पैकेजिंग छिद्रण चाकू are very important in packaging. They help make packaging fast and accurate. These special blades add easy-open parts, let air move, and help products split cleanly. Manufacturers use packaging perforating knives in many ways:

- Food packaging uses them for seals that show tampering and for air holes.

- Bubble wrap and tape use perforations so people can tear them easily.

- Medicine packaging has perforated lines to split pills safely.

- Plastic bottle caps use perforations for more safety and trust.

चाबी छीनना

- Packaging perforating knives make lines and holes in packages. These lines help people open packages easily. The holes help keep food fresh. Micro-perforations let air move in and out. This keeps food fresh for longer. Macro-perforations make it easy to tear open packages. They also show if someone has opened the package before. These knives help factories work faster. They also help use less material. This makes factories run better and smoother. The knives cut in the same way every time. This keeps products safe inside the package. It also makes opening the package safer and easier. Perforated packaging is good for users. It lets people open packages without tools. It also keeps products safe inside. There are different blade materials and tooth shapes. These fit many packaging needs. They make sure cuts are sharp, strong, and clean. Custom knives can fix special packaging problems. They also make packages safer and look better. Working with good suppliers like मैक्सटर Metal is important. It helps factories get high-quality knives. This makes factories work better and products better too.

How Packaging Perforating Knives Work

Mechanism

Packaging perforating knives work by pressing or rolling their sharp edge on packaging. This makes small holes or slits in the material. Some parts stay uncut between the holes. These lines help people tear or fold the package easily. Manufacturers must control the depth of the cuts. If the cuts are too deep, the package may break. If too shallow, it is hard to tear. Rotary perforating blades spin while cutting. This spinning helps make smooth and even cuts. It is important for fast machines in factories. The blade type and material should fit the packaging. This gives the best results.

Types of Perforations

There are different styles of packaging perforations. The two main kinds are micro-perforations and macro-perforations.

Micro-perforations

Micro-perforations are very tiny holes in the package. These small holes let air and moisture move. Food packages like bakery boxes use micro-perforations. French fry containers also use them. The holes help keep food fresh. Air can go in and out. Medicine packages use micro-perforations in blister packs. This protects the medicine and keeps it safe.

Macro-perforations

Macro-perforations are bigger holes or slits. These make it easy to tear open or split the package. Tamper-evident packages use full vertical macro-perforations. You see these on bottle and jar neck bands. When you open the package, the edges break. This shows if someone has tampered with it. E-commerce packages use macro-perforations. This helps people return items or reseal the package.

| Perforation Type | विवरण | विशिष्ट उपयोग का मामला |

|---|---|---|

| Full Vertical Perforations | Used to remove neck bands easily; they break when opened, showing tampering. | Used on jars, bottles, tubs; helps remove shrink sleeves for recycling. |

| Horizontal/Partial Vertical | Used when the sleeve covers the closure; people remove the top part to open. | Shows tampering but keeps the label on the package. |

| Venting Perforations | Small holes let air out during shrink sleeve use. | Used for ventilation when putting on shrink sleeves; not for tamper evidence. |

Comparison with Other Knives

Packaging perforating knives are different from other knives. They have special jobs and shapes. Straight knives cut in a straight line. They are used for things like cloth and plastic films. Rotary knives spin and cut long strips in foil or paper. Toothed knives have jagged edges. They saw or tear tough things like leather. Perforating knives, straight or rotary, make holes or tear lines. This helps people tear or let air in packages.

| चाकू का प्रकार | काटने की प्रणाली | विशिष्ट अनुप्रयोग |

|---|---|---|

| Straight Knives | Long, flat blades cut in a straight line; edges can be smooth or jagged. | Used for cutting cloth, rubber, and plastic films. |

| रोटरी चाकू | Round blades spin and cut long strips. | Used for cutting film, foil, paper, and metal sheets. |

| Toothed Knives | Jagged edges saw or tear tough things. | Used for cutting strong or rough materials like fibers and leather. |

| Perforating Knives (straight or rotary) | Make holes or tear lines; rotary blades spin for neat, quick cuts. | Used for making tear lines on packaging, labels, and bags; found in packaging, printing, and fabric work. |

Perforating knives are very accurate and fast. They make even holes and lines. This makes packages safer and easier to use. Makers can pick blade materials and tooth shapes for each job.

Benefits of Packaging Perforating Knives

क्षमता

Increased Production Speed

Packaging perforating knives help factories work much faster. These knives use creasing and perforating wheels that fit the material. Machines can change knives by themselves very quickly. Workers do not spend much time switching blades. They can focus on making more products. Many companies say automatic cutters finish jobs in hours, not days. Feeders and stackers move materials, so workers do not have to. This makes everything go faster. Automated tools also save money and make it simple to make samples.

- Creasing and perforating wheels help work move faster.

- Automatic knife changes mean less hard work for people.

- Automated handling stops slowdowns.

- Faster work helps companies send products out quickly.

