Lame per Imballaggio sono essenziali per tagliare e sigillare efficacemente i materiali. Il mercato delle lame flessografiche, che include queste lame per imballaggio, è valutato a $1,2 miliardi nel 2023 e si prevede che crescerà a $2,1 miliardi entro il 2032Una corretta manutenzione delle lame, come la pulizia e le ispezioni regolari, ne migliora le prestazioni, ne prolunga la durata e riduce i costi. Aziende come Nanjing Metal Siamo specializzati nella fornitura di lame personalizzate, studiate appositamente per specifiche esigenze di imballaggio. Mantenere le lame in condizioni ottimali è fondamentale per garantire sicurezza e prestazioni elevate. Non esitate a contattarci. Contatti fornitori di fiducia per ricevere assistenza quando necessario.

Punti chiave

- Controllare spesso le lame sull'imballaggio per individuare tempestivamente eventuali danni. Questo evita costose riparazioni e ne preserva il corretto funzionamento.

- Pulisci le lame dopo l'uso per eliminare sporco e acqua. Questo le mantiene affilate e previene la formazione di ruggine.

- Applica gli oli giusti alle lame per ridurre l'attrito e prolungarne la durata. Una buona lubrificazione aiuta le lame a tagliare in modo fluido e agevole.

Comprensione delle lame di imballaggio

Cosa sono le lame per imballaggio e i loro altri nomi?

