Pisau pemotong remuk adalah bilah khusus yang dirancang untuk mesin industri berat. Pisau pemotong remuk ini bekerja dengan menekan dan memecah material alih-alih mengiris, sehingga ideal untuk material keras atau berserat yang sulit dipotong dengan bilah standar. Bilah bekerja dengan menyentuh permukaan keras untuk menghasilkan potongan yang bersih dan efisien.

Poin-poin Utama

- Pisau pemotong remuk menggunakan tenaga kuat untuk memecah bahan keras, bukan mengirisnya. Hal ini membuatnya cocok untuk memotong tekstil, karet, dan plastik.

- Pisau ini memiliki tepi bundar yang menyebarkan gaya. Ini membantu bilah pisau bertahan lebih lama dan menghasilkan potongan yang lebih bersih.

- Sistem pneumatik mengendalikan seberapa keras dan cepatnya bilah bergerak. Hal ini memungkinkan mesin memotong dengan cepat, aman, dan akurat.

- Pemotongan dengan metode crushing menghemat waktu dan uang karena mudah disiapkan. Tidak memerlukan banyak perawatan dan dapat digunakan pada berbagai material dan industri.

- Pisau potong khusus dari Nanjing Metal membantu bilah pisau bertahan lebih lama dan mengurangi penghentian mesin. Pisau ini juga cocok untuk pekerjaan pemotongan khusus dan membantu pabrik bekerja lebih baik.

Gambaran Umum Pisau Crush Cut

Apa Itu Pisau Crush Cut?

Pisau pemotong remuk penting di banyak pabrik. Pisau ini tidak memotong seperti pisau biasa. Pisau ini menggunakan tenaga untuk menghancurkan dan memecah material. Cara ini bekerja dengan baik untuk benda yang keras atau berserat. Cara ini bagus untuk benda yang sulit dipotong dengan pisau tajam. Pabrik menggunakan pemotongan remuk untuk benda seperti tekstil, karet, dan beberapa plastik.

