You want every box to look neat and strong, right? Picking the right 段ボール用ロータリースリッターブレード is very important. Good blades help you make clean and exact cuts. This means you waste less material and have fewer mistakes. You also save time because these blades stop your machines from breaking down. Your machines work better and faster. If you choose the right blade type and material, you work more efficiently. Every package will look great.

- Clean cuts mean you throw away fewer boxes.

- Better blade designs make your packaging stronger.

- Strong blades last longer, so you spend less on new ones.

重要なポイント

- Picking the right rotary slitter blade gives clean cuts. It helps lower waste and mistakes.

- Good blades make machines work better. This means faster work and fewer problems.

- Check and clean blades often to keep them sharp. This stops damage and keeps them working well.

- Choose blades for the material type and thickness. This helps get good cuts and stops the board from getting crushed.

- Custom rotary slitter blades can help with special jobs. They make cuts better.

- Strong materials like tungsten carbide make blades last longer. This saves money on new blades and fixing them.

- Check blade sharpness a lot. Dull blades make rough edges and more returns.

- Use safety steps when working with rotary slitter blades. This keeps you safe at work.

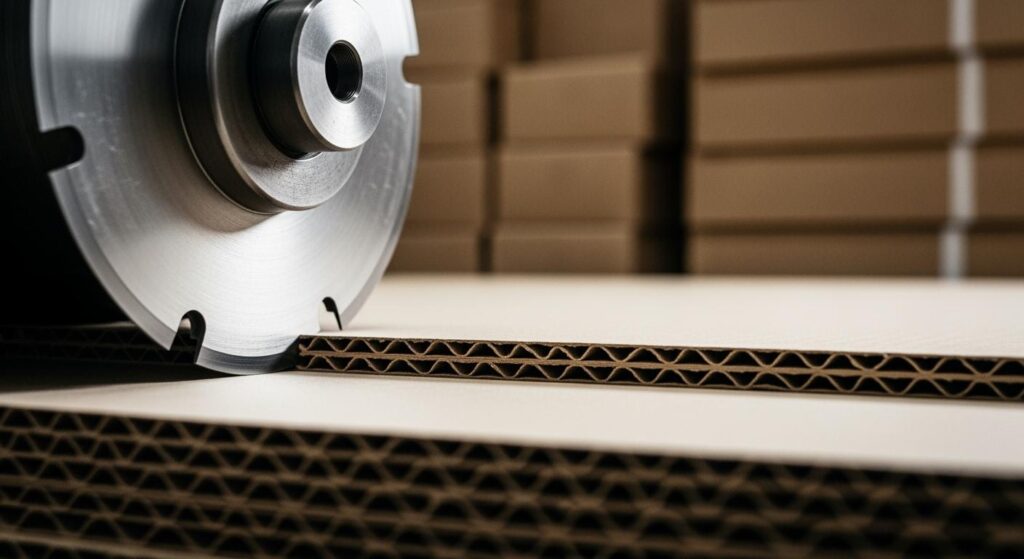

Rotary Slitter Blades: Essential for Corrugated Board

What Are Rotary Slitter Blades?

Rotary slitter blades are used in many factories. These blades cut big rolls of corrugated board into smaller strips. You see them in packaging and printing jobs. They help make cuts that are clean and exact. Good blades last longer and do not wear out fast. Rotary slitter blades come in many shapes and sizes. You can pick the one that fits your job best.

Nanjing Metal Industrial’s Slitter Blades for Slitting Machines are high-quality choices. These blades work well for hard jobs and last a long time. If you need a special blade, you can look at their カスタムブレード service.

Role in Corrugated Board Processing

Rotary slitter blades are important in making corrugated board. You use these blades for many jobs. Here is a quick look:

| 関数 | 説明 |

|---|---|

| 材料の切断 | Rotary slitter blades cut materials into thin strips. |

| 精度と正確さ | They help make cuts that are neat and exact. |

| 効率 | You can cut many strips at once, so work goes faster. |

You want blades that help your machines work quickly. You also want blades that make sharp and clean cuts. Using rotary slitter blades means better work and less waste. These blades help you keep up with busy jobs.

