking the right coil slitting blades and following these tips, your steel service center can do well for a long time.

Maximizing Efficiency with Premium Blades

विस्तारित ब्लेड जीवन

You want your coil slitting blades to last longer. Premium blades use special materials like 5CrW2Si and H13. These materials make the blades hard and strong. When blades are made with strict tolerances, they cut very well. This helps you fix fewer mistakes and make more steel strips.

Here is a table that shows why premium blades last longer:

| गुण | विवरण |

|---|---|

| सामग्री | 5CrW2Si, 6CrW2Si, Cr12Mov, H13, W18Cr4V |

| कठोरता | High hardness keeps blades sharp and strong |

| सहनशीलता | Tight tolerances help you cut with accuracy |

| काटने की गुणवत्ता | Smooth cuts improve your product and reduce waste |

| तीखेपन | Durable sharpness means fewer blade changes |

| Heat Dissipation | Good heat dissipation lowers wear during long runs |

Blades that stay sharp and cool can cut more steel. You do not need to replace them as often. This helps your machines keep running and saves time.

Reduced Changeovers

Changing blades takes time and stops your work. Premium coil slitting blades help you change blades less often. They last longer and work well, even with heavy jobs. This means you stop your machines less and cut more steel.

The table below shows how fewer blade changes help you:

| फ़ायदा | विवरण |

|---|---|

| Longer blade life | Bi-metal designs last up to 50 percent longer, so you change blades less often |

| Consistent performance | Blades stay sharp and efficient, even with tough jobs |

| लागत प्रभावशीलता | Fewer blade changes lower your downtime and replacement costs |

When you do not change blades a lot, your machines run better. This helps you avoid downtime and keep making steel.

High-Grade Coatings and Materials

You can get better cutting by picking high-grade coatings and materials. Tungsten carbide and high-speed steel are good choices for coil slitting blades. Tungsten carbide is best for hard jobs because it is very tough. High-speed steel works well for most cutting and costs less for some jobs.

- Precision slitting blades made from tungsten carbide and HSS cut fast and well.

- These blades give you smooth edges, last longer, and waste less material.

- You can use them for metal, paper, or plastic.

- You can pick custom features like blade size, edge shape, and special coatings like TiN or CrN.

If you need a special blade, you can look at custom blades to find what you need. Custom blades let you pick the best material and coating for your job. This helps your equipment work its best.

By picking the right materials and coatings, your blades last longer and work better. This helps you be more efficient every day.

रखरखाव के सर्वोत्तम अभ्यास

You want your coil slitting blades to work their best. Taking care of them helps you make more and keep quality high. Good maintenance means you use each blade longer and stop less for repairs.

Here are the main steps you should follow:

- नियमित निरीक्षण

Check your blades often for damage or wear. Look for nicks, chips, or spots that look different. Finding problems early keeps your blades working well. Inspections help you fix things before they get worse. - उचित सफाई

Clean your blades after you use them. Use soft tools so you do not scratch them. Clean blades cut better and last longer. This step keeps your machines running and your cuts good. - स्नेहन

Put the right oil or grease on your blades. Lubrication stops heat and rubbing, so blades last longer. Using the right lubricant keeps your blades strong and helps your team do well. Lubrication also stops damage before it starts. - Correct Storage

Keep your blades in a dry, cool place. Good storage stops rust and keeps blades safe. When you store blades right, they stay ready for work. This helps you keep your quality high. - ऑपरेटर प्रशिक्षण

Teach your workers how to use and put in blades. Trained workers know how to keep blades safe and working well. Training helps your team work faster and follow rules for quality.

Tip: Make a checklist for your team to follow. Checking and cleaning often helps you find problems early and keep your machines running.

When you do these things, your blades break less and you stop less. You make more steel, and it is easier to check your work. Good blades and good care help your steel service center do better.

Precision Slitting for Quality Output

Tight Tolerances and Clean Edges

You need to be exact when you cut coils. Premium coil slitting blades help you cut strips to the right size. This means your strips are the right width and have good edges. Blades made for accuracy give you clean cuts every time. When you use these blades, your material fits well in the next steps.

Here is a table that shows the main types of tolerances and why they matter:

| Tolerance Type | परिभाषा | यह क्यों मायने रखती है |

|---|---|---|

| Width Tolerance | Acceptable variation in the width of slit strips | Ensures material fits manufacturing specs |

| Camber Tolerance | Maximum allowable deviation from a straight edge | Prevents misalignment in fabrication |

| Burr Tolerance | Acceptable level of roughness on slit edges | Reduces safety hazards and processing issues |

| Thickness Variation | Allowable difference in material thickness across the strip | Ensures uniform strength and performance |

Keeping tight tolerances helps you avoid problems. You will not have misaligned parts or extra work. Clean edges make your line safer and keep things moving. You can trust each strip will work well in the next job.

