What do Tooth Punch Blades Mean?

The term “Tooth Punch Blades” refers to a specific type of punch blade characterized by a cutting edge that features a series of teeth or serrations. Unlike punch blades with a continuous, smooth cutting edge, Tooth Punch Blades are designed to create holes or perforations with a specific edge profile or to facilitate tearing or separation of the material being punched. The teeth can vary in size, shape, and spacing depending on the intended application and the desired effect. Tooth Punch Blades are particularly useful for processing materials where a clean, shear-like cut is not always desired, or where a specific texture or tear initiation point is needed around the punched feature. These blades operate in punching machines or presses, similar to other punch blades. Tooth Punch Blades are also sometimes referred to as “serrated punch blades,” “perforating punch blades” (if the teeth are small and closely spaced), “notching punch blades” (if used to create edge notches), or “tear-off punch blades,” depending on the specific application and the resulting hole or cut.

Uses and Applications of Tooth Punch Blades

Tooth Punch Blades are used in various industrial and craft applications where a toothed or perforated edge is required in the punched material. Key uses and application scenarios include:

- Packaging Industry: Used to create tear-off lines or perforations on packaging films, pouches, and cardboard boxes, allowing for easy opening by the end-user. The tooth profile is designed for controlled tearing.

- Label Manufacturing: Employed to create perforations on label stock for easy separation of individual labels.

- Textile and Apparel: Used for creating decorative perforations or for controlled tearing features in fabrics.

- Leatherworking: Can be used to create decorative punched patterns or to initiate tear lines in leather goods.

- Paper Converting: Utilized for creating perforations on paper products like tickets, coupons, or continuous forms for easy separation.

- Medical and Hygiene Products: Employed to create perforations on medical tapes, bandages, or hygiene product packaging for controlled tearing.

- Security and Tamper-Evident Packaging: Used to create fine perforations that easily tear if the packaging is tampered with.

- Hobby and Crafting: Can be used for decorative punching or creating unique edge effects in paper crafts, scrapbooking, and other creative projects.

The specific size, shape, and spacing of the teeth on the Tooth Punch Blade are critical to achieving the desired perforation or tear characteristics in the punched material.

Common Materials for Tooth Punch Blades

The materials used to manufacture Tooth Punch Blades are chosen for their ability to maintain the sharp edges of the teeth under repeated impact and to resist wear. Common materials include:

- 高炭素鋼: Offers good sharpness and is suitable for punching softer materials. The teeth can be precisely formed.

- Tool Steels (e.g., D2, M2, A2): Provide a better balance of hardness, toughness, and wear resistance, making them suitable for more demanding applications and longer production runs. Tooth Punch Blades made from tool steel can maintain their toothed edge longer.

- High Carbon High Chromium Steels: Offer excellent wear resistance, which is beneficial for maintaining the integrity of the teeth when punching abrasive materials.

- Powder Metallurgy Steels (PM Steels): Allow for the creation of complex tooth profiles with superior material consistency, leading to high-performance Tooth Punch Blades with excellent wear resistance.

- Carbide Inserts: For very high-speed or demanding applications, Tooth Punch Blades may feature carbide inserts at the toothed cutting edge for maximum wear resistance and extended lifespan of the teeth.

The selection of the appropriate material depends on the material being punched, the required precision and durability of the teeth, and the production volume. Proper heat treatment is essential to ensure the teeth have the necessary hardness and toughness to perform effectively.