Rotary Cutter vs. Other Cutting Tools

You may wonder how rotary slitter blades are different from other cutting tools. Here is what you should know:

- Rotary slitter blades are best for cutting big sheets into thin strips. You use them for lots of packaging and factory work.

- Cutting blades are good for making pieces that are a certain size. They help you get the same size every time.

Rotary cutting is fast and saves time. You can cut more material quickly. Other tools may be good for exact cuts, but rotary slitter blades are better for big jobs.

When you pick rotary slitter blades, you should think about what they are made of. The blade material changes how long it lasts and how well it works. Here is a table that shows some common materials and what they do:

| 材料 | 利点 | デメリット |

|---|---|---|

| Cr12MoV | Very strong, tough, and hard. | Hard to make and costs more. |

| D2 | Very hard and keeps its shape. | Not as tough and hard to make. |

| M2 | Stays hard even when hot and is very tough. | Costs more and is hard to make. |

You want blades that last a long time and do not wear out fast. These materials help blades work better for tough jobs. When you choose the right rotary slitter blade for corrugated board, you get good cuts, better work, and less machine trouble.

Blade Quality & Packaging Precision

Cut Accuracy & Edge Quality

Factors Affecting Cut Precision

You want every box to look neat and nice. The precision of rotary slitter blades matters a lot. If you use recycled paper, it may have hard bits inside. These bits can wear down your blades fast. This hurts how well your blades cut. Dull blades make cuts less exact. You see rough edges and strips that are not even. If you use linerboard with more recycled content, blades may last 40% less. So, you must watch blade choice and care closely.

Influence of Blade Sharpness on Edge Finish

Sharp blades help you get smooth and exact edges. Precision engineered blades give you clean cuts every time. If your blades drag or pull, they need sharpening. Dull blades leave messy edges. Customers may return products because of this. One skincare brand had 18% returns from poor edge quality. You can stop this by checking blade sharpness often.

Preventing Burrs and Debris

You want your packaging to look tidy. Burrs and debris make boxes look messy and weak. Rotary slitter blades that are precision engineered cut with less mess. If you use blades too long, edge problems can go up by 25%. Always check your blades for nicks or scratches. Replace them before they cause trouble.

Techniques for Minimizing Dust and Particles

Dust and tiny bits can ruin your packaging and slow machines. You can cut down dust by using blades with the right edge shape and material. Tungsten carbide blades are precise and strong. They cut clean and make less dust. Make sure blades fit tightly in holders. Test blade alignment with a straight edge or dial indicator. These steps help keep your cutting sharp.

Maintaining Board Integrity

You want your boxes to stay strong. Rotary slitter blades that are precision engineered protect the board’s shape. Blades that crush or tear the board lower strength. Always measure blade thickness with a caliper or micrometer. This keeps blades sharp and cuts exact. Check for cracks near mounting holes often. This keeps blades safe to use.

Avoiding Delamination and Crushing

Delamination and crushing make boxes weak. You can stop these problems by picking blades with the right thickness and edge angle. Precision engineered blades cut corrugated board without hurting the layers. Blades that are too thick or thin can crush or peel the board. Always follow what the maker says for blade choice.

Ensuring Consistent Thickness and Clean Cuts

Consistent thickness means boxes look the same and stack well. Rotary slitter blades with high precision help you do this. Use a caliper to check thickness after cutting. If you see changes, adjust or swap blades. Precision engineered blades give clean cuts and keep work smooth.

Impact on Box Strength and Appearance

Relationship Between Cut Quality and Box Durability

How you cut corrugated board affects box strength. Blades made from tungsten carbide are precise and tough. They keep cuts sharp and boxes strong. If you set cutting speed and feed rate right, you get better cuts and longer blade life. Strong blades mean strong boxes.

Effects of Poor Cutting on Structural Integrity

Poor cutting can wreck your boxes. Dull or misaligned blades make weak edges and crushed corners. This lowers packaging strength. You want blades that are precision engineered for top performance. Regular checks and care help you avoid these problems.

