Are you tired of spending a lot on repairs and losing time at work? Bilah shredder kustom are a smart choice. They help your machines work better and keep things safe. Picking the right blade for your material makes less waste. It also helps your business make more money. New ways to make and change blades fit what you need. Many companies save real money:

- A German factory saved 35% on blade costs with modular blades.

- Fast blade changes mean less waiting and lower worker costs.

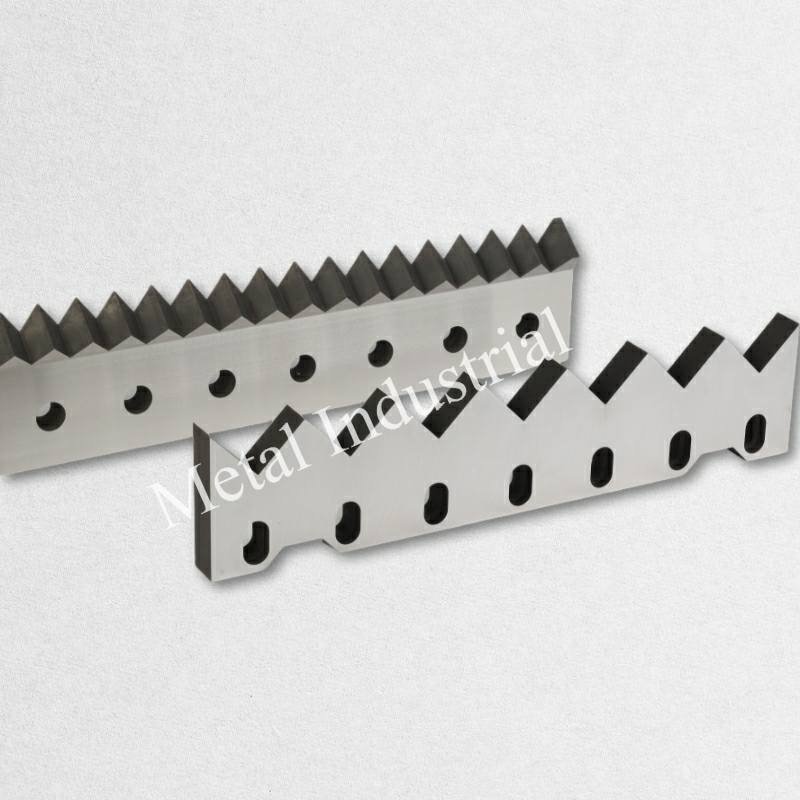

Nanjing Metal Industrial has blades you can change to fit your needs and help you do well.

Poin-poin Utama

- Custom shredder blades are made for your shredding needs. They help your work go faster and stop machines from breaking down. Using custom blades can help your business save money. You will pay less for repairs and energy over time. Custom blades last longer than regular blades. This means you do not need to replace them as often. You also spend less time fixing them. Picking the right blade material and design helps shredding work better. It also makes less waste. Custom manufacturing lets you choose blades for different materials. This gives you better results. Buying custom blades can help your business make more money. You get more work done. Taking care of your blades and teaching staff the right way to use them helps them last longer. It also makes them work better. Working with a good supplier gives you quality blades. You also get help when you need it for shredding.

Standard Blades vs. Custom Shredder Blades

Common Issues with Standard Blades

Standard blades in your metal shredder can cause many problems. These problems slow down your work and cost you more money.

- Dull blades use more energy, about 15–25% extra each time. This makes your bills go up every year.

- Worn blades make your shredder work harder. This can break motors and gears faster.

- Old blades cut uneven pieces and can mix in bad stuff. This messes up the next steps in your process.

- Broken blades can damage other parts. Fixing these problems fast costs more than normal care.

You want your shredder to work well. Standard blades often make this hard. They do not fit every job or material. Using the wrong blade can mean more stops and bigger repair bills.

It is important to know about different blade materials. The right blade for your job helps your shredder work better and saves money. The blade’s design and material change how long your shredder lasts. Picking the wrong blade can cause more breakdowns and less work done.

