You have an important choice to make between ロータリーナイフ and laser cutting for composite materials. The best choice depends on how much precision, speed, and cost matter to you. Many industries use rotary knives because they cut quickly. These include defense, textiles, wind turbine blades, and car parts. Laser cutting is popular in aerospace, cars, and energy. It is good when you need very exact cuts or special shapes. Think about how much you need to make, what material you use, and your budget to decide.

重要なポイント

- Rotary knives cut composite materials quickly and cost less to start. They are good for making many parts with soft or bendy materials. Laser cutting gives very exact, clean, and sealed edges. It is great for hard shapes, small batches, and when you need high accuracy. Rotary knives need their blades sharpened or changed often to keep cuts nice. Lasers do not need much care but cost more at first. Laser cutting makes fumes and needs good airflow. Rotary knives do not make fumes and are safer for some materials. You should pick rotary knives or lasers based on how much you make, what material you use, your budget, and how exact you need to be. Rotary knives are best for easy, straight cuts and fast jobs. Lasers are better for detailed shapes and quick design changes. カスタムブレード for rotary knives can help cut special materials or do special jobs. Experts from experienced companies can help you choose. Both machines need to be set up right, kept in good shape, and run by trained workers to make good cuts and work well.

Rotary Knives vs Laser: Key Considerations for Composite Cutting

Rotary Knives in Industry

Rotary knives are used in many factories. They have been around for a long time in textiles, packaging, and car parts. Rotary knives are good for cutting soft things like fabric, foam, and film. They can cut fast and keep working for a long time. This helps finish big jobs quickly.

A big reason companies pick rotary knives is the lower starting cost. You do not need much money to begin. Taking care of them is easy, but you must change or sharpen blades often.

Rotary knives do not make fumes, so they are safe for materials like PVC. They also let you cut at angles, which helps with some projects. But rotary knives use force, so sometimes the material can move during cutting.

Laser Cutting Advantages

Laser cutting gives new ways to cut composites. Lasers can make very exact cuts, even as close as ±0.05 mm. This means you get smooth, clean edges and do not need extra work. Lasers do not touch the material, so it does not bend or move.

You can cut tricky shapes and detailed patterns with lasers. Lasers work for small jobs and big jobs. Automation lets you change designs fast, which saves time. Lasers also seal the edges of synthetic textiles, so they do not fray.

Here is a table to help you compare the main factors:

| 要素 | Laser Cutting Advantage | Rotary Knives Advantage |

|---|---|---|

| 精度 | High (±0.05 mm possible) | Good for moderate precision |

| エッジ品質 | Sealed, smooth edges | Can make angled cuts |

| スピード | Fast for complex shapes | Faster for straight, simple cuts |

| 料金 | Higher upfront, lower maintenance | Lower upfront, more blade upkeep |

| マテリアルハンドリング | No contact, no deformation | Can deform soft materials |

| Fume Generation | Needs extraction | No fumes |

| 柔軟性 | Easy to change designs | Best for repeat jobs |

Laser cutting is best when you need very exact cuts, tricky shapes, or fast design changes. It also saves material because the cut is thin.

適切な方法を選択する

Think about your project before you pick a cutting method. Here are some tips to help you choose:

- Rotary knives are good for cutting lots of soft or bendy materials fast.

- Rotary knives are cheaper to start with.

- Laser cutting is better for very exact cuts or tricky shapes.

- Lasers work well for hard composites or when you need sealed edges.

- Think about safety. Rotary knives do not make fumes, but lasers need good air flow.

Tip: Sometimes, using both ways at different times gives the best results.