Visual Appeal of Finished Boxes

You want boxes to look good on shelves. Clean cuts and smooth edges make packaging look great. Rotary slitter blades with high precision give a pro finish. Customers notice the difference. Blades that leave burrs or rough edges make boxes look cheap and may get returned.

Reducing Visible Defects and Imperfections

Visible defects hurt your brand. You can lower imperfections by using blades that are precision engineered for your job. Always check for early signs like scratches or nicks. Replace blades before they cause trouble. This keeps cutting sharp and boxes looking perfect.

ヒント:

When picking rotary slitter blades, think about the material, the precision you need, and how fast you work. Choose blades with the right hardness and coating for your job. Regular care and checks help you get the best performance and longest life from your blades.

Choosing Rotary Slitter Blade for Corrugated Board

If you want perfect packaging, you need the right rotary slitter blades for your corrugated board. The blades you pick change how well you cut, how exact your cuts are, and how fast you work. Let’s look at what is most important.

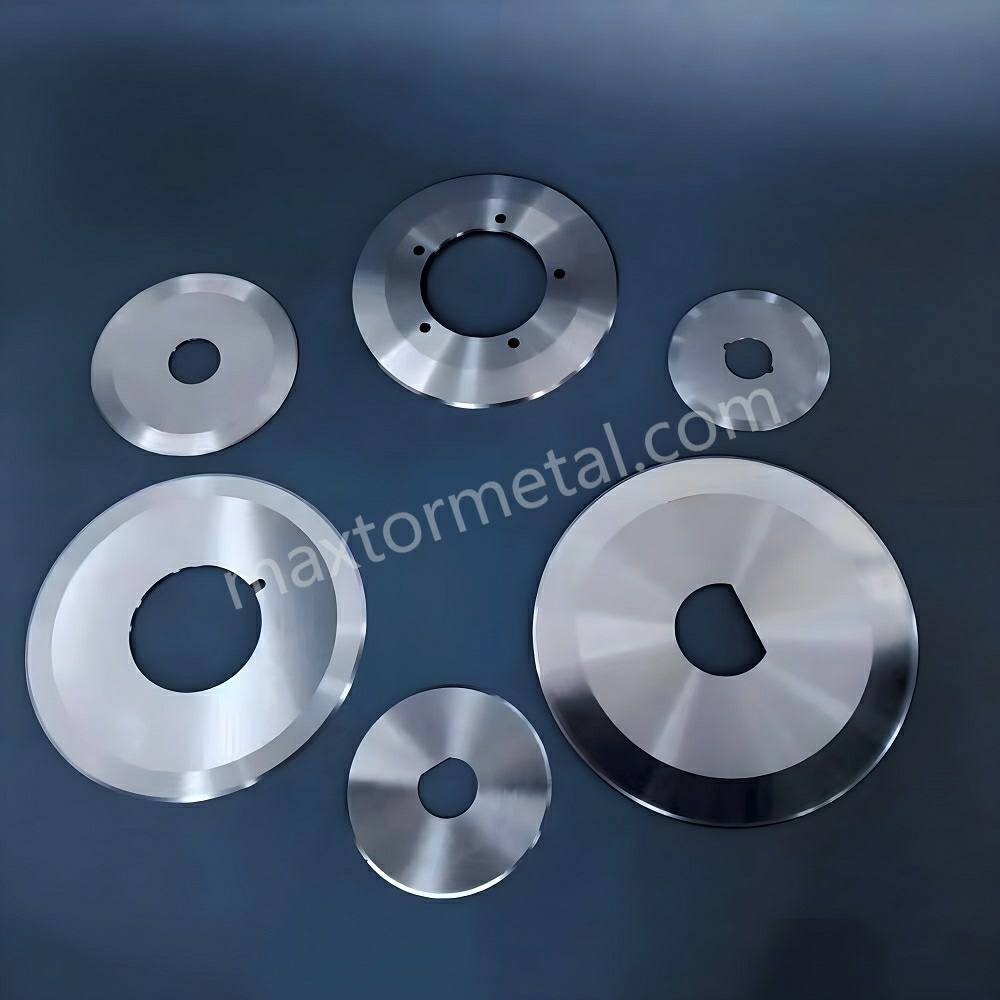

素材に合わせたブレードの選定

There are many rotary slitter blades to choose from. Each type works best for certain jobs and materials. If you match the blade to your board, you get better results and longer-lasting blades. Here’s a quick guide:

Blade Types for Different Applications

You will see many blade shapes and designs in factories. Each one helps you cut in a special way.

| ブレードタイプ | Recommended Applications |

|---|---|

| Solid Disc Blades | High-speed slitting, standard corrugated board lines |

| Inserted Knives | Frequent blade changes, mixed board types |

| Shear Cut Blades | Clean, precise cuts, premium packaging |

| 歯付きブレード | Paper slitting, films, some plastics |

| Straight Razor Blades | Foils, thin metal sheets, thick papers, cardboard |

- Solid disc blades are strong and cut well at high speeds. You use them when you want the same good results every time and blades that last.

- Inserted knives are easy to change. They are good if you work with many board types or need to swap blades often.

- Shear cut blades make the cleanest cuts. If you care about how your packaging looks and feels, these are the best.

Nanjing Metal Industrial can make custom rotary slitter blades for you. You can get the blade shape you need.

材料の適合性

The blade’s material is just as important as its shape. Good materials like high-carbon steel, tool steel, high-speed steel, and tungsten carbide help you cut better.

- Steel blades last long and do not wear out fast, but you must keep them clean so they do not rust.

- Ceramic blades stay sharp for a long time, but they can break if you push too hard.

- Plastic blades are light and safe, but they do not last as long as steel or ceramic.

You also need to think about your cutting speed and the type of board you use:

- For high-speed slitting, use blades with fine carbide grain. This gives you better cuts and less fuzz.

- Harder paper needs a less sharp edge to stop chipping.

- Sticky boards work best with blades that have special coatings so they do not stick.

- If you cut a lot, make sure your grinding wheel matches your blade for even results.

Selecting Blade Size and Thickness

The size and thickness of your rotary slitter blades matter a lot. You want blades that match your board’s flute type and thickness. Here’s a simple table to help you pick:

| Flute Type | 推奨刃厚(mm) |

|---|---|

| Lightweight (E/F) | 1.5 – 2.5 |

| Medium-weight (B/C) | 2.0 – 3.5 |

| 頑丈 | 3.0 – 5.0 |

If you use thick or double-wall boards, pick bigger and thicker blades. This helps you get clean cuts and stops the board from getting crushed. For thin flutes or light boards, thinner blades give you better cuts and help stop the board from peeling. Always test your blades with your boards and follow what the maker says for best results.

ヒント:

Use a caliper to check blade thickness before you cut. This easy step helps you keep your cuts even and your packaging strong.

カスタマイズオプション

Every packaging job is different. Sometimes, you need custom rotary slitter blades for the best results. Nanjing Metal Industrial can make blades just for your machines. You can pick from many blade shapes, sizes, and edge styles.

| カスタマイズの側面 | 詳細 |

|---|---|

| Dimensions | Custom sizes from 50-2000mm diameters |

| Bore Sizes | Tailored to fit your machine |

| Edge Geometries | ATB, TCG, and more for different cutting needs |

| 特殊コーティング | Advanced coatings for better durability and cutting performance |

| 耐久性の向上 | Blades last 3-5 times longer than standard options |

| 表面最適化 | Treatments to reduce friction and keep cutting efficient |

| アプリケーション固有の設計 | Optimized for packaging, metal, plastic film, and more |

- Custom blades last longer and cut better. They fit your machine well, so you have less downtime and better cuts.

- Special coatings and edge shapes help you work faster and make cleaning easier.

- Surface treatments stop blades from sticking and help them work smoothly.

If you want to know more about custom rotary slitter blades, visit the カスタムブレード page for more info.

注記:

Custom blades help you solve special packaging problems. You get blades that fit your needs, cut better, and keep your work running well.

When you pick the right rotary slitter blade for corrugated board, you set yourself up to win. You get better cuts, stronger blades, and faster work. Custom blades and good materials make your packaging look great and last longer.