Why Custom Shredder Blades Matter

Custom shredder blades fix these problems. You get blades made just for your needs. This gives you better results and fewer problems.

| Keuntungan | Bilah shredder kustom | Pisau Standar |

|---|---|---|

| Jangka hidup | Hingga 50% lebih panjang | Shorter, frequent changes |

| Efisiensi | Prevent jams, clean cuts | More jams, rough cuts |

| Waktu senggang | Up to 4x longer operational life | Frequent stops |

| Material Strength | High-speed steel, tungsten carbide | Basic steel |

| Tailored Design | Matches your material and job | One-size-fits-all |

Custom manufacturing lets you pick the best blade for your job. You can choose the metal, shape, and size you need. This helps your shredder work better and last longer. Custom metal shredders need blades that fit their special jobs. With custom blades, you can shred plastics, rubber, wood, or metal easily.

Industri Nanjing Metal is known for quality and custom work. You get strong materials like carbon steel, tool steel, and tungsten steel. Each blade is made with care and checked for quality. Special forging and heat treatment make blades tough and long-lasting. The company checks every blade with tests and inspections to make sure they are the best.

If you want to learn more, visit the halaman bilah khusus.

Custom shredder blades help you save money, stop delays, and get the best from your shredder. The right blade makes your work smoother and more reliable.

Custom Manufacturing for Better Cutting

Custom manufacturing helps you get the best from your metal shredder. When you pick custom shredder blades, each blade fits your job and material. This makes your shredding work better and saves your business money. You skip the problems of standard blades and get what you need.

Precision Engineering in Blades

You want blades that cut well and last longer. Precision engineering makes this happen. Custom manufacturing uses new ways to make blades that improve every cut. Here is how these methods help you:

| Teknik | Keterangan |

|---|---|

| Advanced Material Enhancement | Uses cryogenic treatment, laser hardening, and special coatings to make blades harder and more resistant to wear. |

| Teknik Presisi | CNC-controlled grinding and edge shaping give blades micron-level accuracy and smooth surfaces. |

| Custom Optimization Solutions | Custom coatings and edge shapes are designed for your specific shredding needs. |

| Peningkatan Ketahanan Aus | Special treatments protect blades from abrasion, so they last much longer. |

| Daya Tahan Lebih Lama | Modern manufacturing methods help blades handle high-impact jobs while keeping their precision. |

You notice the difference with every cut. Your metal shredder works better, and you fix it less often. Custom manufacturing lets you pick the right blade for each job, so you always get great results.

Material Choices for Shredding

The right material makes your blades strong and reliable. Custom manufacturing gives you many choices, so you can match each blade to your job. Here are some common shredding jobs and the best materials for each:

| Shredding Application | Recommended Material Choices |

|---|---|

| Konstruksi dan Pembongkaran | High-powered, slow-speed shredders for bulky items like wood, plastics, and paper. |

| E-Waste Shredding & Recycling | Custom systems for breaking down electronics, including copper, steel, and precious metals. |

| Hard Drive Shredding | Special shredders for hard drives and solid-state drives to destroy data. |

| Medical Waste Processing | Slow-speed, high-torque shredders for fabrics, glass, plastics, and stainless-steel tools. |

| Metals Shredding & Recycling | High-torque shredders for tough metals like titanium, magnesium, and electronics. |

| Paper Shredding | Commercial shredders for secure document destruction with low noise and dust. |

| Plastics Shredding & Recycling | Heavy-duty shredders with dual or four-shaft blades for all types of plastics and recycling needs. |

Custom manufacturing helps you pick the best blade for every job. This means your metal shredder works better, and your blades last longer.

Advanced Forging and Heat Treatment

You need blades that stay sharp and strong after lots of use. Custom manufacturing uses advanced forging and heat treatment to make this happen. Here is what these steps do for your blades:

- Forging makes the blade material stronger and helps your custom shredder blades last longer.