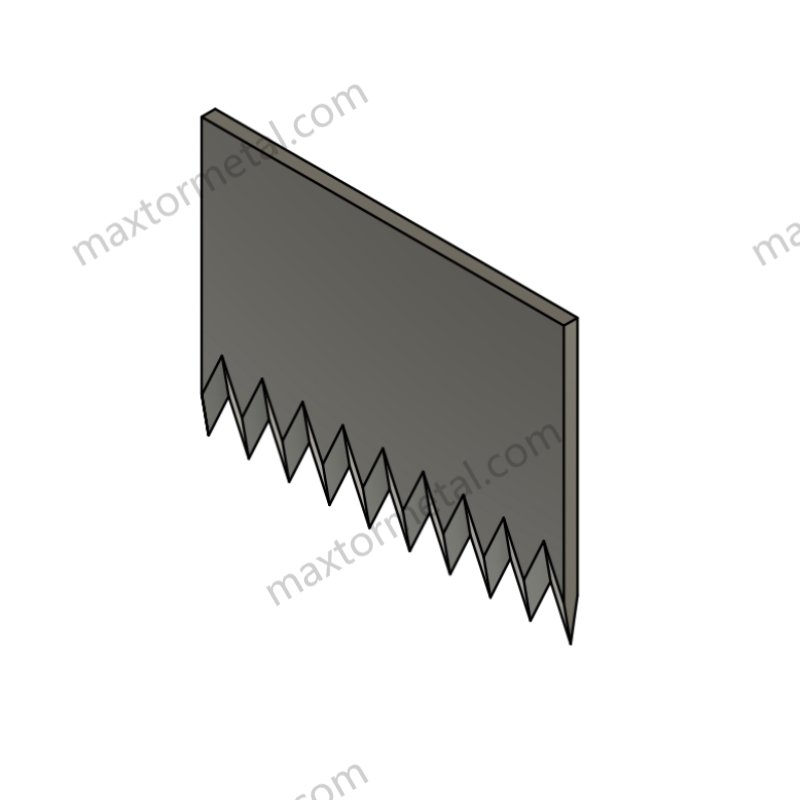

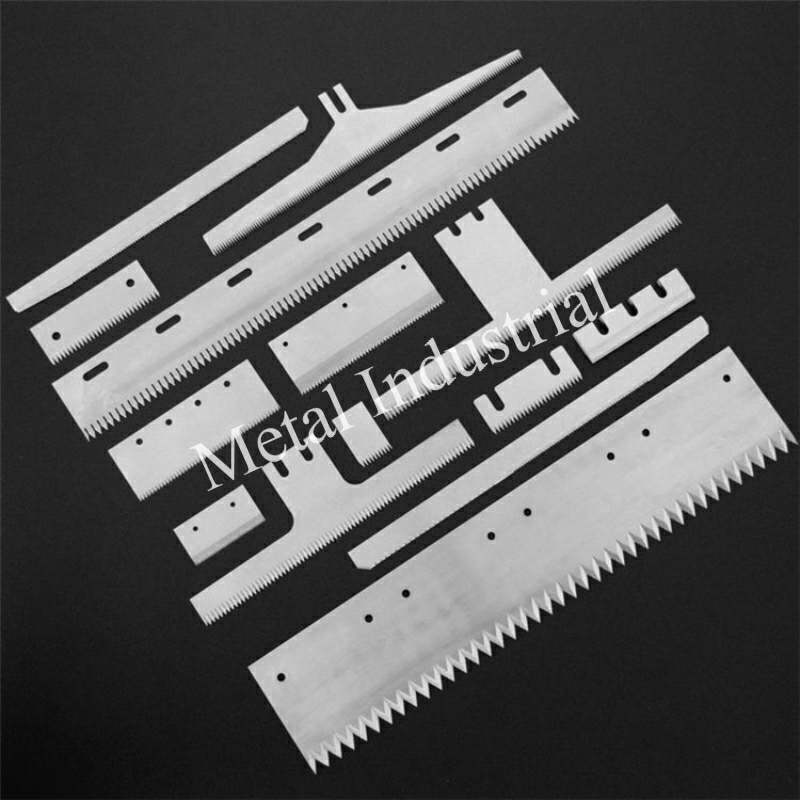

Le lame per imballaggio sono utensili progettati per il taglio negli imballaggi. Sono anche chiamate coltelli industriali, lame da taglio o lame per la conversione. Queste lame tagliano, rifilano o perforano materiali come plastica, carta e cartone. I loro bordi affilati e la struttura robusta le rendono molto utili. Sono necessarie per tagli puliti e precisi in molti settori. Conoscere il loro scopo aiuta a comprendere come mantengono gli imballaggi efficienti e di alta qualità.

Come funzionano le lame per imballaggio?

Le lame per imballaggio tagliano i materiali applicando una forza controllata. I loro bordi affilati rendono il taglio fluido e facile. Alcune lame hanno bordi seghettati per materiali resistenti, mentre altre sono dritte per tagli netti. L'affilatura, la posizione e il tipo di materiale della lama ne influenzano l'efficacia. Prendersi cura delle lame ne garantisce il corretto funzionamento, risparmiando tempo e riducendo gli sprechi.

Dove vengono utilizzate le lame per imballaggio?

Le lame per imballaggio sono utilizzate in molti settori. Nel settore alimentare, tagliano pellicole per snack, surgelati e bevande. Nelle fabbriche, tagliano schiuma, gomma e tessuto. Anche gli ospedali le usano per tagliare confezioni sterili. Queste lame sono fondamentali per qualsiasi lavoro che richieda precisione e velocità. Scegliere la lama giusta aiuta a migliorare il tuo processo lavorativo.

Ispezioni regolari e identificazione dell'usura

I controlli regolari sono fondamentali per mantenere le lame in buone condizioni. Individuare l'usura in anticipo previene riparazioni complesse e mantiene le lame in perfette condizioni. Questa sezione spiega come individuare l'usura, eseguire i controlli e perché è importante intervenire tempestivamente.

Riconoscere i modelli di usura

Segni comuni di usura

Le lame si usurano con l'uso costante nel tempo. L'usura si può notare osservando il modo in cui la lama taglia. Una lama smussata può lasciare bordi ruvidi o irregolari. Un maggiore attrito durante il taglio è un altro indizio. Anche rumori o vibrazioni strane possono indicare usura. Prestare attenzione a questi segnali aiuta a risolvere i problemi in anticipo.

Tecniche di ispezione visiva

Osservare attentamente le lame aiuta a verificarne le condizioni. Usate una luce intensa per vedere chiaramente il filo della lama. Cercate crepe, scheggiature o macchie di ruggine. Una lente d'ingrandimento aiuta a individuare piccoli danni. Ruotate lentamente la lama per individuare piegature o parti irregolari. Controlli regolari come questo mantengono le lame in buone condizioni.