Rotary Cutter: How to Use for Best Results

You want your packaging to look neat and pro. Using a rotary cutter the right way helps a lot. You get better cuts, more exact work, and stay safe. Let’s go over the steps together.

Installation and Setup

Getting your rotary cutter ready is the first thing to do. You must put the blades in right and set up your machine for good cuts. Here’s a table with easy tips you can follow:

| ベストプラクティス | 説明 |

|---|---|

| Selecting the Right Blade Material | High-speed steel is good for busy jobs. Alloy steel lasts long and does not cost too much. |

| 適切なブレードの向き | Put the blades facing the right way. This stops bad cuts. Always check your machine’s guide. |

| 刃の固定 | Turn off the rotary cutter before you start. Clean the holder, line up the blades, and lock them in place. |

| アライメントとキャリブレーション | Set the blade depth for your corrugated board. Check this often to keep your cuts sharp. |

| 運転前の安全確認 | Wear gloves and goggles. Look at the blade and make sure it is tight before you start. |

| 定期的な清掃と潤滑 | Clean and oil the blades often. This helps them last longer and keeps cutting smooth. |

| 摩耗や損傷の検査 | Look for dull spots or chips. Fix problems early to stop bigger trouble. |

| 刃の研ぎまたは交換 | Sharpen blades when they get dull. Change them after a set number of cuts for best results. |

| メンテナンスのための記録保存 | Write down when you clean, sharpen, or change blades. This helps you plan and avoid surprises. |

ヒント:

Always follow the rotary cutter maker’s instructions. This helps you get the best cuts and keeps your blades working longer.

Operating Techniques

You want every cut to be neat and exact. Using the right steps helps you get the most from your rotary cutter. Here are some things you can do:

- Change the speed and pressure for your material. This keeps blades sharp and gives better cuts.

- Clean and check the rotary cutter before each use. Oil the moving parts so the blades move smooth.

- Store blades in a dry spot. Use cases to keep them safe from scratches.

- Sharpen blades often. If cuts are not smooth, sharpen or fix them.

- Keep a log of how many cuts you make. This helps you know when to change blades for best results.

If you want to use a rotary cutter for perfect packaging, start with these habits. You will see better cuts and fewer problems.

注記:

Test your rotary cutter on a small piece of corrugated board before a big job. This helps you check the cut and change settings if needed.

安全のヒント

Rotary cutter safety is very important. You want to keep yourself and your team safe when using blades. Here’s a table with safety rules you should always follow:

| Category | Guidelines |

|---|---|

| Protective Gear and Clothing | Wear safety glasses, earplugs, and gloves. Tie back long hair and tuck in loose clothes. |

| Wear safety shoes that do not slip. | |

| Machine Maintenance | Check the rotary cutter for problems before you start. Make sure guards and safety parts work. |

| Tell your boss if you see any damage or wear. | |

| Machine Operation | Never use the rotary cutter if you feel tired or not focused. Learn the controls before you start. |

| Emergency Procedures | Know where the emergency stop button is. Practice what to do in an emergency. |

| Training and Supervision | Make sure everyone knows how to use a rotary cutter safely. Go over safety steps often. |

警告:

Never hurry when working with blades. Take your time to set up and check everything. Safe work means better results and fewer accidents.

If you follow these steps, you will know how to use a rotary cutter for the best cuts. You get neat cuts, more exact work, and a safer place to work. Your packaging will look great, and your blades will last longer.

Maintaining Rotary Slitter Blades

Taking care of rotary slitter blades helps you get great cuts. You want blades to last longer and work well. Good care keeps your packaging looking neat. Regular blade care makes your work faster and helps blades last.

Routine Inspections & Cleaning

Check your blades often for chips or dents. If you find problems early, you can fix them fast. Cleaning is important too. Dust, glue, and board bits can stick to blades. This makes blades hot and wears them out. Clean blades every day to keep them working well and lasting longer.

Here’s what you get from checking and cleaning:

- You find damage before it gets bad.

- You stop stuff from building up and slowing cuts.

- You lower heat and friction so blades last.

- You keep your rotary cutter working sharp.