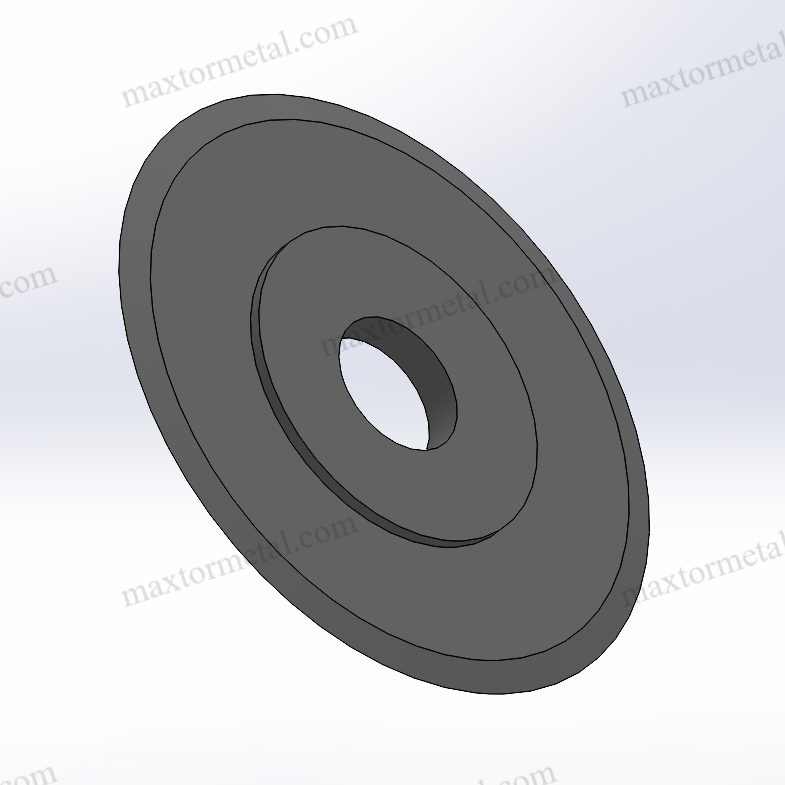

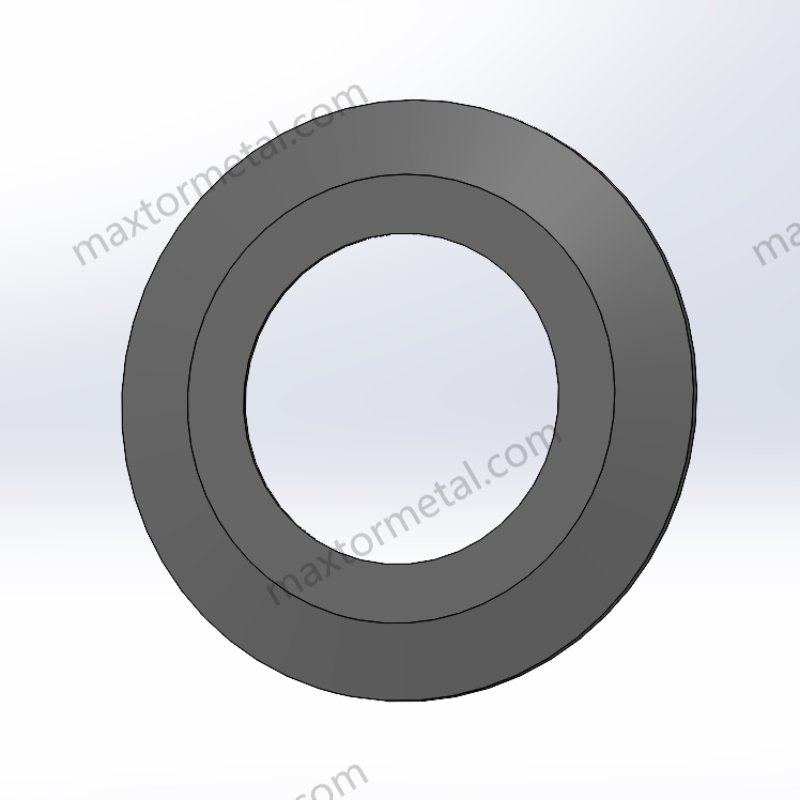

Pisau ini memiliki bilah bundar dengan ujung melengkung. Ujungnya tidak setajam silet. Bilahnya dibuat untuk menekan dengan kuat. Bilahnya berputar dan bekerja dengan landasan logam yang kuat. Tabel di bawah ini mencantumkan beberapa fitur utama pisau ini:

| Fitur/Pengukuran | Deskripsi/Nilai |

|---|---|

| Jenis Pisau | Pisau melingkar berputar dengan tepi melengkung |

| Sudut Bevel Bilah | 30°, 45°, atau 60° (45° adalah yang umum) |

| Radius Tepi | 0,05 mm hingga 0,30 mm (universal: 0,10 – 0,15 mm) |

| Bahan Pisau | Baja perkakas D2, HSS-M2 |

| Kekerasan Gulungan Landasan | 63-65 HRC (lebih keras dari bilah) |

| Memuat Pisau | Dibebani secara pneumatik dengan silinder yang kuat |

| Tekanan Potong | Dapat diprogram dan disesuaikan |

| Kecepatan Pemotongan Maksimum | Hingga 60 pemotongan per menit |

| Akurasi Panjang Pemotongan | +/- 0,1 mm |

Cara Kerja Pisau Crush Cut

Pemotongan dengan metode khusus. Pisau bergerak ke atas dan ke bawah. Pisau mendorong material ke landasan. Hal ini menghasilkan tekanan yang besar di bagian yang bersentuhan. Material tidak teriris. Material pecah karena gaya tersebut. Pengujian pada plastik dan logam menunjukkan hal ini. Itu bahan pecah karena terjepit, tidak terpotong. Misalnya, saat memotong plastik, bilahnya menekan ke bawah. Titik sempit terbentuk, retakan mulai muncul, dan plastik terbelah.

Sistem pneumatik mengendalikan tekanan dan gerakan bilah. Pekerja dapat mengubah tekanan untuk berbagai material. Landasan lebih keras daripada bilah. Jadi, bilah akan aus terlebih dahulu. Ini membantu menjaga potongan tetap bersih dan membuat kedua bagian bertahan lebih lama. Mencocokkan kecepatan bilah, landasan, dan material membantu semuanya berjalan lancar dan memberikan hasil yang baik.