Esecuzione di controlli di routine

Frequenza delle ispezioni

La frequenza di controllo delle lame dipende dal loro utilizzo. Per un uso intenso, è consigliabile un controllo giornaliero o settimanale. Per un uso più leggero, potrebbero essere sufficienti controlli mensili. Una pianificazione consolidata aiuta a individuare tempestivamente i problemi e a garantire un funzionamento fluido.

Strumenti per ispezioni efficaci

Gli strumenti giusti facilitano il controllo delle lame. Una lente d'ingrandimento mostra piccoli difetti. Un righello controlla se la lama è dritta. Un panno pulito può individuare la ruggine pulendo la lama. Questi strumenti rendono le ispezioni semplici e precise.

Importanza della diagnosi precoce

Vantaggi delle riparazioni tempestive

Riparare rapidamente i problemi alle lame offre numerosi vantaggi. Semplifica il taglio e riduce gli sprechi di materiale. Le riparazioni tempestive prevengono anche ritardi e mantengono il lavoro nei tempi previsti. Risolvere i problemi in anticipo aiuta le lame a durare più a lungo e a funzionare meglio.

Risparmio sui costi grazie alla manutenzione preventiva

Prendersi cura delle lame fa risparmiare denaro nel tempo. Riparare piccoli danni costa meno che sostituire una lama. Controlli regolari evitano costose sostituzioni, individuando precocemente l'usura. Le lame ben tenute consumano anche meno energia, riducendo i costi e migliorando l'efficienza.

Pulizia e prevenzione della ruggine

Come mantenere i coltelli puliti e asciutti

Mantenere coltelli È molto importante che le lame siano pulite e asciutte. Durante l'uso, le lame dell'imballaggio raccolgono sporco come polvere di carta, colla o frammenti di plastica. Questi possono attaccarsi alla lama e rendere il taglio più difficile. Per evitare questo problema, pulire le lame dopo ogni utilizzo. Utilizzare un panno morbido per rimuovere lo sporco superficiale. Per lo sporco appiccicoso, utilizzare un sapone delicato e una spugna morbida. Asciugare sempre bene le lame per evitare l'umidità, che causa la ruggine.

L'acqua può danneggiare il tuo lameConservateli in un luogo asciutto e teneteli lontani dall'aria umida. Se lavorate in un ambiente umido, utilizzate un deumidificatore per proteggere i vostri attrezzi. Questi passaggi aiutano a mantenerli coltelli puliti e affilati più a lungo.

Migliori pratiche per la pulizia delle lame di imballaggio

Pulizia Lame per Imballaggio Richiede accorgimenti accurati per mantenerle in buone condizioni. Se possibile, rimuovere la lama dalla macchina per pulirla completamente. Utilizzare una spazzola morbida o un vaporizzatore per rimuovere lo sporco. Per le macchie più ostinate, utilizzare acqua tiepida con sapone neutro o un detergente specifico per lame. Non utilizzare prodotti chimici aggressivi che potrebbero danneggiare la lama.

Pulire sempre seguendo la direzione del filo della lama per evitare di smussarla. Risciacquare con acqua pulita e asciugare subito con un panno privo di lanugine. Pulire spesso facilita il taglio e prolunga la durata delle lame. Seguire questi consigli:

- Pulire le lame dopo ogni turno di lavoro.

- Controllare che non vi siano danni durante la pulizia.

- Per la sicurezza durante la pulizia, indossare i guanti.

Queste abitudini mantengono Lame per Imballaggio forte e affidabile.

Strumenti e soluzioni per la prevenzione della ruggine

La ruggine può rovinare il tuo lame rapidamente. Per prevenire la ruggine, utilizzare un olio o uno spray antiruggine sulla lama. Questi prodotti impediscono all'umidità di raggiungere la superficie. Per riporre le lame, utilizzare delle coperture o avvolgerle in carta antiruggine.

Utilizzare confezioni di gel di silice o deumidificatori per mantenere asciutte le aree di stoccaggio. Se si forma della ruggine, pulirla con una gomma antiruggine o con una lana d'acciaio fine. Dopo aver rimosso la ruggine, applicare nuovamente dell'olio per proteggere la lama. Una cura regolare di questi strumenti mantiene... lame antiruggine e pronto all'uso.

