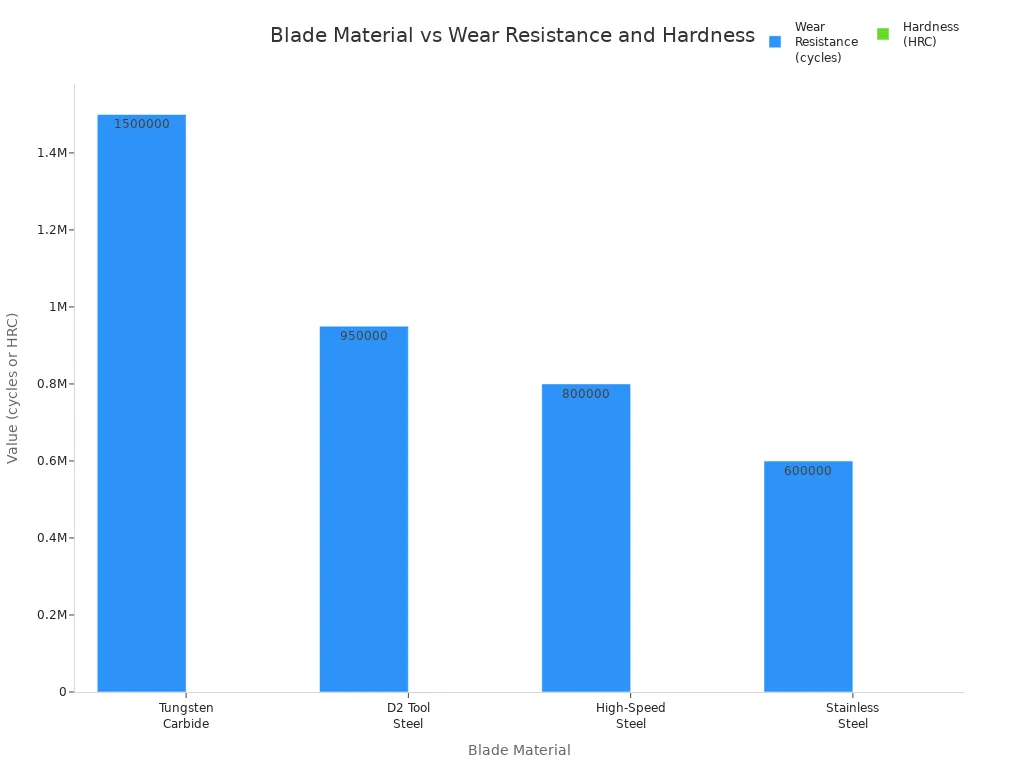

Choosing between custom and standard blades changes your recycling results. The right blade material helps machines work better. It can also save money and make machines last longer. For example, tungsten carbide blades last much longer than regular tool steels. They are great for hard metal shredding jobs. Look at the table below for a quick comparison:

| Bahan Pisau | Ketahanan Aus (siklus) | Kekerasan (HRC) | Kasus Penggunaan Terbaik |

|---|---|---|---|

| Karbida Wolfram | Highest (1,500,000) | Very High (72) | High-speed, high-volume plastic cutting and metal shredding |

| Baja Perkakas D2 | Moderate (950,000) | High (60-62) | Pemotongan serbaguna |

| Baja Berkecepatan Tinggi | Medium (800,000) | High (64) | Pemotongan presisi |

| Besi tahan karat | Lower (600,000) | Moderate (58-60) | Lingkungan korosif |

You get the best results when you pick the right blade. A custom plastic crusher blades manufacturer can help you choose. They will help you find the best blade for your shredding or recycling needs.

Poin-poin Utama

- Custom blades match your machine and plastic type better. They help your machine cut faster and make better cuts.

- Strong materials like tungsten carbide and special coatings help custom blades last longer. They can last up to four times longer than standard blades.

- Standard blades cost less money and are simple to change. But they wear out faster when cutting hard or mixed plastics.

- You need to pick the right blade for your plastic waste, machine, and how much you make.

