ペレタイザーブレードとは何か、そして産業におけるその仕組み

Pelletizer Blades are specialized cutting tools essential in factories for efficiently cutting plastic waste into small, uniform pellets. This process is crucial for recycling and producing new plastic products. With the world having produced 8.3 billion metric tons of plastic, much of which becomes waste, Pelletizer Blades play a vital role in transforming this waste into valuable raw materials. High-quality blades ensure precise cutting, consistent pellet size, and reduced energy consumption. Recent studies show that using advanced blades can boost material recovery by 30% while lowering energy costs. Proper use and maintenance of these blades lead to improved performance, less machine downtime, and positive environmental impact. Nanjing Metal offers custom blade solutions tailored to specific needs, […]

産業機械用プラスチック粉砕機交換ブレード:OEMとアフターマーケットのどちらを選ぶべきか

When you need Plastic Crusher replacement blades, you have two main options. You can choose OEM blades or aftermarket blades. This decision can impact your machine’s performance and your overall costs. OEM blades fit perfectly, offer high quality, and come with a warranty. Aftermarket blades are usually less expensive and more readily available, sometimes featuring new designs. However, their quality can vary. Consider factors like fit, blade durability, warranty, and value before making your choice. Key Takeaways Understanding Plastic Crusher Replacement Blades OEM Parts Overview When you pick OEM parts, you get blades made by the same company as your machine. These blades fit your machine because they match its size and […]

ミシン目ナイフの性能を最大限に引き出す方法

Start by cleaning your perforated knife after each use to maintain a sharp edge and ensure smooth, safe cuts. Proper use and regular maintenance can extend the blade’s lifespan by up to 200% and reduce blade changes by 70%. The table below highlights how best practices improve performance with a perforated knife, delivering greater precision and safety in industrial applications: Performance Metric Scissor-type Knife Conventional Knife Submucosal dissection time (minutes) 6.2 15.6 Circumferential incision time (minutes) 8.4 13.8 En bloc resection (%) 90 70 Adverse events: Perforation or muscle injury (%) 10 70 Perforated knives are widely used in packaging, textiles, and food processing industries. For optimal results, consider a custom blade tailored to your specific […]

産業用途におけるフィルム加工ナイフ

Film process knives play a crucial role in factories, especially when precision cutting of film, foil, and soft materials is required. These knives ensure clean edges and minimize waste, making them essential in various industrial applications. Many factories now demand a custom blade to handle unique materials and specialized tasks. The right knife coating not only extends the blade’s lifespan but also reduces friction and maintains superior cutting quality. With increasing automation and advancements in knife coating technology, the demand for film process knives is rising steadily. The industrial guillotine knife market is expected to grow from USD 1.2 billion in 2023 to USD 2.1 billion by 2032. Metric/Segment Details/Statistics Market Size (2024) USD […]

油圧シャーブレードの交換手順ガイド

Changing hydraulic shear blades requires clear steps and strict safety measures. Always use lockout/tagout procedures and wear the appropriate PPE to ensure your safety. Both new and experienced operators should follow a solid plan. Studies show that step-by-step maintenance improves machine performance, extends its lifespan, and maintains a safe workplace. Regularly inspect your machine and install hydraulic shear blades correctly, making sure they align properly for optimal results. Key Takeaways Safety for Hydraulic Shear Blades You must follow safety rules when changing a hydraulic shear blade. Many people get hurt when they do not follow safety steps or use the wrong tools. You can stay safe by getting ready and using the right […]