- Heat treatment controls how hard each blade is, so it can handle tough jobs without breaking.

- High-temperature tempering makes the steel stronger, more flexible, and tougher.

These steps help your blades handle any shredding job. You get blades that keep their edge and last longer, so you spend less on new ones.

Nanjing Metal Industrial is known for quality and service. The company offers OEM and ODM services for custom shredder blades. You can send your own designs or work with their team to make new ones. Here is how these services help you:

| Service Offered | Benefits to Clients |

|---|---|

| OEM and ODM services for custom shredder blades | Get blades made for your exact needs |

| Ability to draw and manufacture from client inputs | High-quality production every time |

| Assistance in modifying existing designs | Better pricing and improved tooling |

You get help at every step, from design to delivery. Every blade goes through strict checks, so you know you are getting the best.

Custom manufacturing lets you control every detail. You get blades that fit your metal shredder, your materials, and your business goals. This means better cutting, less downtime, and more value from every blade.

Better Cutting for Specific Jobs

Tailored Solutions for Different Materials

You need blades that fit your shredding jobs. Custom shredder blades help you cut better for each job. You can pick blades for plastic, rubber, metal, or wood. Each blade works best with certain materials. The right blade gives you clean cuts and less waste. Your shredding gets faster and safer.

Custom blades come in many shapes and sizes. You can choose sharp blades for plastic or strong blades for metal. Some blades resist heat, so they work well with rubber and plastic. These blades last longer and break less often. You save money and keep your machines working.

Tip: Using the right blade for your material helps your shredder work better and stops delays.

Multi-Shaft and Claw Designs

Some jobs need stronger blades. Multi-shaft and claw designs help you shred big and hard things. Dual shaft blades are good for heavy jobs. Four shaft blades make even pieces and handle tough stuff.

Here is a table that shows what different shredder types do:

| Shredder Type | Keuntungan | Keterbatasan |

|---|---|---|

| Dual Shaft | Good for heavy jobs, works with many materials, low repair costs | Can’t make very small pieces, not always even sizes |

| Four Shaft | Shreds well at slow speeds, makes even pieces, good for hard stuff | Too much for easy jobs |

Claw designs give more power to your shredder. You can get blades with 3, 8, or 12 claws. These blades grab and tear big things. They are great for recycling and waste jobs. You get blades that fit your machine and your work.

Pisau khusus setups also help your shredder work better. Fast machines use hammer or ring blades for quick cuts. Slow machines use high torque shear blades for cool and quiet work. Shear shredders use disk cutters for even pieces. Granulators use many blades on a rotor for plastic and circuit boards. Waste reducers use pointed cutters for rough pieces.

| Shredder Type | Konfigurasi Blade | Dampak Kinerja |

|---|---|---|

| High-Speed Machines | Hammer or Ring Type | Cuts fast, makes more heat and dust, good for big items. |

| Slow-Speed Machines | High Torque Shear Cutting | Stays cool, makes less dust, quieter. |

| Shear-Type Shredders | Interlocking Disk Cutters | Saves money, makes even pieces, can have more than one shaft. |

| Granulators | Multiple Blades on Rotor | Cuts well, good for plastic and circuit boards, can change gap. |

| Waste Reducers | Pointed Cutters | Makes rough pieces, handles big parts, works for many jobs. |

