| Nama lain | Bilah Pembuat Kantong, Pisau Pemotong Kantong, Bilah Perforasi Kantong, Bilah Bentuk T, Pisau Bergerigi, Pisau bergerigi mesin pengemasan vertikal, Pisau bergerigi mesin pengemas vertikal, Pisau bergerigi pengemasan vertikal, Pisau bergerigi pengemasan vertikal, Pisau bergerigi untuk mesin pengemasan vertikal |

|---|---|

| Tempat asal | Cina |

| Aplikasi | Plastik, Kemasan, Tas, Gulungan |

| Bahan | Baja karbon |

| Nomor model | CV-BM |

| Layanan OEM | Tersedia |

| Syarat pembayaran | L/C, T/T, Western Union |

| Kemasan | Kotak karton, Dalam kotak kayu |

| Waktu Pengiriman | 7-20 Hari |

Bagikan ke:

Packaging blades, also referred to as packaging machine knives, are specialized cutting tools designed for integration into packaging machinery. These blades perform a variety of cutting, slitting, perforating, and sealing tasks essential for preparing and processing packaging materials like films, foils, paper, cardboard, and various other flexible or rigid materials used to contain and protect goods. The term “packaging blades” is a broad descriptor encompassing a wide array of blade types tailored to the specific demands of different packaging equipment and processes.

Packaging blades are fundamental components in a multitude of automated packaging processes across diverse industries. Their applications are extensive and include:

The selection of materials for packaging blades is crucial to ensure food safety (where applicable), resist corrosion from various product and packaging material interactions, and maintain a sharp, durable cutting edge for consistent, high-speed operation. Common materials include:

Surface treatments and coatings like Titanium Nitride (TiN) or Chromium plating are often applied to enhance surface hardness, reduce friction, and improve resistance to wear and corrosion, thereby extending the lifespan of packaging blades.

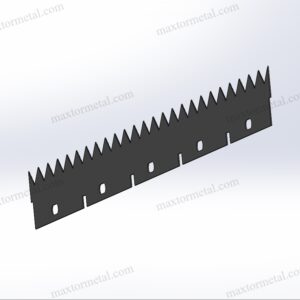

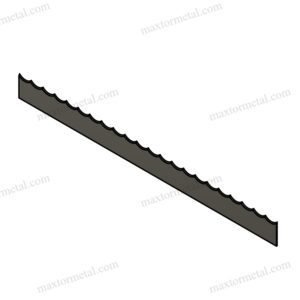

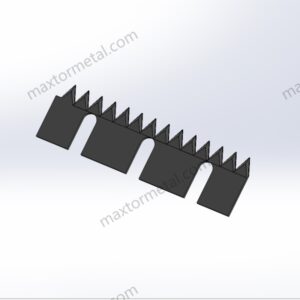

Packaging blades are manufactured in a wide variety of shapes and edge configurations to match the specific cutting or sealing mechanisms of different packaging machines:

The working principle of packaging blades varies depending on their function and the machine they are integrated into. Cut-off blades typically employ a shearing action against a fixed anvil or another moving blade. Sealing knives use heat and pressure to fuse and cut films. Rotary blades provide continuous cutting as they rotate against the material. The precision of the blade’s geometry, the sharpness of its edge, the applied force, and the synchronization with the machine’s operation are all critical factors in achieving clean, accurate cuts and reliable seals in packaging processes.

Selamat Datang di menanyakan!

If you don’t find the blade you are looking for, we can also customize it. See our “Pisau Khusus"untuk mempelajari caranya!

Mudah menikmati kenyamanan impor, dari transportasi hingga bea cukai, kami menangani seluruh prosesnya, Anda hanya perlu membayar PPN dan menunggu barang tiba di perusahaan.

Kami telah melihat bilahnya digunakan dalam banyak aplikasi dan siap menangani proyek apa pun yang Anda lakukan - memberikan akurasi, daya tahan, dan harga kompetitif yang tak tertandingi.

Baik Anda menyediakan gambar, sketsa, atau sampel, kami dapat menggambar dan memproduksi untuk Anda. Kami juga memiliki kemampuan untuk membantu memodifikasi desain dan spesifikasi yang ada untuk meningkatkan hampir semua aplikasi perkakas industri. Silakan hubungi tim penjualan khusus kami untuk mendiskusikan kebutuhan spesifik Anda.

Serangkaian pengujian dan inspeksi dilakukan untuk mengendalikan kualitas, termasuk inspeksi artikel pertama, inspeksi material yang masuk, dan material yang disertifikasi, inspeksi kualitas dalam proses, dan inspeksi kualitas akhir.

Apakah Anda seorang importir, distributor, grosir atau pengguna akhir, kami mengundang Anda untuk bergabung dengan kami dengan MOQ minimum, tanpa kerumitan untuk bertanya dan lebih banyak kebebasan untuk membeli.

Jadilah monitor eksklusif Anda, transmisi rutin setiap simpul penting di jalur produksi, tidak peduli seberapa jauh jaraknya, kemajuan produk sejauh mungkin untuk dipahami!

Nanjing Metal Industri CO., Terbatas

Taman Industri Mingjue, Lishui, Nanjing, Jiangsu, Cina

Ikuti terus berita terbaru kami.