Kiat: Pemotongan dengan metode crush cutting menghasilkan sedikit debu karena bilahnya menekan alih-alih mengiris. Ini membuat area kerja lebih bersih untuk banyak pekerjaan pabrik.

Proses Pemotongan Hancur

Mekanisme Pisau dan Landasan

Prinsip Kontak dan Aplikasi Gaya

Pemotongan remuk menggunakan cara pemotongan yang kuat tetapi sederhana. Pisau pemotong remuk menekan landasan atau rol yang keras. Ini menciptakan garis bertekanan tinggi di mana bilah pisau menyentuh material. Tekanan tersebut tidak mengiris material. Tekanan tersebut meremas dan memecahnya. Ini bekerja dengan baik untuk benda-benda yang sulit dipotong dengan bilah pisau biasa.

Uji mekanis menunjukkan gaya meningkat secara non-linier. Titik khusus terbentuk di bawah bilah yang disebut Zona Penghancur Ujung. Di titik ini, material berubah menjadi potongan-potongan kecil atau bubuk. Ilmuwan menggunakan ide-ide seperti keseimbangan kerja dan energi minimum untuk menjelaskan hal ini. Gagasan ini menunjukkan mengapa material pecah alih-alih teriris. Pisau dan landasan harus tetap sejajar dengan benar. Ini membantu membuat potongan yang bersih dan mencegah material tertekuk terlalu banyak.

Pengaruh Tepi Radius terhadap Kualitas Pemotongan

Tepi yang melengkung sangat penting untuk pisau pemotong remuk. Tepi ini bundar, tidak tajam seperti pisau lainnya. Bentuk bundar menyebarkan gaya ke titik kecil. Ini menjaga bilah dan landasan agar tidak rusak. Ini juga membantu bilah bertahan lebih lama. Tepi yang melengkung membuat pemotongan lebih bersih dan menjaga proses tetap stabil. Pabrik memilih radius tepi yang tepat untuk setiap bahan dan kualitas pemotongan.

Integrasi Mesin Industri

Alur Kerja Aktuasi Pneumatik

Banyak mesin menggunakan tenaga udara untuk menggerakkan pisau pemotong. Silinder pneumatik mendorong bilah ke atas dan ke bawah dengan udara. Pekerja dapat mengubah tekanan udara untuk berbagai material. Hal ini membuat pemotongan cepat, dapat diulang, dan akurat. Menggunakan tenaga udara juga berarti lebih sedikit pekerjaan tangan dan lebih aman.

Langkah-Langkah Integrasi dalam Mesin Industri

Pabrik mengikuti beberapa langkah untuk menambahkan pisau potong hancur:

- Letakkan pisau dan landasan pada rangka mesin.

- Pasangkan saluran udara ke silinder.

- Atur tekanan yang tepat dan sejajarkan bagian-bagiannya.

- Cobalah memotong dengan bahan uji.

Tabel di bawah ini mencantumkan fitur-fitur penting mesin:

| Fitur/Parameter | Mesin Pemotong Pisau Osilasi (dengan pisau potong remuk) |

|---|---|

| Metode Pemotongan | Gerakan bilah naik/turun frekuensi tinggi |

| Kompatibilitas Material | Bahan lunak hingga semi kaku |

| Pemotongan Presisi | Tinggi |

| Kualitas Tepi | Bersih, tidak ada bekas terbakar |

| Kecepatan | Cepat |

| Distorsi Material | Minimal |

| Tingkat Kebisingan | Sedang |

| Pembangkitan Debu & Asap | Rendah |

| Perawatan Alat | Hanya penggantian bilah |

| Kompatibilitas Otomatisasi | Tinggi–dikendalikan CNC |

| Ketebalan Pemotongan | Menangani bahan tebal dengan baik |

| Pemotongan Multi-lapis | Ya |

| Kompleksitas Jalur Pemotongan | Sangat cocok untuk sudut yang rumit dan tajam |

