Karbida Tungsten vs Baja untuk Bilah Industri: Performa, Keausan & Biaya

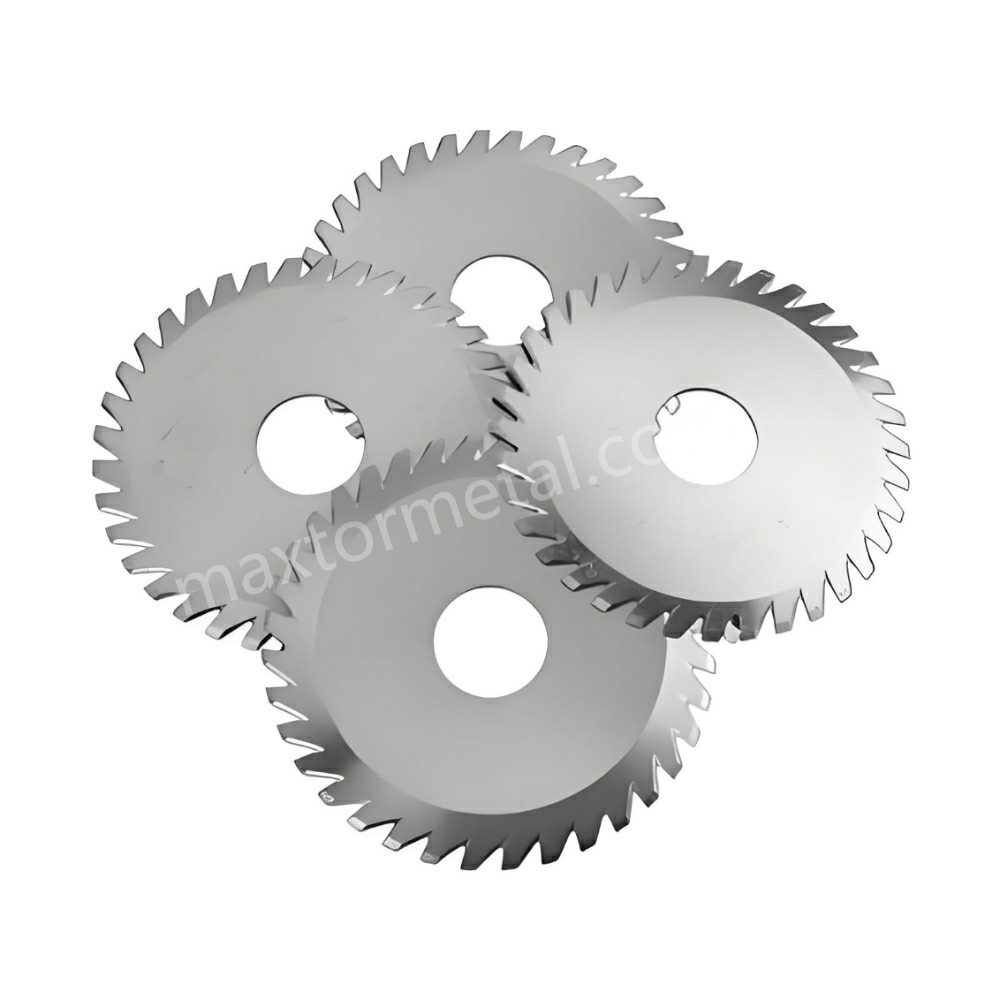

When you compare tungsten carbide vs steel blades, you notice significant differences. Tungsten carbide blades are much harder and do not wear out quickly. They maintain their sharpness even under high temperatures. On the other hand, steel blades are better at absorbing hits and shocks. Initially, steel is less expensive. The table below highlights these main differences: […]

Bilah Slitter Rotary Aftermarket vs. OEM: Analisis Biaya-Manfaat

You want blades that give you good value. Many people pick OEM rotary slitter blades. These blades have high quality. They last a long time. They work well and do not break easily. When you choose blades, you think about cost. You should also consider how long they will last. Check how often they need fixing. […]

