Pisau Karton Bergelombang design has a big effect on how much packaging companies can make. Good cutting tools help make better cuts, work faster, and save money. The table below shows important numbers that explain how new cutting tools help:

| Metrik | Keterangan | Dampak |

|---|---|---|

| Overall Equipment Effectiveness (OEE) | Measured over 12 shifts for an auto corrugation machine, with values ranging from 62% to 78% | Shows how machine time, speed, and quality get better after changing the knife design |

| Downtime Causes | Includes item change process loss, scheduled maintenance, machine breakdown, paper torn, and breaks | Points out main reasons for lost time, so companies know what to fix |

| Kaizen Cost Savings | Reduction in printing travel card pages from 2 to 1 page, saving approximately $174 annually | Shows how fixing machines and steps can save money |

| Quality Improvements | Reduction of defects and rough edges, leading to smoother cuts and higher customer satisfaction | Makes products better and means less fixing is needed |

Nanjing Metal is a trusted company that makes corrugated knives. They have made blades for 20 years. They create special blades for cutting paper, cardboard, and packaging. Their slotter blades from Maxtor Metal cut very cleanly. These blades help factories work faster and need less fixing. The corrugated sample cutter market is worth USD 150 million in 2024. It keeps growing because new machines cut faster and waste less paper. Modern slotter blades help make boxes all the time. They keep cardboard strong and help companies meet tough quality rules.

Poin-poin Utama

- A good corrugated knife design helps factories cut faster and better. It also means less time when machines stop working.

- Picking the best blade material, like high-speed steel or tungsten carbide, helps blades last longer. These materials also help blades cut better.

- Blade shapes like corrugated edges and serrated patterns help cut different cardboard. They also keep the cardboard safe from damage.

- Heat treatment makes blades stronger. This keeps them sharp and tough for a long time.

- Sharp and well-kept blades make less waste. This saves money and helps the environment.

- Custom blades from skilled makers like Nanjing Metal fit many machines. They also help cutting work better.

- Taking care of blades by cleaning and sharpening them helps them last longer. This also keeps the factory working well.

- New cutting tools help factories make stronger and neater boxes faster. They also help save money and stop machines from breaking down.

Corrugated Knife Basics

What Is a Corrugated Knife

A corrugated knife is a special tool for cutting cardboard. It has a special edge that helps it cut through thick paper and cardboard. Factories use this blade to make neat lines and shapes in packaging. The blade needs to stay sharp to cut tough cardboard fibers. Workers in factories use the corrugated knife to keep things running well. The right blade helps cut faster and makes better cuts.

Role in Packaging

Packaging companies use the corrugated knife for many jobs. Workers cut, score, and shape cardboard sheets with this blade. The blade must cut thin and thick cardboard. Good blades help save material and keep boxes strong. Clean cuts mean smooth edges on the cardboard. This keeps items inside safe. The corrugated knife also makes folding lines for easy box assembly. Every cut is important in making packaging. A sharp blade helps each piece fit just right.

Tip: Picking the right blade for each kind of cardboard and paper can make packaging better and help machines work longer.

Slotter Blades Overview

Slotter blades are important in making corrugated packaging. These blades, also called slotting knives, cut slots and lines in cardboard. Slotter blades must be fast and accurate for quick machines.

Fitur Desain

The way a corrugated knife is made is very important for factories. Every part, like the blade’s material, shape, and how it is heated, changes how well it cuts and how long it lasts. These things also affect how good the cardboard packaging looks in the end.

Bahan Pisau

Picking the best blade material helps the knife cut better and last longer. Each material has its own good points for cutting cardboard and paper.

| Bahan Pisau | Keuntungan | Kekurangan |

|---|---|---|

| Baja Kecepatan Tinggi (HSS) | Durable, excellent edge retention | Lebih mahal |

| Baja Karbon | Excellent edge retention, sharp edge achievable | Prone to rust, requires regular maintenance |

| Besi tahan karat | Ketahanan korosi yang baik | May not hold edge as well as carbon steel |

| Keramik | Excellent sharpness and edge retention | Fragile, prone to chipping and breaking |

| Titanium-Coated | Enhanced durability and corrosion resistance | Coating can wear off over time |

| Karbida Wolfram | Very durable, maintains sharpness for long time | Expensive, prone to chipping |

Perkakas Baja

Tool steel is a common choice for cutting blades in packaging. It is hard and tough, so it works well for fast cutting. Tool steel blades do not wear out quickly and keep their sharp edge. This helps factories make neat cuts and stop machines less often.