| Keamanan | Lebih aman (tidak panas tinggi atau api terbuka) |

| Biaya Operasional | Rendah |

Keuntungan dan Kerugian Sistem Pneumatik

Sistem pneumatik memiliki banyak kelebihan. Sistem ini bereaksi cepat dan memungkinkan Anda mengubah tekanan dengan mudah. Perawatannya mudah, biasanya hanya dengan mengganti bilahnya. Sistem ini menggunakan sedikit energi dan memotong dengan cepat. Namun, Anda harus memeriksa kebocoran udara dan menjaga tekanan tetap stabil. Ini membuat sistem bekerja dengan baik. Aktuasi pneumatik paling baik untuk mesin di pabrik. Aktuasi ini tidak bekerja dengan baik untuk perkakas tangan atau pekerjaan non-pabrik.

Pemotongan Hancur vs. Metode Lainnya

Perbandingan Pemotongan Geser

Perbedaan Operasional

Pemotongan geser menggunakan dua bilah yang bergerak saling melewati. Cara kerjanya seperti gunting dan mengiris material dengan rapi. Pemotongan remuk berbeda. Pemotongan ini menekan bilah bundar ke landasan yang keras. Material akan pecah karena tekanan, bukan karena teriris. Beberapa penelitian menunjukkan bahwa pemotongan remuk dapat menghemat lebih banyak material dan uang daripada beberapa alat canggih. Pemotongan geser menghasilkan tepi yang lebih halus dan lebih tepat. Pemotongan remuk lebih baik untuk material yang keras atau berserat.

Persyaratan Pengaturan dan Pemeliharaan

Mesin pemotong geser perlu menyelaraskan kedua bilah dengan benar. Pekerja harus mengatur sudut dan jarak antar bilah. Ini memerlukan waktu tetapi tetap menjaga ketajamannya. Pemotong geser perlu mengasah kedua bilah dan memeriksa kerusakannya. Pengaturan pemotongan dengan metode crush lebih mudah. Pekerja hanya menyelaraskan bilah dan landasan. Perawatannya sebagian besar adalah mengganti bilah saat tumpul. Ini membuat pemotongan dengan metode crush lebih mudah untuk pabrik yang sibuk.

Bahan dan Aplikasi yang Cocok

Pemotongan geser paling cocok untuk bahan yang tipis, lemah, atau mudah pecah. Pabrik menggunakannya untuk film, foil, dan kertas tipis. Pemotongan remuk cocok untuk bahan yang tebal, kuat, atau lengket. Banyak mesin pemotong di pabrik tekstil, karet, dan nonwoven menggunakan pemotongan remuk. Pilihannya tergantung pada apa yang Anda potong dan bagaimana Anda ingin tepinya terlihat.

| Metrik Kinerja | Pemotongan Geser | Pemotongan Hancur |

|---|---|---|

| Kehalusan Tepi | Sangat halus | Kasar, bergerigi |

| Ketepatan Tepi Persegi | Persegi, tepat | Terdeformasi, tergulung |

| Pembangkitan Debu | Minimal | Lebih banyak debu |

| Kehidupan Pisau | Lebih panjang | Singkat |

| Kesesuaian Bahan | Tipis, rapuh | Kuat, berserat |

Perbandingan Pisau Cukur

Perbedaan Operasional

Pemotongan silet menggunakan bilah tajam dan tipis untuk memotong material. Bilah tetap diam saat material bergerak melewatinya. Ini menghasilkan potongan yang sangat bersih. Pemotongan remuk menggunakan gaya untuk memecah material. Pemotongan silet paling baik untuk material ringan. Pemotongan remuk berfungsi untuk produk yang berat atau berlapis.

Persyaratan Pengaturan dan Pemeliharaan

Mesin pemotong silet sering kali memerlukan bilah baru karena cepat tumpul. Pengaturannya sederhana, tetapi pekerja harus memperhatikan bilahnya. Perawatan berarti mengganti bilah dan menjaga mesin tetap bersih. Pengaturan pemotongan dengan alat penghancur bertahan lebih lama sebelum memerlukan bilah baru. Namun, bilah dapat lebih cepat aus jika memotong benda yang sangat keras.