कम सामग्री अपशिष्ट

Factories want to use all their materials. Packaging perforating knives make sharp, even holes that waste less. Strong blades last longer and need fewer changes. Custom-shaped knives cut better, so less gets thrown away. Clean edges from the right blade make packages look nicer and waste less. Easy-tear lines help people open packages without breaking them. Studies show these tools can cut waste by 20% compared to old ways. Serrated zigzag knives are great for fast खाद्य पैकेजिंग. They keep quality high and costs low.

- Sharp, even holes mean less waste.

- Strong blades mean less downtime and trash.

- Custom shapes help cut more exactly.

- Clean edges make packages look and work better.

- Easy-tear lines stop damage.

Streamlined Packaging Processes

Factories need easy steps to make packaging. Packaging perforating knives make neat, perforated lines. These lines let machines run faster and stop less. Workers do not have to fix as many mistakes. Automated systems use these knives to make every package the same. Companies can change designs fast and follow new trends. The whole job gets easier and more dependable.

Tip: Simple steps save time and money, helping companies stay ahead.

शुद्धता

Consistent Perforation Quality

Every package should look and work the same way. Good perforating knives make sure each hole or line is perfect. Studies show special punch shapes can lower the force needed by almost 70%. This helps machines work better and keeps holes the same size and shape. Scientists use tests and computers to find the best designs. These knives help factories make high-quality packages every time.

Accurate Placement of Cuts

Factories use machines to put cuts in the right place. Packaging perforating knives can be made to fit each job. Machines use digital controls and servo motors to move blades very carefully. The pitch, or space between blade edges, is important. Workers pick the right pitch for each material. This keeps packages strong and easy to open. Automated setups make sure every cut is in the right spot. Packages look neat and work well.

| विशेषता | फ़ायदा |

|---|---|

| कस्टम ब्लेड आकार | Cuts go in the right place |

| Servo-driven controls | Very close measurements |

| Automated setup | Same cuts every time |

| Pitch selection | Easy to open, strong packages |

Minimization of Product Damage

Perforated lines must keep products safe inside. Scientists study how different patterns affect package strength. Bridges in the perforation act like supports, keeping packages strong during shipping. Speedi Tear designs make opening easy but keep packages strong. Tests show the right perforation keeps products safe. The FDA says sharp, clean blades help stop damage and germs. Workers check and change blades often to keep cuts safe.

प्रयोगकर्ता का अनुभव

Easy Tearing and Opening

People want packages that are easy to open. Perforated lines make this happen. A survey found 64% of buyers trust brands with good packaging. Easy-open designs help people use products faster and with less work. These features make customers want to buy again. When packages have easy-tear lines, people are about 30% happier. Packaging perforating knives help make these designs possible.

Clean Separation of Packaging Layers

Perforated lines help split layers without mess. People can tear off what they need and keep the rest safe. Clean edges make packages look and work better. Factories use these knives to make sure every layer splits neatly. This is important for food, medicine, and other things that need safe, clean packaging.

Enhanced Consumer Satisfaction

Good packaging makes people happy. Perforated lines let people open packages without tools or extra work. Packages stay strong until someone wants to open them. Brands that use these features get better reviews and more repeat buyers. Packaging perforating knives help companies make packages people trust and like.

Product Safety

Controlled Airflow and Ventilation

Packaging perforating knives help air move in packages. Small holes or slits let air go in and out. This keeps food fresh and stops moisture from building up. Factories use these knives to make sure each package has the right holes. Some products, like fruits and vegetables, need more air. Other products, like snacks, need less air. Companies change the pattern of holes for each product. This helps stop spoilage and keeps items safe longer.

Protection Against Contamination

Factories must keep products clean and safe. Packaging perforating knives help with this job. Many factories use knives made from nylon, plastics, or titanium. These materials do not rust or react with food. Plastic and nylon knives do not leave metal bits behind. They also resist chemicals. This makes them good for food and medicine packaging. Titanium knives last a long time and stop germs from growing. Workers clean and check the knives often. Cleaning and checking keeps blades free from dirt and germs. These steps help stop contamination and protect people who use the products.

Tip: Using plastic or nylon knives lowers the risk of contamination in sensitive packaging places.

Secure Packaging Integrity

Strong packaging keeps products safe from damage. Perforating knives make clean and neat cuts. These cuts help packages open easily but stay closed until needed. The right knife stops packages from opening by accident. It keeps the contents safe. Plastic or nylon knives help keep packages strong. They do not cause tears or weak spots. Titanium knives add extra strength and do not rust. By picking the right knife and keeping it clean, factories make sure every package stays strong from the factory to the customer.

Easy-Open Packaging

Consumer Convenience

Easy-open packaging helps people use things fast and safely. Many store items now have parts that are simple to open. These parts save time and stop people from getting upset. Most packages do not need scissors or knives to open. This makes them safer for kids and older people. Companies use many designs to help buyers. Some easy-open ideas are:

- Tear notches help people tear in a straight line.