- If you work with a pisau khusus manufacturer, you get expert help. You also get blades made just for you and better recycling results.

Blade Types Overview

Pisau Standar

Standard blades are used in many recycling machines. They come in set shapes and sizes. These blades work for many types of plastics and machines. Most are made from high-carbon steel or alloy steel. These materials make the blades tough and strong. There are different types of standard blades. Granulator blades are sharp and thin. They cut bottles and films into small pieces. Single-shaft and double-shaft shredder blades break up big things. They can shred pipes, furniture, and tires.

Standard blades are good for simple shredding jobs. You can put them in fast and change them easily. But they may not work well for special or hard plastic waste. Their designs and materials do not change much. This means they can wear out faster and cut less well with some plastics.

Tip: Standard blades cost less for normal recycling. But you might need to change them more if you cut hard or rough plastics.

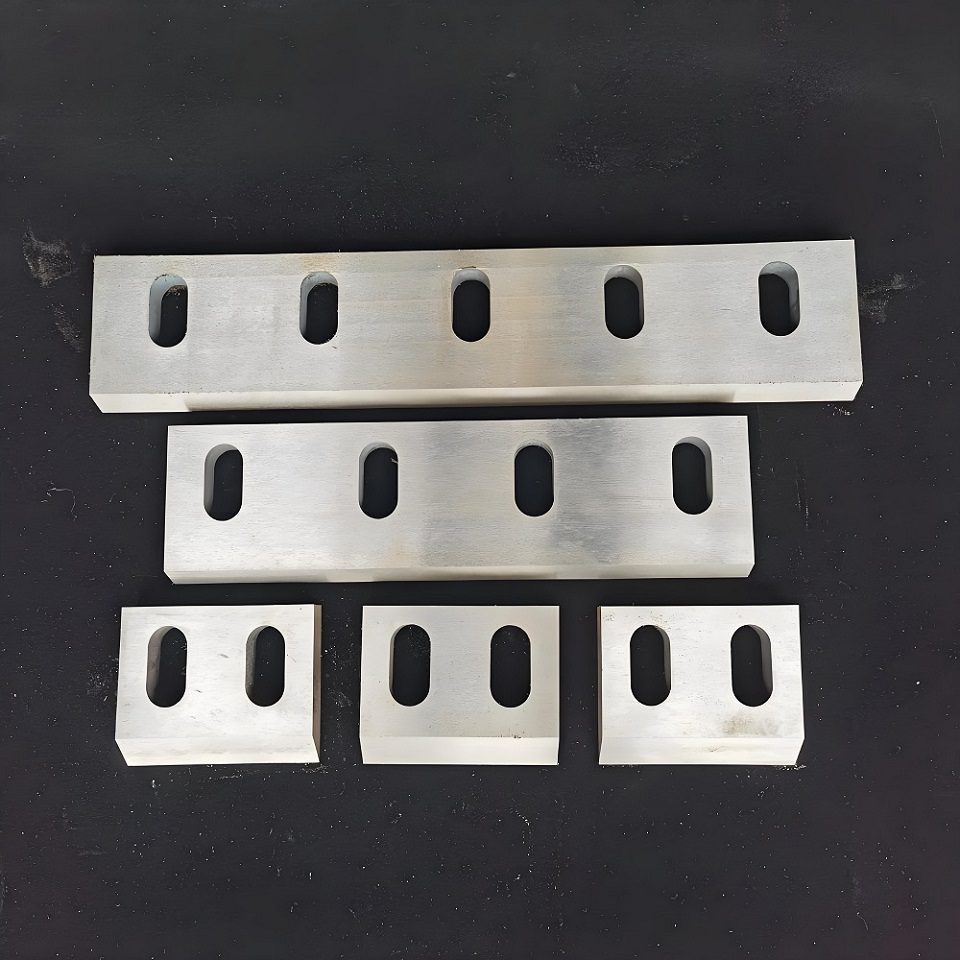

Custom Crusher Blades

Custom blades are made for your special recycling needs. When you pick custom crusher blades, you talk to experts. They help design the blade’s shape, size, tooth count, and material for your job. You can choose strong materials like high-speed steel, hard alloy, or carbide-tipped blades. These choices help the blades last longer and cut better. Custom blades can have special coatings. Some coatings are Titanium Nitride or Diamond-like Carbon. These coatings make the blades last even longer.