Bahan dan Aplikasi yang Cocok

Pemotongan dengan pisau cukur paling baik untuk film tipis, plastik pembungkus, dan kertas tipis. Pemotongan dengan pisau cukur tidak cocok untuk benda tebal atau lengket. Pemotongan dengan pisau cukur lebih baik untuk pita perekat, tekstil, dan kain nonwoven. Pabrik memilih pemotong yang tepat berdasarkan apa yang perlu dipotong.

Kualitas dan Pemeliharaan Tepi

Perbandingan Kualitas Tepi

Kualitas tepi tergantung pada metode pemotongan yang digunakan. Pemotong geser menghasilkan tepi yang paling halus dan paling presisi. Pemotong silet juga menghasilkan tepi yang bersih tetapi dapat meninggalkan gerinda kecil jika bilahnya tumpul. Pemotongan remuk sering kali menghasilkan tepi yang lebih kasar dengan beberapa tonjolan. Pengujian menunjukkan pemotongan remuk dapat menghasilkan lebih banyak gerinda dan tepi yang kurang bengkok. Pabrik yang membutuhkan tepi yang sempurna biasanya memilih pemotongan geser atau silet.

Tuntutan Pemeliharaan

Kebutuhan perawatan berbeda untuk setiap metode. Pemotong geser perlu diasah dan sering disiapkan dengan hati-hati. Pemotong silet sering membutuhkan bilah baru. Sistem pemotongan remuk memerlukan lebih sedikit penyiapan tetapi mungkin memerlukan bilah baru lebih sering, terutama untuk material keras. Pengujian menunjukkan bilah yang bagus bertahan lebih lama, tetapi semua pemotong perlu pemeriksaan rutin untuk menjaga agar pemotongan tetap aman dan bersih.

Catatan: Memilih alat pemotong dan metode pemotongan yang tepat membantu pabrik menyeimbangkan kualitas tepi, kecepatan, dan biaya perawatan.

Aplikasi Pemotongan Hancur

Industri yang Menggunakan Crush Cut Slitting

Banyak pabrik menggunakan crush cut slitting setiap hari. Metode ini membantu banyak industri besar. Setiap industri memiliki bahan dan kebutuhan yang berbeda. Mesin slitter membantu pekerjaan ini. Berikut adalah beberapa industri utama yang menggunakan crush cut slitting:

- Industri Kertas

Pabrik kertas menggunakan mesin pemotong kertas untuk memotong gulungan kertas besar. Ini menghasilkan gulungan kertas yang lebih kecil untuk buku catatan dan kemasan. Mesin harus bekerja cepat dan menangani gulungan kertas besar. - Industri Kain Nonwoven

Pabrik yang memproduksi tisu basah dan popok menggunakan teknik slitting. Bahan nonwoven bersifat lembut dan terkadang lengket. Pemotong harus memotongnya dengan bersih tanpa menimbulkan debu. - Industri Tekstil

Pabrik tekstil menggunakan mesin pemotong kain dan kain felt. Mesin ini memotong serat yang tebal dan kuat. Dengan demikian, tepi kain tetap rapi dan bahan tetap terjaga. - Industri Karet

Lembaran dan pita karet perlu dipotong dengan hati-hati. Pemotongan dengan metode crush slitting bekerja dengan baik untuk karet yang kuat dan elastis. Mesin pemotong ini dapat memotong karet alam dan karet palsu. - Industri Film Plastik

Pabrik yang memproduksi bungkus dan kantong plastik menggunakan teknik crush slitting. Mesin pemotong harus memotong film tipis tanpa merobeknya. Ini membantu membuat gulungan yang halus untuk pengemasan.

Catatan: Industri lain seperti pita, insulasi, dan mobil juga menggunakan pemotongan dengan metode crush slitting. Metode ini cocok untuk material yang kuat atau berlapis yang memerlukan pemotongan cepat dan bersih.

