産業用シュレッダーブレードとその用途に関するガイド

産業用シュレッダーブレードは、様々な用途で材料を効率的に切断するために不可欠です。工場、リサイクル、廃棄物処理において重要な役割を果たします。これらのブレードは、シュレッダーの性能と精度を向上させます。適切な産業用シュレッダーブレードを選択することで、作業速度を大幅に向上させ、遅延を防ぐことができます。特殊な要件については、カスタムブレードで特定の課題に対応できます。サポートが必要な場合は、Nanjing Metalまでお気軽にお問い合わせください。専門家のアドバイスをご提供いたします。お客様のニーズに最適なツールの選択をサポートいたします。重要なポイント 産業用シュレッダーブレードの理解 定義と機能 産業用シュレッダーブレードとは? 産業用シュレッダーブレードは、シュレッダーで使用される材料を切断するためのツールです。物を小さな破片に砕きます[…]

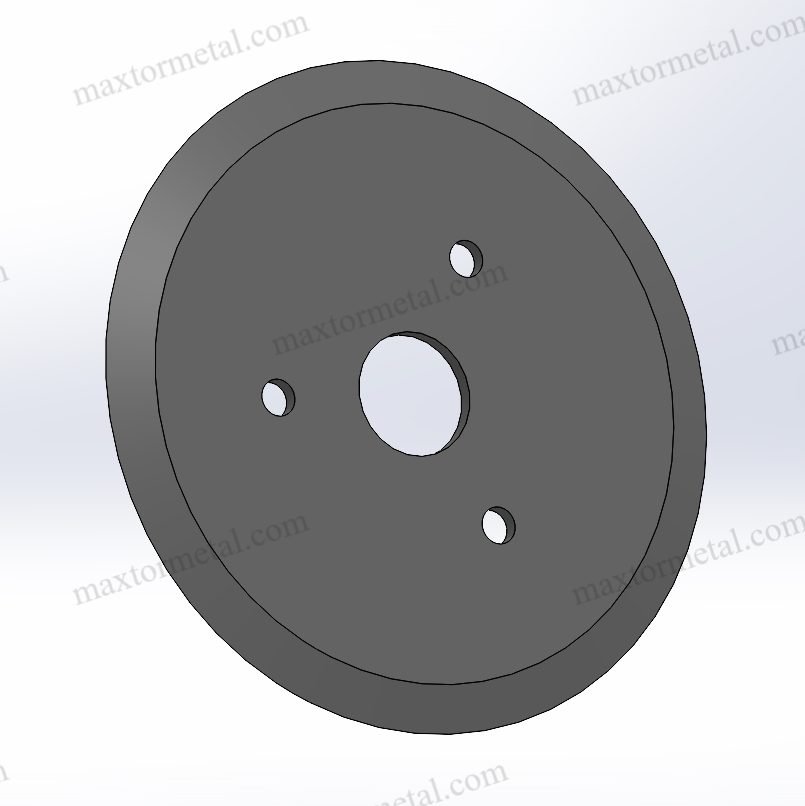

丸刃とは何か、そして産業でどのように使われているのか

丸刃

適切な円形スリッターブレードの選び方と長持ちする性能

Choosing circular slitter blades can seem confusing at first. You need to think about compatibility, price, and how you’ll use them. Using the wrong blade can cause bad cuts and waste materials, leading to delays in work. Picking high-quality circular slitter blades is very important. Whether cutting paper, metal, or fabric, custom blades from Nanjing Metal work best for specific needs. Companies like Nanjing Metal manufacture blades for different industries. If you’re unsure, don’t hesitate to contact a reliable supplier for help. Key Takeaways Understanding Circular Slitter Blades What Are Circular Slitter Blades? Circular slitter blades are tools made for cutting materials precisely. These round blades spin while cutting to make clean, exact slices. They are […]

