Many workers notice their blades chip, get dull, or break when used a lot. Picking the right Bahan Bilah Lingkar can stop these issues. Bimetal (laminated steel) blades are special because they mix hardness for sharp cuts and toughness to stop damage. This mix helps users get better results, longer blade life, and more value from each blade.

Poin-poin Utama

- Bimetal blades have a hard edge and a strong back. This makes them last longer and not break easily. They do not chip or snap quickly.

- You should pick the right blade for your job. Bimetal blades are good for many tasks. They are sharp and also strong.

- Bimetal blades last longer than other blades. They help you save money because you change them less. You also spend less time fixing them than HSS, carbide, or ceramic blades.

- Clean and sharpen bimetal blades often to keep them safe. Most workers can do this with simple tools.

- Nanjing Metal makes special bimetal blades for different jobs. These blades help people get the best results and save money.

Key Properties of Circular Blade Materials

Hardness and Edge Retention

Hardness shows how well a blade can stay sharp. A hard blade can cut tough things and does not get dull fast. Tests like the CATRA test prove that more hardness means better edge holding. When the Rockwell hardness (HRC) goes up, the blade can cut more before it gets dull. Each HRC point can let a blade cut up to 15.8 mm more cardstock in these tests. So, harder circular blade materials often last longer before they need sharpening.

But just being hard is not always best. Some very hard steels, like high carbide steels, can chip or break if they get hit. They might do well in tests but can fail when used for real jobs with bumps and side pressure. Studies show that blades with both hardness and toughness, like Nitro-V steel, keep their edge better when cutting for real. The CATRA test checks how well a blade resists wear, but real use also needs the blade to avoid chipping and rolling.

Here is a table with common circular blade materials and their hardness:

| Bahan Pisau | Typical Rockwell Hardness (HRC) | Catatan |

|---|---|---|

| Bi-metal (laminated steel) | 64 – 66 (tooth hardness 66-68) | Vacuum heat treated blades |

| Cr12MoV | Tinggi | High wear resistance and toughness |

| D2 | Tinggi | Good for abrasive materials |

| M2 | Tinggi | Retains hardness at high temperatures |

Tip: Hardness helps a blade stay sharp, but the best blades also need toughness to avoid chipping.

Toughness and Flexibility

Toughness means a blade can take hits and not break or chip. Flexible blades can bend a little and not crack, which helps when cutting hard or bumpy things. Toughness and flexibility help blades last longer and handle accidents.

If a blade is too hard, it might crack or chip if it hits something hard. If it is too soft, it will wear out fast. The best circular blade materials have both hardness and toughness. For example, bimetal blades have a hard edge and a tough, bendy back. This lets the blade cut well and not break from hits or bends.

What you cut also matters for blade life. Softer things, like mild steel, are easier to cut and do not wear the blade as much. Harder things need blades with more toughness to stop damage. Studies show that a blade’s base can help lower shaking and noise when cutting. Better base design can make sawing over 50% better and help blades last longer.

Here is a table that compares popular circular blade materials:

| Bahan | Key Properties Affecting Performance | Keuntungan |

|---|---|---|

| Cr12MoV | High wear resistance, toughness, hardness | Good for high-speed cutting, reduces cracking |

| D2 | High wear resistance, hardness, stability | Maintains precision, good for abrasive materials |

| M2 | Wear resistance, toughness, heat resistance | Ideal for high-speed cutting, keeps hardness |

Nanjing Metal is a trusted circular blade materials manufacturer with over 20 years of experience making custom industrial blades. Their team designs blades that balance hardness and toughness for many jobs. Customers can ask for Pisau Kustom to fit their needs, so they get the right mix of strength and performance.

Note: Picking the right hardness and toughness for what you cut helps stop cracks and fast wear. This balance gives cleaner cuts and makes blades last longer.

Types of Circular Blade Materials

Circular blade materials come in a few main types. Each type has special features for different cutting jobs. Picking the right material helps blades work better and last longer. It also saves money on repairs. The main types are High-Speed Steel (HSS), Carbide, Ceramic, and Bimetal (Laminated Steel).

| Bahan | Defining Characteristics | Suitability and Notes |

|---|---|---|

| Baja Berkecepatan Tinggi | Cost-effective; flexible; retains edge at high speeds; easy to sharpen | Good for general use; wears faster than carbide |

| Karbit | Highly durable; retains sharpness longer; ideal for hard materials; fast cutting | More expensive; brittle and heat sensitive |

| Keramik | Extremely hard; corrosion resistant; lightweight; keeps sharpness | Best for soft or abrasive materials; brittle |

| Bimetal | Combines hard HSS edge with tough spring steel backing | Best balance of hardness and toughness; versatile |