Mancia: Pulisci spesso le lame per rimuovere sporco e colla. Questo riduce l'attrito e ne prolunga la durata.

Tecniche di lubrificazione

Perché la lubrificazione è importante per la manutenzione della lama

La lubrificazione è fondamentale per mantenere Lame per Imballaggio Funziona bene. Riduce l'attrito, rendendo il taglio più fluido e facile. Senza di esso, le lame possono surriscaldarsi, usurarsi rapidamente o rompersi. La lubrificazione previene anche la ruggine e la corrosione, che indeboliscono le lame nel tempo. Lubrificare le lame spesso le aiuta a durare più a lungo e a funzionare meglio.

Mancia: Controlla se la lama è secca o ruvida. Questo significa che ha bisogno di olio.

Scelta dei migliori lubrificanti per le lame di imballaggio

Non tutti i lubrificanti funzionano per Lame per ImballaggioScegline uno adatto al materiale della lama e al suo scopo. Per il confezionamento alimentare, utilizza oli per alimenti per soddisfare le norme di sicurezza. Per lavori pesanti, scegli oli o spray industriali aggressivi. Non utilizzare normali oli per uso domestico, poiché potrebbero danneggiare la lama o non proteggerla adeguatamente.

Come applicare correttamente i lubrificanti

Usare i lubrificanti nel modo giusto ne ottimizza l'efficacia. Per prima cosa, pulire la lama per rimuovere sporco e polvere. Quindi, applicare una piccola quantità di olio uniformemente sulla lama. Utilizzare un panno morbido per distribuirlo sulla superficie. Non usare troppo olio, poiché potrebbe accumulare sporco. Assicurarsi di lubrificare le lame spesso, soprattutto dopo la pulizia o un uso intenso.

Nota: Conservare i lubrificanti in un luogo fresco e asciutto per mantenerli freschi.

Affilatura e manutenzione del filo

Perché le lame affilate per l'imballaggio sono importanti

Migliori prestazioni di taglio

Affilato Lame per Imballaggio Rendere il taglio più veloce e preciso. Le lame smussate richiedono più sforzo, rallentando il lavoro e causando errori. Gli studi dimostrano che le lame affilate fanno risparmiare tempo e riducono gli errori. Questo mantiene le attività di confezionamento fluide e affidabili. Nell'industria alimentare e medica, lame affilate assicurano tagli puliti, migliorando la sicurezza e la qualità dei prodotti.

Meno spreco di materiali

Le lame smussate possono rovinare i materiali producendo tagli irregolari. Ad esempio, i bordi ruvidi di plastica o carta possono renderle inutilizzabili. Mantenere le lame affilate riduce gli sprechi e fa risparmiare denaro. Le lame da taglio ben manutenute tagliano in modo pulito, aumentando la produttività. Affilarle regolarmente aiuta a utilizzare i materiali in modo efficiente, mantenendo standard elevati.

Sapere quando affilare

Risultati di taglio scarsi

Se la lama fa fatica a tagliare o lascia bordi ruvidi, è smussata. Questo rende il lavoro più difficile e ne riduce la qualità. Prestare attenzione a questi segnali aiuta ad affilare prima che i problemi peggiorino.

Maggiore attrito durante il taglio

Una lama smussata crea resistenza e non scorre fluidamente. Questo può causare surriscaldamento, danneggiando la lama o il materiale. Anche rumori o vibrazioni strane indicano che è il momento di affilare.

Modi per affilare le lame degli imballaggi

Affilatura a mano

L'affilatura a mano è un metodo affidabile per mantenere le lame affilate. Usate una pietra per affilare e tenete la lama a un'angolazione di 20-30 gradi. Muovetela con movimenti costanti sulla pietra su entrambi i lati fino a ottenere un'affilatura perfetta. Questo metodo richiede tempo, ma vi dà il pieno controllo.

Utilizzo di temperamatite elettrici

Gli affilatori elettrici sono veloci e facili da usare. Impostano automaticamente l'angolazione corretta, ideale per i principianti. Basta inserire la lama e la macchina la affila per voi. Prima di utilizzarla, verificate che il tipo di lama sia compatibile con l'affilatore.