Common Shapes and Features of Tooth Punch Blades

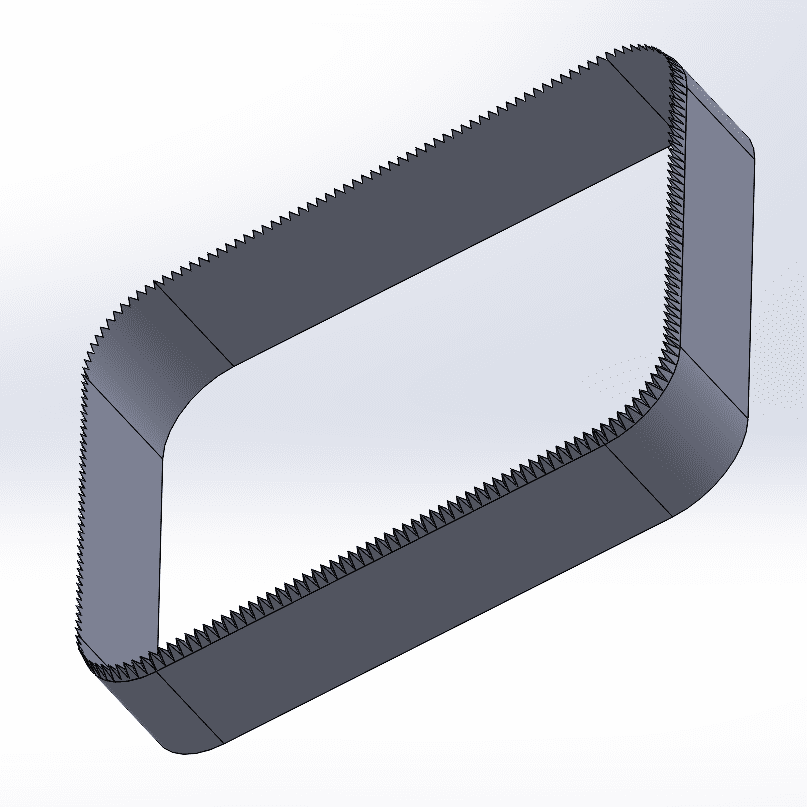

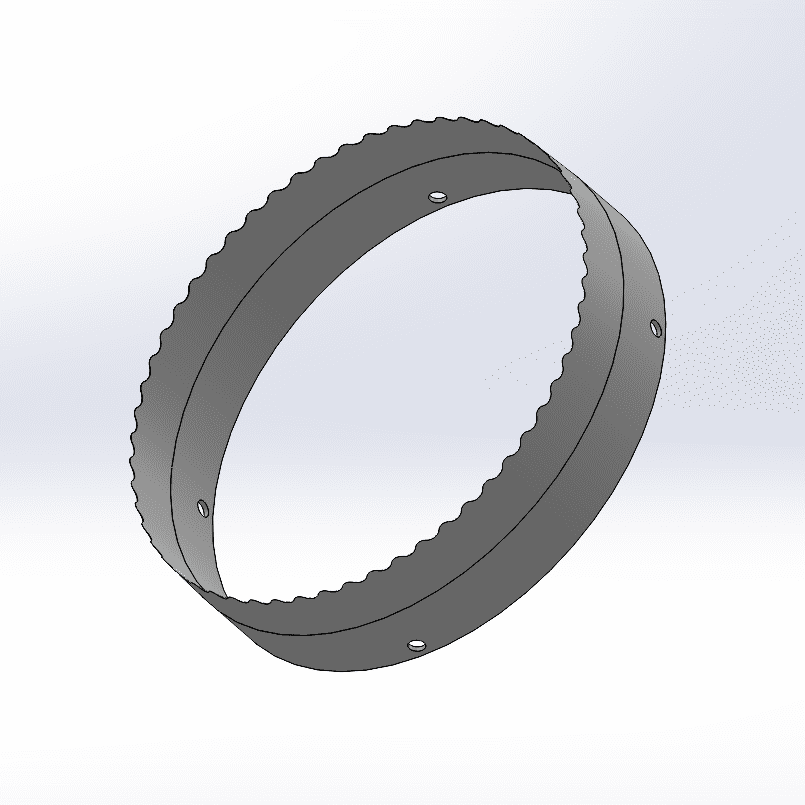

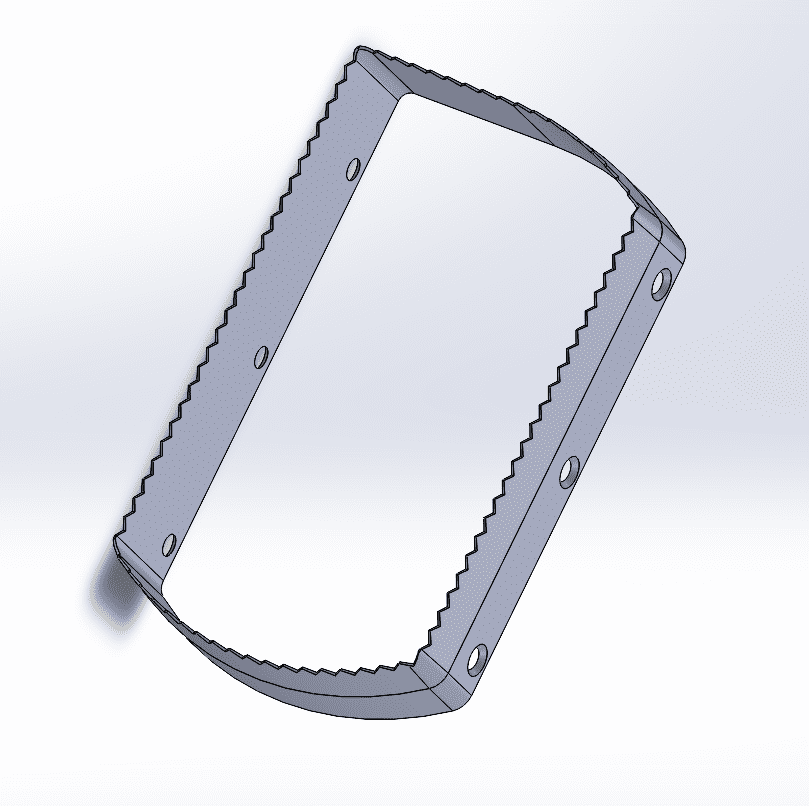

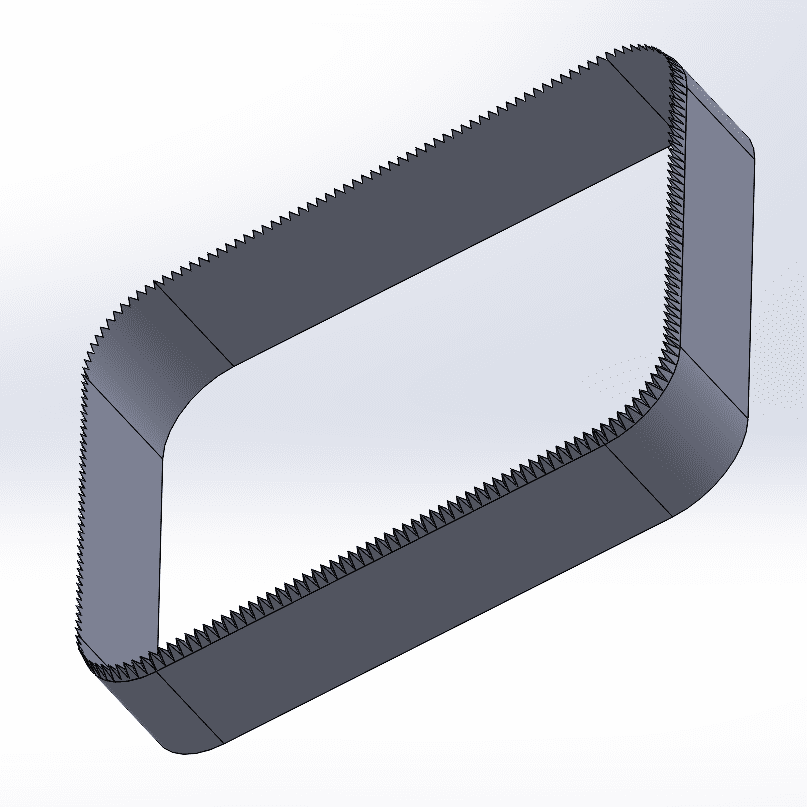

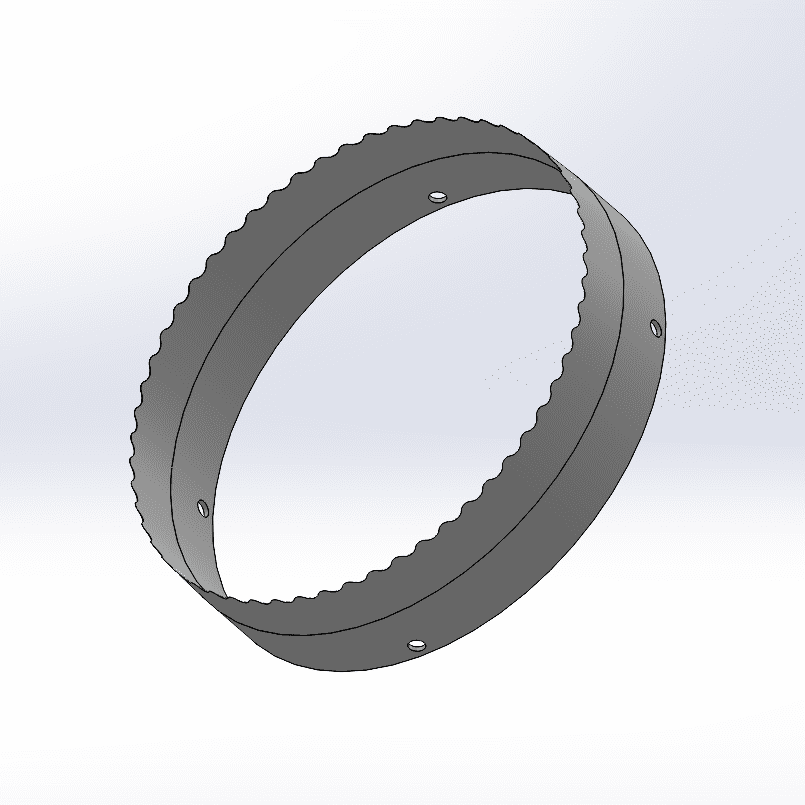

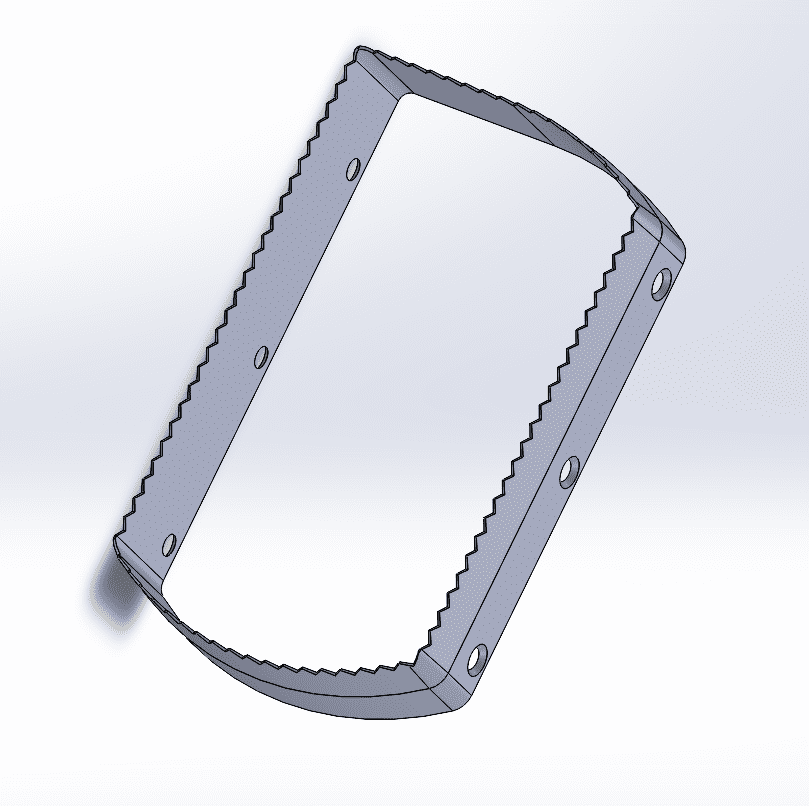

The defining characteristic is the toothed cutting edge. Beyond this, Tooth Punch Blades can have various overall shapes and tooth configurations:

- Round Tooth Punches: Used to create circular holes with a toothed or perforated edge. The teeth can be fine or coarse depending on the application.

- Rectangular Tooth Punches: Create rectangular openings with a toothed edge, often used for tear-off features.

- Custom Shaped Tooth Punches: Manufactured in unique shapes with teeth along the cutting edge to create specific perforated outlines or decorative effects.

