パン切断ブレードの必須ガイド:適切な選択でベーカリーの効率を最適化しましょう!

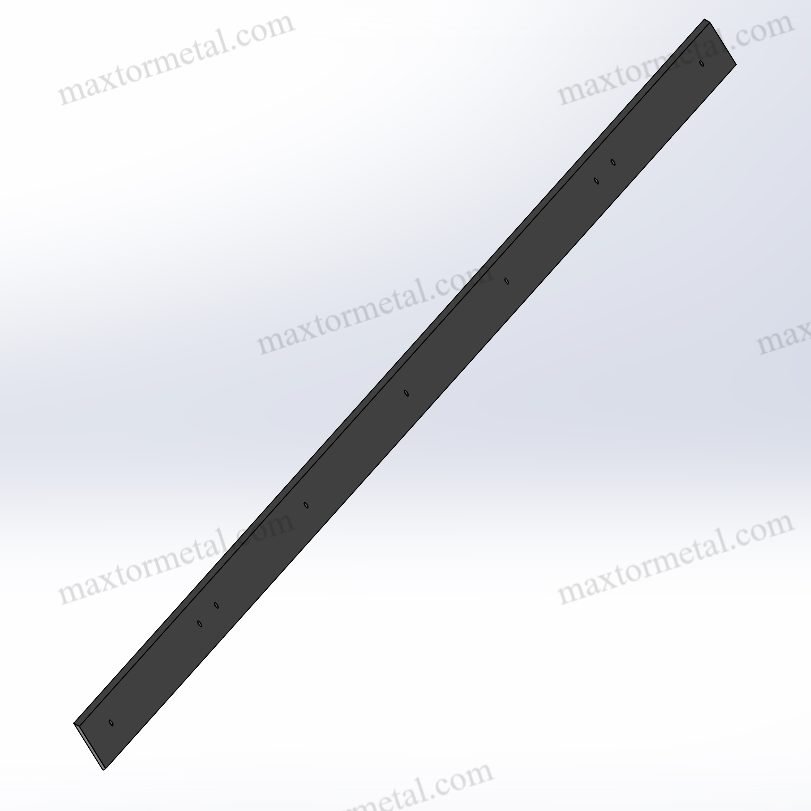

In industrial settings, Bread Cutting Blades are essential for producing neat, uniform slices of bread. These high-quality Bread Cutting Blades ensure that each loaf maintains its appearance and freshness, contributing to both the look and taste of the final product. Choosing the right custom blade guarantees consistent results and helps workers operate more efficiently. The selection of Bread Cutting Blades directly impacts production costs and overall efficiency. When selecting a blade, it’s important to consider its durability, maintenance requirements, and compatibility with various types of bread and production volumes. Key Takeaways Blade Types Overview Serrated Blades Serrated bread knives are used a lot in factories. They can cut both soft and hard bread easily. […]

素材に合ったミシン目ナイフの選び方

Choosing the right perforating knives from Nanjing Metal for your job can make or break your production line. Every material behaves differently when cut, so selecting a custom blade that matches its properties is essential. For instance, studies show that altering blade shapes, such as pitch length and corner radius, affects how polypropylene sheets bend and fold. Using the wrong knife might result in weak creases or even damage your materials. Refer to the table below to see how selecting the right knife material impacts performance and efficiency: Material Type Benefits in Use Tungsten Carbide Lasts long, handles tough materials, boosts speed Stainless Steel Resists rust, works well in packaging and food Ceramic Stays sharp, […]

ローリングシアーブレードとは何か、そしてその仕組み

Rolling Shear Blades are essential components in the metal processing industry, and Nanjing Metal is a leading provider of these high-quality industrial blades. These custom blades operate in heavy-duty machines, performing precise slitting and cutting of metal sheets. Factories rely on Nanjing Metal’s Rolling Shear Blades for continuous, high-speed production, ensuring clean edges and minimal waste. The metal processing industry has seen significant growth, with the hydraulic shearing machines market reaching USD 5.7 billion in 2023 and expected to rise further. Technological advances, such as CNC integration and automation, help maintain blade sharpness and reduce burrs, supporting the demand for accuracy in every cut. For more information or to request a custom blade, please contact […]

プレスブレーキパンチの板金曲げ加工における仕組み

A press brake punch is an essential industrial machine blade used in a press brake machine to shape and bend sheet metal with precision. Nanjing Metal specializes in manufacturing high-quality press brake punches that work seamlessly with press brake dies to create accurate bends in metal sheets. Many factories depend on Nanjing Metal’s custom blades to produce parts for cars, appliances, and buildings. The global press brake market reached $568.2 million in 2022 and continues to grow as companies seek better efficiency and safety. For those interested in enhancing their metal bending processes, please contact Nanjing Metal to learn more about their advanced press brake punch solutions. Key Takeaways Press Brake Punch Basics Definition and […]