Baja Berkecepatan Tinggi

High-speed steel blades are even stronger and stay sharp longer. These blades are good for busy factories that cut a lot of cardboard. They do not need to be changed as often, so workers save time and money.

Geometri Bilah

The shape of a corrugated knife changes how it cuts cardboard and paper. The right shape makes smooth, clean cuts and keeps the packaging strong.

Corrugated Edge

A corrugated edge has a wavy line that matches the shape of corrugated cardboard. This shape stops the blade from shaking and makes the edges cleaner. It also keeps the cardboard from getting crushed. Corrugated edge blades are best for new and high-quality packaging. They help keep the edges smooth and the boxes looking nice. Factories use these blades to make boxes that pass tough tests.

Corrugated edge blades are best for making neat, strong boxes that need perfect cuts and strong sides.

Serration Patterns

Serration patterns have small teeth close together to help the blade cut better. These teeth move bits of cardboard away and stop the blade from getting stuck. Serrated blades are great for cutting recycled or thick cardboard. They work well when the cardboard has different layers or dirt inside. These blades also cut thick materials where it is hard to keep the blade clean.

- Serrated blades cut recycled and thick cardboard easily.

- The special teeth make cutting easier and protect the blade.

- Factories use these blades to cut tough materials quickly and neatly.

Perawatan panas

Heating the blade the right way is very important. It makes the blade hard, tough, and last longer. Nanjing Metal uses special heating steps to make sure every blade is strong and works well.

| Perawatan panas Teknologi | Key Features & Benefits | Impact on Blade Performance & Industry Standards |

|---|---|---|

| Perlakuan Panas Vakum | Prevents oxidation and decarburization; precise temperature control; energy efficient | Superior surface quality; maintains hardness and wear resistance; ideal for high-precision blades |

| Pemanasan Induksi Frekuensi Tinggi | Rapid, localized heating; selective hardening of edges; contamination-free; reduces cycle time; energy savings | Hardened edge with tough core; enhances cutting performance and impact resistance |

| Tindakan Pengendalian Mutu | Rockwell hardness testing; microstructural analysis; edge retention tests | Ensures blades meet or exceed industry benchmarks; guarantees durability and reliability |

| Sustainability Benefits | Lower energy consumption; reduced emissions; material efficiency | Aligns with sustainable manufacturing; positions Nanjing Metal as an eco-friendly leader |

Nanjing Metal uses vacuum heat treatment and high-frequency induction heating to make blades hard and tough. These steps stop the blade from rusting and keep the heat just right. They also make sure the edge stays sharp for a long time. The company checks each blade with special tests to make sure it works well every time.

Special heat treatment helps blades last longer, need less fixing, and is better for the planet.

Cutting of Corrugated Cardboard

Pemotongan Presisi

It is very important to cut corrugated cardboard accurately. Many things affect this, like the type and thickness of the cardboard. The cutting machine must be steady. The person using the machine needs skill. Good corrugated knives and slotter blades help make cuts that are exact. These blades stay sharp and do not wear out fast.

Some cutting machines use special motion control systems. Oscillating knife CNC cutters are one example. These machines pick the best tools and settings by themselves. Keeping machines clean and oiled helps them work well. This also keeps the cuts the same every time.