- Perforations make weak spots for easy tearing.

- Peel-back strips let people open packages easily.

- Tear-away corners give controlled ways to open.

- Zipper locks let people close packages again.

- Peel and reseal keeps things fresh.

You can find these features on snack bags, medicine packs, and bottle caps. Perforating knives are important for making these easy-open parts.

Tear Strips

Tear strips help people open packages quickly and safely. They use small cuts made by perforating knives. People pull the strip to open the package without tools. This works well for food, medicine, and shipping boxes. Tear strips have many good points:

1. People open packages fast and safely. 2. They give a clean opening with one pull. 3. They lower the chance of getting hurt. 4. Packages can often be closed again to stay fresh. 5. They help people who have weak hands. 6. They are used in food and medicine packaging. 7. They save time and are easier than old ways.

Tear strips make opening packages better for everyone. They also help keep products safe and fresh.

Ventilation Features

Perforating knives help make holes for air in packages. Small holes or slits let air move in and out. This keeps food and other goods fresh. Ventilation helps in many ways:

- Air moving stops moisture and mold.

- Airflow keeps things at the right temperature.

- Holes let vapor out but block water and dust.

- Ventilation keeps products good for longer.

- Holes can change size with the package.

These features are needed for fruits, dairy, frozen foods, and flowers. Good airflow keeps products safe in storage and shipping. Companies use perforating knives to make these holes just right.

पैकेजिंग में अनुप्रयोग

खाद्य पैकेजिंग

Typical Products

Food packaging uses perforated blades for many things. Bread bags, snack pouches, and bakery boxes have perforated lines. These lines are found on packages for chips and cookies. Frozen foods also use them. Meat trays and cheese packs need perforated blades too. Many food makers use perforated packaging. It helps keep food fresh and easy to open.

Benefits of Perforation

Perforated blades help food packaging in many ways. They make easy-open spots so people can tear packages. You do not need scissors or other tools. Micro-perforations let air move. This keeps baked goods from getting soggy. Macro-perforations make seals that show if someone opened the package. Perforated packaging controls moisture and airflow. This helps food last longer. Food stays fresh, and customers can open packages easily.

| फ़ायदा | विवरण |

|---|---|

| Easy Opening | Tear lines let people open packages quickly |

| Freshness | Air holes keep food from spoiling |

| सुरक्षा | Tamper-evident seals protect products |

| Portion Control | Perforations allow for single servings |

Tip: Perforated packaging helps food makers follow safety rules and make customers happy.

Customization Needs

Food packaging often needs special perforated blade designs. Makers pick blade shapes and patterns for each food. Bread bags may need tiny holes for air. Snack packs need strong tear lines. Some companies want special patterns for their brand or for portion control.

Bubble Wrap & Film

Typical Products

Bubble wrap and film are used for shipping and storing things. These materials protect electronics and glassware. Fragile items need bubble wrap and film. Perforated blades make tear lines in bubble wrap rolls. Plastic film sheets also use these lines. Moving boxes and store displays use perforated sections. This makes handling easier.

Benefits of Perforation

Perforating knives help bubble wrap and film tear easily. They let workers separate sheets fast and neatly. This makes packing quicker and cleaner. Precise perforation keeps the film strong. It reduces waste and keeps packaging quality high. Clean cuts do not damage the material. Workers can pack and ship faster.

Customization Needs

Bubble wrap and film need different perforation styles. Some rolls need short tear lines for small packages. Others need long sections for big items. Companies ask for special blade shapes for their packaging. Maxtor Metal makes blades with serrated, scalloped, or straight edges. कस्टम ब्लेड help businesses pack things safely and quickly.

Cardboard & Cartons

Typical Products

Cardboard boxes and cartons are used for shipping and selling. Shipping boxes and display cartons have perforated sections. Tear-away coupons and easy tabs are common. Ventilation holes are found on many packages. Corrugated cardboard uses perforated blades for shipping. Kraft paper is used for eco-friendly packaging.

Benefits of Perforation

- Perforating knives make tear lines for easy opening.

- They help people take only what they need.

- Perforations improve airflow and keep products fresh.

- Packages stay strong and safe during shipping.

- Custom perforations make packages look better.

- Neat openings reduce waste and help users.

- Eco-friendly packaging uses kraft paper and cardboard.

- Different perforations help with opening, airflow, and portioning.

- Retail packages use perforations for coupons and tabs.

Perforating knives cut cardboard sharply and cleanly. They make tear-off sections and display features. Packages stay strong and do not break. These blades help factories work faster and waste less. They are important for easy-open boxes and inserts. Packages stay safe during shipping.

Perforated cartons help workers in warehouses. They give easy access points and lower the risk of damage. Smooth edges stop cuts to products and workers. Uniform openings save time and make work safer. Pick and pack jobs go faster and cost less.

