複雑な金属プロファイル用プレスブレーキ金型の完全ガイド

You need strong tools to shape tricky metal profiles. More than 80% of metal projects use press brake tooling for complex metal profiles to achieve good and steady results. Special and custom tools help you get better accuracy and make work faster. Nanjing Metal provides press brake tooling for complex metal profiles that adhere to tough industry standards. Technology Impact on Metalworking Advanced Materials Make tools last longer and work better. Lightweight Composites Make production go faster. Automation Help make more and better products. Key Takeaways Press Brake Tooling Basics What Is Press Brake Tooling Press brake tooling helps shape metal sheets into many forms. The tooling has punches, dies, holders, and adapters. Each part […]

プレスブレーキ金型の真のコスト:総所有コスト(TCO)分析

The real cost of press brake tooling is more than the price you pay at first. You need to think about every cost that comes up over time. You spend money on more than just the tool. You also pay for maintenance, downtime, and resale value. Key Takeaways Total Cost of Press Brake Tooling What Is TCO? You need to look beyond the price tag when you buy press brake tooling. The total cost of press brake tooling, or TCO, means you count every expense that comes with your tooling over its life. You pay for more than just the tool itself. You also pay for installation, setup, maintenance, and even lost […]

独自の金属プロファイル用特殊プレスブレーキ金型

Selecting specialized press brake tooling for unique metal shapes requires careful consideration. You must match the tooling to the complexity of the shape. Additionally, you need to think about the type of material you are using. Ensure that the tooling is compatible with your machine. Consider how precise you need the work to be. More than 80% of metal projects utilize specialized press brake tooling for high-quality and consistent results. The right tooling provides accurate bends and saves time. Nanjing Metal allows you to customize options to meet your needs in automotive, construction, and electronics. Key Takeaways Choosing Specialized Press Brake Tooling Profile Complexity Working with unique metal shapes can be hard. Some shapes, like Z-shapes, […]

プレスブレーキの曲げ力とトン数を計算する方法

You must know how to calculate press brake bending force and tonnage to ensure safe and effective metal bending. The formulas below are commonly used in metalworking: Formula Description P (lbs.) = 2 × b × t² × Fy/W This is the basic method to calculate press brake bending force. P (tons/foot) = 0.012 × t² × Fy/W This is a straightforward way to calculate press brake bending tonnage. Obtaining the correct calculations prevents issues. If you do not apply enough force, the bends will not be accurate. Conversely, using too much force can damage your material or machine. Impact of Miscalculations Consequence Insufficient Force Bends are not accurate Excessive Force Material and machine […]

初心者向けプレスブレーキ金型ガイド:正しいVダイ開口部の選び方

Choosing the right V-die opening starts with knowing your material thickness. You can refer to our press brake tooling guide for beginners to help you with this process. This guide assists in keeping your bends correct and your shop safe. Picking the right V-die lowers the chance of accidents and provides you with better results. A wider V-die helps bridge the die safely, reducing the risk when bending. The easy chart included in the guide helps you feel confident at every step. Key Takeaways V-Die Basics What Is a V-Die You might wonder what a V-die is when you first hear about press brake tool types. A V-die looks like a block of metal […]

プレスブレーキ金型究極ガイド:摩耗を防ぐための最適な材料選び

Choosing the right press brake dies material is very important. It helps stop wear and gives better results. You need a strong material for repeated bending. It should not lose accuracy. Studies show high-strength steel makes dies last much longer. Dies can last 30% to 50% longer with this steel. Special alloys help dies last even longer. They can boost life by over 60%. Material Type Longevity Improvement High-Strength Steel 30% to 50% longer Special Alloys Over 60% longer You can make your dies work better and last longer. Pick materials that fit what you need. Key Takeaways Press Brake Dies Material Overview Types of Press Brake Die Material There are many materials for […]

エアベンディング vs. ボトミング:あなたのプロジェクトに最適なプレスブレーキ金型を選ぶ

Imagine you have to pick between air bending vs. bottoming for your metal project. This choice can change your costs, your speed, and how exact your parts are. Look at the table below to see how each method affects your work: Criteria Air Bending Bottom Bending Tooling Costs Lower tooling costs More money spent on tooling Precision Not as exact Very exact Production Speed Works faster Works slower Maintenance Needs less fixing Needs more fixing Think about your material, how exact you need to be, your budget, and how many pieces you want to make. Your choice is important! Key Takeaways Air Bending vs. Bottoming Air Bending Overview Air bending is a […]

ヨーロッパ式 vs. アメリカ式プレスブレーキ金型:あなたの工場に最適なのはどちらか?