Technology Overview

Rotary Knives Principles

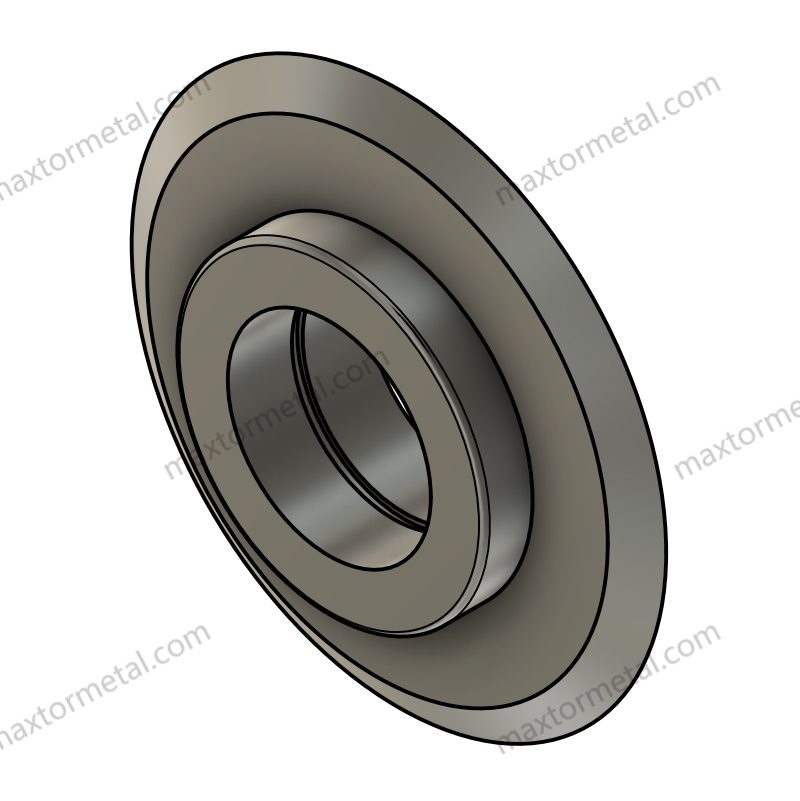

ブレードデザイン

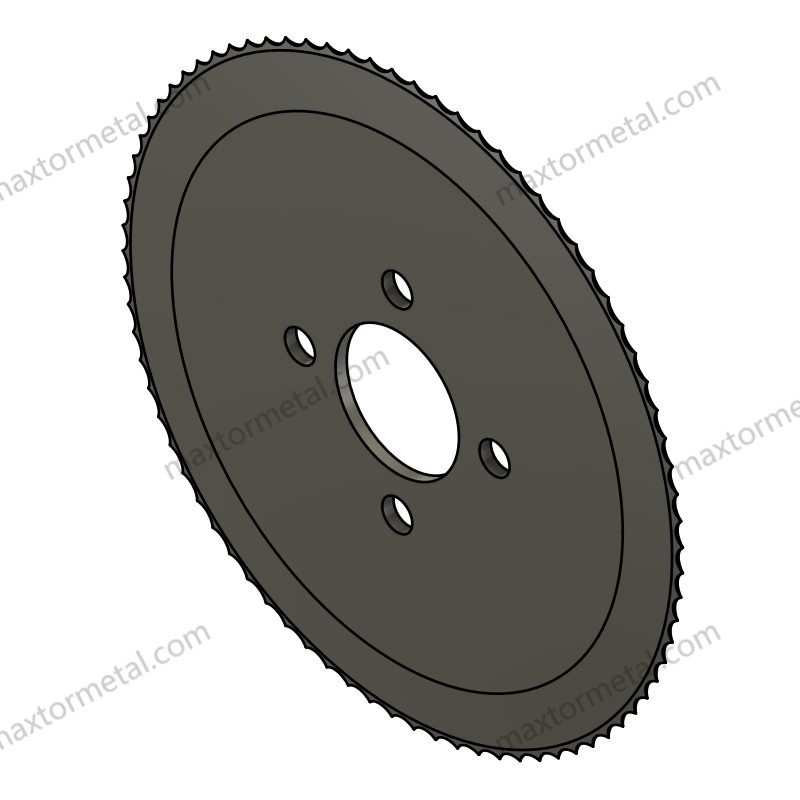

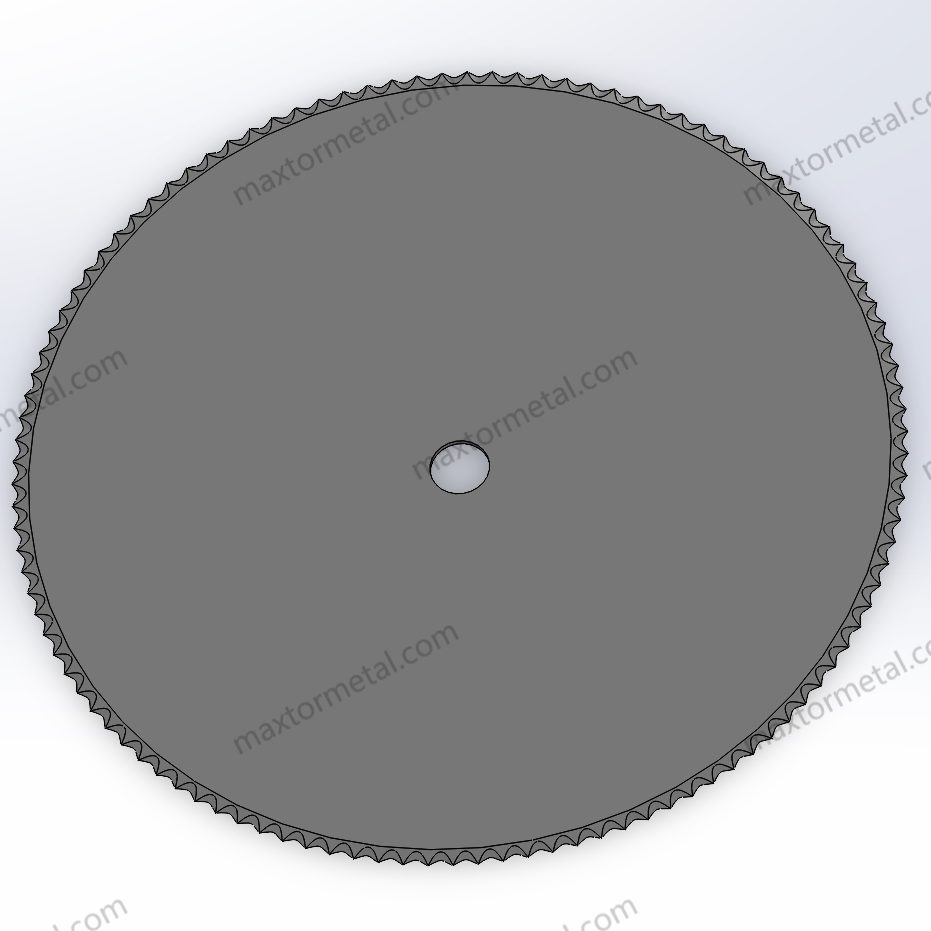

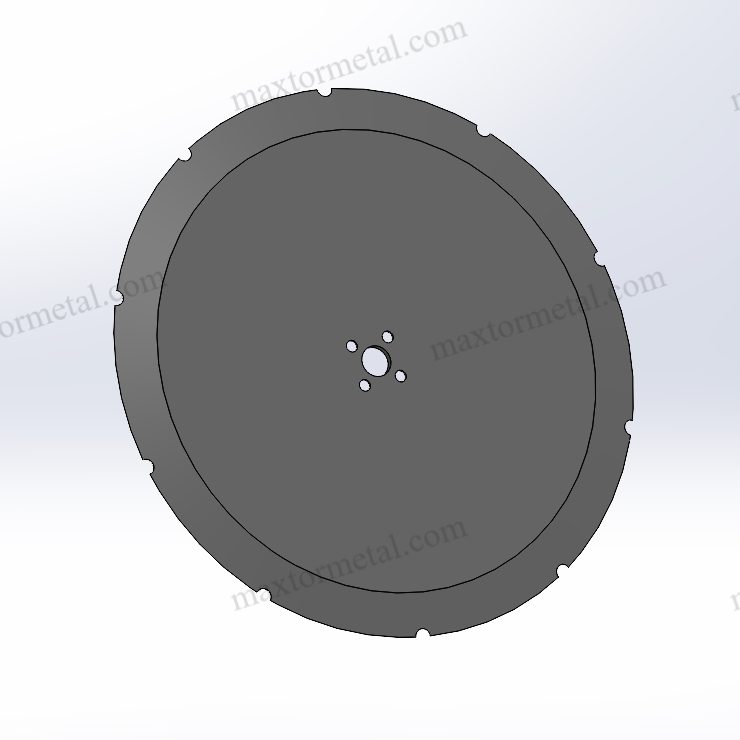

You will find that rotary knives use a simple but powerful design. The main part is a round blade that spins at high speed. The blade works together with a fixed bar to cut through materials. You can control the speed, usually from 700 to 3000 RPM, to match the type of composite you want to cut. The blade and bar create a shearing force that slices the material cleanly. This design lets you cut many types of composites, from soft films to tougher layers.

If you need a custom blade for your job, you can look for a rotary knives manufacturer with a strong background. Nanjing Metal is a trusted name in the industry. With over 20 years of experience, their team designs and makes custom industrial blades for many uses. You can explore their カスタムブレード to find the right fit for your project.

アプリケーション

You can use rotary knives in many industries. These blades work well for cutting paper, plastic film, nonwoven fabric, and rubber. In factories, rotary knives often run in sync with moving material webs. Servo motors and sensors keep the blade and material moving together. This keeps the cuts even and reduces fraying or stretching. You can change the cutting recipe quickly, which helps when you need to switch jobs without stopping the machine. Rotary knives fit well in high-speed, high-volume production lines.

Laser Cutting Process

Laser Types

You will see several types of lasers used for cutting composites. The most common are CO₂ lasers and fiber lasers. CO₂ lasers work well for non-metallic composites, like plastics and fabrics. Fiber lasers handle some metals and special composites. Each laser type uses a focused beam of light to melt or vaporize the material. You can pick the right laser based on the thickness and type of composite you need to cut.

エッジ品質

Laser cutting gives you very smooth and sealed edges. The process starts with preparing your material and setting the right laser power, speed, and focus. You should run test cuts to check the quality. The laser beam moves along the path you set, guided by a computer. Gas flows over the cut to clear away melted material and cool the edge. This keeps the cut narrow and clean. After cutting, you may need to clean or finish the part, but the edge usually looks neat and does not fray.

Precision and Quality

Rotary Knives Tolerances

Mechanical Factors

Many things can change how well rotary knives cut. You must check these things to get good results:

- The blade must be sharp. If it gets dull, cutting mistakes can go up by 25%. A dull blade can make the material move or edges look rough. It can even bend the material in ways you do not want.