Industry Applications in Shredding

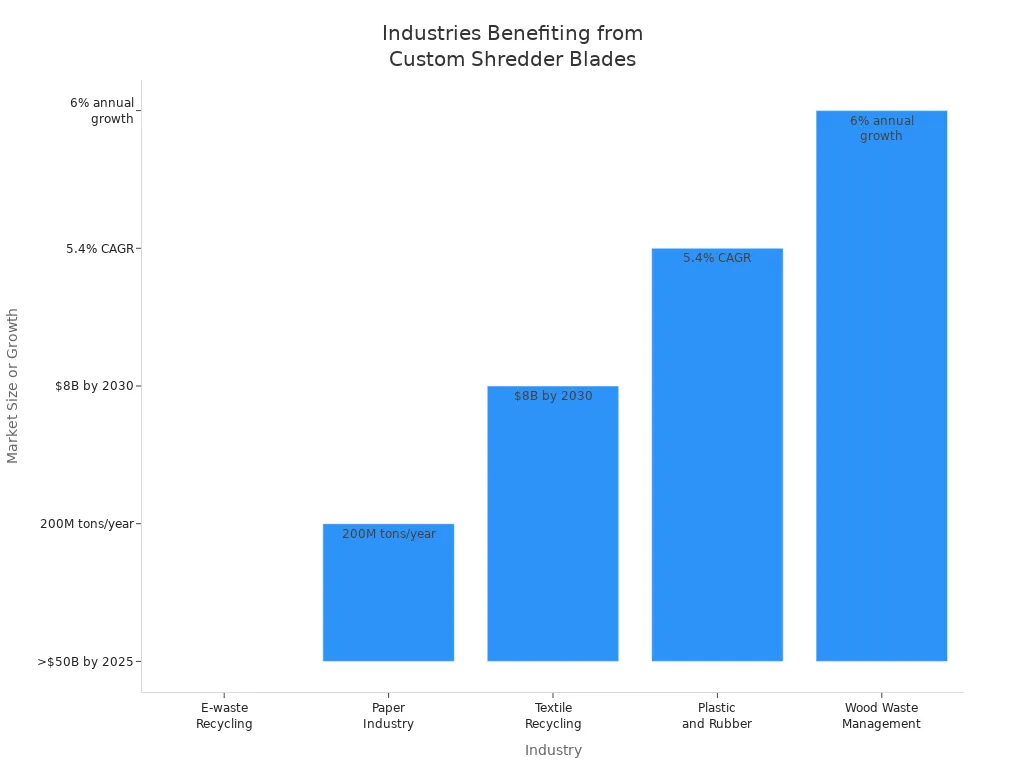

Custom shredder blades are used in many industries. You see them in e-waste, paper, textiles, plastic, rubber, and wood. Each industry needs blades that fit its jobs and materials.

| Industri | Benefits of Custom Shredder Blades | Examples of Applications |

|---|---|---|

| E-waste Recycling | Sharp blades for circuit boards and hard drives, keeps data safe. | E-waste market may be over $50 billion by 2025, so good shredding is needed. |

| Industri Kertas | Cuts pulp well to help make recycled paper. | Over 200 million tons of paper made each year, so special shredders are needed. |

| Textile Recycling | Strong blades for fabric, stops fibers from wrapping. | Textile recycling could reach $8 billion by 2030, more money is going into recycling. |

| Plastic and Rubber | Heat-resistant blades for lots of plastic and rubber. | Plastic recycling may grow 5.4% each year until 2030, so shredding is important. |

| Wood Waste Management | Blades for thick and tough wood, stops clogging. | Wood recycling may grow almost 6% each year, so shredding must be good. |

You get blades that help your business do better. Custom blades make shredding faster and help your machines last longer. You see better results in recycling and waste jobs. Custom blades keep your work running well and save you money.

Financial Benefits of Custom Shredder Blades

Lower Maintenance and Downtime

You want your metal shredder to work well every day. Custom shredder blades help you do this. These blades are made for your materials, so you have fewer breakdowns. You spend less time fixing your shredder. Custom manufacturing gives you blades that fit your machine and job. This means you can shred more and fix less.

- Custom shredder blades match your materials and last longer.

- You do not need to change blades as often, so you save money.

- Your shredder does not wear out fast, so you avoid big repairs.

Custom manufacturing gives you stronger blades and less downtime. Your business keeps moving. Your shredder works better and is more reliable.