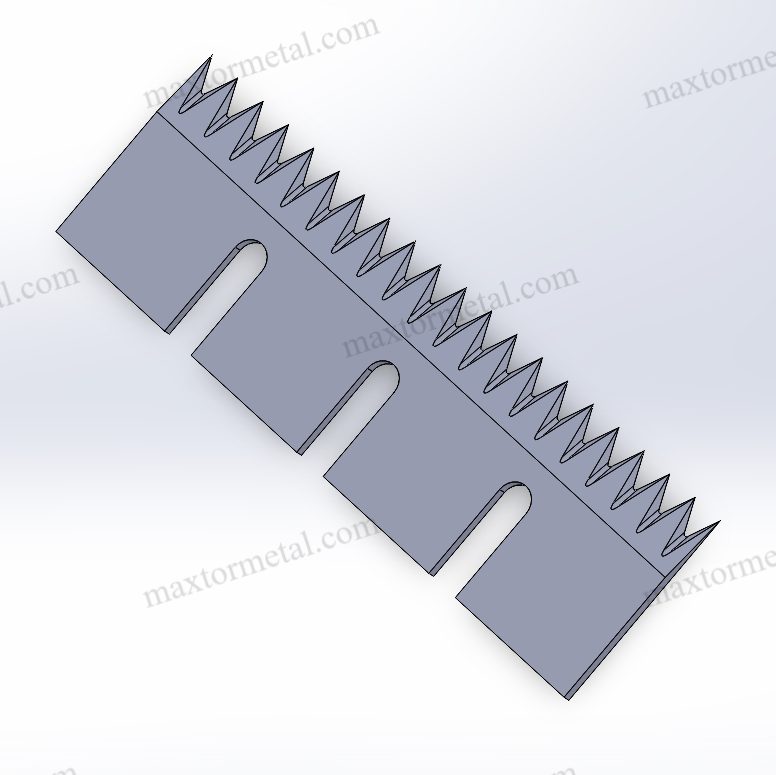

鋸歯状刃と平刃:どちらが切れ味が良いですか?

Have you noticed some knives cut easily while others don’t? The difference is the blade type. Serrated blades are made for different jobs and are great for cutting things like rope or cardboard. Plain blades are good for smooth and accurate cuts. Here’s a cool fact: in one study, serrated blades worked 99.83% of the time. Regular blades only worked 96.51% of the time. This shows how special designs can really help. If you need a tool for a specific job, try a custom blade from Nanjing Metal. Whether you’re slicing, sawing, or chopping, the right blade makes work easier. Ready to choose your perfect blade? Let’s get started! Key Takeaways Serrated Blades What […]

セラミック刃とスチール刃:切れ味の比較

セラミックブレード

プラスチック造粒機のブレードのメンテナンスと研磨方法

プラスチック造粒機ブレードのメンテナンスと研磨は、機械の最適な性能とコスト削減に不可欠です。この側面を怠ると、機械の故障が頻繁に発生し、費用が増加する可能性があります。実際、メンテナンスは造粒機のランニングコストの最大80%を占める可能性があります。新しい設計により、切断室へのアクセスが容易になり、ダウンタイムが最小限に抑えられます。Nanjing Metalのような企業は、長寿命設計のカスタムブレードを提供しています。これらのブレードを定期的にメンテナンスすることで、コストを節約できるだけでなく、機械の寿命も延びます。ブレードのメンテナンスについては、いつでも専門家にご相談ください。重要なポイント プラスチック造粒機ブレードの理解 プラスチック造粒機ブレードとは? プラスチック造粒機ブレードは、ローターナイフまたはステーターナイフとも呼ばれ、造粒機の主要部品です。 […]

アリゲーターシアーブレードを選ぶためのトップヒント

最適なパフォーマンスを得るには、適切なアリゲーターシアーブレードを選ぶことが重要です。これらのブレードは、材料の切断効率と安全性に大きく影響します。高品質のブレードは、安全性を確保しながら作業の成功に貢献します。一方、低品質のブレードは摩耗が早く、切断効率が低下し、コストの増加につながる傾向があります。最良の結果を得るには、材料と作業量に適したブレードを選択することが不可欠です。Nanjing Metalのような企業は、お客様の特定のニーズに合わせてカスタマイズされたブレードの作成を専門としています。信頼できる企業と提携することで、パフォーマンスが向上するだけでなく、長期的にはコスト削減にもつながります。詳細については、お気軽にお問い合わせください。重要なポイント アリゲーターシアーブレードについて アリゲーターシアーブレードとは […]

