You need a smooth surface to make accurate cuts. A mirror-polished edge on 円形スリッターナイフ helps you cut better and faster. This finish stops burrs and friction that slow work. It also keeps material from sticking to the blade. Stuck material can hurt blades and make cuts less exact. Nanjing Metal Industrial makes each blade with great skill. They always give you high quality for tough jobs.

重要なポイント

- A mirror finish on circular slitting knives helps make clean cuts. It lowers friction and stops material from sticking.

- Blades with a mirror finish last longer because they do not get as hot. They wear down less, so you save time and money on new blades.

- Check the space between knives often in your slitting machine. This stops material from stretching and keeps burrs from forming.

- Mirror polishing makes blades sharper. This is important when cutting thin materials. It helps blades work better and you change them less.

- Keep your blades clean and dry to keep their mirror finish. This stops rust and helps blades work well for a long time.

- You can choose custom blade options for special cutting needs. This makes your work faster and helps you waste less material.

- Make a plan to clean and polish your blades on a schedule. This keeps blades working well and helps them last longer.

- Using mirror-finished blades can help many industries work better. You get cleaner cuts and waste less material.

Mirror Finish and Cutting Precision

Why Mirror Finish Matters

You want your blade to make clean cuts every time. A mirror finish on circular slitting knives helps you do this. The smooth surface makes the blade slide easily over the material. This means there is less rubbing and less heat. Less heat helps the blade last longer. You get better cuts and your blade works for more time. When you use a slitting machine, a shiny blade edge keeps things running well. Nanjing Metal Industrial makes blades with care and skill. You can trust their blades to work hard in tough places. If you need a special blade, you can look at custom choices ここ.

Preventing Burrs and Material Stretching

Burrs can slow down your work and hurt your finished product. A mirror finish helps stop burrs by letting the blade move smoothly through steel and other stuff. The shape of the blade matters too. A wide, square blade lets the material slide gently under the edge. This helps stop stretching. A sharp angle blade can bend the material more, which causes stretching. You need to keep the right space between knives in your slitting machine. If the space is too small, it can tear the material. If the space is too big, it can stretch the material and make cuts uneven. By picking blades with a mirror finish and the right shape, you keep your materials safe and get better results.

Tip: Always check the space between knives before you start a job. Setting up right helps you stop stretching and burrs.

Enhancing Sharpness and Durability

You want blades that stay sharp and last a long time. Mirror polishing makes circular slitting knives sharper, especially for thin metal foil. It also helps stop burrs and flakes, so your blades stay sharp for more uses. The table below shows how mirror finishing makes blades sharper and stronger:

| Improvement Aspect | 説明 |

|---|---|

| シャープネス | Mirror polishing makes circular slitting knives cut better, especially for thin metal foil. |

| 耐久性 | Polishing stops burrs and flakes, so blades last longer. |

When you use blades with a mirror finish, you spend less time fixing or changing them. You get more for your money and your work goes smoothly.

Benefits for Circular Slitting Knives

Reduced Friction and Wear

Circular slitting knives need to last a long time. A mirror finish makes the blade smooth. This smoothness helps the blade slide easily when cutting steel or other things. Less friction means less heat builds up. Less heat keeps the blade from getting damaged. The blade stays sharp for more cuts. You do not have to stop and change blades often. Your slitting machine works better and does not slow down.

- The mirror finish helps the blade last longer.

- You do not need to change blades as much.

- The cutting edge stays strong, even with hard jobs.

Corrosion and Rust Protection

You want blades that stay clean and do not rust. A mirror-polished blade protects against corrosion. The smooth finish stops water and chemicals from sticking. This keeps rust away and helps every cut stay good. Blades with this finish do not get rusty or corroded. Your blades work well in tough places and last longer.

Tip: Keep your blades dry so they stay in good shape.

Improved Efficiency in Industrial Applications

You want your work to go smoothly and waste less. Mirror-finished circular slitting knives help you do this. The shiny surface keeps the blade edge steady for each cut. Special coatings stop glue and bits from sticking to the blade. You can use the blade longer before changing it. Some companies say they get up to 40% longer runs. There is almost no wasted material when using these blades.