Bahan dan Pilihan Mata Pisau

Memilih bilah pisau yang tepat penting untuk pemotongan dengan metode crush cut. Bahan yang berbeda membutuhkan bilah pisau dan tingkat kekerasan yang berbeda. Tabel di bawah ini menunjukkan bilah pisau mana yang paling cocok untuk setiap bahan:

| Industri | Bahan Umum | Bahan Pisau | Jenis Tepi Pisau |

|---|---|---|---|

| Kertas | Kraft, dilapisi, didaur ulang | Baja perkakas D2 | Radius, 45° |

| Kain bukan tenunan | Polipropilena, poliester | HSS-M2, karbida | Radius, 60° |

| Tekstil | Katun, kain felt, campuran | HSS-M2, D2 | Radius, 45° |

| Industri Karet | Alami, sintetis | D2, karbida | Radius, 30° |

| Film Plastik | PE, PET, PVC | HSS-M2, karbida | Radius, 60° |

Pabrik memilih bahan bilah berdasarkan seberapa keras atau lengketnya bahan tersebut. Baja perkakas D2 bagus untuk kertas dan karet karena tahan lama. Bilah HSS-M2 lebih baik untuk tekstil yang keras atau kain nonwoven yang lengket. Bilah karbida bekerja untuk bahan yang kasar atau tebal. Tepi yang melengkung membantu melindungi bilah dan landasan.

Mesin pemotong sering kali menggunakan tenaga udara untuk mengendalikan tekanan bilah. Pekerja dapat mengubah gaya untuk setiap material. Bilah, tepi, dan tekanan yang tepat menghasilkan potongan yang bersih dan membantu bilah bertahan lebih lama.

Kiat: Memeriksa dan mengganti bilah pisau secara rutin akan membuat mesin bekerja dengan baik. Menggunakan bilah pisau yang tepat untuk setiap pekerjaan berarti lebih sedikit penghentian dan menghasilkan produk yang lebih baik.

Pisau Potong Remuk Kustom

Manfaat Kustomisasi

Pabrik memiliki masalah yang berbeda saat memotong bahan. Pisau potong khusus membantu dengan menyesuaikan kebutuhan setiap pekerjaan. Perusahaan seperti Fasco Machine dan Muraplast telah berbagi cerita tentang hal ini. Cerita mereka menunjukkan bahwa pisau khusus berfungsi untuk bentuk khusus atau pemotongan cepat. Pisau standar tidak selalu dapat melakukan pekerjaan ini.

Industri kertas membutuhkan bilah yang dapat memotong dengan bersih dan tahan lama. Pisau industri khusus menggunakan material yang kuat seperti baja berkecepatan tinggi atau karbida. Hal ini membuat pisau tersebut tangguh dan dapat diandalkan. Setiap bilah dibuat agar pas dengan mesin. Ini berarti lebih sedikit limbah dan lebih banyak produk yang dihasilkan. Perusahaan yang menggunakan bilah khusus memiliki lebih sedikit waktu henti dan lebih sedikit perbaikan. Tabel di bawah ini menunjukkan bagaimana bilah khusus lebih baik daripada bilah standar:

| Metrik | Pisau Standar | Pisau Kustom |

|---|---|---|

| Umur Pisau | ~10 hari | Lebih dari 40 hari |

| Pengurangan Waktu Henti | Garis dasar | 65% lebih sedikit waktu henti |

| Perbaikan Darurat | Garis dasar | 70% lebih sedikit perbaikan |

| Biaya Penggantian Tahunan | $25,000 | $9,500 |

Pisau industri yang dibuat khusus membantu perusahaan menghemat uang dan tetap aman. Misalnya, perusahaan daur ulang Jerman menghemat biaya penyimpanan sebesar 40%. Pembuat furnitur Tiongkok memperoleh $1,2 juta lebih banyak setelah menggunakan pisau khusus.

Solusi Nanjing Metal

Nanjing Metal adalah perusahaan terpercaya produsen pisau industri. Mereka memiliki pengalaman lebih dari 20 tahun. Perusahaan ini dikenal karena tim desain dan manufakturnya yang terampil. Nanjing Metal membuat pisau industri khusus untuk banyak pekerjaan pabrik. Teknisi mereka bekerja sama dengan klien untuk merancang pisau sesuai kebutuhan tertentu.