Customization Needs

Cardboard and cartons need special perforation patterns. Stores want tear-away coupons and display windows. Shipping companies need strong tear lines. Some packages use tiny holes for air. Custom blades help make packaging safe, nice-looking, and easy to use.

Bottle Caps & Seals

Typical Products

Bottle caps and seals are used in many types of packaging. Companies use them for drinks, medicine, food jars, and beauty products. Tamper-evident bands wrap around bottle and jar necks. Shrink sleeves cover the tops to keep things safe inside. These products need exact perforated lines for safety and easy use.

- Water bottles

- Juice containers

- Medicine bottles

- Food jars

- Cosmetic bottles

Benefits of Perforation

Perforating knives are very important for bottle caps and seals. They make small cuts or rows of cuts in shrink sleeves and neck bands. These bands seal the product and stop leaks or spills. People can take off the tamper-evident band without scissors or knives. The band shows buyers the product is safe and good quality.

- Tamper-evident bands with perforations give a strong seal.

- Perforated edges make it easy to open bottles.

- Perforations show if someone has opened the package.

- Tear tab blades make tabs for simple opening.

- Horizontal and vertical perforations help keep labels and make recycling easier.

Perforated edges on tamper-evident labels let people pull off the seal without sticky mess. This makes opening bottles simple and quick.

Companies pick different perforation types for each package. Full vertical, horizontal, and partial vertical perforations have special uses. These features make tamper-evident packaging work better and easier to use.

| Perforation Type | आवेदन क्षेत्र | फ़ायदा |

|---|---|---|

| Full Vertical | Neck bands, shrink sleeves | Easy removal, clear tamper evidence |

| Horizontal | Sleeve tops, label edges | Preserves label, aids recycling |

| Tear Tab | Sleeve tabs | Simple opening, no tools needed |

Customization Needs

Bottle cap and seal packaging often needs special perforated blade designs. Companies choose blade shapes and patterns for each closure and material. Some products need tear tabs for easy opening. Others need strong bands for more safety. Custom blades help each package stay safe, look good, and open easily.

Medicine Packaging

Typical Products

Medicine packaging uses many types that must be safe and exact. Blister packs, pill bottles, sachets, and medical pouches all have perforated lines. These packages keep medicine clean and easy to get.

- Blister packs for tablets and capsules

- Pill bottles with tamper-evident seals

- Medical sachets and pouches

- Child-resistant packaging

- Sterile wraps for medical devices

Benefits of Perforation

Perforating knives and special blades make neat, exact cuts in medicine packaging. These blades keep the package clean and sealed until it is used. This stops germs and keeps the seal strong, which is very important for safety. Companies use perforated lines for child-resistant and tamper-evident features. These blades help meet strict FDA and WHO rules for medicine packaging.

- Perforating knives make neat tear lines for safe opening.

- They keep the package sealed and clean.

- Mechanical perforation works well and helps the environment.

- Exact perforations stop germs and keep seals strong.

- Blades help make safe and rule-following packages.

Good perforated packaging keeps medicine fresh and lowers the risk from bad seals.

Companies use these blades to make sure medicine is safe and works right. The best perforation design helps follow rules and builds trust with buyers.

Customization Needs

Medicine packaging needs special perforated blade solutions. Companies pick blade materials and shapes for each package and medicine. Some medicines need tiny holes for air. Others need strong tear lines for child safety. Custom blades help each package stay safe, work well, and open easily.

Materials & Designs

ब्लेड सामग्री

Manufacturers pick blade materials for packaging perforating knives based on what each job needs. The right material keeps the knife sharp, strong, and cutting well. Different steels or ceramic have their own good points. The table below lists common materials and how they are used:

| ब्लेड सामग्री | Key Properties and Benefits | Typical Applications and Notes |

|---|---|---|

| 52100 Steel | Strong and hard; contains chromium and carbon; good for blades and automotive parts. | Delivers hardness and strength for packaging perforating knives. |

| Solid Carbide | Extremely high wear resistance; lasts longer; reduces downtime. | Works best for long production runs and tough packaging materials. |

| स्टेनलेस स्टील | Contains chromium for corrosion resistance; several types for different needs. | Ideal for food packaging and places where blades need washing. |

| उच्च कार्बन इस्पात | Retains sharpness well; not corrosion resistant; harder but can be brittle. | Used in dry environments for durable cutting and scoring. |

| चीनी मिट्टी | Stays sharp; highly wear resistant; brittle if dropped or hit. | Good for harsh environments; needs protection from impacts. |

| डी2 स्टील | High chromium and carbon; resists wear and corrosion; balanced hardness. | Popular for packaging perforating knives needing durability and corrosion resistance. |

| एम2 स्टील | Excellent wear resistance; withstands higher temperatures. | Used where heat and wear resistance are important. |

Picking the best blade material helps knives work better and last longer. Stainless steel and D2 steel are favorites for food and medicine packaging. They do not rust and can handle lots of use.