Strumenti per affilare

Scegliere la pietra giusta

La pietra per affilatura giusta è fondamentale per ottenere buoni risultati. Le pietre a grana grossa riparano i bordi danneggiati, mentre quelle a grana fine lucidano la lama. Le pietre combinate offrono entrambe le opzioni e sono versatili. Assicurati che la pietra sia adatta al materiale della tua lama per evitare danni.

Altri strumenti per affilare

Oltre alle pietre, altri strumenti possono essere d'aiuto. Le bacchette per affilatura sono adatte per riparazioni rapide, mentre le smerigliatrici da banco sono adatte anche ai lavori più impegnativi. Le affilatrici diamantate sono adatte anche alle lame più dure. Scegli gli strumenti più adatti alle esigenze della tua lama per ottenere il risultato migliore.

Mantenere il bordo affilato

Controllare spesso l'affilatura della lama

Dopo l'affilatura, ispezionare regolarmente la lama per verificare che non sia smussata o danneggiata. Verificare la presenza di bordi irregolari o piccole scheggiature. Controlli rapidi prima dell'uso fanno risparmiare tempo e mantengono le lame in perfetta efficienza.

Pulisci dopo l'affilatura

Pulire le lame dopo l'affilatura per rimuovere eventuali residui metallici. Pulire con un panno morbido e applicare un leggero strato d'olio per prevenire la ruggine. Evitare detergenti aggressivi che potrebbero danneggiare la lama. La pulizia mantiene le lame sicure e pronte all'uso.

Mancia: Conservare le lame in un luogo asciutto e sicuro per proteggerle dall'affilatura.

Uso e gestione corretti

Manipolazione sicura delle lame di imballaggio

Indossare dispositivi di protezione

La sicurezza inizia indossando dispositivi di protezione. Guanti Proteggere le mani da tagli e scivolamenti. Gli occhiali di sicurezza proteggono gli occhi dai detriti volanti. Gli stivali con punta in acciaio prevengono infortuni in caso di caduta di oggetti pesanti. Queste misure rendono il posto di lavoro più sicuro.

Lo sapevate? Nel 2016, l’India aveva 48.000 morti sul lavoroMolti casi prevedevano l'uso di utensili affilati, a dimostrazione dell'importanza della sicurezza.

Utilizzare tecniche di presa appropriate

Presa lame correttamente per la sicurezza. Afferrare saldamente la maniglia e tenere le dita lontane dal bordo. Usare entrambe le mani per i materiali duri. Non spingere troppo forte, perché può causare scivolamenti. Una buona presa migliora il controllo e riduce gli incidenti.

Errori comuni da evitare

Posizionamento improprio della lama

Un posizionamento errato della lama può causare incidenti. Fissare sempre la lama nel suo supporto prima dell'uso. Le lame allentate potrebbero oscillare e tagliare in modo non uniforme. Controllare la posizione della lama prima di iniziare il lavoro per motivi di sicurezza.

Trascurare i protocolli di sicurezza

Violare le norme di sicurezza è pericoloso. Spegnere le macchine prima di riparare. lame Per evitare infortuni. Controllare l'affilatura delle lame o eventuali danni per evitare guasti. Seguire le misure di sicurezza garantisce la sicurezza di tutti e un lavoro fluido.

Promemoria importante: Nel 2019, le fabbriche statunitensi hanno registrato 15.380 infortuni da taglio. Molti avrebbero potuto essere evitati rispettando le norme di sicurezza.

Formazione per i dipendenti

Condurre sessioni di formazione regolari

La formazione aiuta i lavoratori a utilizzare lame In sicurezza. Organizza sessioni frequenti per insegnare la corretta gestione e cura del veicolo. Fai dimostrazioni per aumentare la sicurezza. La formazione riduce gli incidenti e aumenta l'efficienza.

Fornire manuali di istruzioni chiari

I manuali di istruzioni sono utili per i lavoratori. Fornire guide di facile lettura su lama Utilizzo e cura. Includere passaggi, suggerimenti per la sicurezza e consigli per la risoluzione dei problemi. Un team qualificato gestisce lame in modo responsabile.