研磨と交換

Sharp blades make clean cuts. Dull blades leave rough edges and slow you down. Sharpen blades based on how much you use them. Do not sharpen too much or blades get too small. When blades wear out, replace them with new ones. Pick blades made from strong materials for better cuts and longer life.

If you use custom blades, follow the maker’s advice. Custom blades need special care to stay sharp. Write down when you sharpen or change blades. This helps you plan and avoid problems.

ブレードの寿命を延ばす

You want blades to last a long time. Good care helps you do this. Here’s a table with ways to make blades last:

| 戦略 | 説明 |

|---|---|

| 定期検査 | Look for chips, dents, or weird sounds. Early checks stop problems and keep cuts sharp. |

| Cleaning Blades | Clean off dust and glue after each job. Use safe cleaners to protect blade surfaces. |

| タイムリーな研ぎ | Sharpen blades when needed. Do not sharpen too much or blades get too small. |

| Proper Blade Selection | Pick blades and materials that fit your job. This lowers wear and keeps cuts neat. |

| 適切な保管と取り扱い | Store blades in cases. Handle gently to avoid damage. Good storage helps blades last. |

If you use custom blades, store them in a safe spot. Handle all blades with care. Pick blades made from good materials for the best results. Nanjing Metal Industrial gives help and checks to keep blades working well.

Regular care keeps rotary slitter blades cutting sharp. You get better packaging, less waste, and blades that last longer. Take care of your blades and your rotary cutter will work well every time.

Business Benefits of Quality Rotary Slitter Blades

If you use good rotary slitter blades, your business gets better. These blades do more than just cut board. They help your machines work faster and smoother. You also waste less material.

Reducing Waste & Downtime

You want your machines to keep working. You also want to throw away less board. Blades made from high-carbon steel and tungsten carbide stay sharp longer. You do not need to stop often to change them. This means your team keeps working and orders get done on time.

- You spend less time swapping blades, so machines keep running.

- Sharp blades help you make fewer mistakes and waste less board.

- One company saved $50,000 by cutting waste from 1.9% to 1.4%. They did this by using better blades and checking them often.

- If you set up your machines the same way and do regular maintenance, you stop surprise breakdowns.

Improving Efficiency & Output

You want to make more boxes in less time. Good rotary slitter blades help you do this. These blades last longer because they are tough. You can cut more before you need to change them. This helps you work faster and fill orders quickly.

- Tough blades mean you stop less for repairs.

- Better cuts help you make more boxes.

- You use less energy when cutting, so costs go down.

- Some companies saved up to 20% on making boxes by using strong blades.