Umur Pisau Lebih Panjang

Blade life is important for shredding. Good blades make your shredder work better. Custom manufacturing lets you pick the best materials and designs. This helps your blades last longer and gives you better results.

| Faktor | Impact on Operational Costs |

|---|---|

| Blade Longevity | Fewer replacements needed |

| Biaya Pemeliharaan | Lower because you change blades less |

| Machine Uptime | More uptime, so you make more products |

| Konsumsi Energi | Uses less energy, so you save money |

| Processing Quality | Better cuts, less waste, and more good output |

| Dampak Volume Produksi | If blades break, costs go up with more production |

Custom shredder blades stay sharp and strong. Your shredder runs longer without stopping. You save money on new blades and repairs. Your shredding gets better, and you get more value from each blade.

Nanjing Metal Industrial makes blades that last and work well. Many companies have 40% less downtime after using these blades. Premium alloy steel blades can cut replacement costs by 40% each year. You also get 20% more production because you change blades less.

Improved ROI for Businesses

You want your money to work for you. Custom shredder blades help you get better results. Blades made for your job give you better performance and lower costs. Your business shreds more and wastes less.

| Company Name | Location | Improvement Achieved |

|---|---|---|

| Dubois Metal Recycling Solutions | France | Blades last longer and less downtime |

| Tanaka Recycling Solutions | Japan | 76% less downtime and 37% lower costs |

| Sarah Müller | Jerman | Blades last 40% longer |

These examples show custom blades work better. Companies see longer blade life, fewer repairs, and more uptime. You get more done with less work.

Good blades also make your shredding safer. Reliable blades mean fewer accidents and smoother work. Better blades save you money and help your business. You spend less on repairs and get more from your shredder.

Picking the right blade is important for shredding and your business success.

Choosing the Right Blades Supplier

What to Look for in Custom Manufacturing

You want blades that work well for your jobs. The right supplier helps your machines do better. First, think about what you need to shred. Not every blade works for every job. Custom manufacturing gives you blades that fit your needs. Here is how you pick the best blade for your business.

- Look at what you make and what you shred.

- Find out about blade types and materials.

- Talk to different suppliers and compare what they offer.

- Try the blades at work and choose the best ones.

Custom manufacturing lets you pick blade shapes, sizes, and materials. You get blades that help your shredder work faster and better. The right supplier gives you choices and listens to you. This helps your machines last longer and saves you money. When you focus on what matters most, you get better results and less waiting.

Importance of Service and Support

You need more than just good blades. Service and support are important too. A good supplier helps you pick, install, and care for your blades. You get advice for each job. Good support helps you fix problems fast and keep shredding.

Nanjing Metal Industrial is known for great support. Their team helps you design blades for your needs. They answer your questions and help with custom manufacturing. You get help with blade changes and tips for better shredding. This support makes you feel sure and keeps your machines working well.

Tip: Pick a supplier who trains you, answers fast, and helps often. This makes your shredding safer and more steady.

Quality Assurance in Shredding

Quality is important for every blade. Good blades help your shredder work well and last longer. You want blades made from strong materials and with good coatings. This keeps them sharp and safe. Custom manufacturing checks every blade to make sure it is good.

- Good materials and coatings keep blades strong and stop rust.

- Careful design gives you even cuts and saves energy.

- Expert suppliers help you solve hard shredding problems.

Nanjing Metal Industrial checks every blade before sending it to you. You get blades that pass tough tests. This means your shredder works better and lasts longer. When you care about quality, you protect your machines and get better results.

A good supplier helps you pick the right blades and supports you all the way. You get blades that fit your needs and help your shredder work better. Choose a partner who cares about quality, service, and trust.

Maximizing Shredding Performance

Praktik Terbaik Pemeliharaan

You want your shredder to work well every day. Good care keeps blades sharp and machines running. Here are some easy steps to follow:

- Check your blades every day. Look for cracks, leaks, or things blocking the way before you start.

- Add grease to bearings every 100 hours. Use the grease your machine maker says to use.

- Clean your blades after each shift. Take out any trash from where the material goes in and comes out.