Baja Kecepatan Tinggi (HSS)

High-Speed Steel blades are popular because they are tough and not too expensive. HSS blades use alloys like M2, M35, and M42. These alloys have tungsten, molybdenum, vanadium, and cobalt. These elements help the blade stay hard even when it gets hot.

| Nilai | Carbon (C) % | Tungsten (W) % | Vanadium (V) % | Molybdenum (Mo) % | Chromium (Cr) % | Cobalt (Co) % |

|---|---|---|---|---|---|---|

| M2 | 0.83-0.88 | 5.6-6.0 | 1.75-1.95 | 4.6-5.0 | 3.8-4.4 | Tidak tersedia |

| M35 | 0.83-0.88 | 5.6-6.0 | 1.75-1.95 | 4.6-5.0 | 3.8-4.4 | 4.6-4.8 |

| M42 | 0.9-1.0 | 5.6-6.0 | 1.75-2.25 | 4.6-5.0 | 3.8-4.4 | 1.8-2.0 |

HSS blades can cut fast, over 60 meters each minute. They keep their edge even when very hot, above 600°C. These blades are easy to sharpen and cost less than carbide blades. People use HSS blades for cutting steel tubes, shapes, and sticky things. Special coatings like Titanium Nitride (TiN) or Titanium Aluminium Nitride (TiAlN) help the blade last longer and cut faster.

Key Features of HSS Blades:

- Good for most cutting jobs

- Easy to sharpen again

- Lower price at first

- Needs sharpening more often than carbide

HSS blades are a smart pick for people who want good value and performance.

Karbit

Carbide blades are known for being very hard and staying sharp a long time. These blades have tips made from tungsten carbide or titanium carbide. This lets them cut tough and rough things easily. Carbide blades keep their edge much longer than HSS blades. They also work well at high speeds.

Advantages of Carbide Blades:

- Very hard and resist wearing out

- Great for fast, careful cutting

- Can handle heat above 1100°C

- Do not need sharpening as often

Kekurangan:

- Cost more to buy

- Can break if dropped or hit

- Need special tools to sharpen

Carbide blades are best for big jobs in car, plane, and furniture factories. They are great for cutting hard wood, metals, and mixed materials. In factories, carbide blades can last up to 20 times longer than bimetal blades. This makes them a top choice for hard work.

Keramik

Ceramic blades have special uses for some jobs. They are made from things like zirconia, silicon carbide, or alumina. Ceramic blades are very hard and do not rust. They stay sharp longer than metal blades and do not rust, so they are good for wet or sour places.

| Milik | Bilah Keramik | Pisau Baja |

|---|---|---|

| Kekerasan | Very hard (8.2 on Mohs scale) | Generally softer |

| Kerapuhan | High (prone to chipping) | Low (more flexible) |

| Daya tahan | Hard but brittle | Tough and flexible |

| Tahan Benturan | Rendah | Tinggi |

| Kasus Penggunaan Terbaik | Precision cutting of soft materials | Heavy-duty cutting tasks |

Ceramic blades are light, so machines do not wear out as fast. They use less energy too. These blades work well in food, electronics, and medical jobs. But ceramic blades can chip or break if used on hard or frozen things. People should use them carefully and not for heavy work.

Tip: Use ceramic blades for soft things and careful cuts, not for hard or frozen items.

Bimetal (Laminated Steel)