Custom blades help when you need to cut tough, mixed, or dirty plastics. The team can change the blade’s shape and hardness to fit your machine and plastic. This means less time fixing machines and lower costs. It also makes your output better. If you want to know more about custom crusher blades, visit the halaman bilah khusus.

- Custom blades work better with hard materials than standard blades.

- They last longer and give you even-sized pieces.

- Custom blades are made to fit your machines just right.

Applications in Plastic Recycling

Common Uses for Standard Blades

Standard blades are used in basic recycling jobs. They cut up bottles, containers, and films. You put them in granulators and shredders. These blades break plastic into small flakes. They work well with PET and HDPE plastics. You get steady results for most recycling tasks. Many places use standard blades for big jobs. The plastic type stays the same most of the time.

Standard blades help you save money. They are easy to take out and put in. You can change them fast when you have lots of plastic waste.

Standard blades fit many machines. You do not need to change your setup often. They help your recycling line run without stopping.

Custom Blades for Unique Waste

Custom blades help with hard or mixed plastic waste. They are made for special jobs. You can ask for blades for certain materials or shapes. Some blades have very sharp edges for cutting PVC pipes. Others are strong for cutting electronic waste plastics. Custom blades also help shred biodegradable plastics for composting.

Big shredders need custom blades for different plastics. You can pick blade shapes for your waste type. Fordura’s knives show how custom blades cut better and save time. You get clean cuts and better recycled plastic.

Here is a table that shows how custom blades help with different plastic waste:

| Plastic Waste Stream Type | Custom Blade Requirement | Example Benefit |

|---|---|---|

| Mixed plastics (PA, PVC, PMMA, PC, PE, PP, ABS, PS, PET) | Interchangeable blades for hard or soft plastics | Pro Model blades shred PVC pipes 20% faster, so you get more output |

| Rigid plastics (e.g., PVC pipes, PC) | Very sharp edges for quick and clean cuts | 1600 RPM blade speed saves work time |

| Flexible plastics (e.g., PE) | Custom blade shapes for thick or bendy plastics | Shredding works better |

| Specialty plastics (composites, fiberglass) | Special blade designs for tough plastics | Shredding is smoother |

| Biodegradable plastics | Blades made for composting | Helps eco-friendly recycling |

| Electronic waste plastics | Strong blades with hard edges | Cuts circuits cleanly without breaking them |

Custom blades make recycling better for special waste. You get faster work, less fixing, and better recycled plastic.

Perbedaan Utama

Design and Material

Standard Blades: Typical Designs and Materials

Standard blades come in common shapes and sizes. You see these blades in many recycling machines. They are made from high-carbon steel or stainless steel. These materials make the blades hard and tough. Standard blades have simple, straight edges. This helps them fit many different machines. You get reliable oem parts with these blades. They work well for most plastic waste. But the crusher blade design does not change much. This means they may not work best for special or tough plastics. The sharp edges on standard blades do most jobs. But they can wear out faster with hard or rough materials.

Custom Blades: Tailored Designs and Specialized Materials

Custom blades are made for your special recycling needs. You can work with a manufacturer to design a crusher blade. The blade will match your machine and plastic waste. Custom blades use strong materials like solid carbide or high-speed steel. Some use special tool steels like D-2 and CPM 10V. Some custom blades have coatings like titanium nitride. These coatings help the blade stay sharp longer. They also lower friction and heat.

You can pick oem parts with special shapes and sizes. This makes sure the blade fits your equipment just right. Custom blades often have special tooth shapes for better cutting. Heat treatments and coatings make them last longer. These features help custom blades work better, even with tough or mixed plastics.

Note: Custom blades can be made for certain plastics. They work for soft, hard, or heat-sensitive materials. This helps your recycling and lowers machine downtime.