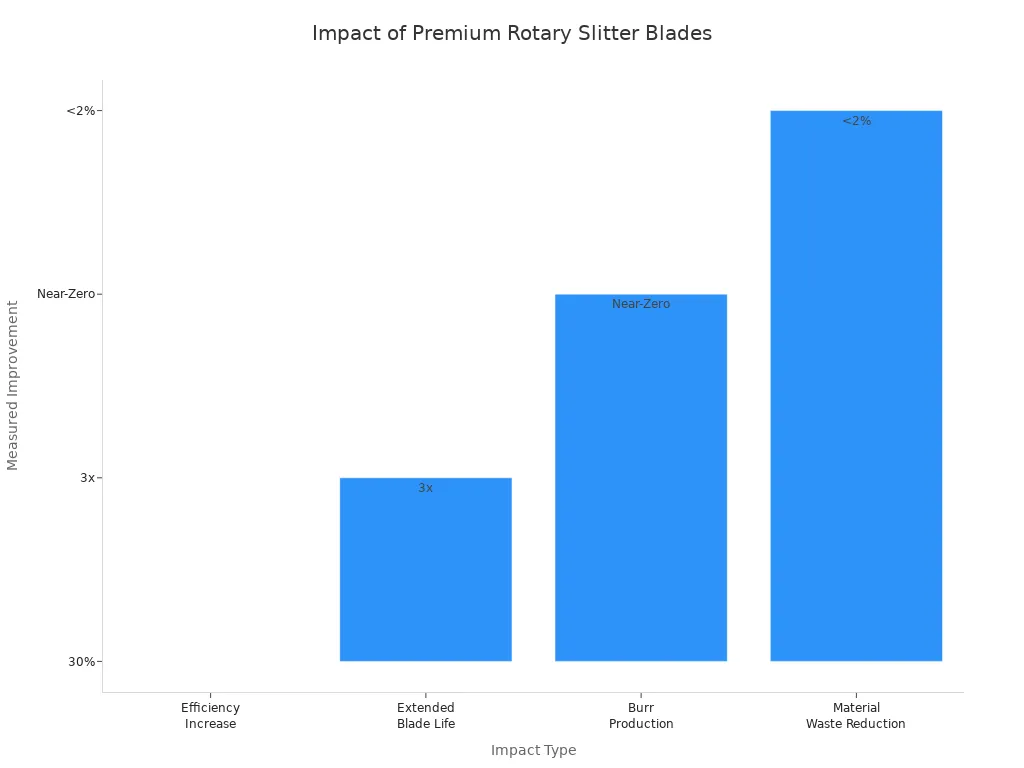

Enhancing Product Quality

You want every box to look neat and be strong. Premium rotary slitter blades give you smooth edges. You see almost no burrs and very little waste. Your boxes stack better and look more pro.

| インパクト | 測定 |

|---|---|

| Efficiency Increase | 30% |

| ブレード寿命の延長 | 3x longer lifespan |

| Burr Production | Near-Zero |

| Material Waste Reduction | Under 2% |

Custom rotary slitter blades are made for your job. They help you keep your work neat and quality high. You can use smart tools to check blade performance and plan when to change them.

If you want your packaging to stand out, pick a partner. You get good prices, easy ways to buy, and a team ready to help. Custom blades and strong support help you beat your competition.

Tip: Custom blades and regular care keep your machines working well. You save money, work faster, and make better boxes every time.

Picking the right rotary slitter blade for corrugated board helps make your packaging stronger. It also makes your job easier. If you keep rotary slitter blades sharp and clean, your cuts will be better. You will throw away less material. Many companies have fewer problems and make more boxes every day.

- Checking and cleaning blades often helps stop machine breaks.

- Using better blade materials and coatings makes blades work better and last longer.

Do you want to get better packaging? 弊社のセールスエンジニアにご相談ください for expert help with custom solutions.

よくある質問

What is a rotary slitter blade for corrugated board?

A rotary slitter blade for corrugated board is a sharp, round blade. You use it to cut large sheets of corrugated board into smaller, neat strips. This tool helps you get clean, straight cuts for packaging.

How often should I replace my rotary slitter blade?

You should check your blade every day. If you see dull edges or rough cuts, it’s time to replace it. Most people change blades after a set number of cuts or when quality drops.

Can I use the same blade for all types of corrugated board?

No, you shouldn’t. Different boards need different blades. Thick or double-wall boards need stronger, thicker blades. Thin boards work better with thinner blades. Always match the blade to your material.

How do I keep my rotary slitter blade sharp?

You can keep your blade sharp by cleaning it after each use. Sharpen it when you notice rough cuts. Store blades in a dry place. Use a blade cover to protect the edge.

Why does my rotary slitter blade leave rough edges?

A dull or damaged blade often causes rough edges. You might also have the wrong blade type for your board. Try sharpening the blade or switching to a better fit for your material.

What safety tips should I follow when using rotary slitter blades?

Always wear gloves and safety glasses. Turn off the machine before changing blades. Keep your hands away from the blade edge. Follow your machine’s safety rules every time.

Can I get custom rotary slitter blades for special packaging jobs?

Yes, you can order custom rotary slitter blades for corrugated board. Custom blades fit your machine and job needs. They help you get better cuts and less waste.

How do I know if my rotary slitter blade is the right size?

Check your board’s thickness and flute type. Use the blade size your machine maker suggests. If you see crushed or uneven cuts, you may need a different blade size.

参照

一般的な円形スリッターブレードの摩耗問題と効果的な修復ソリューション: ブレードの寿命とパフォーマンスを最大化

スリッターブレードの切れ味を最大限に高めて優れた切断性能を実現する方法