Buone pratiche per l'utilizzo della lama

Seguire le linee guida del produttore

Seguire le istruzioni del produttore per lama cura. Questi suggerimenti migliorano le prestazioni e la sicurezza. Alcuni lame necessitano di detergenti speciali o metodi di affilatura. Ignorare queste regole può danneggiare l' lama.

Monitorare le prestazioni della lama

Controlla quanto bene il lama Funziona spesso. Se fa fatica o taglia male, affilalo o sostituiscilo. Monitorare le prestazioni fa risparmiare materiali e mantiene i risultati costanti.

Mancia: In India, 47 operai si infortunano ogni giorno per aver ignorato le norme di sicurezza. lama Le prestazioni e i consigli forniti possono prevenire gli infortuni.

Migliori pratiche di archiviazione

Conservazione Lame per Imballaggio Mantenerle affilate, prive di ruggine e sicure. Segui questi consigli per far durare le tue lame più a lungo e mantenerle in ottima forma.

Condizioni di conservazione ideali

Mantenere l'area asciutta

L'umidità fa male lameCausa ruggine, rendendoli deboli e meno efficaci. È importante che l'ambiente sia asciutto. Mantenere l'umidità al di sotto di 50°C (50°F) per rallentare la ruggine. Ad esempio:

| Livello di umidità (%) | Tempo prima della formazione della ruggine (lame in acciaio non protette) |

|---|---|

| 30% (ambiente asciutto) | 2–4 settimane |

| 50% (umidità moderata) | 5–7 giorni |

| 70% (umidità elevata) | 48 ore |

| 90%+ (Umidità estrema) | 12 ore |

Utilizzare confezioni di gel di silice o deumidificatori per assorbire l'umidità. Questi strumenti aiutano a proteggere il tuo lame dalla ruggine.

Controllare la temperatura

Grandi variazioni di temperatura possono causare la formazione di acqua su lameQuesto porta alla ruggine. Conservare lame in un luogo fresco e stabile tra 60°F e 75°F. Evitare fonti di calore, in quanto possono piegare o danneggiare il lame.

Mancia: Utilizzare un termometro e un igrometro per controllare le condizioni di conservazione.

Organizzazione delle lame di imballaggio

Utilizzare i porta-lame

I porta-lame mantengono lame Sicuro e organizzato. Previene graffi e danni. Porta-plettri realizzati in materiali morbidi. I ripiani a muro o gli scomparti per cassetti sono ottimi per riporre molti lame ordinatamente.

Spazi di archiviazione delle etichette

Le etichette facilitano la ricerca del prodotto giusto lamaContrassegnare slot o supporti con il tipo o la dimensione della lama. Questo fa risparmiare tempo ed evita errori. Un'archiviazione organizzata migliora l'efficienza fino al 30%.

Lo sapevate? Una buona organizzazione riduce i tempi di manipolazione delle lame e gli errori.

Prevenire i danni

Proteggere dalla luce solare

La luce solare può riscaldare lame in modo non uniforme, causando deformazioni o sbiadimenti. I raggi UV danneggiano anche i rivestimenti protettivi, causando ruggine. Conservare lame in zone ombreggiate o coperte per evitare danni causati dalla luce solare.

Mantenere le lame asciutte

L'acqua è dannosa per lameAnche piccole quantità possono causare ruggine. Non conservare lame Vicino a lavandini o tubi. Se l'area è umida, utilizzare inibitori di corrosione da vapore (VCI) per bloccare l'umidità.

Consiglio da professionista: Aggiungere uno strato sottile di olio antiruggine prima di riporre lame per una protezione extra.

Controlli regolari della lama

Cerca la ruggine

Controlla memorizzato lame spesso per la ruggine. La ruggine si manifesta sotto forma di macchie, aree ruvide o scolorimento. Pulire la ruggine con una gomma antiruggine o con una lana d'acciaio fine. Dopo la pulizia, applicare dell'olio per proteggere la superficie. lama.