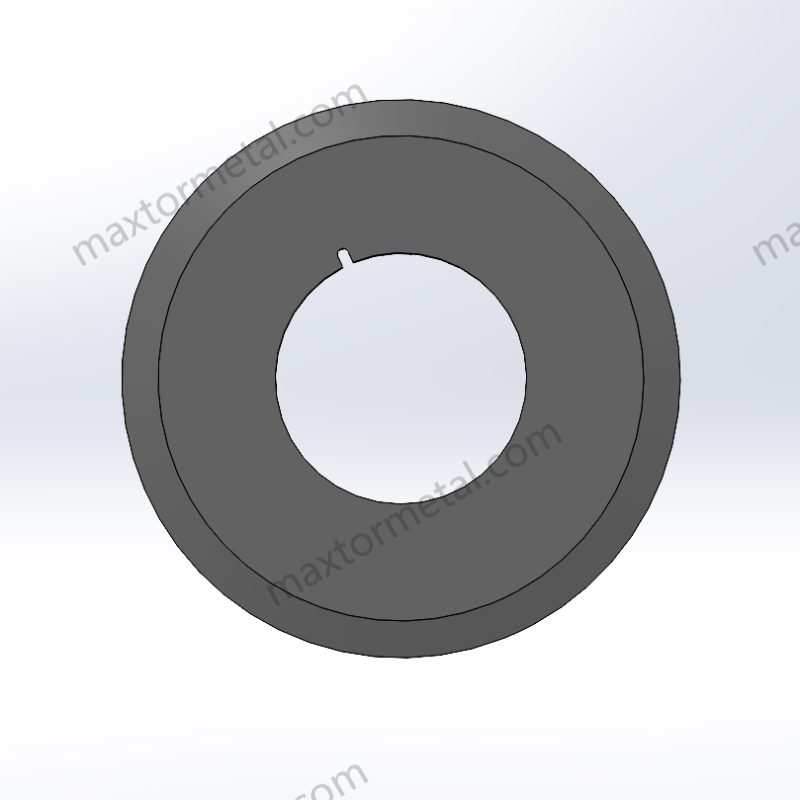

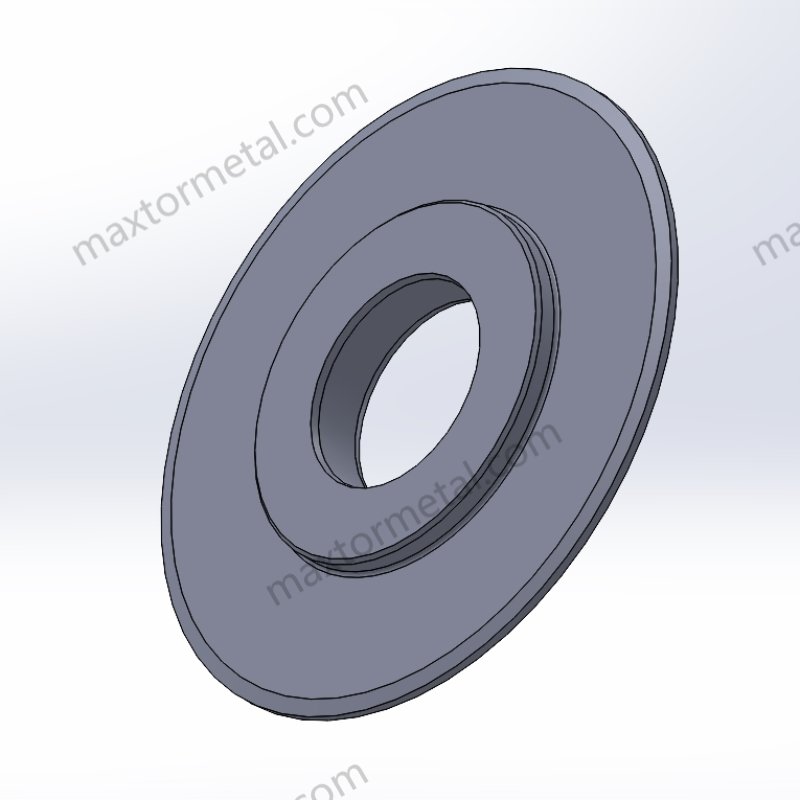

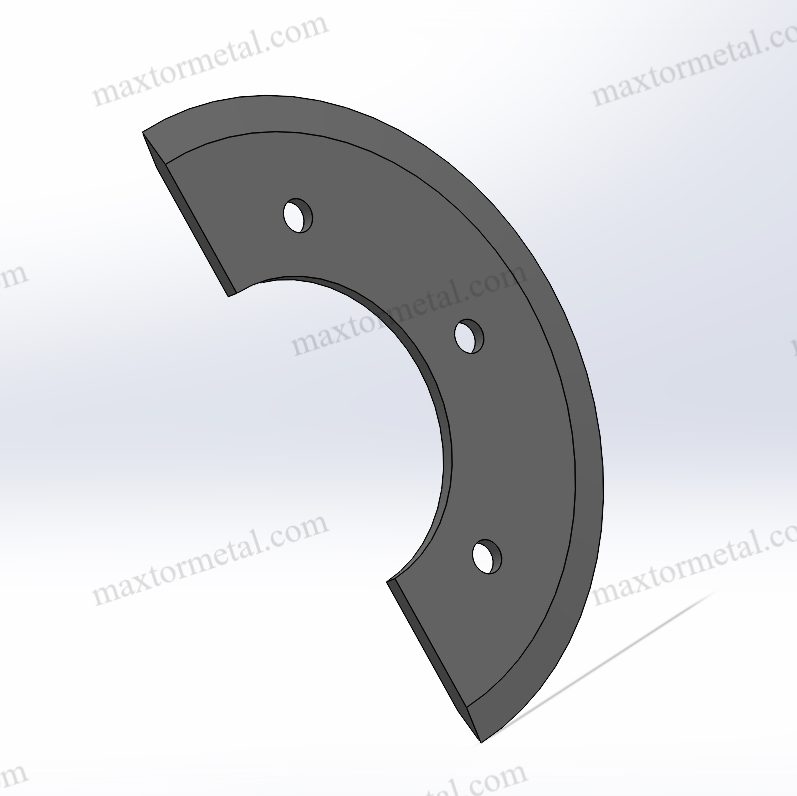

Bimetal blades mix the best parts of two metals. The edge is hard and made from High-Speed Steel (HSS). The back is tough and bendy, made from spring steel. Makers join these metals with electron beam welding, which makes a strong blade.

How Bimetal Blades Are Made:

- Makers pick a bendy spring steel for the blade’s body.

- High-Speed Steel is used for the teeth, making them hard and sharp.

- The two metals are welded together, so the blade does not break or bend easily.

- Some blades add cobalt or carbide to the teeth for better heat resistance and cutting.

This way, bimetal blades get both hardness and toughness. The hard HSS edge stays sharp and cuts well. The spring steel back lets the blade bend without breaking. Bimetal blades cut faster and last longer than many other blades. They also handle shaking well, so cuts are smoother and more exact.

Advantages of Bimetal Blades:

- Last longer and cost less to replace

- Make clean cuts with less shaking

- Can cut steel, aluminum, plastic, and more

- Safer and easier for workers

Performance Comparison

Efisiensi Pemotongan

Cutting efficiency means how fast and smooth a blade cuts. The blade material, its hardness, and the edge shape all matter. In factories, workers want blades that cut quickly and last longer. The table below shows how bimetal, HSS, carbide, and ceramic blades compare in tests.

Comparative Cutting Speed Data

| Bahan Pisau | Kekerasan (HRC) | Kasus Penggunaan Ideal | Typical Bevel Angle (°) | Cutting Force Index | Lifespan (days)* |

|---|---|---|---|---|---|

| Bimetal | Tidak tersedia | Increased blade life, maintenance reduction | ~30 (bevel) | Sedang | 3× longer life |

| Baja Kecepatan Tinggi (HSS) | 60–64 | Kertas, kayu, plastik | 16–25 | Sedang | 5–7 |

| Karbit | 75–85 | Metal, karet, komposit | 26–35 | Tinggi | 10–15 |

| Keramik | 80–90 | Foil, mikrofilm, optik | 10–15 (ultra-thin) | Rendah | 2–3 |

*Based on 8-hour daily industrial operation