Performa dan Daya Tahan

Cutting Efficiency and Consistency

Crusher blade design affects how well blades cut. Standard blades give steady results with normal plastics. They are good for basic recycling jobs. But you might see uneven cuts or more jams with hard plastics.

Custom blades help machines work better and last longer. They have sharp edges and special shapes. These features help you cut faster and more accurately. Custom blades keep their edge longer. You get even pieces and fewer machine stops.

- Custom blades can match your machine’s speed and power.

- They fit your recycling line better.

- The right oem parts help save energy and cut waste.

Wear Resistance and Lifespan

The material and coatings affect how long blades last. Standard blades made from high-carbon steel or stainless steel last for most jobs. But you may need to replace them often with rough plastics.

Custom blades are made to resist wear. They use materials like tungsten carbide. Some have coatings like titanium nitride. These upgrades make custom blades last up to four times longer. For example, tungsten carbide blades last about three times longer than high-speed steel blades. Coatings like nitriding and titanium can make blades last 40-50% longer. This means you spend less time and money changing blades.

| Jenis Pisau | Wear Resistance / Lifespan | Manfaat Tambahan |

|---|---|---|

| Pisau Standar | Last about 10 days under typical recycling conditions | Higher downtime (~16 hours/month), higher replacement costs ($25,000/year) |

| Pisau Kustom | Last over 40 days (4x longer lifespan) | Downtime reduced to ~5 hours/month, replacement costs drop to $9,500/year; use of high-quality materials like tungsten carbide increases wear resistance by ~3x compared to high-speed steel; surface treatments (nitriding, titanium coatings) extend lifespan by 40-50%; fewer jams and emergency repairs improve productivity and safety |

Custom blades help your recycling line run longer. You get fewer jams and less emergency fixing. This means better work and safer machines.