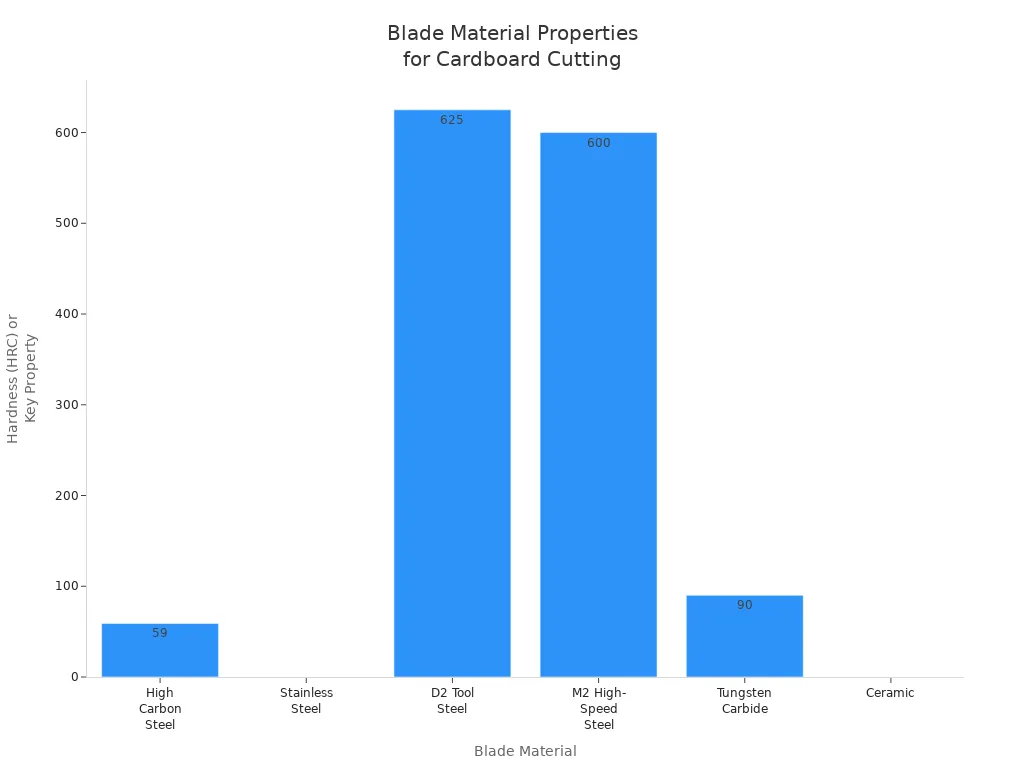

The blade material also matters for making good cuts. The table below shows how each material works when cutting corrugated cardboard:

| Bahan Pisau | Properti Utama | Application in Corrugated Cardboard Cutting |

|---|---|---|

| Baja Karbon Tinggi | Hardness 58-60 HRC; cost-effective but corrodes | Pemotongan serbaguna |

| Besi tahan karat | High corrosion resistance (90% under saline) | Food and medical packaging requiring rust resistance |

| Baja Perkakas D2 | High wear resistance (600-650 MPa under load) | Pemotongan volume tinggi di lingkungan abrasif |

| Baja Kecepatan Tinggi M2 | Retains sharpness up to 600°C | Pemotongan kecepatan tinggi untuk pembungkus industri |

| Karbida Wolfram | Very high hardness (up to 90 HRC), excellent wear resistance | Abrasive materials, extends blade life significantly |

| Keramik | Chemically inert, lightweight, brittle under impact | Precision cutting in delicate applications |

Tungsten carbide blades last much longer than high-carbon steel blades. They can last three times longer in tough cutting tests. This means better cuts and less time fixing machines.

Clean Cuts and Scoring

Good packaging needs clean cuts and straight scoring lines. Corrugated knives and slotter blades do this with sharp edges and special blade shapes. Some blades have coatings like Teflon. Teflon can make cutting easier by up to 80%. Zr-based coatings can lower friction by 51%. These coatings help blades stay sharp and make smoother cuts.

The table below shows what makes a blade cut well:

| Fitur | Pisau Berkualitas Tinggi | Pisau Standar |

|---|---|---|

| Kualitas Bahan | Engineered for sharpness and durability | Lower durability |

| Pemotongan Presisi | ±0,01 mm, limbah minimal | ±0,03 hingga ±0,05 mm, kurang presisi |

| Daya tahan | Hingga 300.000 potongan | 150.000 hingga 200.000 potongan |

The tip of the blade is important too. A lamella edge is thin and makes very clean cuts. A bevel edge is strong and good for tough jobs. Rounded and straight edges are not as exact but work for simple cuts. Changing how the blade is set and moved can make cuts better and safer.

- Lamella edge: Makes clean, even cuts.

- Bevel edge: Cuts tough stuff and stops mistakes.

- Rounded edge: Good for easy scoring jobs.

Slotter blades from Nanjing Metal use these designs. Their blades help factories waste less and make boxes look better.

Preserving Material Strength

It is important to keep corrugated cardboard strong when cutting. The right way to cut stops the board from getting crushed. Oscillating knife-cutting machines help keep the cardboard’s shape and strength. These machines also help make better box designs and stop damage.

Different perforation patterns help balance easy tearing and strength. Some examples are:

- Speedi Tear: Keeps boxes strong but easy to open.

- Cascade: Easy to tear but may change how the box looks.

- Zipper: Lets people open boxes fast, used in online shopping.

Special knives, like the 5/5 standard knife, are made for these patterns. The way the holes are made and the cutting method should not make the box weak. Crush cutting with a circular knife helps keep the board strong and makes neat cuts.