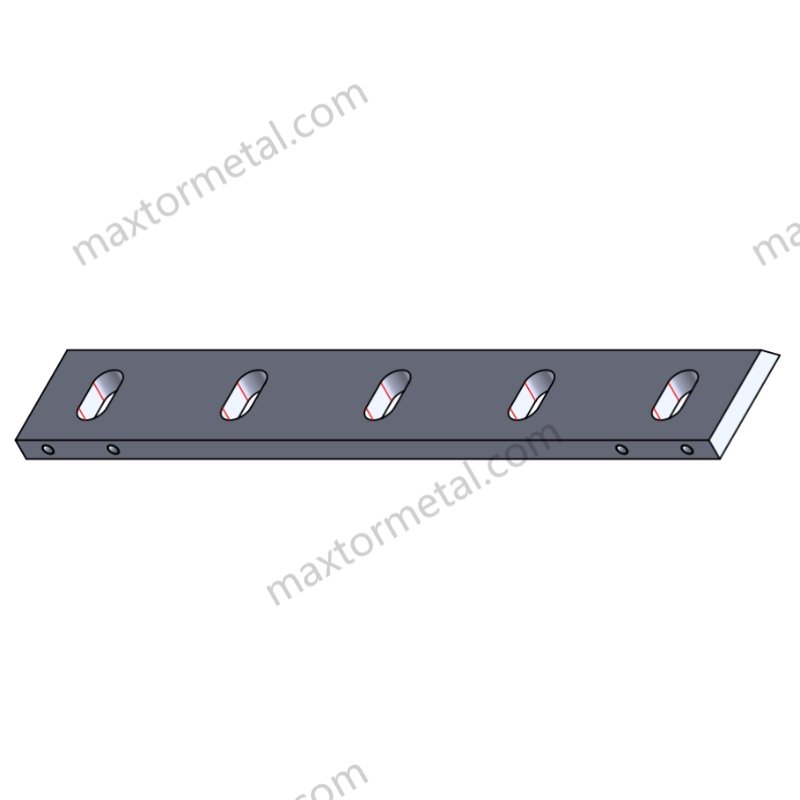

製造業における金属スリットブレードの用途を探る

Metalスリッターブレードは、金属コイルを細く精密なストリップに切断するために不可欠なツールです。これらのブレードは、製造効率と品質の向上に重要な役割を果たします。自動車製造や包装などの業界では、材料の無駄を最小限に抑えながら正確な金属切断を可能にするスリッターに大きく依存しています。これはコスト削減だけでなく、生産性の向上にもつながります。Nanjing Metalのような企業は、様々なニーズに合わせたカスタムブレードの製造を専門としています。生産能力を向上させるには、信頼できるサプライヤーに高品質の金属スリッターブレードをご相談ください。重要なポイント Metalスリッターブレードとは? Metalスリッターブレードの定義 特殊切断ツール Metalスリッターブレードは、幅広の金属コイルを細長いストリップに切断するためのツールです。 […]

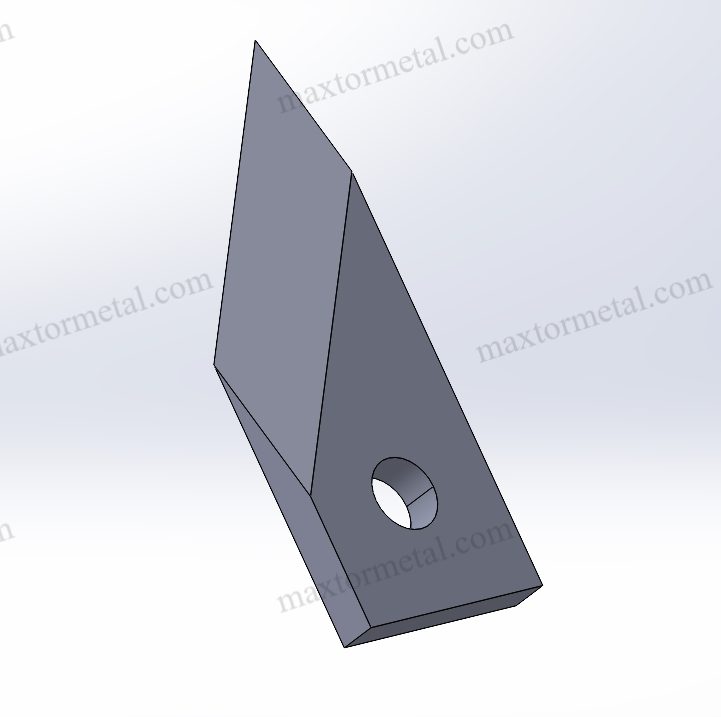

とがった先端のブレード: 知っておくべきこと

尖端刃とは、先端が鋭く細い工具です。細かく丁寧な切断作業に適しています。特殊な形状により、狭い箇所や切り込みの入りにくい箇所でも、きれいで正確な切断が可能です。これらの刃は繊細な作業に適しており、多くの業界で重宝されています。尖端刃は工場や医療現場でも使用されています。また、工芸品や日常の雑用にも適しており、その汎用性の高さが伺えます。Nanjing Metalのような企業は、特定のニーズに合わせてカスタム刃を製造し、最高の仕上がりを提供しています。ご質問や特注品については、お気軽にお問い合わせください。重要なポイント 尖端刃とは? 別名と用語 尖端刃には様々な種類があります […]

サーモカッターブレードが切断とシーリングを簡素化

サーモカッターブレードとは?定義と別名 サーモカッターブレードは、熱を利用して切断とシールを行う工具です。ホットナイフブレード、またはサーマルカッターとも呼ばれます。これらのブレードは、材料を切断すると同時に端をシールします。これにより、ほつれを防ぎ、きれいに仕上がります。サーモカッターブレードには、様々な用途に合わせて様々な種類があります。軽量のものは工芸品に適しており、高耐久性のものは難しい作業に適しています。例えば、AZTC-20は発泡スチロールや薄いプラスチックに最適です。ZETZ-24は、ソーラーパネルのトリミングやゴムの切断に適しています。主な機能と特徴 サーモカッターブレードには、他に類を見ない特別な機能があります。電動ブレード[…]