- You should sharpen the blade often. For most jobs, sharpen every 50,000 cuts. For harder jobs, sharpen every 20,000 cuts. This keeps your cuts neat and correct.

- Some blades have special coatings. Titanium nitride can help a blade last 30% longer. This helps the blade stay sharp for tough work.

- The machine must be lined up right. Even a small mistake of 0.1 mm can make cuts uneven and waste material.

- Laser tools can help you line up the machine better. This helps you cut straighter and have fewer edge problems.

- The blade must be put in the machine the right way. If it is too tight or too loose, the blade can shake and lose accuracy.

- Shock absorbers and hydraulic clamps help keep the blade steady. This is important when you cut fast.

- Keep the machine clean and oiled. Oil helps the parts move smoothly and stops them from rubbing too much.

- Train workers well. Good training helps stop mistakes and keeps cutting accurate.

Typical Use Cases

Factories use rotary knives to cut and trim composite materials fast. These knives are best when you need good speed and okay precision. Most rotary knife machines can cut with tolerances from ±0.1 mm to ±0.5 mm. This depends on the material and how well you care for the machine.

Laser Cutting Accuracy

許容範囲

Laser cutting is more accurate than most other ways. The laser does not touch the material. You do not have to worry about dull blades or the material moving. The table below shows what tolerances you can get for different materials:

| 材質タイプ | Typical Laser Cutting Tolerance Range |

|---|---|

| Metals (Steel, Aluminum, Stainless Steel) | ±0.005” to ±0.010” |

| Plastics (Acrylic, Polycarbonate) | ±0.007” to ±0.015” |

| Wood and Composites | ±0.010” to ±0.020” |

For composites, you can usually get tolerances from ±0.010” to ±0.020”. This is great when you need parts to fit together well or have tricky shapes.

Edge Finish

Laser cutting makes edges that are smooth and sealed. The edges do not fray or come apart, which is important for composites. The edge quality depends on the laser power, speed, and material. Sometimes, you might see a small area changed by heat. But this is small if you set up the machine right.

Note: If you use heat-sensitive composites, you might want to try vibration knife cutting. This uses a blade that moves back and forth to cut. It does not melt or burn the material. This keeps the material strong and stops heat damage. Vibration knives can also cut many layers at once and make smooth edges.

Speed and Throughput

Rotary Knives Efficiency

Continuous Operation

Rotary knives cut fast and keep working for a long time. Many factories use them because they do not need to stop often. For example, the Eastman Machine Company’s S125 Static Table Cutting System can cut carbon fiber and hybrid materials at speeds up to 60 inches per second (152.4 cm/s). This high speed helps finish big jobs quickly. Rotary knives work in lines that keep moving, so you do not have to stop between cuts. This makes them great for making lots of parts.

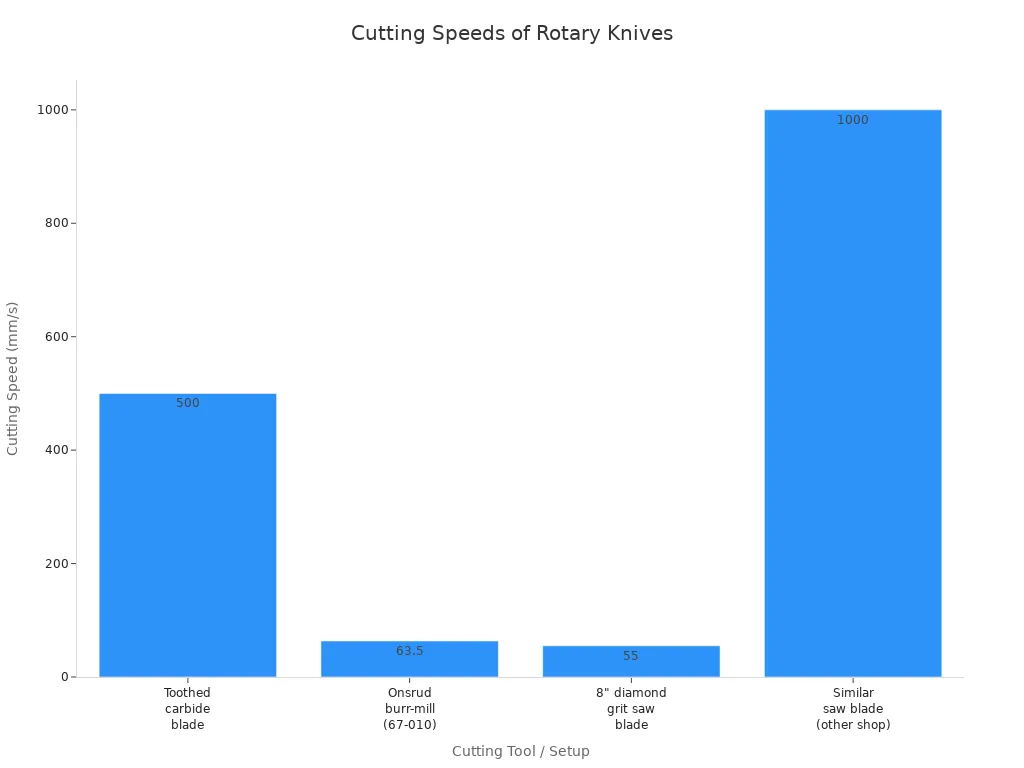

Here is a table that shows how fast different cutting tools work with composites:

| Cutting Tool / Setup | Cutting Speed / Feed Rate | Additional Details / Observations |

|---|---|---|

| Toothed carbide blade | 500 mm/s | Much faster than diamond saw; some rigidity issues noted |

| Onsrud router bit (1/2″) 67-033 | Tool wear in ~5 days | Possible speed/feed imbalance |

| Onsrud burr-mill (67-010) | 150 IPM (63.5 mm/s) | Feed considered low; machine full rapid speed |

| 8″ diamond grit saw blade | ~55 mm/s | Blade loads up beyond this speed; pushing part away |

| Similar saw blade (reported by another shop) | 1000-2000 mm/s (claimed) | Much faster than typical, but not confirmed in this setup |

| Robot spindle with Colombo tooling | 24,000 RPM | High spindle speed for trimming fiberglass parts |

You can see rotary knives are some of the fastest tools for cutting composites.

マテリアルハンドリング

Rotary knives can cut many kinds of materials, from soft films to tough composites. You can put rolls or sheets into the machine. The system keeps the material moving, so it does not jam or slow down. You can change the setup for thick or thin materials. This means you can switch jobs fast with little waiting.

Laser Cutting Speed

Prototyping

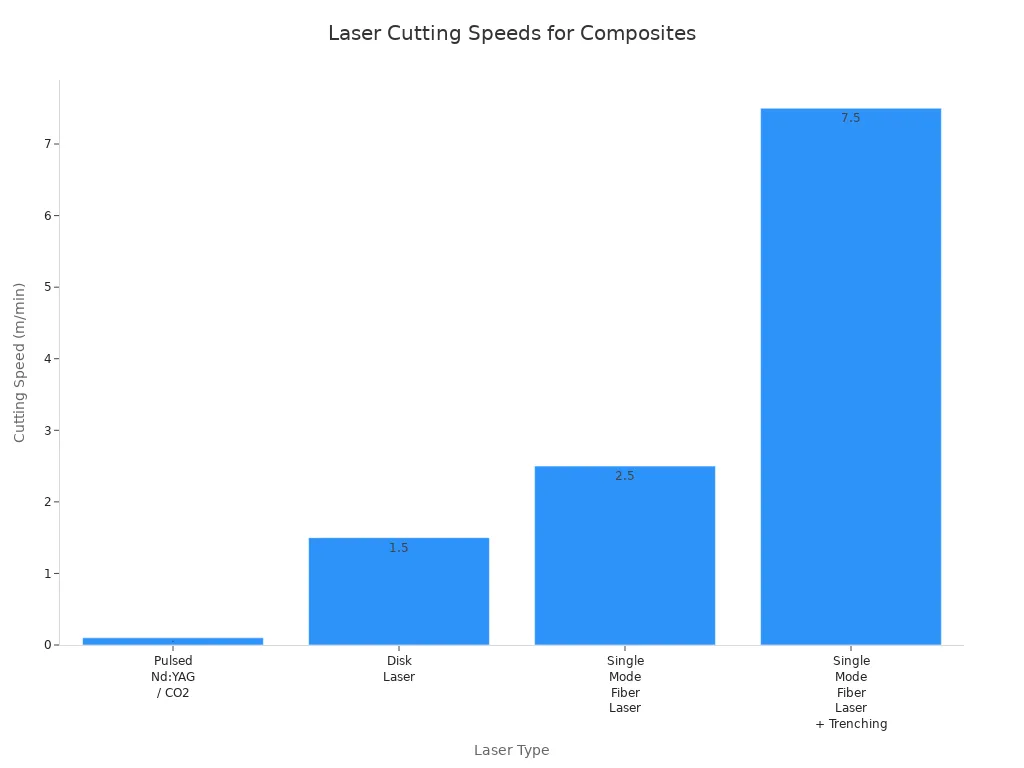

Laser cutting is good when you need to make a few samples or small batches. You can change your design fast and do not need to switch tools. The speed depends on the laser type and the material. For example, pulsed Nd:YAG or CO₂ lasers can cut thick composites at 0.1 m/min, while single mode fiber lasers can go up to 7.5 m/min. You can see the different speeds in the chart below.

Laser cutting and rotary knives have about the same speed for many composites. Vibrating knife systems can be twice as fast, but for most jobs, rotary knives and lasers are close in speed.