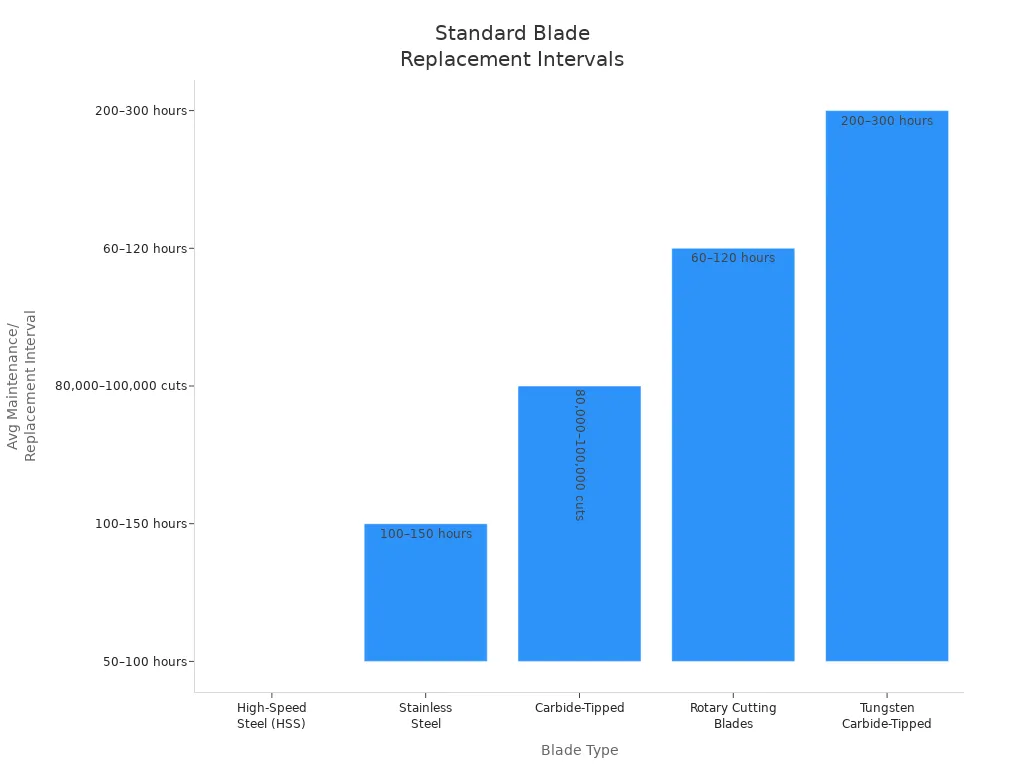

Frekuensi Perawatan dan Penggantian

You need to check and change blades to keep machines working. Standard blades need more checking and changing. You may need to replace them every 10 days in busy plants. This causes more downtime and higher costs.

Custom blades last much longer because of their strong materials and coatings. You can use your machines for over 40 days before changing blades. This means less downtime and lower yearly costs. Using oem parts with digital tracking helps you know when to change blades. Companies that change blades at 80% wear see 25% less downtime and 40% lower maintenance costs.

Custom blades give you more control over maintenance. They fit better, so machines run smoother. This helps you work better and save money over time.

Pro dan Kontra

Standard Blades: Advantages and Drawbacks

Advantages of Standard Blades

Standard blades work for many recycling jobs. They have some good points:

- You spend less money because they cost less.

- You can find them fast since suppliers keep them ready.

- They fit many recycling machines without changes.

- You can put them in and take them out quickly.

Standard blades are often used as oem parts. You can use them as replacements when you need them fast. Their simple design makes them popular for places with lots of plastic waste.

Standard blades help your recycling line keep moving. You do not wait long because you can change them easily.

Drawbacks of Standard Blades

Standard blades can have problems with hard or rough plastics:

- They are made from materials that do not last as long.

- They wear out fast, so you must sharpen or change them more.

- They are not very tough and can break or get dull quickly.

- Some metals can make them wear out even faster.

- Blades without cryogenic treatment do not last as long.

- They do not resist wear and impact as well as tungsten carbide.

Standard blades are good for simple recycling jobs. But they may not cut special plastics well. You might see uneven cuts or more jams with tough plastics. You also spend more time and money changing them.

Custom Blades: Benefits and Limitations

Manfaat Pisau Kustom

Custom blades are made for your special plastic waste. They give you some big benefits:

| Jenis Pisau | Function and Benefits |

|---|---|

| Tepi Lurus | Makes clean, accurate cuts for plastic and metal. This helps things fit right and work well. |

| Pisau Geser | Cut thick or tough stuff like scissors. They need less force and last longer. They make clean cuts for special jobs. |

| General Benefit | Picking the right blade helps you cut better and faster in factories. |

Custom blades are made for your recycling needs. You can pick oem parts with special coatings to last longer. Serrated tooth knives give even cuts for different films. Custom blades help you work longer, waste less, and keep products good. They can be made to fit special machines for hard jobs.

Custom blades help you do better with tough or mixed plastics. You get steady work and fewer stops in your recycling.

Limitations of Custom Blades

There are some things to think about before picking custom blades:

- Custom blades cost more than standard ones. The price is higher because they are special.

- You might wait longer to get them. It can take about 20 days to make and send them.

- You need to give details and talk to experts to get the right blade.

- Custom blades may not be needed for easy or small jobs. For simple work, standard oem parts might be better.

- The blade must fit your shredder model. The wrong blade can break your machine.

- Things like humidity and chemicals can change how blades work. You should talk to suppliers about testing and support to stop fast wear or rust.

Custom blades work better, but you should think about the cost, wait time, and what you need before buying.

Choosing the Right Plastic Crusher Replacement Blades

Assessing Your Needs

Picking the right plastic crusher replacement blades starts with knowing your job. You need to think about the kind of plastic you use. Hard plastics break apart fast. Flexible plastics need stronger blades to cut well. The way your plastic acts, like how dense it is or how it melts, changes how blades work. Some plastics melt at low heat. These need crushers that go fast but use less force. Tough plastics that fight chemicals need heavy-duty blades.