Packaging Applications

Corrugated Box Production

Making corrugated boxes needs careful cutting of cardboard and paper. Pisau slotter putar are very important for this job. These blades cut, slot, score, crease, and punch holes in cardboard sheets. This lets factories make boxes in the right shapes and sizes. Each blade shape, like straight, curved, or wavy, does a special job. Some make straight cuts, while others make round slots. High-speed rotary slotter machines move cardboard sheets through spinning shafts. This helps factories make lots of boxes that all look the same. The sharp blades make neat crease lines and slots. These lines help fold and put boxes together. Factories waste less material and make stronger boxes. Custom rotary slotter blades fit certain machines and packaging styles. They help factories work faster and stop less often. Keeping machines clean and changing blades on time keeps everything working well. This makes sure every box is good quality.

Specialty Packaging

Specialty packaging needs special shapes and features. Cutting cardboard for displays or fancy packaging must be very exact. Slotter blades with special angles and teeth stop damage to the cardboard’s flute. This keeps the box strong and looking nice. Factories use these blades to make packaging that looks good in stores and keeps products safe. Custom blades can cut different thicknesses and flute types. This means they work for many packaging styles. Nanjing Metal makes sure each blade is high quality and fits what the customer needs. Their blades help with easy folding, putting together, and even opening, like tear lines or holes.

Note: Custom slotter blades help specialty packaging by matching each project’s needs.

Internal Partitions and Inserts

Cardboard partitions and inserts protect things inside boxes. Factories use die-cut machines with many blades to make these parts. They cut out shapes, slots, and holes to fit each product. These inserts keep items away from the box walls and give them a cushion. This stops things from moving and getting broken. Using strong cardboard, like Kraft or white finishes, makes the inserts last longer and look better. Custom inserts are easy to put together without tools. This helps factories pack things quickly. Customers like how these cutting methods make packing fast and neat.

Efisiensi Pemotongan

Speed and Output

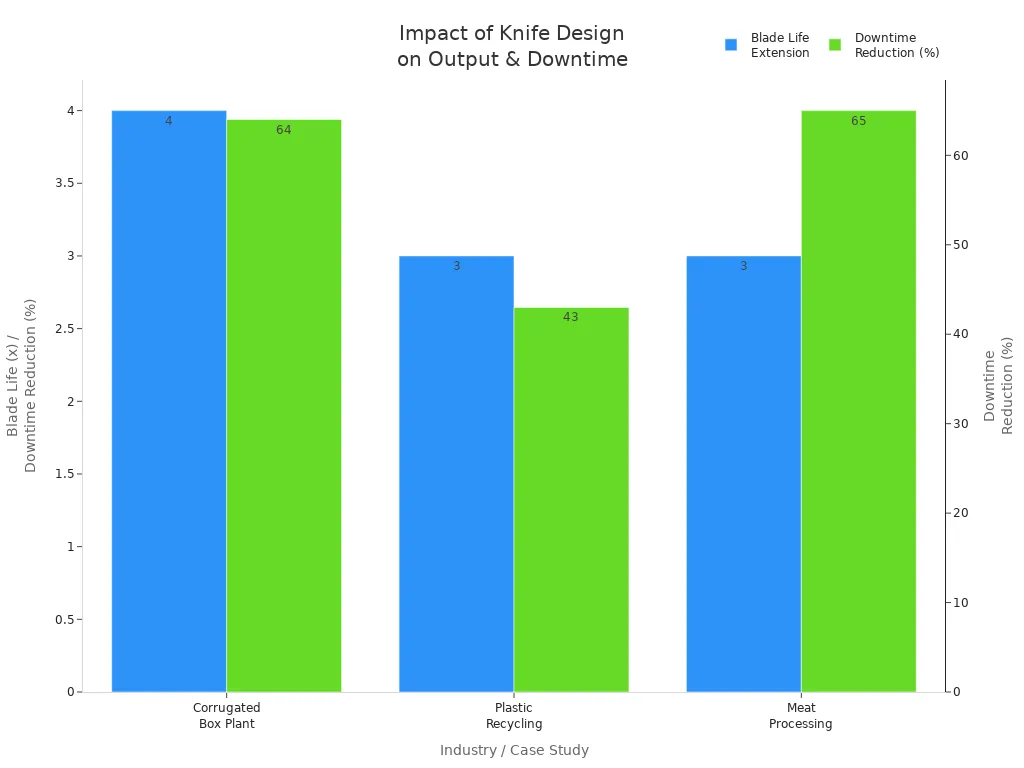

Corrugated knife design helps factories cut faster and work better. The wavy edge lets the blade move through cardboard with less push. This makes cutting and creasing easier and quicker. When factories use new cutting methods, they make more boxes in less time. For example, one box plant changed from regular slitter knives to custom micro-tooth blades. After the change, their downtime each month dropped from 14 hours to less than 5 hours. They also did not have to change blades as often. This gave them more time to cut boxes and less time fixing things.