Presisi dan Daya Tahan: Pisau Pemotong Rotary untuk Pemotongan Karet & Plastik

You use rotary slitter blades for rubber and plastic to make accurate and strong cuts. Good blades help you get cleaner cuts and last longer. This is true when you pick blades that fit your needs. Companies like Nanjing Metal Industrial have many choices. They focus on making blades that work well for you. The table below shows how […]

5 Cara Terbukti untuk Memperpanjang Umur Bilah Slitter Rotary

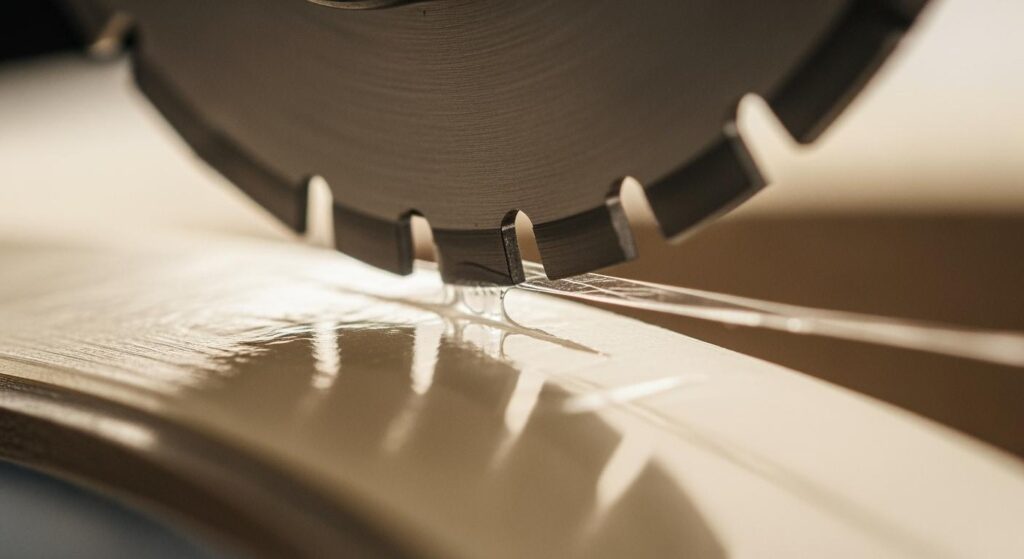

You want your rotary slitter blades to last a long time and extend rotary slitter blade life. By keeping your blades sharp, you save money while also experiencing less downtime and improved product quality. For instance, using high-speed steel or carbide-tipped blades significantly contributes to this goal. These blades can enhance your productivity by making you […]

10 Faktor Kunci yang Perlu Dipertimbangkan Saat Memilih Pemasok Pisau Slitter Rotary

Choosing the right rotary slitter knife supplier can change your cutting results. You need slitting tools that work well and give steady quality. A good supplier with smart manufacturing and helpful service can lower downtime and make your results better. Key Takeaways Blade Quality Standards Precision and Consistency You want slitting knives that work the same every […]

Bilah Slitter Rotary untuk Selotip: Memotong Melalui Daya Rekat Perekat

You use rotary slitter blades for tape to cut sticky materials. These blades help you handle tough sticky problems. Sticky problems can slow down how fast you work. If you pick good blades, you get cleaner cuts. Cleaner cuts mean you waste less tape. Blades made from tungsten carbide and high-speed steel last longer. These materials also […]