- Perforating Punches: Feature many small, closely spaced teeth to create a line or area of perforations for easy tearing.

- Notching Tooth Punches: Designed to create notches on the edge of a material, with teeth to facilitate tearing or gripping.

- Single Tooth Punches: Used to create individual small tears or indentations.

- Variable Tooth Pitch: The spacing between teeth can vary along the cutting edge to create specific tear patterns.

- Variable Tooth Height or Shape: The size and shape of the teeth can be customized for different materials and desired effects.

- Stripper Plates: Often used in conjunction with Tooth Punch Blades to ensure the material is cleanly removed from the teeth after punching.

The design of the teeth (size, shape, pitch, angle) is critical and is tailored to the specific material being punched and the desired outcome of the perforation or tear. Precision manufacturing is essential to ensure the teeth function correctly and consistently.

If you don’t find the blade you are looking for, we can also customize it. See our “カスタムブレード” to learn how! Welcome to お問い合わせください!

Metal を選ぶ理由

-

手間いらずのワンストップ輸入サービス

輸入の利便性を簡単に享受できます。輸送から通関まで、当社が全プロセスを処理するので、お客様はVATを支払い、商品が会社に到着するのを待つだけです。

-

競争力のある価格設定

当社は、そのブレードが数え切れないほどのアプリケーションで使用されているのを見てきており、精度、耐久性、そして比類のない競争力のある価格を提供することで、お客様がどのようなプロジェクトに取り組んでも対応する準備ができています。

-

ODMとOEMも利用可能

図面、スケッチ、サンプルなど、どのようなものでも、弊社が図面を作成し、製造いたします。また、既存の設計や仕様を変更して、ほぼすべての産業用ツール アプリケーションを改善するためのサポートも行っています。お客様の具体的な要件についてご相談いただくには、弊社の専任営業チームにお問い合わせください。

-

品質管理

品質管理のために、初回品検査、受入材料検査、材料認証、工程内品質検査、最終品質検査など、一連のテストと検査が行われます。

-

柔軟な調達、無制限の協力

輸入業者、販売業者、卸売業者、エンドユーザーのいずれであっても、最小 MOQ、問い合わせの手間なし、購入の自由度の高さで、当社にご参加いただけることを歓迎いたします。

-

海外モニター、生産進捗リアルタイムレポート

あなたの専属モニターになり、生産ラインのあらゆる重要なノードを定期的に送信し、どんなに離れていても、製品の進捗状況を可能な限り把握します。