- Once a month, do a deep clean. Turn each blade and check screens for stuff stuck on them.

- Do not put too much in your shredder. Too much can break blades and slow things down.

- Sharpen your blades often. Keep the edge strong, but do not sharpen too much.

- Make sure blades are lined up right. This stops uneven wear and blades breaking early.

Tip: Taking care of your blades helps them last longer and keeps shredding safe and smooth.

Pelatihan dan Keselamatan

You need trained workers to get the best from your blades. Training helps your team use blades the right way. Safety is always important when shredding. Make sure everyone knows how to use blades and follow safety rules.

- Teach your team to check and change blades safely.

- Show workers how to see when blades are worn out and need changing.

- Remind everyone to wear gloves and eye protection when working with blades.

- Put safety signs near your shredder to help stop accidents.

When your team knows about blade care and safety, you have less downtime and protect your machines.

Monitoring and Upgrades

New technology helps you watch your blades and make shredding better. Use control systems to see how your blades are working. These systems give you reports and help you plan care before problems start.

| Monitoring Technology/Strategy | Keterangan |

|---|---|

| Control Systems | Get reports on how blades work and how well shredding goes. |

| Pelatihan Operator | Trained workers help machines run longer and save money. |

| Downstream Equipment Optimization | Make sure all parts work together for smooth shredding. |

| Upgraded Control Systems | New systems let blades work with less help from workers. |

| Rotor Type Retrofitting | Change rotors to help blades work better and save money. |

Upgrade your blades and systems when you find new choices. Changing your shredder with better blades or rotors can save money and help you get better results. Watch for new technology to keep your shredding ahead.

Picking custom shredder blades is a smart choice for your business. You get better results, spend less money, and get blades made for your needs. The table below shows the main benefits:

| Keuntungan | Keterangan |

|---|---|

| Peningkatan Efisiensi | Makes shredding faster and stops long waits. |

| Penghematan Biaya | Cuts down on repairs and energy bills over time. |

| Keberlanjutan | Uses less power and helps with recycling. |

| Reduced Energy Use | Sharp blades use less power to work. |

You also get long-lasting blades, less waiting, and better value. To get started, do these steps:

- Ask for a quote and give clear details.

- Look at what each supplier says.

- Pick the supplier that fits your needs.

- Tell all suppliers about your choice.

Ready to help your business? Kontak a sales engineer for a custom quote.

Tanya Jawab Umum

What are custom shredder blades?

Custom shredder blades are blades made to fit your specific shredding needs. You choose the size, shape, and material. These blades help you shred different materials better and last longer than standard blades.

Why should I choose custom shredder blades over standard ones?

You get better performance with custom shredder blades. They match your machine and material. This means less downtime, fewer repairs, and more savings for your business.

How do I know which custom shredder blades are right for my job?

You should look at what you need to shred. Think about the material, size, and how much you process. A supplier can help you pick the best custom shredder blades for your work.

Can custom shredder blades handle tough materials like metal or rubber?

Yes! Custom shredder blades can cut through tough materials like metal, rubber, and wood. You get blades made from strong materials that stay sharp and resist wear.

How often do I need to replace custom shredder blades?

You replace custom shredder blades less often than standard blades. Their strong design and material help them last longer. Regular checks and good care make them last even more.

Are custom shredder blades more expensive than standard blades?

Custom shredder blades may cost more at first. You save money over time because they last longer and reduce downtime. You spend less on repairs and replacements.

Can I get help with installing or maintaining custom shredder blades?

Most suppliers offer support for installation and maintenance. You get advice, training, and tips to keep your custom shredder blades working well.

Do custom shredder blades work with all shredding machines?

Custom shredder blades can fit almost any shredding machine. You just need to share your machine’s details with the supplier. They will make blades that match your equipment.

Lihat Juga

Cara Memilih Bilah Shredder Plastik untuk Daur Ulang yang Efisien

Panduan Utama Desain Bilah Shredder Poros Tunggal