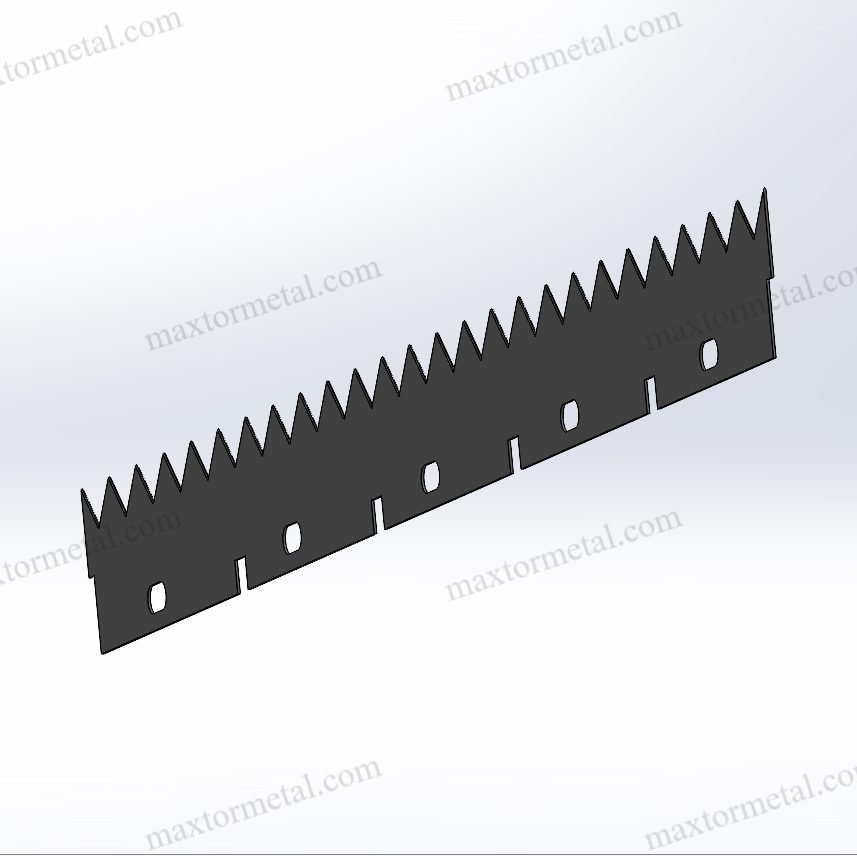

Shapes & Configurations

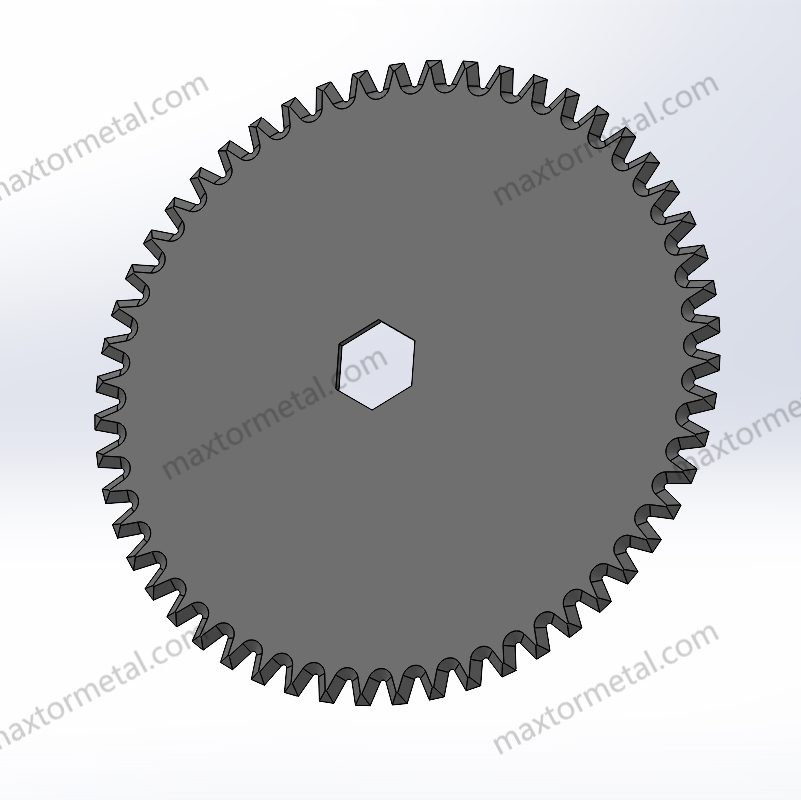

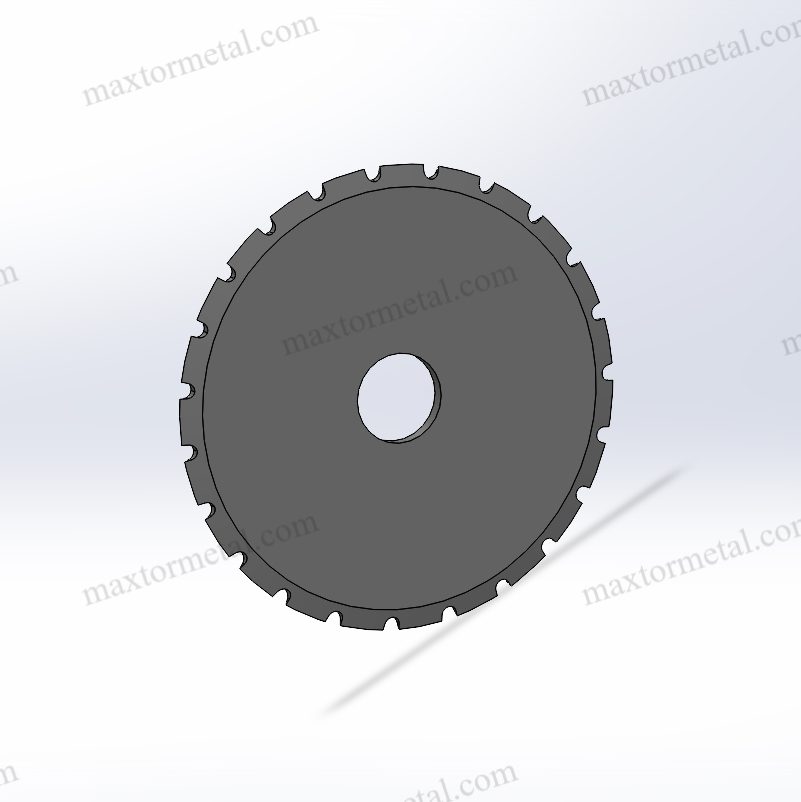

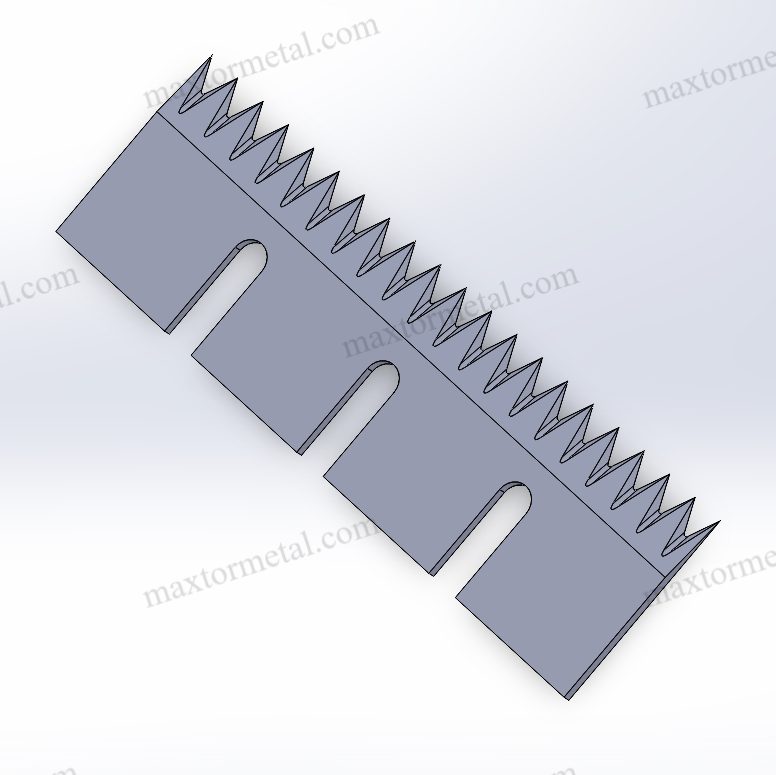

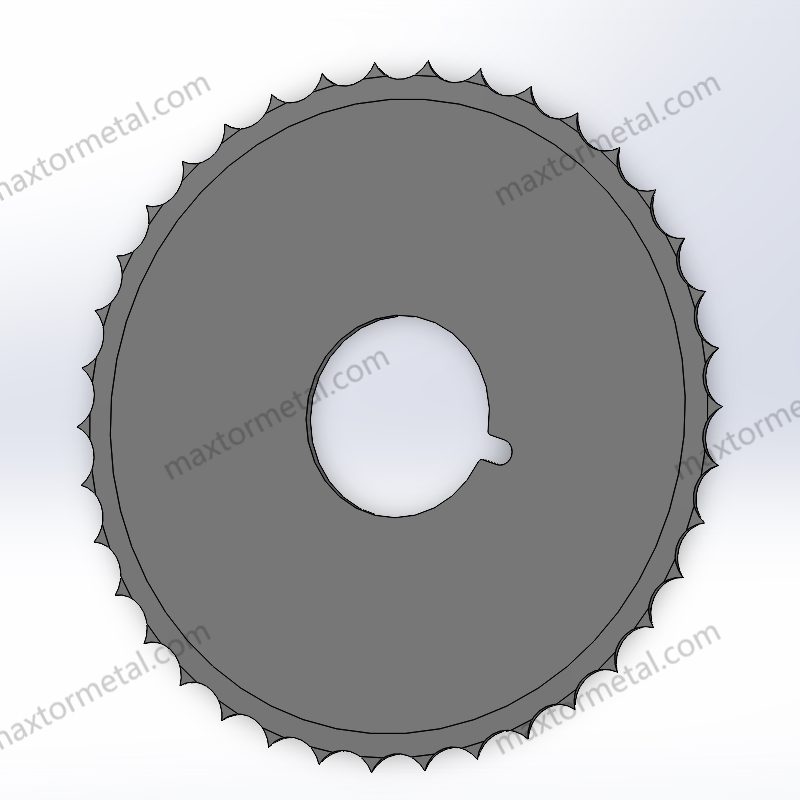

Packaging perforating knives come in many shapes and setups. Each shape helps the knife do a special job. Straight blades make straight cuts. Rotary blades spin to make lines of holes in long rolls. Toothed blades have jagged edges for easy tearing or cutting tough stuff.

- Guillotine blades cut across the whole package.

- Cutoff blades slice through in one quick move.

- Circular blades cut along rolls and sheets.

- Slitter blades split packaging into strips.

- Tray sealing knives seal and make holes in food and medicine trays.

Tooth shapes matter too. Engineers make blades with different tooth patterns like high-low teeth, v-shapes, scalloped, or peg styles. These designs help machines cut faster and more neatly. Special tooth shapes make knives work better for each kind of packaging.

अनुकूलन विकल्प

Sometimes, companies need special knives for tricky jobs. Custom knives fit the machine and the packaging just right. Companies can pick the blade shape, tooth pattern, cut-and-tie length, and blade size. The table below shows some common ways to customize:

| अनुकूलन पहलू | Options / Details |

|---|---|

| ब्लेड डिजाइन | Circular blades, cutoff blades, guillotine blades |

| Tooth Configurations | Alternating high-low v-style, standard v-style, variable depth v-style, scalloped, peg style, slant tooth |