Reducing Scrap and Rework

You want to waste less steel in your service center. Blades that hold tight tolerances help you cut strips right every time. This means you make less scrap and do not need to fix as many mistakes. When your blades cut clean and straight, you spend less time fixing errors.

Think about these benefits:

- Less scrap saves you money on steel.

- Fewer mistakes mean you work faster.

- Good quality makes customers happier.

Tip: Watch your scrap rates before and after you use premium blades. You will probably see less waste and more good strips.

By keeping tight tolerances, you save money and help the environment.

Supporting Just-in-Time Manufacturing

You need to send out material that is ready to use. Premium blades help you cut coils that meet strict rules. This helps you keep less inventory and work faster.

You get these benefits:

- Less waste because your strips are always the right size.

- Faster production since your material is ready to go.

- You do not need to store big coils.

- Your line works better with even strips and clean edges.

- You save money by making less scrap and doing less extra work.

When your material meets the right specs, your customers can use it right away. This makes them trust you and helps your service center stay strong in the market.

Steel Coil Slitting Machine Setup and Automation

Setting up your steel coil slitting machine the right way helps you make more steel. It also keeps your line running smoothly. Automation and good planning help you cut more steel and stop less. These steps also help keep your team safe. Let’s look at some easy ways to set up and use automation.

Proper Alignment and Coil Preparation

Start with the basics. When you get coils ready for your steel coil slitting machine, you protect your tools and get better results. If you skip these steps, you might break your machine or waste steel.

- Handle and store coils with care. This stops dents or bends before you put them on the steel coil slitting machine.

- Check each coil for marks or hidden problems. If you see any issues, put those coils aside so you do not have trouble when cutting.

- Make sure coils unwind without problems. Keep the tension steady so the steel goes into the steel coil slitting machine smoothly.

- Set up the slitting line so every part is in the right spot. Use alignment tools to check that arbors and blades are straight.

- Check alignment often. Even small changes can mess up your steel strips.

- Automated alignment systems can fix the setup while the steel coil slitting machine is working. This keeps your cuts good and helps you waste less.

Tip: Companies that use smart alignment tools get better steel and less scrap. You can save time and steel by checking alignment a lot.

Automated Blade Change Systems

You can save lots of time by using automated blade change systems on your steel coil slitting machine. Old setups need many workers to change blades and keep things moving. Automation makes this easier and gives you many benefits.

| पहलू | Traditional Setup | Automated Setup |

|---|---|---|

| Number of Operators | 6-9 (including supervisors) | 1 (orchestrator) |

| Labor Cost Savings | High (multiple wages, benefits) | Significant (single higher-paid role) |

| प्रवाह | Limited (manual operation) | High (24/7 operation) |

| Quality and Waste | Higher defect rates | Reduced defects (40% improvement) |

With automation, you only need one skilled worker to watch the steel coil slitting machine. The system can work all day and night, putting on up to 60 straps each minute. This fast speed means you can cut more steel and meet orders. Automated systems also make your cuts more even, so you have fewer mistakes and waste less steel. One company saw 40% less rejected steel after switching to automation.

- Old lines need 2-3 workers each shift, plus bosses.

- Automated systems work without stopping, so you make more steel.

- Blade changes are always the same, so you get better steel strips.

Note: Automation saves money on workers and helps you finish jobs on time.

Optimizing Material Tension

You need to control tension when cutting steel to get the best results from your steel coil slitting machine. If tension is wrong, you can hurt the steel or make coils unsafe.

| तरीका | विवरण | Measurable Benefits |

|---|---|---|

| Strapping Techniques | Put straps around coils the way they need. | Makes loads safer and more stable. |

| तनाव नियंत्रण | Keep tension steady to stop damage and help moving. | Lowers risk of damage and keeps things safe. |

| Automated Strapping Machines | Use machines to strap fast and evenly. | Saves time and helps workers avoid tiredness. |

When you use the right strapping and keep tension steady, your steel coils stay safe when you move or store them. Automated strapping machines work fast and put straps on evenly, which saves time and helps your team stay safe. Good tension control also lets your steel coil slitting machine run faster without hurting quality.

- Always check tension before you start new coils.

- Use automated systems to keep tension steady, even when coil size changes.

- Good tension stops edge damage or coils falling apart.

Callout: Keeping tension steady helps you send safe, good steel coils to your customers every time.

By focusing on alignment, automation, and tension, you get the most from your steel coil slitting machine. These steps help you cut more steel, stop less, and keep your work running well.