Here is a table that shows how mirror finish helps:

| 特徴 | 利点 |

|---|---|

| Mirror-like surface | Cuts down on flying pieces during cutting |

| Enhanced cut quality | Makes the cut look better |

| Extended production runs | Lets you use the blade longer |

- Your slitting machine works for more time.

- You get cleaner cuts with less mess.

- You save money by wasting less and changing blades less.

Mirror-finished circular slitting knives give you the strong and steady performance you need for tough jobs.

Glue and Particle Adhesion Prevention

When you use a slitting machine, you can have problems. Sometimes glue and dust stick to the blade. If this happens, your cuts are not as good. The blade might pull on the material. This can make the material tear or bend. You want every cut to look nice and smooth.

A mirror finish on circular slitting knives helps stop these problems. The shiny surface makes it hard for glue or steel bits to stick. You do not need to clean the blades as much during work. This saves time and keeps your work moving. You get better results and your products look nicer.

Here are some good things about this:

- The slitting knife stays clean for a longer time.

- Sticky stuff does not hurt the blade as much.

- Every cut stays sharp and right.

Note: Check your blades often to find sticky stuff early. Clean blades last longer and work better.

When you pick blades with a mirror finish, you work faster and save money. Your blades work well and your products turn out great every time.

Material Selection for Roller Shearing Blades

Choosing the right material for your roller shearing blades makes a big difference in how well they perform and how long they last. At Nanjing Metal Industrial, you get access to a range of premium materials. Each option brings unique benefits for your cutting needs. The right choice helps you achieve a mirror finish, which keeps your blades sharp and strong through many uses.

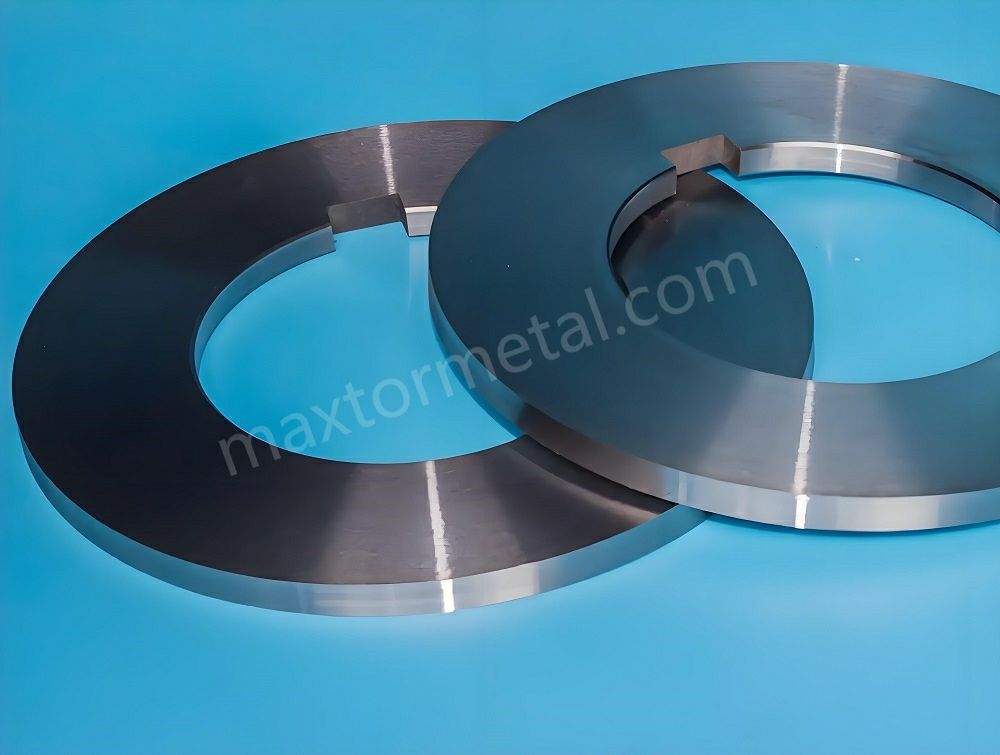

Tungsten Steel Round Blades

You want blades that stay sharp and resist wear, even in tough jobs. Tungsten steel round blades give you this advantage. These blades use tungsten, a metal known for its hardness and strength. When you use tungsten steel round blades, you get:

- Excellent edge retention, so your cuts stay clean.