| Cut and Tie Measurements | Adjustable distances between cuts and uncut ties |

| ब्लेड सामग्री | 52100 steel, stainless steel, ceramic, solid carbide |

| Edge Styles & Tooth Geometry | Customizable for cutting, scoring, and perforation |

| Blade Sizes | Custom sizes for different machines and packaging needs |

| उद्योग अनुप्रयोग | Corrugated boxes, bubble wrap, food wraps, medicine packaging, plastic bottle caps |

| Engineering Support | Expert design and manufacturing help for industry requirements |

Custom knives help factories cut better, faster, and safer.

Tip: Custom packaging perforating knives help companies fix special packaging problems and get better results.

Perforated Industrial Machine Knives

औद्योगिक उपयोग

Perforated industrial machine knives are used in many industries. These knives help make products safer and easier to use. Factories use them to make easy-tear edges on paper items. You see these edges on checkbooks, labels, bills, calendars, stamps, and notebooks. Paper towels and toilet tissue also have these tear lines. People can pull off one sheet without scissors or folding. Factories also use these knives to make holes in plastic wraps and steam bags. The holes let air move and keep fruits and veggies fresh. Steam can escape during cooking, so food is safer and tastes better. Garbage bags use perforated lines so you can tear off one bag at a time. Air fresheners use these knives to control how much scent comes out. This makes the smell last longer.