包装におけるロータリースロッターブレードの必須ガイド

Rotary slotter blades are vital industrial machine blades widely used in the packaging industry for cutting, slotting, and scoring corrugated cardboard boxes with exceptional speed and precision. Nanjing Metal, a leading manufacturer, offers high-quality rotary slotter blades that help operators significantly enhance both productivity and product quality. Recent advancements from Nanjing Metal demonstrate remarkable improvements: Metric Value/Improvement Productivity Increased by 500% Fatigue Resistance Improved by 300% Die Cutter Load Capacity Increased by 60% Choosing the right rotary slotter blades, including custom blade options from Nanjing Metal, enables professionals to achieve efficient and reliable packaging solutions. For more information or to discuss your specific needs, please contact Nanjing Metal directly. Key Takeaways Rotary Slotter Blades Overview What […]

金属シャーブレード 完全トラブルシューティングハンドブック

You often face unexpected issues with metal shear blades in industrial machinery. Partnering with Nanjing Metal ensures fast troubleshooting to keep your production line moving and reduce costly downtime. A McKinsey study shows that companies using predictive maintenance can cut downtime by up to 50% and lower maintenance costs by 30%. Problems like burrs, warping, and chipping disrupt sheet metal shearing, but with a custom blade from Nanjing Metal, each blade endures millions of cycles and resists vibration, surface stress, and cracks. For more information or to contact Nanjing Metal, reach out today to keep your blades performing at their best. Key Takeaways Common Problems Burrs You may notice burrs on the edge of your cut metal. Burrs are […]

ペーパーロールスプリッターブレードのメンテナンスで効率を最大化

Maintaining paper roll splitter blades is crucial for optimal machine performance and cost savings. Neglecting this maintenance can lead to excessive heat buildup, with worn blades reaching temperatures of 475 °C, while new ones typically operate around 300 °C. This high heat can damage the blades and result in poorer cuts. Over time, this can lead to defective parts, compromised materials, and increased downtime for repairs. Regular maintenance ensures that the blades function effectively and keeps the workplace safe. For custom blade solutions, be sure to contact trusted suppliers like Nanjing Metal for assistance. Key Takeaways Understanding Paper Roll Splitter Blades What Are Paper Roll Splitter Blades? How They Work Paper roll splitter blades are special tools […]

パン切り刃のメンテナンスに役立つヒント

Taking care of bread slicing blades is very important. It helps them work well and saves money over time. Good care makes each slice neat, safe, and the same size. Today, people want faster and cleaner slicing because of new technology and safety rules. Whether you use regular or custom blades, cleaning them often stops germs and keeps the slicer working well. For great help, contact Nanjing Metal, a trusted company in this field. Key Takeaways Understanding Bread Slicing Blades Types of Bread Slicing Blades Standard Blades Standard blades are the most used in bread slicers. They work well for most bread types and slice evenly. These blades are dependable and affordable, making […]

ストレートカッティングナイフとは何か、どのように使うのか

A straight cutting knife is a special tool used for exact cutting. Its straight blade makes neat and accurate cuts, which is very useful in industries needing perfect results. It works well for cutting fabric, paper, and other materials, helping to avoid mistakes and save time. The Straight Knife Cutting Machine is made to cut different materials in straight lines. It gives smooth and fast results, cutting down production time. These tools are becoming more important worldwide. In 2023, their market value was USD 1.3 billion and is expected to grow to USD 2.1 billion by 2032. This growth is due to better technology and more demand in industries like textiles. Companies […]

段ボール包装ブレードとその産業用途とは

Corrugated packaging blades are essential components of industrial machines, designed to cut and shape corrugated materials with precision. These blades play a crucial role in the production of corrugated cardboard, where accuracy and speed are paramount. The significance of these blades is underscored by the growing demand for corrugated packaging. For instance: Nanjing Metal specializes in manufacturing high-quality corrugated packaging blades to optimize machine performance. Whether you require a standard or custom blade, Nanjing Metal can produce the perfect solution for your needs. To learn more, please contact them today. Key Takeaways Understanding Corrugated Packaging Blades What Are Corrugated Packaging Blades? Role in Industrial Machines Corrugated packaging blades are important tools in factory machines. These […]