Cost-Effectiveness and ROI in Coil Processing

मालिकाने की कुल कीमत

You want to make smart choices in coil processing. Looking at the total cost of ownership helps you see the real value of your coil slitting blades. Many people only look at the price tag, but you need to think about more than that. When you use premium blades, you often spend less over time, even if you pay more at first.

Here is what you should include when you figure out the total cost of ownership for your coil processing tools:

- Purchase price of the blades

- How often you need to replace the blades

- Downtime caused by blade changes or failures

- Maintenance costs for keeping blades in good shape

Premium blades, such as those made from tungsten carbide, may cost more at the start. You will notice, though, that they last much longer. You do not have to stop your coil processing line as often to change blades. Less downtime means you keep your machines running and your productivity stays high. Over time, you spend less on replacements and repairs. This makes your coil processing operation more cost-effective.

Tip: Track how often you change blades and how much downtime you have. You will see the savings add up when you use premium blades.

Calculating Cost-Per-Ton

You need to know how much it costs to process each ton of steel. This helps you set prices, plan budgets, and find ways to save money in coil processing. The cost-per-ton formula gives you a clear picture of your expenses.

Here is a simple way to calculate cost-per-ton in coil processing:

- Total cost = Unit price × Tonnage + Freight + Duties + Packaging + Inland delivery

For example, if the price per ton is $700 and your coil weighs 20 tons, you add ocean freight of $1,000 and an import tax of 5%. The total cost would be:

- (700 × 20) + 1,000 + (700 × 20 × 0.05) = $15,700

When you use premium blades in coil processing, you can lower your cost-per-ton. You get more tons processed before you need to change blades. You also reduce scrap and rework, which means you use your materials better. This keeps your productivity high and your costs under control.

Note: Review your cost-per-ton numbers every month. Small changes in blade quality or maintenance can make a big difference in your coil processing budget.

दीर्घकालिक बचत

You want your coil processing line to stay strong for years. Investing in premium blades gives you long-term savings that go beyond the first purchase. You spend less on replacements, repairs, and lost time. Your machines run smoother, and your team works with fewer stops.

Here are some ways you save money over time:

- Fewer blade changes mean less downtime and more steel processed.

- Longer blade life reduces the number of blades you need to buy each year.

- Better cuts mean less scrap, so you use more of your material.

- High-quality blades help your machines last longer, lowering repair costs.

You also boost your productivity. When your coil processing runs without many stops, you can take on more jobs and meet customer needs faster. Your reputation grows as a reliable supplier. Over time, these savings help your business grow and stay competitive.

Callout: Choosing the right blades for coil processing is not just about today’s price. It is about building a strong, cost-effective operation for the future.

Industry Applications of Roller Shearing Blades

Roller shearing blades are important in many industries. You use these blades to cut and slit materials with accuracy. They work for steel coils, plastics, and more. You can pick blades that fit your job. This helps you get good results every time.

Automotive and Manufacturing

You find roller shearing blades in car factories and other plants. These blades cut metal sheets for car parts. They also slit steel and aluminum coils to the right size. This helps you make lots of parts and follow strict rules.

- You cut car panels with smooth edges.

- You slit coils for stamping and shaping.

- You work fast to keep lines moving.

If you need special blades, you can ask for custom ones. Nanjing Metal Industrial helps you pick the best blade shape, material, and coating. This makes your cutting jobs easier and keeps your products high quality.

Electrical, Appliances, and Packaging

You use roller shearing blades to cut thin metal sheets for electrical and appliance parts. These blades also help you slit foils, films, and coated papers in packaging plants.

| आवेदन क्षेत्र | Typical Slitting Task | Benefit to Your Operation |

|---|---|---|

| Electrical | Slitting copper and aluminum sheets | Precise cuts for safe connections |

| Appliances | Slitting stainless steel for housings | Smooth edges for assembly |

| पैकेजिंग | Slitting foils and films | Consistent width for wrapping |

You get good results with each cut. Clean edges and right sizes help you avoid mistakes and keep your work fast.

Construction, New Energy, and Plastics

You use roller shearing blades to slit steel for buildings. In new energy, you cut battery foils and solar panel frames. Plastic makers use these blades to slit sheets for packaging, insulation, and car interiors.

- You slit steel for building parts.

- You cut battery foils for energy.

- You process plastic sheets for many uses.

You can ask for blades with special coatings or shapes for hard jobs. Nanjing Metal Industrial works with you to design blades that fit your needs. This help lets you cut better and keep your work going strong.

Tip: Pick roller shearing blades made for your industry. This helps you work faster and stop less. Custom blades and expert help keep your cuts clean and your jobs easy.