Prova di nitidezza

Anche inutilizzato lame può diventare opaco se conservato male. Testa l'affilatura tagliando qualcosa di semplice. Se il taglio non è liscio, affila il lamaI controlli regolari mantengono lame pronto all'uso.

Promemoria: Ispezionare immagazzinato lame ogni mese per individuare tempestivamente i problemi e mantenerli in condizioni ottimali.

I vantaggi delle lame personalizzate

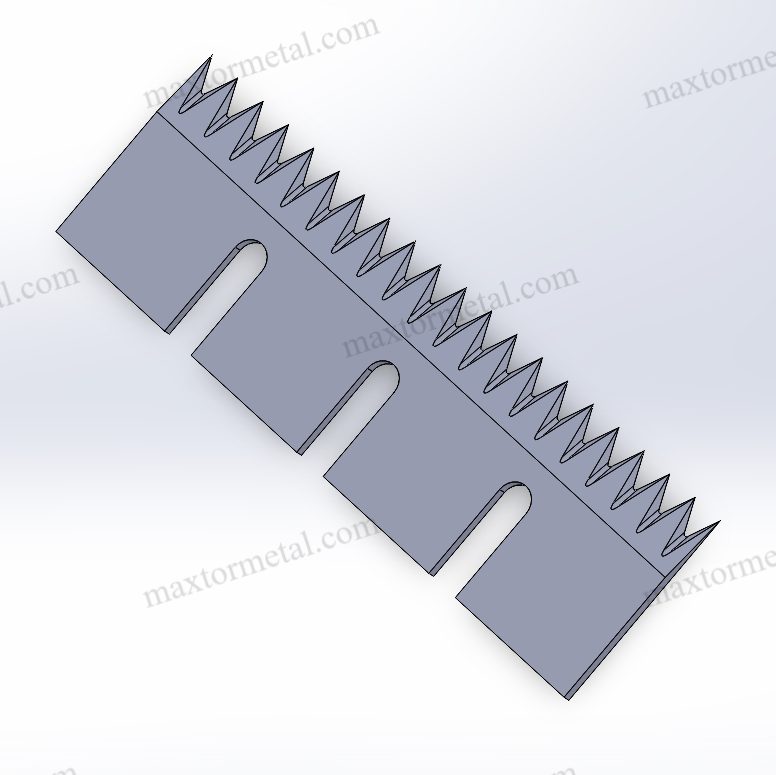

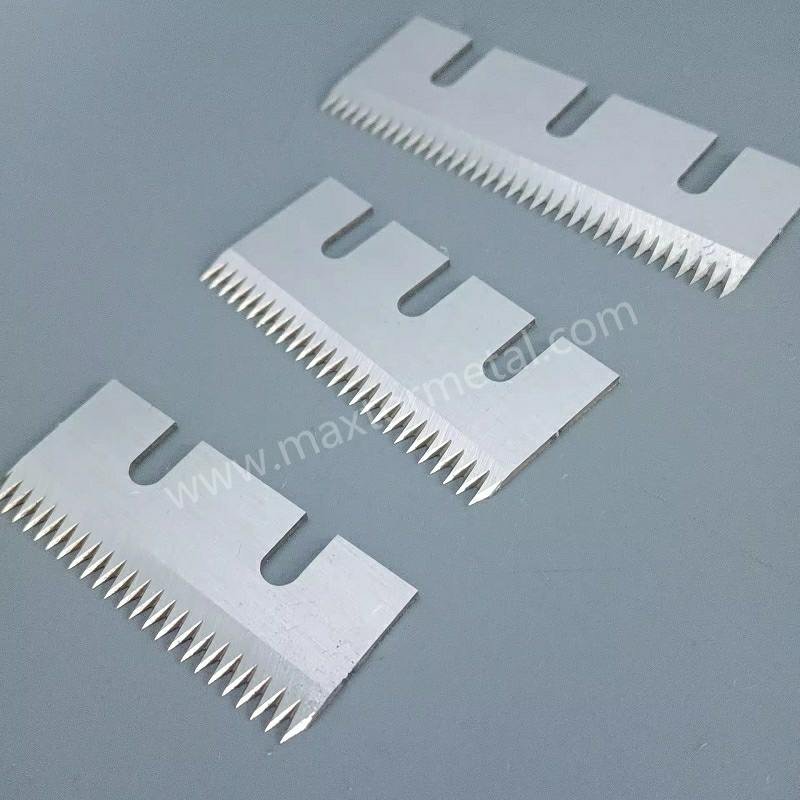

Cosa sono le lame personalizzate?