| Jenis Pisau | Penggantian Bulanan | Waktu henti (jam) | Total Biaya Bulanan |

|---|---|---|---|

| Standard Slitter | 12 | 14 | Tinggi |

| Custom Micro-Tooth | 3 | 4 | Rendah |

The table shows how better cutting can help factories do more work. Good cutting methods let workers finish big jobs faster and with less effort.

Mengurangi Sampah

Cutting and creasing well does more than make things faster. It also helps factories waste less material. Clean cuts mean less cardboard gets ruined or thrown away. Factories using special slotter blades from Nanjing Metal see smoother edges and fewer mistakes. This means less scrap and better use of materials. Good cutting also keeps the cardboard strong, so boxes meet quality rules. Workers can trust these cutting ways to keep waste low and make more boxes.

Tip: Using the right cutting ways and sharp blades helps factories save money and care for the planet.

Lower Downtime

Less downtime is a big plus of new die-cutting systems. Custom blades made from tough materials like tungsten carbide or hardened steel last up to 50% longer than regular blades. This means workers do not have to change blades as much. Less time is spent fixing and cleaning. Cleaning, storing, and sharpening blades the right way makes them last even longer. Factories that check blades often can find problems early and stop sudden breakdowns.

Better corrugated knife design helps factories make more boxes. It also helps make boxes stronger and faster. Sharp, tough blades cut neatly and waste less material. Using strong materials like tungsten carbide makes blades last longer. Experts say to check how you cut now and try new blade materials. Keeping blades clean and sharp helps every cut stay the same.

1. Always check that cuts are neat and correct.

2. Pick strong blade materials and coatings for longer use.

3. Watch how fast you cut and how long blades last.

4. Clean and sharpen blades to keep them working well.

5. Buy good cutting tools to save money over time.

6. Learn about new cutting machines and tools.

Nanjing Metal makes custom blades for all kinds of cutting jobs. To find the right blade, see Pisau Kustom. If you need help, talk to a Nanjing Metal sales engineer Di Sini.

Tanya Jawab Umum

What is the main purpose of a corrugated knife in packaging?

A corrugated knife helps factories cut cardboard very accurately. This tool makes smooth edges and the right shapes. These things are important for strong and safe packaging.

How does blade material affect cutting performance?

The blade material changes how sharp and tough the blade is. High-speed steel and tungsten carbide last a long time. Factories pick the material based on the cardboard type and how fast they need to cut.

Why do factories use different blade geometries for cutting?

Factories use different blade shapes for special cutting jobs. Wavy edges help stop crushing the cardboard. Serrated blades work well for recycled or thick boards. Each shape helps with certain packaging needs.

What maintenance helps extend the life of cutting blades?

Cleaning blades, storing them right, and sharpening them on time helps them last longer. Factories also check blades for damage. Good care means less downtime and better cutting every time.

Are Nanjing Metal slotter blades compatible with most cutting machines?

Yes, Nanjing Metal makes slotter blades that fit many machines. Their blades meet industry rules and work for many packaging jobs. This makes it easy for factories to upgrade their cutting tools.

What are the benefits of using advanced cutting blades in manufacturing?

Advanced blades help factories cut faster and waste less. They also lower downtime and make better products.

Lihat Juga

Panduan Esensial untuk Bilah Slotter Rotary dalam Kemasan

Cara Memperpanjang Umur Pisau Pemotong Karton Anda: Tips & Trik Ahli

Pisau Slotter & Pisau Untuk Bergelombang

Apa itu Pisau Kemasan Bergelombang dan Aplikasi Industrinya

Meningkatkan Efisiensi dan Kualitas: Pilihan Penting Pisau dan Bilah Mesin Pengemas yang Tahan Lama

Tingkatkan Efisiensi Anda dengan Pemasangan dan Pengaturan Pisau Slotter Rotary yang Tepat

satu Respon

Your article helped me a lot, is there any more related content? Thanks!