Note: Perforated industrial machine knives help make everyday products more helpful and easy for everyone.

बहुमुखी प्रतिभा

Perforated industrial blades can be used in many ways. Companies can change the tooth shape, blade material, or cut-and-tie length for each job. These blades work in packaging, paper, food, metal, plastic, and other goods. They help make easy-tear packaging like bubble wrap and food wrap. They also add safety to bottle caps and medicine packs. In produce and steam bags, these blades make vents to keep food fresh. Manufacturers can pick different blade designs, like circular or cutoff blades. Tooth styles such as high-low v-style, scalloped, or peg style help the blades work better. The blade material is important too. Choices include 52100 steel, solid carbide, stainless steel, ceramic, D2, M2, and CPM-10V steel. Each material has its own good points, like being strong, not rusting, or staying sharp.

The table below shows how these blades fit different jobs:

| उद्योग | Common Application | Blade Feature Example |

|---|---|---|

| पैकेजिंग | Easy-tear lines, air vents | Scalloped or v-style teeth |

| कागज उत्पाद | Tear-off sheets | Straight or peg style |

| या खाद्य उद्योग | Steam bag vents, portion packs | Stainless steel, circular |

| Consumer Goods | Garbage bags, air fresheners | Custom cut-and-tie lengths |

Perforated industrial machine knives help factories solve many cutting and perforating problems. Their ability to work for many jobs makes them very important in today’s factories.