You also need to look at your machine’s design. Blade shapes like rotor, stator, claw, or tubular must fit your crusher. The space between blades matters for good cutting and nice crushed pieces. How much you make is important too. If you make a lot, custom blades made from strong materials help you work longer and fix less. For small jobs, standard or aftermarket blades may save money and still last long.

Tip: Always make sure your plastic crusher replacement blades fit your machine. This stops jams and keeps things running smoothly.

Decision Checklist

Use this checklist to help pick your plastic crusher replacement blades:

- Know what kind of plastic you use (hard, soft, flexible, or mixed).

- Pick blade material that fits your needs (tool steel, alloy steel, carbide-tipped, or ceramic).

- Choose blade shape and setup that matches your machine.

- Think about how much you make to pick standard, aftermarket, or custom blades.

- Decide if you need coatings or heat treatments to make blades last longer.

- Make sure blades fit your crusher model.

- Balance price with how long blades last and how well they work.

- Plan to check and change blades often so you do not lose time.

| When to Consult a Custom Plastic Crusher Blades Manufacturer | Mengapa Hal Ini Penting |

|---|---|

| Processing many or strange plastic types | Makes sure blade design fits each material |

| Wanting blades to last longer or work better | Custom blades help you work faster and save money |

| Having blades wear out fast or machines jam a lot | Special blades make machines more reliable |

| Changing or upgrading equipment | Makes sure blades fit and work right |

If you use special plastics, make a lot, or have special machines, talk to a custom plastic crusher blades manufacturer. They know how to help you get the best aftermarket replacement blades for your work.

Value of a Custom Plastic Crusher Blades Manufacturer

Customization and Support

If you work with a custom plastic crusher blades manufacturer like Nanjing Metal, you get help from real engineers. You can ask for oem parts that fit your machine and plastic waste. The manufacturer gives you lots of ways to customize your blades. You can change blade size, pick the right material, and choose the best edge for your job. The table below shows some common ways you can customize:

| Aspek Kustomisasi | Options Offered |

|---|---|

| Dimensi Bilah | Circular or straight blades, adjustable in diameter, thickness, and width |

| Bahan | High-Speed Steel, Tungsten Carbide, Stainless Steel |

| Edge Profiles | Standard, razor-sharp, or serrated edges |

| Pelapis | Titanium Nitride, Diamond-Like Carbon, Chrome plating |

| Customization Process | Consultation, design, prototype, quality check, production |

You can also change screen mesh size, feeding and discharge ways, and even pick machine color or add your logo. The manufacturer helps you at every step, from talking about your needs to getting your order. This support makes sure you get a solution that helps your recycling work. You get oem parts that fit your machines well and help you handle any plastic waste.

Quality and Service

A good custom plastic crusher blades manufacturer gives you more than just oem parts. You get strong quality checks and good service. Nanjing Metal uses tough materials like heat-treated high alloy steel and tungsten carbide. Every blade gets tested for hardness and checked with digital tools to make sure it is right. The company has ISO 9001 certification and follows safety rules from around the world. You get inspection reports and even videos before your blades ship.

You also get fast delivery, blade warranties, and help after you buy. The manufacturer gives advice on picking blades, keeping them sharp, and fixing them. This help lets you use blades longer and stop machines from breaking down. For example, a recycling plant using custom blades from Nanjing Metal handled 60% more material and cut waste storage by 40%. With oem parts made for you, your machines work better and you spend less money.

If you want to know more about custom choices, visit the halaman bilah khusus. You will see how a custom plastic crusher blades manufacturer can give you the oem parts and help you need for great results.

