| Nama Lain | Pengikis Tinta |

|---|---|

| Tempat Asal | Tiongkok |

| Aplikasi | Mesin cetak, Pencetakan gravure, Pencetakan fleksibel, Pencetakan plastik |

| Bahan | SK4, C100, 20C |

| Nomor Model | GP-DB |

| Layanan OEM | Tersedia |

| Ketentuan Pembayaran | L/C, T/T, Western Union |

| Kemasan | Kotak Karton, Peti Kayu |

| Waktu Pengiriman | 7-20 Hari |

Bagikan ke:

Metal Industrial telah memprioritaskan pemenuhan kebutuhan pelanggan selama bertahun-tahun dengan terus menambahkan fitur-fitur baru pada bilah tinta mereka. Bilah kami digunakan dalam pengemasan gravure, pencetakan fleksografik, UV flexo, pelapisan pernis offset, pencetakan bahan dekoratif, pencetakan peka tekanan, sablon, dan aplikasi pelapisan.

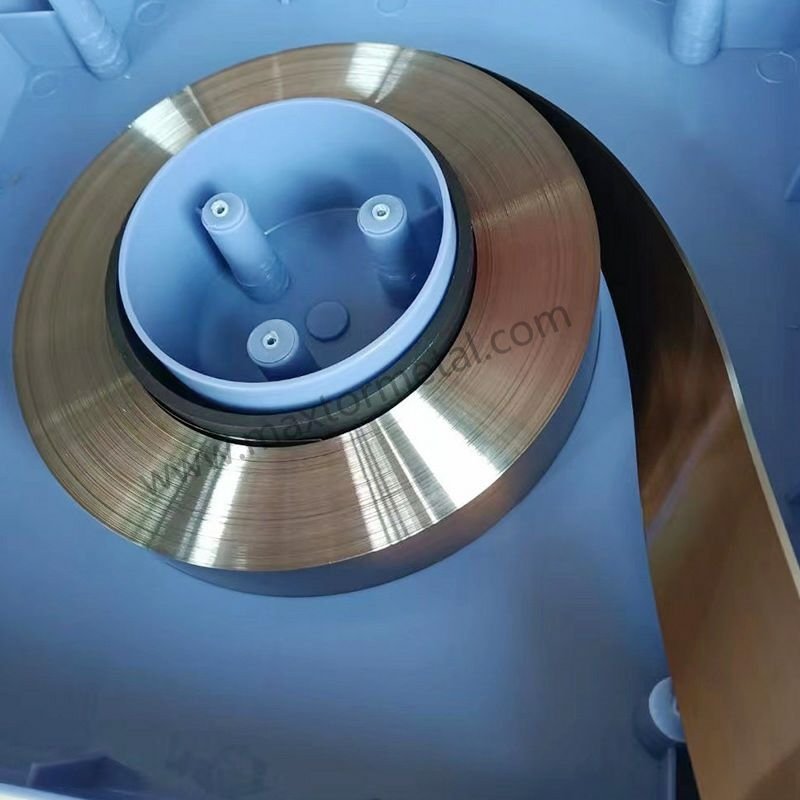

Metal Industrial menggunakan jalur produksi CNC presisi untuk memproduksi bilah pencampur tinta berkualitas tinggi. Proses produksi dan pemeriksaan ketat kami memastikan produk kami menonjol dalam industri bilah pencampur tinta.

Dengan mematuhi standar kualitas yang utama dan berfokus pada persyaratan pelanggan, Metal Industrial memungkinkan klien untuk mempertahankan kualitas cetak yang konsisten dalam proses cetak yang panjang dan meminimalkan waktu henti.