सही चाकू का चयन करना

चयन कारक

Picking the right packaging perforating knife helps factories make neat cuts and safe packages. Many things matter when choosing a knife. Each thing changes how well the knife works for each job.

| कारक | विवरण | Application Examples |

|---|---|---|

| सामग्री संगतता | The type of material, like paper or plastic, affects which blade to use. | Paper, plastic films, metal sheets |

| काटने की गति | Fast cutting needs blades that can handle heat, like M2 steel. | Industrial wraps, high-volume production |

| Desired Perforation | The depth, width, and space between holes must fit the product. | Food packaging, medical packaging |

| दाँत प्रोफ़ाइल | Different tooth shapes change how the knife cuts and how long it lasts. | Soft materials, multi-layer packaging, tough surfaces |

| ब्लेड सामग्री | How hard, rust-proof, or heat-proof the blade is changes how long it works. | Stainless steel for rust, tungsten carbide for tough jobs |

| रखरखाव | Keeping blades sharp and clean helps them last longer. | Sharpening every 1-2 months |

| अनुकूलन | Special blade designs help with tricky jobs, like eco-friendly packaging. | Biodegradable materials, smart packaging |

Factories should pick a knife that matches the packaging material. Paper needs a different blade than plastic. The tooth shape changes how the knife cuts and how long it stays sharp. Hi-low V blades make machines work less and cut better. Thin blades with small tips cut sharp but wear out faster. Blade experts help pick the best tooth size for each job. The blade material is important too. Stainless steel does not rust. Ceramic blades stay sharp for a long time. Factories need to think about how much they use the knife and where it works. Custom blades help fix special packaging problems and make better results.

Tip: Always ask blade experts for help picking the best tooth shape and blade material for your packaging perforating knife.

Working with Suppliers

Working with good suppliers gives factories better packaging perforating knives. Factories do better when they talk clearly and trust their suppliers.

- Tell the supplier what you need, like the material and job details. This helps them pick the right knife.

- Pick suppliers with good reviews and lots of experience. Good service helps you in the long run.

- Choose knife materials that fit your packaging. High-speed steel, carbon steel, and carbide last longer and cut better.

- Check how the knives are made. New machines and careful checks make better knives.

- Ask for custom knives if regular ones do not work. Tell the supplier what you need for special jobs.

- Trusted suppliers, like Maxtor Metal, check quality at every step. They use laser tools and heat to make strong, exact knives.

- Custom perforated knives help factories work faster, make products look better, and keep workers safe. They last longer and save money.

Note: Working well with your supplier helps you get the best packaging perforating knife for every job.

Factories that work closely with suppliers can fix cutting problems, make better packages, and keep things running smoothly. The right knife and a good supplier help factories do a better job and make customers happy.

Packaging perforating knives are very important in packaging today. They help factories finish work faster and cut things exactly. These knives make it simple to open packages. They can be used for many different products. This makes things better for people who buy them. Maxtor Metal is a trusted company for good perforating blades. As packaging gets better, these knives will help make new and improved packages.

सामान्य प्रश्न

What are packaging perforating knives?

Packaging perforating knives are special blades. They make small holes or slits in packaging. These knives help add easy-tear lines and air vents. They also help show if someone opened the package.

Why do manufacturers use packaging perforating knives?

Manufacturers use these knives to make work faster. They help cut down on waste. Packages are easier to open with these knives. They also help keep products safe and fresh.

Can packaging perforating knives work on different materials?

Yes. These knives can cut paper, plastic, and cardboard. They also work on film and foil. Companies pick the right blade for each package.

How do packaging perforating knives improve user experience?

These knives make packages easy to open. People can tear packages quickly and safely. They do not need scissors or other tools. This makes packaging better for everyone.

What is the difference between micro-perforation and macro-perforation?

Micro-perforation makes tiny holes for air and moisture. Macro-perforation makes bigger holes or slits for tearing. Both types help packages work better.

यह भी देखें

अपने छिद्रित चाकू से सर्वश्रेष्ठ प्रदर्शन कैसे प्राप्त करें

अपनी सामग्री के लिए सही छिद्रक चाकू कैसे चुनें

छिद्रण ब्लेड क्या हैं और उनका उपयोग कैसे किया जाता है

छिद्रित औद्योगिक ब्लेड: पैकेजिंग और उससे परे सटीक कटाई की कुंजी

छेदने वाले ब्लेड चाकू में असमान छेद और असंगत रेखा की लंबाई का निवारण और अनुकूलन

2 प्रतिक्रियाएं

Hi there I am so thrilled I found your blog page, I really found you by mistake, while I was searching on Yahoo for

something else, Regardless I am here now and would just like to say

many thanks for a incredible post and a all round thrilling

blog (I also love the theme/design), I don’t have time to browse it all at

the moment but I have bookmarked it and also added your RSS feeds,

so when I have time I will be back to read a lot more, Please do keep up the excellent b.

Thanks. That means we’re meant to meet.