- High resistance to wear, which means fewer blade changes.

- A smooth surface that helps achieve a mirror finish.

Tungsten steel round blades work well in high-speed cutting and heavy-duty applications. You can rely on them for precise cuts in steel, aluminum, and other metals. The mirror finish on these blades reduces friction and keeps the edge from dulling quickly.

High-Speed and Alloy Tool Steel Options

You have more choices when you need blades for different tasks. High-speed steel and alloy tool steel both offer strong performance, but each has its own strengths.

- High alloy tool steel gives you toughness and wear resistance. Elements like vanadium and tungsten help the blade keep its edge longer. You get durability and long-term sharpness, which is great for jobs that need steady performance.

- High-speed steel keeps its hardness even when it gets hot. This makes it a good choice for high-friction cutting. You get edge stability and abrasion resistance. High-speed steel can be brittle, so it works best in jobs without heavy impact.

These materials help you achieve a mirror finish that protects the blade and keeps it sharp. The right steel choice means your blade lasts longer and needs less maintenance.

Customization for Industry Needs

Every industry has its own cutting challenges. You may need a special blade shape, size, or material. Nanjing Metal Industrial offers customization services to match your needs. You can work with their engineers to pick the best material and design for your job.

- Choose the right blade geometry for your material.

- Select coatings or treatments that boost performance.

- Get blades made for your machine and your process.

A custom blade with the right material and mirror finish gives you better results. You cut faster, waste less, and keep your blades working longer.

Tip: Talk to a blade expert before you order. The right advice helps you pick the best material and finish for your job.

製造プロセスの概要

Grinding and Shaping

You begin with a raw blade blank. Grinding and shaping turn this blank into a cutting tool for your slitting machine. Each step helps the blade work well and last longer.

- Cutting/Profiling: You cut the blade to its first shape. This step gives the blade its outline and size.

- 硬化: You heat the blade in a furnace at 1,750°F. This makes the steel strong for tough jobs.

- 焼入れ: You cool the blade fast, usually in water. Quick cooling keeps the blade hard and ready for more steps.

- 焼き入れ: You heat the blade again at a lower temperature. This makes the blade less brittle and more tough.

- Machine Finishing, Grinding, and Sharpening: You flatten and tighten the blade. Then, you grind the edge to make it sharp and the right shape. This step is important for accuracy and helps the blade fit in your machine.

Tip: Careful grinding and shaping help you get even cuts and keep blades from wearing out too soon.

熱処理

Heat treatment makes blades strong and tough for hard jobs. This process changes the inside of the blade so it lasts longer.

- Heat treatments make blades stronger and harder to wear out.

- Cryogenic treatments freeze blades at very cold temperatures to make them tougher.

- Treated blades stay sharp even after lots of use.

Heat treatment has two main steps:

- 硬化: You heat the blade very hot, then cool it fast. This makes a hard structure inside the steel.

- 焼き入れ: You heat the blade again at a lower temperature for a set time. This makes the blade less brittle and more tough.

How well heat treatment works depends on the austenitizing temperature. Higher temperatures make blades resist wear and heat better. You must control the cooling temperature to save energy and get the right blade features. When you do this right, blades last longer and work better.

Ultra-Precision Mirror Grinding

Ultra-precision mirror grinding gives the blade its final edge. This step uses special polishing to make the surface very smooth and shiny. The goal is to make blades with a great finish and exact shape.

- Surface shape error is measured in peak-to-valley values, with top blades reaching 1.78 λ.

- Surface roughness (Rq) can be as low as 3.91 nm, while after grinding, roughness may be around 44.56 nm.