Mengapa Bilah Slitter Rotary Presisi Tinggi Sangat Penting untuk Operasi Anda

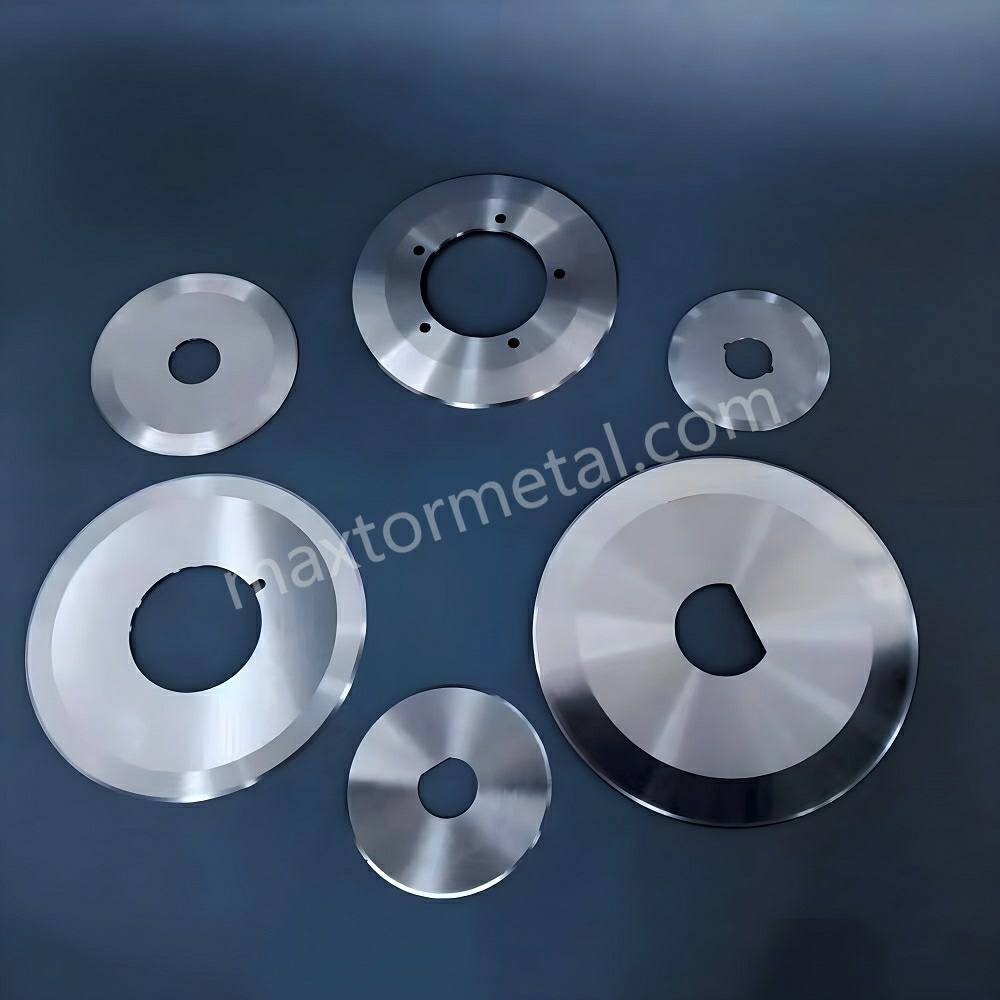

You need high precision rotary slitter blades for your work. These blades help your machines run well and not break down. Sharp and balanced rotary slitter blades make clean cuts. They also help you use less material and waste less. This tool cuts wide rolls into smaller pieces with exact sizes. It helps you keep your products […]

Penggantian Bilah Slitter Rotary: Panduan Langkah demi Langkah

If you do not perform a rotary slitter blade replacement the right way, you can lose time making products. About 25% of machine downtime occurs because tools break, such as blades. Good blades help you cut better and waste less. These blades also enhance workplace safety by reducing accident risks. There are many blade types and custom […]

Seni dan Ilmu Pengetahuan di Balik Pembuatan Bilah Slitter Rotary Presisi

You work with rotary slitter blade manufacturing. This job needs both smart engineering and skilled hands. People want blades that cut very well and very accurately. This need helps the market grow around the world: Nanjing Metal Industrial makes very good blades. They use ISO-certified places to make them. They use many kinds of materials and sizes. […]

Bilah Slitter Rotary Terbaik untuk Pemotongan Tekstil Berkecepatan Tinggi

When you choose the best rotary slitter blades for textiles, you enhance the speed and quality of your cutting process. Poor-quality rotary slitter blades can lead to several issues, such as: Nanjing Metal Industrial offers a wide selection of rotary slitter blades for textiles, crafted from premium materials. You can select blades with specialized edges, exceptional durability, […]