Banyak pabrik memilih Nanjing Metal karena layanannya yang cepat dan kualitasnya yang tinggi. Perusahaan ini menggunakan mesin CNC canggih dan material berkualitas tinggi. Ini memastikan setiap bilah pisau memenuhi aturan yang ketat. Bilah pisau khusus Nanjing Metal membantu pabrik mendapatkan potongan yang lebih bersih dan masa pakai bilah pisau yang lebih lama. Bilah pisau ini juga membantu pabrik bekerja lebih cepat dan lebih baik.

Pembaca yang tertarik dapat Kontak seorang teknisi penjualan Nanjing Metal untuk berbicara tentang solusi bilah khusus untuk mesin mereka.

Keuntungan dan Keterbatasan

Manfaat Utama

Pisau pemotong remuk memiliki banyak keunggulan untuk mesin di pabrik. Banyak pabrik menyukai metode ini karena mudah, murah, dan dapat digunakan untuk berbagai pekerjaan. Pekerja menggunakan pisau ini untuk berbagai macam material. Hal ini menjadikannya pilihan utama di banyak tempat.

- Penghematan Biaya: Pisau pemotong remuk memiliki ujung yang kuat. Pisau ini tidak perlu sering diganti. Ini menghemat uang seiring berjalannya waktu.

- Kesederhanaan: Desainnya sederhana. Pekerja dapat memasang dan memperbaiki bilah ini dengan mudah. Mereka tidak memerlukan banyak pelatihan.

- Keserbagunaan: Mata pisau ini dapat digunakan untuk berbagai hal. Mata pisau ini dapat memotong tekstil, karet, kertas, dan kain nonwoven.

- Daya tahan: Mata pisaunya tidak terlalu tajam tetapi kuat. Dapat menahan tekanan tinggi tanpa patah. Mengasah mata pisau akan membuatnya lebih tahan lama dan membuat potongan merata.

- Presisi: Pabrik dapat membuat potongan yang akurat. Ini berfungsi bahkan untuk bentuk yang rumit atau ruang yang kecil.

- Kemampuan beradaptasi: Pekerja dapat mengubah tekanan dan pengaturan. Ini membantu dalam berbagai pekerjaan dan perubahan kebutuhan.

Tabel di bawah ini menunjukkan seberapa baik pisau ini bekerja dan apa saja manfaatnya di pabrik:

| Metrik Efektivitas | Keterangan | Manfaat Utama Telah Terbukti |

|---|---|---|

| Kekerasan dan Ketahanan Aus yang Luar Biasa | Pisau karbida tetap tajam lebih lama karena lebih keras dari baja. | Pisau lebih awet, lebih sedikit memerlukan penggantian, dan hemat uang. |

| Kinerja Pemotongan Unggul | Mereka membuat potongan yang bersih dan rapi pada banyak bahan dengan sedikit usaha. | Potongannya selalu bagus, dan prosesnya dapat diandalkan. |

| Peningkatan Daya Tahan & Umur Panjang | Tidak cepat rusak atau bengkok, bahkan pada pekerjaan berat atau suhu tinggi. | Lebih sedikit waktu henti, lebih sedikit perbaikan, dan kecepatan kerja lebih baik. |

| Kemampuan Pemotongan Presisi | Mereka dapat memotong bentuk yang keras dan ruang kecil dengan sangat baik. | Lebih sedikit kesalahan, produk yang lebih baik, dan hasil yang sama setiap saat. |

| Keserbagunaan di Berbagai Aplikasi | Mereka bekerja di banyak industri dan dengan banyak material. | Lebih fleksibel, pemotongan lebih baik, dan lebih sedikit pergantian mata pisau. |

Kiat: Pabrik dapat memilih jenis tepi yang berbeda, seperti melengkung atau bergerigi, agar sesuai dengan material dan mendapatkan potongan yang lebih baik.

Batasan Utama

Pisau pemotong remuk memiliki banyak kelebihan, tetapi ada juga beberapa masalah. Hal-hal ini dapat mengubah cara kerjanya dan tampilan produk akhir.

- Kualitas Tepi: Potongan mungkin memperlihatkan serat, bulu halus, atau tampak sedikit remuk. Tepinya tidak semulus potongan dengan gunting atau silet.

- Pembangkitan Debu: Memotong kertas atau benda serupa dapat menghasilkan debu. Debu dapat menumpuk dan menghentikan mesin jika tidak dibersihkan.