Choosing between European vs. American style press brake tooling depends on what your shop needs. You should think about how accurate you need to be, how fast you want to set up, if the tools will fit your machines, and how much money you want to spend. In metal fabrication, these factors influence how you work and the results you achieve. The table below illustrates why manufacturers may prefer one system over the other: Decision Factor Choose American Tooling If… Choose European Tooling If… Application Type You need to change jobs quickly You need every part to be the same Budget You want to spend less at first You want to save […]

ステンレス鋼に最適なプレスブレーキ金型の選び方

Choosing the best Press Brake Tooling for Stainless Steel helps you work better. You get more accurate bends. Your tools last longer. You spend less money making things. You need exact tools because stainless steel bends in a special way. It does not bend like other metals. Special tooling can help you save time and money: Key Takeaways Press Brake Tooling for Stainless Steel Bending stainless steel is tricky. You need to know the problems before picking press brake tooling for stainless steel. Stainless steel is strong and hard. It does not bend easily. These features make it popular in many jobs. But you must be careful when bending it. Stainless Steel […]

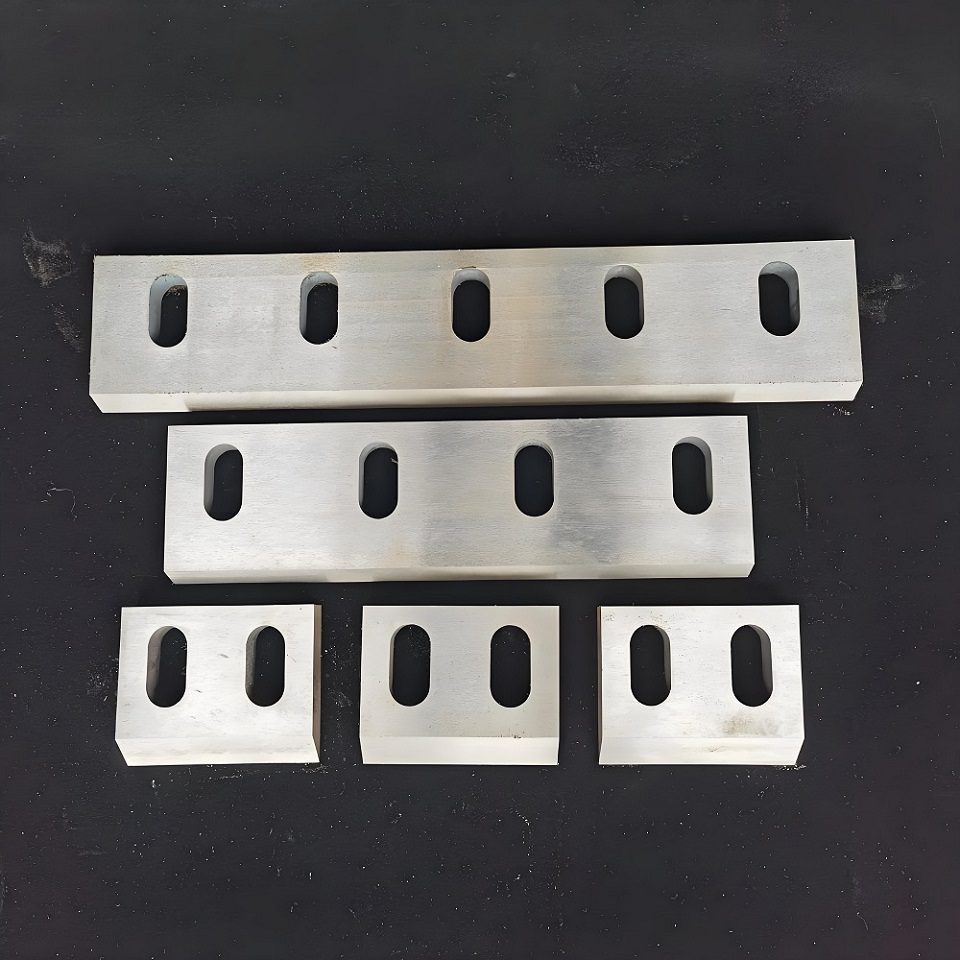

プラスチックシュレッダーが動かない理由:よくある刃の問題とトラブルシューティング

Your plastic crushing machine might stop working or produce uneven flakes, often due to issues with plastic crusher blade wear. Troubleshooting plastic crusher blade wear is essential because worn or broken blades cause frequent machine shutdowns and poor cutting performance. When blades become dull or cracked, the efficiency of your machine drops significantly. Using high-quality blades made from strong steels and special coatings can extend blade life and keep your shredding operations running smoothly. You can rely on Nanjing Metal for durable blade options that help maintain fast and efficient plastic crushing. Addressing blade wear promptly is key to ensuring your machine operates at its best. Key Takeaways Troubleshooting Plastic Crusher Blade Wear Signs […]