Complex Designs

Laser cutting is great for tricky shapes and detailed patterns. Lasers follow computer paths, so you can cut curves, holes, and special shapes with high accuracy. If you set the laser power and speed right, you keep the heat-affected zone small. This helps keep your composite parts strong. For example, tests show you can cut carbon fiber reinforced plastics at speeds up to 2700 mm/min with very little heat damage. Special holders keep the material still, so you get the same good results every time. You can use laser cutting for car panels, battery covers, and other parts that need exact shapes.

コストとメンテナンス

When you pick a way to cut composites, you must think about how much money you spend at first and later. Rotary knives and laser cutting have different costs. Let’s look at both so you can choose what works best for you.

Rotary Knives Costs

Equipment Investment

Rotary knives do not cost as much to buy as laser machines. You need to pay for the slitting machine, rotary knife parts, and some safety gear. Most factories can start using rotary knives without spending too much. This is good if your business is small or medium, or if you want to save money.

ブレードのメンテナンス

You have to take care of rotary knives to keep them working. The blades get dull after a while, especially if you cut hard stuff or use them a lot. You will need to sharpen or change blades often. Sometimes, you do this every few days or weeks, depending on what you cut. You also need to check if everything lines up and oil the moving parts. If you skip this, your machine might stop working or make bad cuts.

It is important to have sharp blades ready when you need them. The cost for workers to do this is not high, but you should plan for it.

Tip: If you take care of your blades, your machine will work better and your cuts will look nice.

Laser Cutting Costs

Capital Expense

Laser cutting machines cost a lot more at the start. For cutting composites, you might pay $100,000 to $500,000 for a new laser. Most cost about $300,000. This price covers the laser, the moving parts, cooling, and safety covers. These machines lose value over time, but fiber lasers keep their value better because they do not need as much fixing. You might need to borrow money or rent if you want a laser cutter.

Energy and Upkeep

Laser cutters use a lot of power, especially strong ones. Fiber lasers use up to half as much power as CO2 lasers, so your bills are lower. You also need to pay for things like new lenses, filters, and cleaning the laser parts. Lasers do not have blades, so you do not need to worry about changing them. This means you spend less time fixing the machine.

You need trained workers to keep your laser running well. You do not need to fix lasers as often as rotary knives, but when you do, it can cost more and take longer. Lasers also need good air flow to get rid of fumes.

Here is a table to help you compare energy use and upkeep:

| 側面 | Fiber Laser Cutting System | CO2 Laser Cutting System |

|---|---|---|

| エネルギー消費 | Up to 50% less electricity than CO2 lasers | Higher electricity consumption |

| Electro-Optical Efficiency | 30-50% | 10-15% |

| メンテナンス要件 | Lower due to simpler design and fewer consumables | Higher due to complex cooling and mirror replacement |

| Operating Costs | より低い | より高い |

Note: Laser cutters cost more at first but need less fixing and use less power over time. Rotary knives are cheaper to buy but need more care because of blade wear.

Which Should You Choose?

If you want to cut a lot and save money, rotary knives are a good pick. They are great for big jobs where you do not need super exact cuts. If you need very exact cuts, special shapes, or want to change designs, laser cutting might be worth the higher price.

材料の適合性

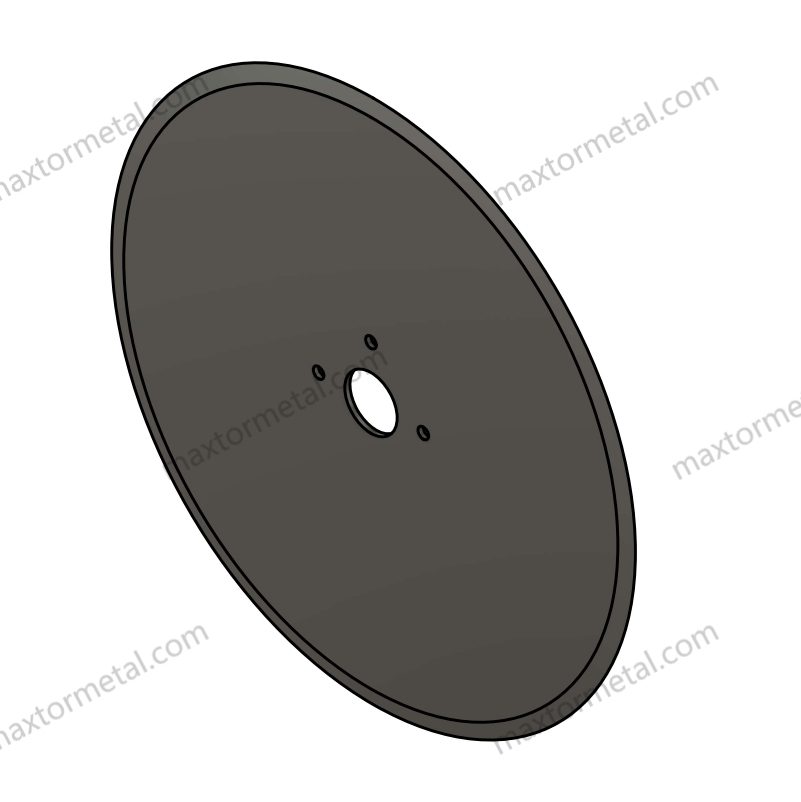

Rotary Knives Materials

Common Composites

Rotary knives can cut many kinds of composite materials. These materials mix things like ceramics, metals, and polymers. They are strong but not heavy. This is important for cars and airplanes. Here are some composites you might see cut with rotary knives:

- Carbon fiber composites

- High-strength polymers

- Laminated films

- Nonwoven fabrics

- Rubber sheets

Rotary knives work well because they cut soft and tough layers. For hard jobs, use blades made from tool steels or high-chromium steels. These blades last longer and stay sharp.

制限事項

There are some limits when using rotary knives. Very thick or super hard composites can wear out the blade fast. Some layered composites might move or stretch if you do not keep them tight. Rotary knives are not the best for tricky shapes or tiny details. For those jobs, you may need a different cutting method.

Laser Cutting Materials

Suitable Types

Laser cutting lets you cut more types of composites. Lasers can cut:

- Carbon fiber: This material is strong and light. Lasers cut it very well, but you must watch the heat so it does not come apart.

- Fiberglass: Lasers are good for cutting and marking fiberglass. You need good air flow because cutting fiberglass makes dangerous fumes.

- Plastic composites: Things like polypropylene, polyethylene, and ABS cut well with lasers if you set the machine right.

Here is a table that shows which lasers work best for each composite:

| Composite Type Composition | Recommended Laser Type | Wavelength | Laser Power Range | Additional Considerations |

|---|---|---|---|---|

| Mostly Organic (e.g., carbon fiber epoxy) | CO2 Laser | 10.6 micron | 25–150 Watts | Use exhaust and air assist to manage fumes and particles |

| Mostly Metallic | Fiber Laser | 1.06 micron | 40–50 Watts | Take safety steps for metal composites |

| Plastic Composites (PP, PE, ABS) | CO2 Laser | 10.6 micron | 変数 | Adjust laser settings for clean cuts |

Tip: Always check what safety steps you need for your material. Some composites make dust or fumes that need special air systems.

Thickness and Reflectivity

How thick and shiny the material is matters for laser cutting. Thick composites need more power and slower speed. Sometimes you must cut more than once to get through. Shiny materials, like ones with aluminum or brass, can bounce the laser beam. This makes cutting harder and you need a fiber laser and careful power control.

Here is a table to help you see how these things matter:

| 要素 | Effect on Laser Cutting Suitability for Composites |

|---|---|

| 材料の厚さ | Thicker materials need higher power and slower speed. You may need multiple passes for layered composites. |

| Reflectivity | Reflective surfaces need special lasers and settings to avoid beam bounce and ensure a clean cut. |

| Composite Details | Layered and variable composites need advanced controls and assist gases for the best results. |

| Laser Settings | You must adjust power, speed, and focus for each material. Use assist gases like oxygen or nitrogen to improve cut quality. |

If you want to cut many kinds of composites with high accuracy, laser cutting gives you lots of options. You can change the machine for each job and cut both thin and thick materials.

Limitations and Challenges

Rotary Knives Issues

Alignment and Tension

When you use rotary knives, you must keep the blade straight and the material tight. If the blade moves, your cuts will not be straight. Loose material can stretch or move, making rough edges. Blades can wear out fast or even break if tension is wrong. Here are some problems you might see:

- Abrasive composite blades can wear out quickly and not cut as deep.

- Side pressure on the blade can crack or break it.

- Gasoline or oil can make the blade’s resin weak and unsafe.

- Carbide blades can lose tips or break if not checked often.

- Safety rules say to test fiber blades at full speed away from people.

| Operational Issue | Cause/Mechanism | Impact on Operation | Mitigation Approach |

|---|---|---|---|

| Bluntness and breakage | Impacts and chiseling during cutting | Shorter blade life, poor cut quality | Use coatings, improve blade design |

| Fatigue failure at root | Repeated stress and weak spots | Blade damage, sudden failure | Add reinforcement, use vibration control |

| Wear resistance problems | Tough materials and friction | Frequent blade changes, more downtime | Use metal-ceramic coatings |

| Shock loads and high friction | Unbalanced forces during operation | More stress, possible deformation | Optimize structure, use vibration theory |

Maintenance Impact

If you do not take care of rotary knives, problems show up fast. Dull blades and loose parts make cuts less accurate. You might waste more material or break the machine. If you do not replace worn parts, the machine can stop working suddenly. This means lost time and less production. Dust, heat, and humidity can also hurt your machine if not controlled. A good maintenance plan helps you avoid these problems and keeps things running well.