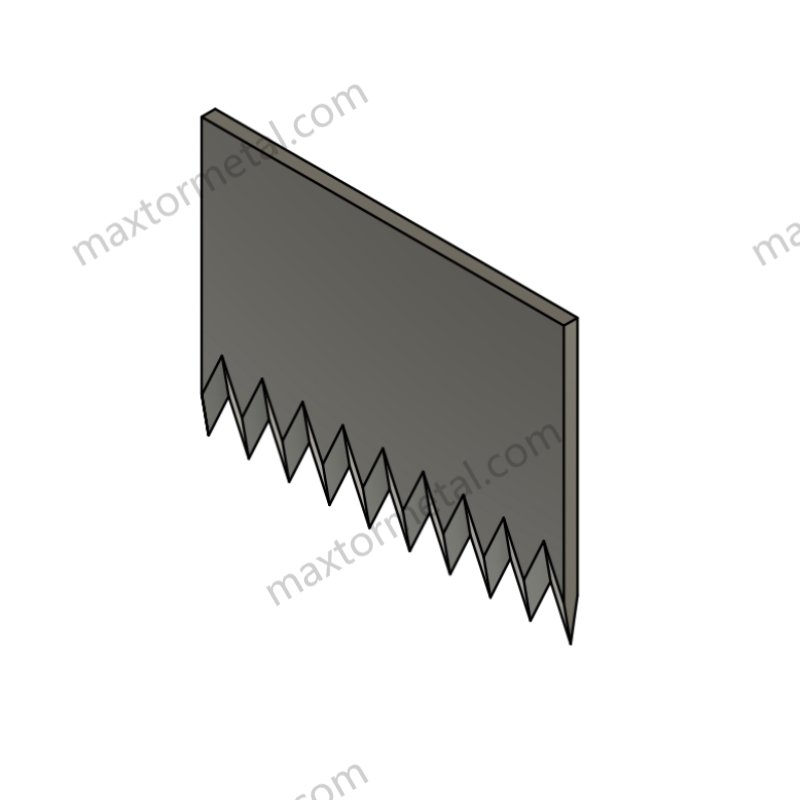

スクラップMetalせん断ブレードのメンテナンス完全ガイド

スクラップ金属せん断刃を適切にメンテナンスすることで、機器の効率的な稼働を確保できます。刃のメンテナンスを行うことで、ダウンタイムが短縮され、よりスムーズな切断が可能になります。刃のメンテナンスを行うことで、寿命が延び、突然の故障を防ぎ、作業員の安全を確保することで、コスト削減につながります。重要なポイント せん断刃の基本 スクラップ金属せん断刃とは Metal せん断刃 スクラップ金属せん断刃は、金属を切断する機械で使用されます。これらの刃は、リサイクルや金属加工の作業において非常に重要です。金属せん断刃を使用すると、刃は金属板、梁、またはパイプを強力な力で切断します。ほとんどの刃は、高速度鋼、D2合金鋼、またはタングステンカーバイドで作られています。これらの材料は、刃を硬くします[…]