Lame Personalizzate Sono utensili speciali realizzati per specifiche attività di imballaggio. A differenza delle lame normali, sono progettate per materiali, macchine o metodi di taglio specifici. Queste lame contribuiscono a rendere l'imballaggio più preciso ed efficiente. Un'azienda affidabile come Nanjing Metal Crea lame personalizzate per soddisfare perfettamente le vostre esigenze. Con 18 anni di esperienza, Nanjing Metal è nota per la produzione di lame industriali di alta qualità. Il suo team di esperti garantisce che ogni lama soddisfi elevati standard qualitativi e le esigenze dei clienti.

Vantaggi delle lame personalizzate per le esigenze di imballaggio

Le lame personalizzate offrono numerosi vantaggi al settore dell'imballaggio. In primo luogo, tagliano con maggiore precisione, riducendo gli sprechi e garantendo risultati impeccabili. In secondo luogo, fanno risparmiare tempo, poiché richiedono meno sostituzioni o regolazioni. In terzo luogo, proteggono i macchinari riducendone l'usura. Ad esempio, le aziende che utilizzano lame personalizzate hanno riscontrato i seguenti miglioramenti:

| Titolo del caso di studio | Vantaggio(i) chiave |

|---|---|

| Ridurre attraverso la riprogettazione | Risparmio di denaro e materiali per i servizi satellitari. |

| Maggiore efficienza | Maggiore efficienza per un fornitore globale di imballaggi $1B. |

| Riduzione dei danni | Riduzione dei danni ai server blade durante la spedizione per un'azienda globale. |

| Costi di trasporto ridotti | Ridurre i costi di spedizione per un importante distributore di cosmetici. |

Questi esempi dimostrano come le lame personalizzate possano far risparmiare tempo, ridurre i costi e migliorare i risultati.

Quando investire in lame personalizzate

Scegli lame personalizzate quando quelle standard non funzionano bene. Se gestisci materiali speciali, hai bisogno di tagli precisi o sostituisci spesso le lame, le lame personalizzate sono la soluzione ideale. Sono ideali anche per i settori che richiedono elevati standard di sicurezza e pulizia, come il confezionamento alimentare o medicale. Collaborare con esperti come Nanjing Metal ti garantisce lame realizzate su misura per le tue esigenze. Le loro competenze contribuiscono a migliorare le prestazioni e a farti risparmiare denaro nel tempo.

Vuoi migliorare il tuo processo di confezionamento? Contatta il team di Nanjing Metal oggi per saperne di più sulle lame personalizzate.

Prendersi cura delle lame da imballaggio ne garantisce il corretto funzionamento e la sicurezza. Pulirle, affilarle e conservarle correttamente ne prolungano la durata. Affidarsi a un produttore di lame affidabile come Nanjing Metal garantisce la massima qualità e opzioni personalizzate. Scopri subito le loro competenze. 👉 Contatta il loro team per migliorare il tuo lavoro di imballaggio.

Domande frequenti

Con quale frequenza si dovrebbero pulire le lame dell'imballaggio?

Pulisci le lame dopo ogni utilizzo. Questo impedisce l'accumulo di sporco. Inoltre, riduce l'attrito e ne prolunga la durata. Asciugale sempre bene per evitare la formazione di ruggine.

Quali sono gli utensili migliori per affilare le lame degli imballaggi?

Le pietre per affilare offrono risultati precisi. Gli affilatori elettrici sono più veloci. Usa le barre di affilatura per riparazioni rapide. Scegli utensili adatti al tipo di lama.

Le lame possono essere conservate in luoghi umidi?

Non conservare le lame in luoghi umidi. L'umidità le fa arrugginire e le indebolisce. Utilizzare confezioni di gel di silice o deumidificatori per mantenere asciutto il luogo di conservazione.

3 risposte