Carbide blades are the hardest and cut tough things fast. They last the longest but need more force to use. Ceramic blades are very sharp and work well on thin, soft things. But they break easily and do not last long. HSS blades are good for softer things and are easy to sharpen. Bimetal blades give a good mix of long life and less fixing.

Catatan: The best cutting comes from using the right blade for the job. For big jobs, carbide blades are picked for their long life. For jobs with lots of bumps or shaking, bimetal blades are better because they do not chip or break as much.

Durability and Blade Life

Durability is how long a blade lasts before you need a new one. Blade life depends on what it is made of, how much it is used, and what it cuts. In plastic recycling, workers often see blades chip, get dull, or break.

User Feedback from the Plastic Recycling Industry

- Bimetal blades do not chip or break easily. Workers say these blades last up to twice as long as some regular blades when cutting hard things like particle board or plastics.

- Carbide blades can last up to 50 times longer than bimetal blades in some jobs. But they can chip or break if they hit something hard or get dropped.

- HSS blades are easy to sharpen and cost less, but they wear out faster and need to be replaced more often.

- Ceramic blades stay sharp for a short time but break easily. Workers say they chip or break a lot, especially in tough jobs.

Many workers in recycling plants like bimetal blades for their toughness and long life. These blades handle bumps and shaking better than carbide or ceramic blades. Workers say bimetal blades help them work longer and save money on new blades.

Bimetal blades with M42 cobalt steel teeth and alloy steel backs break less and last longer in tough jobs. Workers see less chipping and dulling than with other blades.

Maintenance and Resharpening

Keeping blades sharp and in good shape is important for safe and easy cutting. Each blade type needs different care and sharpening.

Practical Maintenance and Resharpening Analysis

- Bimetal Blades: Need regular cleaning and sharpening to stay sharp. Most workers can sharpen them with normal machines. The tough back helps stop breaking during sharpening.

- HSS Blades: Easy to sharpen with simple tools. Workers must keep the tooth shape and angle right. HSS blades may need new teeth after many sharpenings.