These numbers show the blade meets high standards for cutting. Ultra-precision grinding keeps the surface strong, which is important for electronics, optics, and other advanced uses. Blades with this finish give cleaner cuts and last longer. The mirror surface also stops material from building up and lowers friction when cutting.

Note: Ultra-precision mirror grinding is needed for blades in high-speed slitting machines. It helps every cut stay clean and even.

A blade that goes through grinding, heat treatment, and ultra-precision mirror grinding will work well and give good results in your production line.

Quality Control and Inspection

You want every circular slitting knife and roller shearing blade to be made well. Quality control and inspection help make sure each blade with a mirror finish works right. Many steps are used to check each blade so you can trust the process.

At every part of making the blade, workers do careful checks. A special team works in a lab just for testing blades. They use advanced tools to look at each blade closely. This way, almost all blades pass the tests, with a 99% success rate. You can ask for test reports or certificates if you want them.

| 品質管理ステップ | 説明 |

|---|---|

| Inspection at Every Stage | All products are checked at every step. |

| Quality Inspection Team | A special team and lab do the inspections. |

| Advanced Equipment | Advanced tools help reach a 99% pass rate. |

| Test Reports or Certificates | You can get reports or certificates if you ask. |

There are several important steps in the checking process:

- 材料の準備: You start with ISO-certified K10/K20 carbide blanks. Ultrasonic testing looks for tiny cracks before grinding starts.

- CNC Precision Grinding: Five-axis CNC machines shape the blade. Diamond wheels and automatic angle checks keep the blade within ±0.05°.

- Quality Verification: Each blade edge is checked with digital microscopes. Runout tests make sure the blade spins within 0.003mm for perfect cuts.

- Final Treatment: Diamond polishing makes the blade very sharp and shiny. Laser marking puts a code on each blade for tracking.

Note: Careful checks at every step help stop problems and make sure every mirror-finished blade works for you.

You get good results from this careful process. Each blade with a mirror finish is checked many times. This means you get blades that work well, last longer, and give you the same good cuts every time.

Surface Topology and Thermodynamic Control

Ra Value and Contact Area

You want your circular slitting knives to cut well and last longer. The Ra value tells you how rough the blade surface is. A mirror finish makes the Ra value very low, under 0.01μm. This means the blade is super smooth. When the blade is smooth, it touches less of the material.

- A lower Ra value means there is less rubbing.

- The blade slides easily and does not wear out fast.

- You see fewer scratches and less dirt on the blade, even with sticky or dusty stuff.

- It is easier to clean off oxidation, so your blade stays nice.

The table below shows how Ra value changes cutting:

| Ra Value (μm) | Contact Area | 切削性能 |

|---|---|---|

| < 0.01 | 最小限 | High precision, low wear |

| > 0.01 | Larger | More friction, faster wear |

A mirror finish with a low Ra value gives you cleaner cuts. It also helps your blades stay sharp for more uses.

Minimizing Cutting Heat

Cutting can make the blade and material hot. Too much heat can hurt both. You need to keep the temperature down when cutting fast. A mirror finish helps because it lowers friction. But you also need to set up your machine the right way.

Tip: Less friction means less heat, but always check your machine settings.

You can keep the blade cool by doing these things:

- Use the right spindle speed, between 18,000 and 24,000 RPM.

- Set the feed rate to 500-800mm/min to keep things steady.

- Use air cooling or MQL to cool the blade.

- Do not use water-based coolants with PMMA. Water can change the surface.

These steps help your blade edge stay strong. They also stop melting or burning. You get smoother cuts and protect your blade and material.

Preventing Edge Softening

The blade edge can get soft if it gets too hot. You want the blade to stay hard and sharp. You can stop edge softening by keeping heat low and using good cutting methods.

Here are some ways to keep your blade edge strong:

- Lower the spindle speed and use the right feed rate to stop heat.

- For laser cutting, use 30W-50W power and set the speed to 15-25mm/s. This keeps the hot area small.

- Use air cooling or MQL to stop heat and melting.

- For thin plates (5mm or less), use lower laser power to stop bending.

- For thick PMMA, cut in layers and remove 2-3mm each time. This stops burn marks and keeps the edge clean.