Pisau ink doctor kami cocok untuk pencetakan gravure dan fleksografi. Masalah seperti rona warna, goresan, filamen, garis, dan keausan lapisan krom biasanya muncul karena beragamnya mesin cetak dan bahan substrat. Metal Industrial menawarkan berbagai pisau untuk mengatasi berbagai kebutuhan ini. Untuk pencetakan kemasan gravure, tinta yang lebih kental sering kali menyebabkan goresan dan keausan ekstra pada pisau dan silinder. Pisau kami beradaptasi dengan tinta ini dan dapat digunakan kembali, sehingga mengurangi waktu henti.

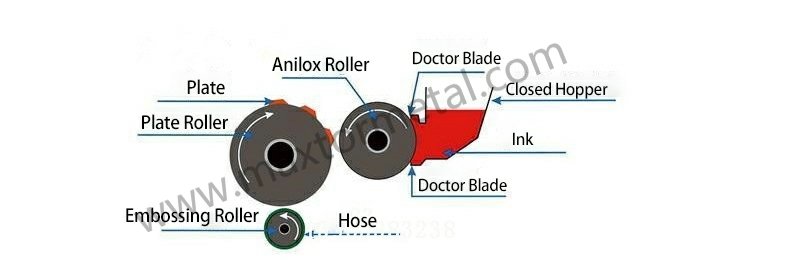

Bilah keramik Metal Industrial ideal untuk proses pelapisan dan laminasi dalam pencetakan fleksografi. Mesin cetak flekso modern biasanya menggunakan rol aniloks dan bilah doktor untuk pemindahan tinta. Lebar cetak mesin cetak flekso berkisar antara 200 mm hingga 4000 mm. Sistem bilah tunggal berfungsi untuk mesin cetak yang lebih kecil, sedangkan sistem tertutup lebih baik untuk mesin cetak sedang hingga besar. Kecepatan cetak berkisar antara 50 hingga 450 meter per menit. Bilah terbalik biasanya memiliki sudut 30°-40°. Karena permukaan rol aniloks keramik yang halus, tekanan bilah seharusnya minimal. Faktor yang memengaruhi masa pakai bilah meliputi bentuk dan jumlah garis sel aniloks serta ketebalan bilah.

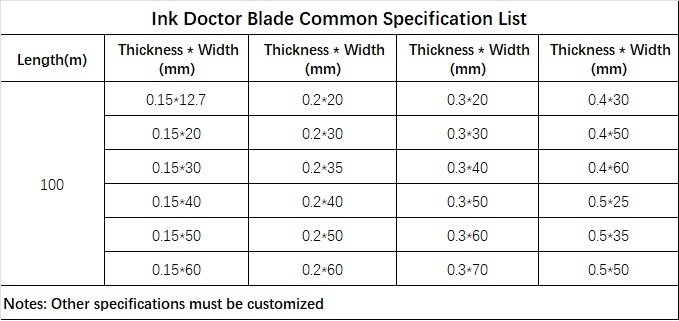

Mata pisau keramik Metal Industrial sesuai untuk pencetakan fleksografi, dengan mata pisau setebal 0,20 mm dan terkadang 0,15 mm. Sistem tertutup tidak memerlukan mata pisau cadangan, jadi mata pisau standar, miring, dan komposit semuanya dapat digunakan.

Untuk pencetakan halftone, seperti pencetakan label, ketebalan bilah biasanya 0,075 mm. Prinsip umumnya adalah bilah yang lebih tipis memiliki kinerja yang lebih baik.

Persyaratan Pemasangan: Untuk pencetakan gravure, sudut kontak ideal untuk pemasangan bilah adalah 55-65°. Sudut yang lebih kecil dapat mengakibatkan pengelapan tidak tuntas dan pelat berembun.