- Pisau Karbida: Need special diamond tools or machines to sharpen. Only trained workers should sharpen these blades. Carbide blades need less sharpening but are harder to fix if broken.

- Pisau Keramik: Hard to sharpen. Most people replace them when dull or chipped. These blades need careful handling to stop breaking.

Steps for Blade Maintenance:

- Clean the blade with the right cleaner to remove dirt.

- Hold the blade in a vise with pads to protect it.

- Match the tooth angle using a guide.

- Sharpen each tooth with the correct tool.

- Check the blade balance and remove rough spots.

- Wear safety gear while sharpening.

- Use electric machines for lots of sharpening.

- Follow the maker’s instructions for best results.

Cleaning, sharpening, and following safety steps help blades last longer and cut better.

High-Impact Environment Performance Table

The table below shows how each blade type works in tough jobs like recycling or metal cutting.

| Bahan Pisau | Resistance to Chipping | Resistance to Breakage | Retensi Tepi |

|---|---|---|---|

| Bimetal | Tinggi | Tinggi | Tinggi |

| HSS | Sedang | Sedang | Sedang |

| Karbit | Sedang | Medium-Low | Sangat Tinggi |

| Keramik | Rendah | Rendah | Tinggi |

Bimetal blades do best in tough jobs. They do not chip or break as much as other blades. Carbide blades keep their edge the longest but can break if hit hard. Ceramic blades chip and break easily, so they are not good for heavy work.

In real jobs, bimetal blades give the best mix of toughness and sharpness for work with lots of bumps or shaking.

User Insights and Applications

Industry Use Cases

Bimetal circular blades are used in many industries because they are strong and useful. Companies that make furniture, cars, wood, and buildings use these blades every day. Workers use them to cut wood, plastic, glass, aluminum, and metal. These blades also work well for hard jobs like cutting titanium and nickel.

Industries like aluminum, wood, steel pipes, and metal tubes like these blades for being tough and exact. In paper and packaging, blades need to be both sharp and strong for jobs like cutting and trimming. Food factories need blades that do not rust and are safe for food. Stainless steel and ceramic blades are used for this, but bimetal blades are also a good choice when sharpness and strength are needed. Blade coatings and tooth shapes can be changed to fit each job.

Bimetal blades help companies make neat cuts and waste less material.

User Feedback and Testimonials

People who work with metal say bimetal blades last a long time and work well. Many say these blades last five to ten times longer than regular steel blades. Workers see smoother cuts and less waste, especially with high-speed steel bimetal blades. They also like that these blades can be sharpened many times, which saves money.

Some workers talk about the spring steel back and high-speed steel teeth. This lets the blade cut many kinds of metal, like carbon steel, stainless steel, aluminum, and titanium. Makers find that bimetal blades mean less stopping and lower costs for each cut. In woodworking, people like that these blades can cut old wood with nails without breaking.

“Bimetal blades give us straight, clean cuts and last much longer than plain steel blades,” one user said online.

Bimetal blades are special because they mix hardness and toughness. This helps blades last longer and means less stopping for changes. When you compare bimetal to HSS, carbide, or ceramic blades, bimetal lasts longer and saves money over time. People say they do not have to change blades as much. It is also easier to take care of these blades. When picking a blade, think about where you work, what you cut, and what tools you use. Nanjing Metal is a trusted circular blade materials manufacturer and makes custom blades for many jobs. If you have a tough job, you can talk to a sales engineer Di Sini.

Tanya Jawab Umum

What makes bimetal blades different from other circular blades?

Bimetal blades have a hard edge for cutting and a strong, bendy back. This helps them stay sharp and not break easily. Many companies pick these blades because they last long and work well.

How do users maintain bimetal circular blades?

People should clean the blades after using them. They need to sharpen the blades when they get dull. Most workers can use normal sharpening tools. Taking care of blades helps them last longer and cut better.

Which industries use bimetal circular blades the most?

Industries like packaging, recycling, food, and metalworking use bimetal blades a lot. These blades are good for cutting paper, plastic, metal, and cloth.

Lihat Juga

Pisau Melingkar Industri: Perbandingan Kinerja dan Bahan

10 Tips Teratas agar Bilah Cukur Melingkar Anda Bertahan Lebih Lama

Cara Memilih Pisau Pemotong Bundar yang Tepat untuk Kinerja yang Tahan Lama

Cara Menjaga Pisau Bundar Anda Tetap Tajam dan Tahan Lama

Cara Memilih Bilah Bundar yang Tepat untuk Aplikasi Anda: Panduan Lengkap

5 Masalah Keausan Umum pada Pisau Gunting Bundar dan Solusi Perbaikan Ahli