Note: Air cooling and MQL help chips move away from the blade. This keeps the blade steady and sharp.

If you follow these steps, your mirror-finished blade stays strong. You get good results, your blade lasts longer, and your cuts are always nice.

Maintenance and Longevity

清掃と取り扱い

You keep the mirror finish safe by cleaning blades often. Clean blades stay sharp and do not get scratched. Every day, you wipe off dust, dirt, and metal bits from knives and rollers. This stops tiny things from hurting the shiny surface.

- Check hydraulic systems for leaks.

- Put oil on chains and moving parts.

- Wipe knives and rollers to clear away dust and chips.

- Write down what you do in a maintenance log.

You use ultrasonic cleaning with strong chemicals to get rid of tough stuff like aluminum and grease. After cleaning, rinse blades two times. First, use tap water. Then, use special water with rust protection. This keeps the mirror finish nice and helps blades last longer. Dry blades with air and a hot dryer so no water stays.

Tip: Clean blades often to keep them sharp and avoid sharpening too much.

Scheduled Re-polishing

You plan re-polishing to make blades shiny again and work well. Even with cleaning, blades can get dull after lots of use. You check blade surfaces for dull spots or small scratches. If you see wear, send blades to get polished by experts.

A mirror finish needs careful grinding and polishing. You use diamond wheels and special machines to make blades smooth and shiny. Re-polishing helps you:

- Keep cuts accurate.

- Stop burrs from forming.

- Wait longer before changing blades.

You write down when you polish blades and how they look in your log. This helps you get ready and stop surprise problems.

| メンテナンスタスク | 頻度 | 利点 |

|---|---|---|

| クリーニング | 毎日/毎週 | Keeps mirror finish safe |

| Re-polishing | When needed | Makes blades sharp again |

| 検査 | 使用する前に | Finds wear early |

Note: Polishing blades often helps them work well and last longer.

ストレージのベストプラクティス

You store roller shearing blades the right way to stop rust and damage. Good storage keeps the mirror finish safe and blades ready to use.

- Put blades in a cool, dry place.

- Use racks or shelves, not the floor.

- Keep air dry with fans or dehumidifiers.

- Make sure blades are dry before storing.

- Add a thin coat of oil or rust spray.

- Use silica gel packs to soak up water.

- Cover blades with wraps or cases to block dust and bumps.

- Keep blades away from chemicals that cause rust.

- Check blades often for rust or damage.

🛡️ Always look at blades before using them. Good storage keeps blades shiny and saves money on repairs.

You do these things to keep the mirror finish and help blades last longer. Clean, polish, and store blades with care. You get good cuts and blades that work for a long time.

Industry Applications and Outcomes

Steel Service Centers

You work in a place where steel moves fast. Steel service centers need tools that can handle heavy loads and keep up with demand. You use circular slitting knives to cut wide coils into narrow strips. These strips go into many products. A slitting machine helps you finish jobs quickly and with less waste. When you use blades with a mirror finish, you see fewer burrs and less downtime. You do not need to stop for cleaning as often. This means you get more work done each day.

Tip: Clean blades help you avoid problems with sticky residue from steel coils.

You can ask for custom blades if your center has specific needs.

Automotive Manufacturing

You want every car part to fit just right. In automotive manufacturing, you cut steel sheets for doors, roofs, and body panels. You also cut cardboard for packaging and shipping. High-speed cardboard production lines need blades that stay sharp and do not slow down. If you use blades with a mirror finish, you get clean edges on every piece. This helps you avoid rework and keeps your line moving.

A table shows how mirror-finished blades help you in car factories:

| 用途 | 利点 |

|---|---|

| Cutting steel panels | Smooth edges, less rework |

| High-speed cardboard production | Fewer blade changes, steady output |

| パッケージ | きれいなカット、無駄の削減 |

You can trust these blades to last longer, even when you run machines all day.

Electrical and New Energy Sectors

You work with materials that need careful handling. In the electrical and new energy sectors, you cut thin metals and cardboard for batteries, wires, and insulation. High-speed cardboard production lines need blades that do not wear out fast. A mirror finish on your blades helps you get precise cuts every time. You see less dust and fewer particles sticking to the blade. This keeps your products clean and safe.