Doctor blade adalah bilah tipis dan fleksibel, biasanya terbuat dari logam atau plastik, yang digunakan dalam berbagai proses pelapisan dan pencetakan industri untuk mengendalikan ketebalan lapisan cair yang diaplikasikan pada suatu permukaan. Dalam pencetakan, khususnya fleksografi dan gravure, doctor blade memainkan peran penting dalam menghilangkan kelebihan tinta dari permukaan silinder cetak (rol anilox atau silinder gravure), memastikan bahwa hanya tinta yang tertahan di dalam sel terukir yang dipindahkan ke substrat. Istilah "doctor blade" berasal dari fungsinya untuk "menghapus" atau mengendalikan jumlah cairan.

Selain untuk pencetakan, doctor blade juga digunakan dalam aplikasi pelapisan lain guna mengukur atau meratakan ketebalan pelapisan yang diaplikasikan ke berbagai substrat.

Pisau dokter memiliki beragam aplikasi di beberapa industri:

Pemilihan material untuk doctor blade sangat penting dan bergantung pada aplikasi spesifik, material yang diproses (tinta, larutan pelapis), substrat, dan kecepatan operasi. Material umum meliputi:

Pisau dokter tersedia dalam berbagai profil tepi dan ketebalan untuk mengoptimalkan kinerja untuk berbagai aplikasi:

Ketebalan Doctor Blade juga bervariasi tergantung pada aplikasi dan fleksibilitas serta kekakuan yang dibutuhkan. Ketebalan umum untuk bilah logam berkisar antara 0,004″ hingga 0,020″ atau lebih.

Pisau dokter beroperasi dengan memberikan tekanan terkendali terhadap permukaan silinder yang berputar (anilox atau gravure) atau substrat yang dilapisi.

Sedang dicetak:

Dalam pelapisan:

Efektivitas bilah pisau bergantung pada faktor-faktor seperti bahan bilah, profil tepi, ketebalan, sudut saat bilah pisau dipegang pada silinder atau substrat, tekanan yang diberikan, kondisi permukaan silinder atau substrat, dan sifat tinta atau pelapis yang digunakan. Pemilihan, pengaturan, dan perawatan bilah pisau yang tepat sangat penting untuk mencapai hasil optimal dalam proses pencetakan dan pelapisan.

" Selamat datang untuk bertanya!

Jika Anda tidak menemukan bilah geser yang Anda cari, kami juga dapat menyesuaikannya, lihat “Pisau Kustom" " untuk mempelajari caranya!

Nikmati kemudahan impor yang mulus. Dari transportasi hingga bea cukai, kami menangani seluruh proses. Anda hanya perlu membayar PPN dan menunggu barang tiba di perusahaan.

Kami telah melihat pisau kami digunakan dalam berbagai aplikasi dan siap menangani proyek apa pun yang Anda berikan kepada kami – memberikan akurasi, daya tahan, dan harga kompetitif yang tak tertandingi.

Baik Anda menyediakan gambar, sketsa, atau sampel, kami mampu menggambar dan memproduksi untuk Anda. Kami juga memiliki kemampuan untuk membantu memodifikasi desain dan spesifikasi yang ada untuk meningkatkan hampir semua aplikasi perkakas industri. Silakan hubungi tim penjualan khusus kami untuk mendiskusikan persyaratan spesifik Anda.

Serangkaian pengujian dan inspeksi dilakukan untuk mengontrol kualitas, termasuk inspeksi artikel pertama, inspeksi bahan masuk dan bahan bersertifikat, inspeksi kualitas dalam proses, serta inspeksi kualitas akhir.

Baik Anda seorang importir, distributor, grosir, atau pengguna akhir, kami menyambut Anda untuk bergabung dengan MOQ minimum, tanpa kerumitan untuk pertanyaan, dan lebih banyak kebebasan untuk pembelian.

Jadilah pemantau eksklusif Anda, transmisi reguler setiap node penting dalam lini produksi, tidak peduli seberapa jauh, kemajuan produk sejauh mungkin untuk dipahami.

1. Cara menggunakan Doctor Blade yang benar dalam industri percetakan

Temukan Lebih Banyak Blog Terkait~

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China

Tetap ikuti berita terbaru kami.