Laser Cutting Issues

Ventilation

Laser cutting makes fumes and tiny bits when you cut composites. You need strong airflow to keep the air clean and safe. Without good ventilation, fumes can hurt your health and the machine. Some materials, like fiberglass, make dangerous dust that needs special filters. You must set up your workspace with the right exhaust systems and keep them working well.

You may also have other problems:

- Fiber peeling and burrs can make cuts less accurate.

- Cutting thick composites needs more laser power, which costs more and is harder.

- Waste from laser cutting can be hard to handle and may need special disposal.

Operator Skills

Laser cutting machines need skilled workers. You must know how to set up the machine, adjust the laser, and keep things safe. Training teaches you about the machine, CAD software, and how materials react to lasers. You also learn safety steps, like using gear and what to do in emergencies. Operators must check the machine, fix problems, and keep the area clean. Training helps you stay up to date with new technology and safety rules.

Here is what you need to know as a laser operator:

- Learn how the machine works and use CAD software.

- Get safety training for lasers and emergency steps.

- Practice setting up, adjusting, and caring for the machine.

- Fix problems like misalignment or software errors.

- Keep learning with new classes and updates.

Decision Guide

アプリケーションシナリオ

大量生産

You should choose your cutting method based on how much you need to produce. If you run a factory that makes thousands of parts every day, rotary knives work well. These machines cut fast and keep going for long hours. You can use them for materials like paper, film, and nonwoven fabrics. Many factories use rotary knives because they help finish big jobs quickly. You do not need to stop often to change tools. This means you save time and keep your production line moving.

Prototyping and Complex Cuts

If you need to make samples or test new designs, laser cutting gives you more flexibility. You can change your design on a computer and start cutting right away. Lasers also help when you need to cut special shapes or detailed patterns. You do not need to buy new blades for every shape. Laser cutting works well for small batches, custom parts, or when you want to try new ideas. You get clean edges and high precision, which is important for prototypes.

Tip: For カスタムブレード needs, you can work with a rotary knives manufacturer that has a strong reputation. Nanjing Metal is a trusted name in the industry. With 20 years of experience, their skilled team designs and produces custom blades for many industries. Many customers choose them for reliable solutions.

予算の考慮

Upfront vs Ongoing Costs

You need to think about both the money you spend at the start and the money you spend over time. Rotary knives cost less to buy. You can start using them without a big investment. However, you must pay for blade sharpening and replacement as you keep using the machine. Laser cutting machines cost much more at the start. You pay for the laser, safety covers, and special parts. Over time, you spend less on parts because there are no blades to replace, but you pay more for energy and skilled workers.

| Cost Type | ロータリーナイフ | レーザー切断 |

|---|---|---|

| 初期費用 | 低い | 高い |

| メンテナンス | Moderate (blades) | Low (no blades) |

| Energy Use | 低い | 高い |

| 柔軟性 | より低い | より高い |

ダウンタイム

Downtime can affect your business. Rotary knives may need to stop for blade changes or maintenance. If you keep extra blades ready and follow a good maintenance plan, you can reduce these stops. Laser cutters do not need blade changes, so you have fewer stops for tool changes. However, when a laser needs repair, it may take longer and cost more to fix. You should train your team to handle small problems quickly.

Picking between rotary knives and laser cutting depends on what you need. You should think about a few things:

- Production volume: Rotary knives are best for making lots of parts. Laser cutting is good for small jobs or testing new ideas.

- Material type: Rotary knives cut soft or bendy composites well. Lasers are great for thin or detailed materials.

- 予算: Rotary knives are cheaper to buy at first. Lasers cost more but do not need as much fixing later.

| 要素 | ロータリーナイフ | レーザー切断 |

|---|---|---|

| スピード | Fast for big batches | Quick for tricky shapes |

| 精度 | わかった | 非常に高い |

| 柔軟性 | Not as flexible | More flexible |

よくある質問

What are the main benefits of rotary knives for composite cutting?

Rotary knives cut fast and do not cost much to use. They are good for big jobs and work well with things like films or fabrics. You can change or fix the blades easily.

When should you choose laser cutting over rotary knives?

Pick laser cutting if you need very exact cuts or special shapes. Lasers are ideal for samples, custom parts, or when you need sealed edges on synthetic materials.

Can rotary knives handle all types of composite materials?

Rotary knives can cut most regular composites like paper, plastic film, and nonwoven fabric. If the material is very hard or thick, you might need another cutting way.

How often do you need to replace or sharpen rotary knife blades?

Check if the blade is sharp often. For most jobs, sharpen or change blades every few days or weeks. How long a blade lasts depends on what you cut and how much you cut.

What is the typical edge quality difference between laser and rotary cutting?

Laser cutting makes edges smooth and sealed with almost no fraying. Rotary knives can make neat cuts, but soft materials might have a little roughness on the edge.

参照

クラッシュカッティングロータリーナイフ:接着剤、ゴム、フィルムのスリット加工における半径、角度、ブレードの選択

ロータリースロッターナイフの適切な取り付けとセットアップで効率を向上