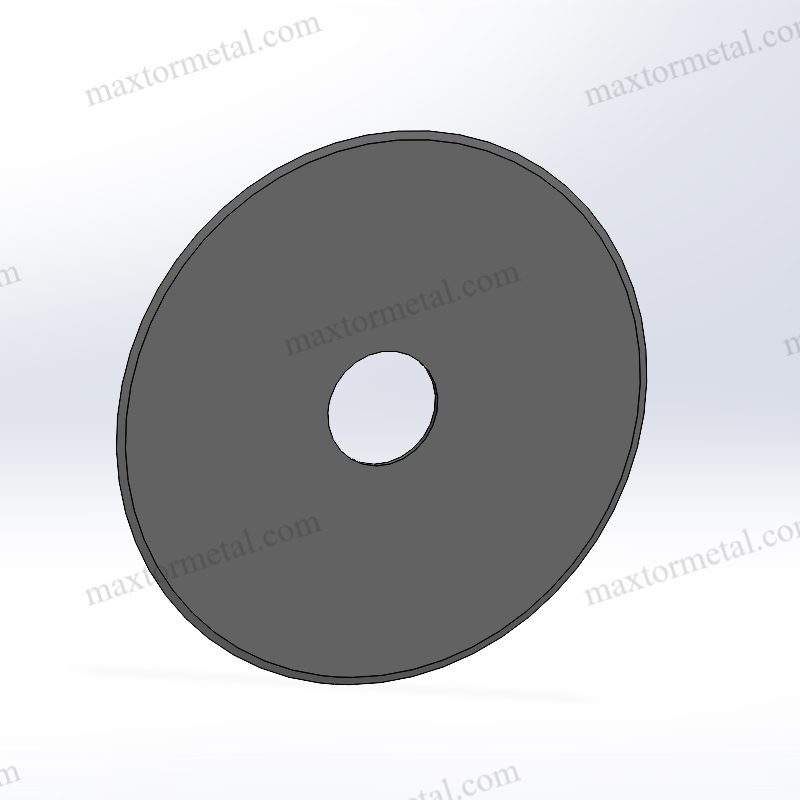

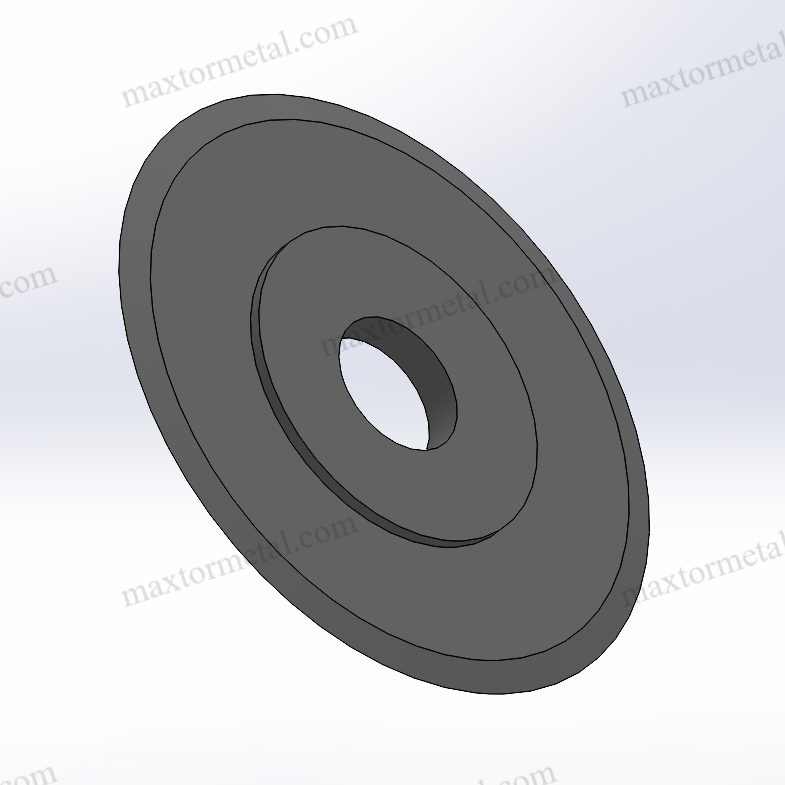

丸型カミソリ刃を長持ちさせるためのトップ10のヒント

産業機械のスムーズな稼働には、円形カミソリ刃が不可欠です。刃の寿命が長ければ、ダウンタイムやコストを削減し、毎回より正確なカットを実現できます。適切なメンテナンスを行うことで、刃の寿命を2~3倍延ばすことができます。一部の刃には、自動研磨技術や特殊コーティングが施されており、カスタム刃はこれらの技術により最大80%も長持ちします。以下の表は、刃の種類とお手入れ方法が寿命にどのように影響するかを示しています。刃の種類 平均寿命 寿命に影響を与える主な要因 寿命延長技術と影響 ペレタイザーナイフ 6~12か月 高速切断、耐摩耗性 自動研磨刃:最大80%の長寿命 グラニュレーターブレード 12~18か月 汚染、研磨性 タングステン […]

クラッシュカットナイフとは何か、そして産業界でどのように機能するのか

Crush cut knives are specialized blades designed for heavy industrial machinery. These crush cut knives operate by pressing and breaking materials rather than slicing, making them ideal for tough or stringy materials that are difficult to cut with standard blades. The blade works by contacting a hard surface to achieve a clean, efficient cut. Key Takeaways Crush Cut Knives Overview What Are Crush Cut Knives Crush cut knives are important in many factories. These blades do not cut like regular knives. They use force to crush and break materials. This way works well for tough or stringy things. It is good for items that are hard to cut with sharp blades. […]

ニーズに最適な肉スライサーブレードの選び方

Choosing the best meat slicer blades depends on your specific needs. Consider what type of meat you want to slice and how much slicing you will be doing. Whether you need a custom blade for deli meats or serrated blades for frozen foods, Nanjing Metal offers high-quality options to ensure each slice meets your standards. The right commercial meat slicer blades not only improve safety but also make your work faster and more efficient. For more information or to request a custom blade, please contact Nanjing Metal directly. Below is a table highlighting current trends in industrial meat slicer blades, showing their applications and market insights: Segment Subcategories Market Insights Slicer Type Manual, Automatic, Semi-automatic Automated […]

プロジェクトに合ったゴム切断ブレードの選び方

Have you tried to cut rubber and ended up with rough edges or wasted pieces? You’re not alone! Choosing the right rubber cutting blade is crucial for a clean cut. Before you start, consider the type and thickness of your rubber. Also, think about your specific cutting needs. Even small variations in your rubber can affect how you should cut it and impact your results. For example, take a look at this table: Applied Normal Force Carbon Black Structure Compound Behavior Effect on Cut and Chip Wear Low Force High Structure Stiffer compound, less deflection Minimizes wear by stiffening the compound High Force Low Structure Softer compound, enables strain-induced crystallization Minimizes wear by […]