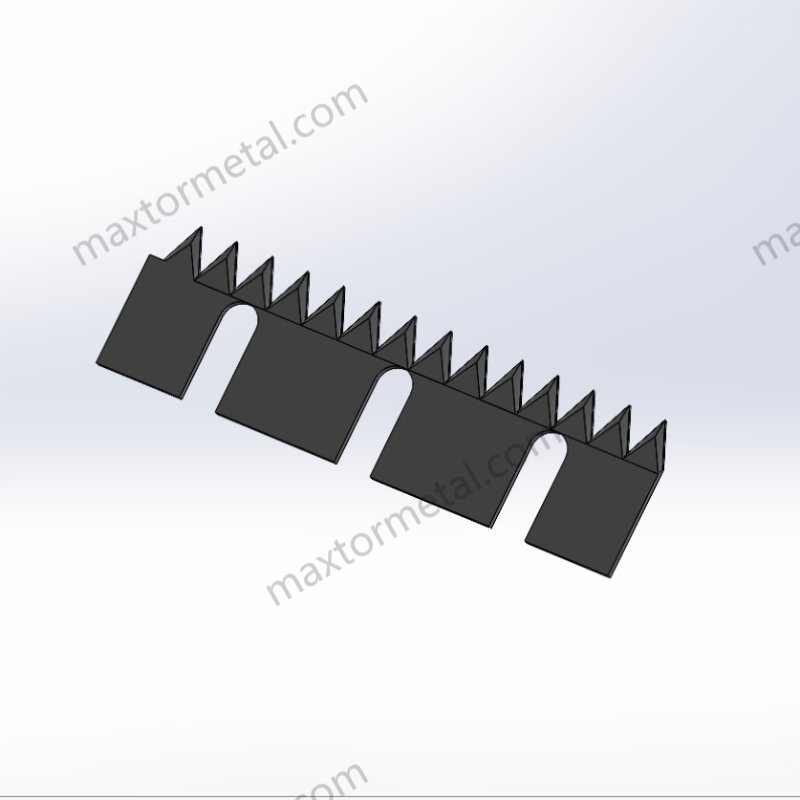

カスタム製造がブレードの未来である理由

Custom manufacturing is changing how industrial blades are made. It gives better accuracy and flexibility than old methods. Using new tech like robots and 3D printing, production is faster with fewer mistakes. For example, companies using robots saw a 35% rise in work speed and 70% fewer errors. These changes make work smoother and cut down waste a lot. The 3D printing market might grow to $57.1 billion by 2028. Custom manufacturing is growing quickly. It helps blades match exact needs while saving time and resources. Key Takeaways The Drawbacks of Traditional Blade Manufacturing Limited Customization Struggles to meet specific industry needs Old blade-making methods often fail to meet modern […]