Overcoming Concerns and Ensuring Safety

Addressing Upfront Costs

You might worry about paying more for premium blades. Some people think the higher price is not worth it. But you should think about how much you save later. Premium blades let you cut more material before you need new ones. This means you stop your machines less and spend less on repairs. Over time, your cost for each ton goes down, and your line works better.

Some people do not understand how blades work. The table below explains two common mistakes:

| Misconception | Correction |

|---|---|

| Elasticity in blades is independent of hardness | Elasticity can change with heat treatment and is not fixed. |

| All knife blades have the same flexibility | Flexibility varies based on heat treatment, hardness, and tempering. |

Not all blades are the same. If you pick blades made for precision slitting, you get better flexibility and hardness. This helps your blades last longer and your machines stop less. You also lower the chance of blade breaks, which can slow you down.

Note: Buying good blades for precision slitting saves money over time. You do not need to replace them as often, and your line keeps moving.

Compatibility with Equipment

You want your new blades to fit your machines. Many steel service centers worry about this. When you buy blades for precision slitting, check the size, thickness, and how they mount. Most top blade makers can make custom blades for your machines.

Think about what kind of metal you cut. Some blades work better with certain metals or thicknesses. Picking the right blade helps you avoid bad cuts or machine problems. This keeps your line safe and working well.

- Check your machine’s specs before you buy new blades.

- Work with suppliers who can help you with custom blades.

- Try new blades on a small batch before using them for everything.

When your blades fit your machines, you get the best cuts. You also protect your machines and your blades.

Operator Safety and Training

You need to keep your team safe when using slitting machines. These machines use sharp blades and strong motors. Training and safety rules help stop accidents and injuries.

Operators must follow safety rules every day. Here are the main steps:

- Train and certify all workers to use the slitting line safely.

- Teach how to run the machine, what to do in emergencies, and how to use safety tools.

- Give regular safety classes to keep everyone up to date.

- Check the machine every day for damage or wear.

- Look at the blades before each shift to make sure they are sharp and straight.

- Make workers wear safety glasses, gloves, and hearing protection.

Tip: A trained team has fewer accidents and keeps your slitting line running well.

You should also remind your team to report any problems with blades or machines right away. When you focus on safety, you protect your workers and your machines.

Precision slitting has many good points, but you need to think about cost, fit, and safety. By making smart choices and following good rules, you keep your slitting line safe and working well. You also make sure your machines give you the best results.

Premium coil slitting blades help you cut more steel and stop less. These blades let your steel service center work faster and better. You get clean cuts because of strong materials and special coatings. Automation and fast knife-change systems help your line keep moving.

| फ़ायदा | विवरण |

|---|---|

| High Productivity | You cut more steel with blades that work well. |

| Energy-Efficient Design | Smart systems help you use less energy and save money. |

| High-Quality Performance | You get smooth edges without burrs every time you cut. |

| कम डाउनटाइम | You can change blades quickly and work longer without stopping. |

Look at how you do things now and see if you can do better. Try solutions like Nanjing Metal Industrial Roller Shearing Blades. हमारे बिक्री इंजीनियर से संपर्क करें if you want help from an expert.

सामान्य प्रश्न

What are coil slitting blades used for?

Coil slitting blades cut big metal coils into thin strips. These strips are used in cars, buildings, and packaging.

How do premium coil slitting blades reduce downtime?

Premium coil slitting blades stay sharp for a long time. You do not need to change them as much. This keeps machines working and lets you cut more steel.

Which materials work best for coil slitting blades?

Tungsten carbide, high-speed steel, and alloy tool steel work best. These materials are strong and keep blades sharp while cutting a lot.

How often should you inspect coil slitting blades?

Check coil slitting blades before every shift. Regular checks help you find damage early. This keeps your cuts good and your machines safe.

Can you use coil slitting blades for different metals?

You can use coil slitting blades for steel, aluminum, and copper. Pick the right blade material and shape for each metal.

What maintenance steps help extend blade life?

Clean blades after using them and add oil or grease. Store blades in a dry place. Teach your team how to handle blades the right way so they last longer.

यह भी देखें

धातु के लिए रोलर शीयरिंग ब्लेड

रोलिंग शीयर ब्लेड क्या हैं और वे कैसे काम करते हैं?

विनिर्माण में Metal स्लिटिंग ब्लेड के अनुप्रयोगों की खोज

अपनी ज़रूरतों के लिए सही रोलर शियरिंग ब्लेड का चयन कैसे करें

आफ्टरमार्केट बनाम OEM रोटरी स्लीटर ब्लेड: एक लागत-लाभ विश्लेषण