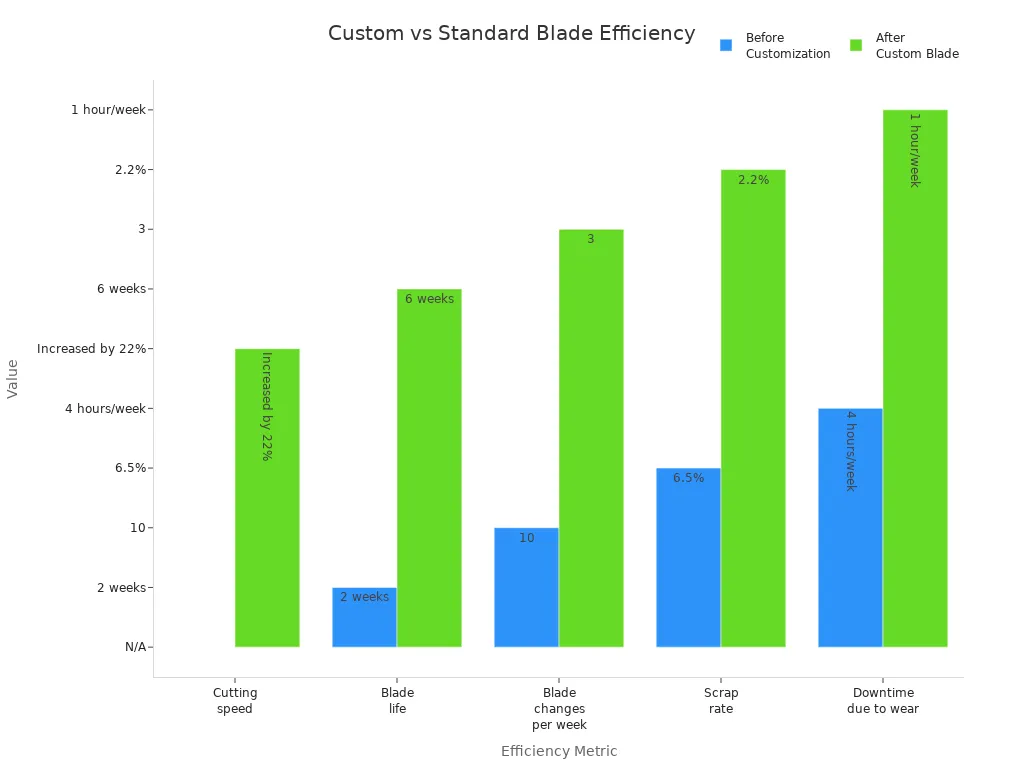

Picking between standard and custom blades depends on your plastic waste and machine. Custom blades help your machines work better. The table below shows how they improve things:

| Metrik | Pisau Standar | Pisau Kustom | Peningkatan |

|---|---|---|---|

| Kecepatan pemotongan | Tidak tersedia | +22% | Faster |

| Umur bilah pisau | 2 minggu | 6 minggu | Lebih panjang |

| Scrap rate | 6.5% | 2.2% | Less waste |

You get better results if you talk to a custom blade manufacturer when recycling is hard. For help or a special answer, Kontak our sales engineer.

Tanya Jawab Umum

What types of plastic can you process with custom crusher blades?

Custom crusher blades can cut many plastics like PET, PVC, and HDPE. They also work with mixed plastics. These blades help you cut tough plastics. They make it easier to handle special waste.

How do custom blades improve machine performance?

Custom blades fit your machine and plastic type. They help you cut faster and get better results. You will have less downtime. The right blade shape stops jams and lowers repairs.

When should you choose custom blades over standard blades?

Pick custom blades for hard, mixed, or special plastics. They are best for big jobs or when you want blades to last longer. Custom blades also cut better and save time.

Can custom blades handle metal shredding tasks?

Custom blades can cut metal if your recycling has metal parts. They use strong materials and special shapes. This helps them cut both metal and plastic waste.

How do you maintain plastic crusher blades for longer life?

Check your blades often and keep them clean. Change them when they get worn out. Blades with special coatings or heat treatments last longer. This helps you save money on new blades.

Lihat Juga

Memilih Antara Bilah Pengganti Penghancur Plastik OEM dan Aftermarket untuk Mesin Industri

Panduan Penggantian Pisau Penghancur Plastik: Kapan dan Bagaimana Melakukannya dengan Benar

Kapan Harus Mengganti Bilah Penghancur Plastik: Tanda-tanda Keausan dan Tips Perawatan