| Nama Lain | 1TP1Pisau Tlurgis, 1TP1Pisau Tlurgis |

|---|---|

| Tempat Asal | Tiongkok |

| Aplikasi | Metallurgi, Jalur Pengawetan, Pabrik pengerolan dingin, Pabrik baja tahan karat, Pabrik baja listrik, Pabrik galvanisasi lelehan panas |

| Bahan | H13, H13K, LD |

| Nomor Model | MT-MB |

| Layanan OEM | Tersedia |

| Ketentuan Pembayaran | L/C, T/T, Western Union |

| Kemasan | Kotak Karton, Peti Kayu |

| Waktu Pengiriman | 7-20 Hari |

Bagikan ke:

Istilah "Rebar Shear Blade" mengacu pada alat pemotong tugas berat yang secara khusus dirancang untuk menggunting atau memotong batang tulangan baja (tulang baja). Bilah-bilah ini merupakan komponen penting dalam mesin pemotong tulangan, yang digunakan di lokasi konstruksi, pabrik prafabrikasi, dan fasilitas pemrosesan baja untuk memotong tulangan sesuai panjang yang dibutuhkan untuk tulangan beton. Rebar Shear Blades direkayasa untuk menahan kekuatan tarik dan kekerasan tulangan yang tinggi, menghasilkan pemotongan yang bersih dan efisien. Bilah-bilah ini biasanya tersedia berpasangan, dengan bilah bawah yang tetap dan bilah atas yang bergerak yang memberikan gaya yang signifikan untuk menggunting tulangan. Desainnya menekankan daya tahan, kekuatan, dan tepi pemotongan yang presisi untuk memastikan pemrosesan tulangan yang akurat dan aman. Rebar Shear Blades juga terkadang disebut sebagai "bilah pemotong tulangan," "bilah geser batang baja," "bilah pemotong batang tulangan," "bilah guillotine tulangan," atau "bilah geser hidrolik (untuk tulangan)," tergantung pada jenis mesin pemotong tulangan yang digunakan.

Bilah Geser Rebar terutama digunakan dalam industri konstruksi dan pemrosesan baja untuk memotong batang tulangan baja hingga panjang tertentu. Desainnya yang kokoh dan aksi pemotongan yang kuat membuatnya sangat diperlukan untuk berbagai aplikasi, termasuk:

Ukuran dan desain Pisau Pemotong Besi Beton, serta kekuatan mesin geser, menentukan diameter maksimum dan mutu tulangan yang dapat dipotong.

Bahan-bahan yang digunakan dalam pembuatan Rebar Shear Blades sangat penting karena kemampuannya menahan gaya yang sangat besar dan sifat abrasif dari pemotongan batang tulangan baja. Bahan-bahan ini harus memiliki kekerasan, ketangguhan, dan ketahanan aus yang tinggi. Bahan-bahan yang umum termasuk:

Perlakuan panas untuk mencapai kekerasan dan ketangguhan yang optimal merupakan langkah penting dalam proses pembuatan Rebar Shear Blades. Proses perlakuan panas khusus disesuaikan dengan paduan baja yang digunakan dan aplikasi yang dimaksudkan.

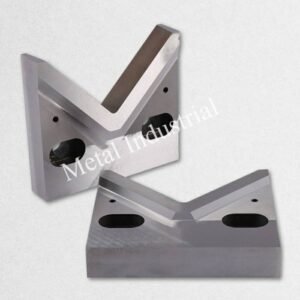

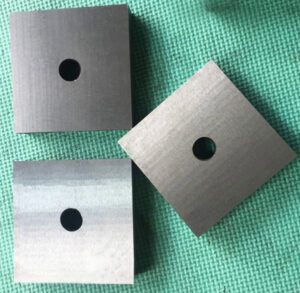

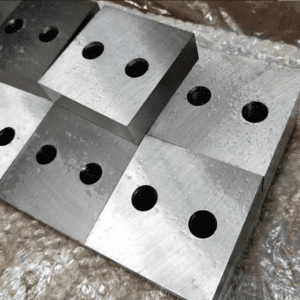

Bilah Geser Rebar biasanya tersedia berpasangan, terdiri dari bilah atas (bergerak) dan bilah bawah (tetap). Geometri tepi pemotongan sangat penting untuk pemotongan yang bersih dan efisien. Bentuk dan fitur umum meliputi:

Bentuk dan sudut khusus dari ujung pemotongan, serta dimensi keseluruhan dan konfigurasi pemasangan Rebar Shear Blade, ditentukan oleh jenis dan kapasitas mesin pemotong tulangan serta kisaran ukuran tulangan yang dirancang untuk ditangani.

Jika Anda tidak menemukan pisau yang Anda cari, kami juga dapat menyesuaikannya. Lihat “Pisau Kustom" " kami untuk mempelajari caranya! Selamat datang untuk bertanya!

Nikmati kemudahan impor yang mulus. Dari transportasi hingga bea cukai, kami menangani seluruh proses. Anda hanya perlu membayar PPN dan menunggu barang tiba di perusahaan.

Kami telah melihat pisau kami digunakan dalam berbagai aplikasi dan siap menangani proyek apa pun yang Anda berikan kepada kami – memberikan akurasi, daya tahan, dan harga kompetitif yang tak tertandingi.

Baik Anda menyediakan gambar, sketsa, atau sampel, kami mampu menggambar dan memproduksi untuk Anda. Kami juga memiliki kemampuan untuk membantu memodifikasi desain dan spesifikasi yang ada untuk meningkatkan hampir semua aplikasi perkakas industri. Silakan hubungi tim penjualan khusus kami untuk mendiskusikan persyaratan spesifik Anda.

Serangkaian pengujian dan inspeksi dilakukan untuk mengontrol kualitas, termasuk inspeksi artikel pertama, inspeksi bahan masuk dan bahan bersertifikat, inspeksi kualitas dalam proses, serta inspeksi kualitas akhir.

Baik Anda seorang importir, distributor, grosir, atau pengguna akhir, kami menyambut Anda untuk bergabung dengan MOQ minimum, tanpa kerumitan untuk pertanyaan, dan lebih banyak kebebasan untuk pembelian.

Jadilah pemantau eksklusif Anda, transmisi reguler setiap node penting dalam lini produksi, tidak peduli seberapa jauh, kemajuan produk sejauh mungkin untuk dipahami.

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Tetap ikuti berita terbaru kami.