- Kebutuhan Perawatan: Pekerja harus mengawasi pisau dan landasan dengan saksama. Tekanan atau kekerasan yang salah dapat merusak atau membuat alur pada bilah pisau.

- Kesesuaian Bahan: Metode ini paling cocok untuk benda yang keras, berserat, atau berlapis. Metode ini tidak cocok untuk benda yang sangat tipis atau mudah pecah.

- Batasan Kecepatan: Kebanyakan dudukan pneumatik bekerja hingga 300 m/menit. Jika kecepatannya terlalu tinggi, bilahnya bisa aus, menghasilkan lebih banyak debu, dan membutuhkan lebih banyak oli.

- Kontrol Operasional: Tekanan harus tepat. Tekanan yang terlalu besar dapat merusak bilah atau landasan. Tekanan yang terlalu kecil dapat menyebabkan pemotongan yang buruk.

Catatan: Bentuk pisau, tekanan udara, dan desain dudukan semuanya penting untuk hasil yang baik. Otomatisasi membantu menjaga hasil potongan tetap sama, terutama saat membuat banyak produk.

Mengetahui sisi baik dan buruk pisau potong hancur membantu pabrik memilih cara terbaik untuk memotong material mereka.

Pisau pemotong remuk merupakan peralatan penting di banyak pabrik. Pisau ini menggunakan tenaga yang kuat dan bentuk khusus untuk menghancurkan benda keras dengan cepat. Banyak industri memilih pisau ini karena bekerja dengan baik dan dapat menangani pekerjaan berat.

- Jari-jari dan sudut bilah seperti 30°, 45°, atau 60° membantu menghasilkan potongan yang lebih baik.

- Pabrik memilih D2, HSS-M2, atau karbida agar bilah lebih tahan lama.

- Pelapis dan desain khusus membantu setiap pisau melakukan tugasnya dengan lebih baik.

Memilih alat pemotong yang tepat dan menggantinya untuk setiap pekerjaan dapat membantu pabrik memproduksi lebih banyak produk. Jika Anda menginginkan solusi khusus, Anda dapat menghubungi teknisi penjualan Nanjing Metal.

Tanya Jawab Umum

Bahan apa yang bisa diproses dengan pisau potong hancur?

Pisau pemotong remuk berfungsi untuk banyak hal. Pisau ini dapat memotong tekstil, karet, kertas, kain nonwoven, dan film plastik. Pabrik menggunakan pisau ini untuk memotong benda yang keras, berserat, atau lengket. Pisau standar tidak berfungsi dengan baik untuk bahan-bahan ini.

Seberapa sering pabrik harus mengganti bilah pemotong penghancur?

Lamanya bilah pisau bertahan tergantung pada apa yang dipotong dan seberapa sering digunakan. Sebagian besar pabrik memeriksa bilah pisau setiap hari. Mereka mengganti bilah pisau jika potongannya terlihat kasar atau tidak rata. Memilih bahan bilah pisau yang tepat membantu bilah pisau bertahan lebih lama.

Mengapa pabrik menggunakan sistem pneumatik dengan pisau pemotong hancur?

Sistem pneumatik memberikan tekanan yang stabil dan bergerak cepat. Ini membantu menghasilkan potongan yang selalu sama. Pekerja dapat mengubah tekanan udara untuk setiap pekerjaan. Ini membuat pemotongan lebih aman dan mudah.

Bisakah Nanjing Metal membuat pisau potong hancur khusus untuk mesin khusus?

Ya. Nanjing Metal adalah perusahaan tepercaya yang membuat pisau industri. Tim mereka membuat pisau khusus untuk banyak mesin. Pabrik dapat meminta bentuk, ukuran, atau bahan khusus.

Lihat Juga

Bilah Pisau Melingkar Industri

Atas 5 Masalah Keausan Umum pada Pisau Gunting Bundar dan Solusi Perbaikan Ahli

Cara Menjaga Pisau Bundar Anda Tetap Tajam dan Tahan Lama

HCara Memilih Bilah Bundar yang Tepat untuk Aplikasi Anda: Panduan Lengkap