- You cut battery foils and insulation sheets with less waste.

- You keep your machines running longer without stopping for blade changes.

- You protect sensitive materials from damage.

Note: Using the right blade helps you meet strict industry standards and deliver quality products.

Packaging, Rubber, and Plastics

You work in places where every cut is important. In packaging, rubber, and plastics, you need blades that make clean and exact cuts. Mirror-finished circular slitting knives and roller shearing blades help you do this. These tools have a sharp edge and a smooth surface. You get neat cuts without working too hard.

When you use blades with a mirror finish, you see the change fast. The smooth blade makes less rubbing. Your materials move through the machine easily. They do not stick or drag. This helps you work faster and stop less for problems. You also see less dust and fewer bits on your finished products. Clean cuts help you meet rules and keep customers happy.

You want blades that last a long time. Mirror-finished blades do not wear out quickly, even if you use them all day. The hard, shiny edge can handle tough jobs in rubber and plastics. You do not have to change blades as much. You spend more time making things and less time stopping. This helps you work better and keeps your line moving.

Here is a table that shows how mirror-finished blades help in packaging, rubber, and plastics:

| 特徴 | 説明 |

|---|---|

| Superior Precision | Makes clean and exact cuts every time. |

| 耐久性の向上 | Made to last a long time, even with hard work. |

| 効率性の向上 | Lets you cut faster and stop less. |

| Minimal Material Waste | Sharp blades help you waste less material. |

| Reliable Performance | Checked for quality so they work well each time. |

| メンテナンスが簡単 | You can change blades quickly and get back to work. |

| Cost-Effective Solution | Saves money by working better and lasting longer. |

You want to waste less. Mirror-finished circular slitting knives help you use more of your materials. The sharp edge makes clean cuts, so you throw away less. This saves you money and helps the planet.

You also need tools that are easy to clean. Mirror-finished blades do not let dust, glue, or plastic bits stick. You can wipe the blade and start working again. This means you spend less time cleaning and more time making things.

Tip: Check your blades often for wear. Quick checks help you find problems early and keep your line running well.

You count on your machines to do a good job. Mirror-finished roller shearing blades and circular slitting knives give you what you need in packaging, rubber, and plastics. You get sharp, steady cuts, less stopping, and better use of your materials. Your products look nicer and your business works better.

You get better cuts and longer blade life by picking good materials and a mirror finish. Careful making and regular care help blades work their best. You need to look for damage often, clean blades to get rid of sticky stuff, and keep them dry. Use holders that control tension and sharpen blades when needed. If you want blades that work well for your factory, talk to Nanjing Metal Industrial’s team ここ.

よくある質問

What is a mirror finish on circular slitting knives?

A mirror finish means the blade surface is polished until it looks shiny and smooth. You get fewer scratches and less friction. This finish helps you make cleaner cuts and keeps your blade sharp longer.

Why does mirror finish matter for blade longevity?

Mirror finish reduces friction and stops material from sticking. You see less wear and fewer burrs. Your blade stays sharp for more uses. This finish helps you save money by changing blades less often.

How do you clean mirror-finished blades?

You wipe blades with a soft cloth to remove dust and chips. Use ultrasonic cleaning for tough dirt. Always dry blades with air or a hot dryer. Clean blades keep the mirror finish safe and help you get better cuts.

Can you use mirror-finished blades for different materials?

You can use mirror-finished blades for steel, aluminum, rubber, plastics, and cardboard. The smooth surface works well for many materials. You get clean cuts and less waste in different industries.

How often should you re-polish mirror-finished blades?

You check blades for dull spots or scratches before each use. Re-polish blades when you see wear. Regular re-polishing keeps the edge sharp and the mirror finish strong. You get more accurate cuts and longer blade life.

What is the Ra value, and why is it important?

Ra value measures how rough the blade surface is. A low Ra value means the blade is very smooth. You get less friction and better cutting performance. Mirror finish blades have a low Ra value for high precision.