プラスチックシュレッダーブレード vs. グラニュレーターブレード:プラスチックフィルムとバッグに最適な破砕機を選ぶ方法

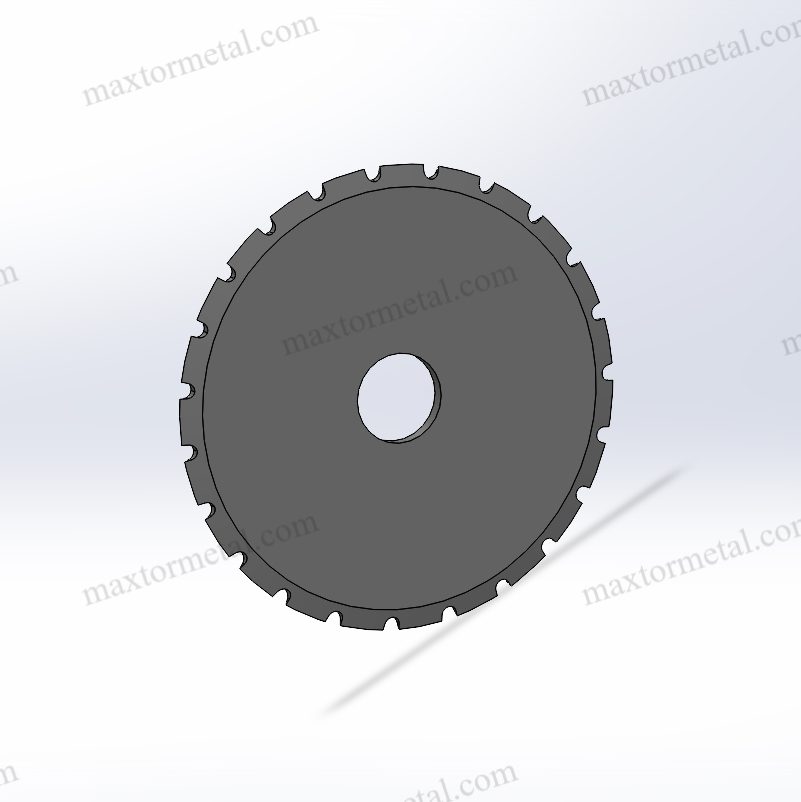

If you want to pick the right crusher for plastic film and bags, understanding the difference between plastic shredder blades vs granulator blades is essential. For thin plastic waste like films and bags, crusher blades with one sharp edge make clean cuts and improve recycling efficiency. The blade you choose directly impacts how well you can process plastic waste and the amount you can recycle. Better recycling results come from matching the blade material, blade design, and machine compatibility. When comparing plastic shredder blades vs granulator blades, selecting the right crusher blades helps you handle plastic waste with less tool damage and more consistent output. Learning how blade choice affects plastic recycling will help […]

プラスチック廃棄物処理に特化したカスタムブレードと標準ブレードの比較(カスタムプラスチック破砕ブレードメーカー)

Choosing between custom and standard blades changes your recycling results. The right blade material helps machines work better. It can also save money and make machines last longer. For example, tungsten carbide blades last much longer than regular tool steels. They are great for hard metal shredding jobs. Look at the table below for a quick comparison: Blade Material Wear Resistance (cycles) Hardness (HRC) Best Use Case Tungsten Carbide Highest (1,500,000) Very High (72) High-speed, high-volume plastic cutting and metal shredding D2 Tool Steel Moderate (950,000) High (60-62) General-purpose cutting High-Speed Steel Medium (800,000) High (64) Precision cutting Stainless Steel Lower (600,000) Moderate (58-60) Corrosive environments You get the best […]

プラスチック破砕機ブレードの交換コストと総所有コスト(TCO)

The cost of plastic crusher blades replacement involves more than just the initial price. Companies incur annual expenses to replace these blades, which can range from $9,500 for custom blades to $25,000 for standard blades. The table below outlines the costs: Blade Type Average Lifespan Annual Replacement Cost (for 100 Blades) Through-Hardened Knife 12 months $10,000 Surface-Hardened Knife 6 months $12,000 Custom Blade Over 40 days $9,500 Standard Blade 10 days $25,000 Additional expenses such as downtime and routine maintenance also contribute to the total cost of ownership. Innovative designs for plastic crusher blades, like those offered by Nanjing Metal, help reduce the cost of plastic crusher blades replacement by extending blade life […]

プラスチック破砕機ブレードの材料:D2 vs. SKD-11 vs. HSS

Selecting the right plastic crusher blade materials is important. It can change how well the blades cut and how long they last. D2 and SKD-11 tool steels are strong. They resist wearing out and are tough. This makes them good for most recycling jobs. High-Speed Steel (HSS) is even better. It keeps its sharp edge longer and wears out less. HSS works best for hard or rough plastics. The chart below shows how often you need to replace each blade. It also shows how strong each blade is. Nanjing Metal sells blades made from all three materials. These blades are made to last a long time. Key Takeaways Why Material Choice Matters Performance Impact The blade’s […]

最大の効率と寿命のためのプラスチック破砕機ブレードの研磨

If you want to sharpen plastic crusher blades well, use the right grinding methods and keep the blades cool while sharpening. Sharp blades help your granulator work better, use less energy, and last longer. Studies show that sharpening blades often and in the right way can make them last up to 18% longer. Granulator blades from Nanjing Metal are made from strong steel. These blades do not wear out fast and stay sharp longer. You can use blade sharpening services or special sharpening plans to keep your granulator working safely and at its best. Key Takeaways Why Sharp Blades Matter Crushing Efficiency Sharp blades help the machine work better and faster. When you sharpen plastic […]

PETボトル用プラスチック破砕機ブレード:スループット向上に関するケーススタディ

Choosing the right plastic crusher blades for PET bottles helps improve how much is recycled and saves money. Studies from the industry show that better blades can recycle up to 500 more tons of PET each month. They also help cut waste storage costs by 40%. Nanjing Metal makes strong blades that do not bend, even when crushing hard. This means PET bottles are always processed the same way. Their tough blade materials and smart designs help recycling centers work better and spend less on repairs during recycling. Key Takeaways Plastic Crusher Blades for PET Bottles Blade Design and Geometry Straight Blades Straight blades are important for cutting plastic PET bottles. Their flat edge makes […]

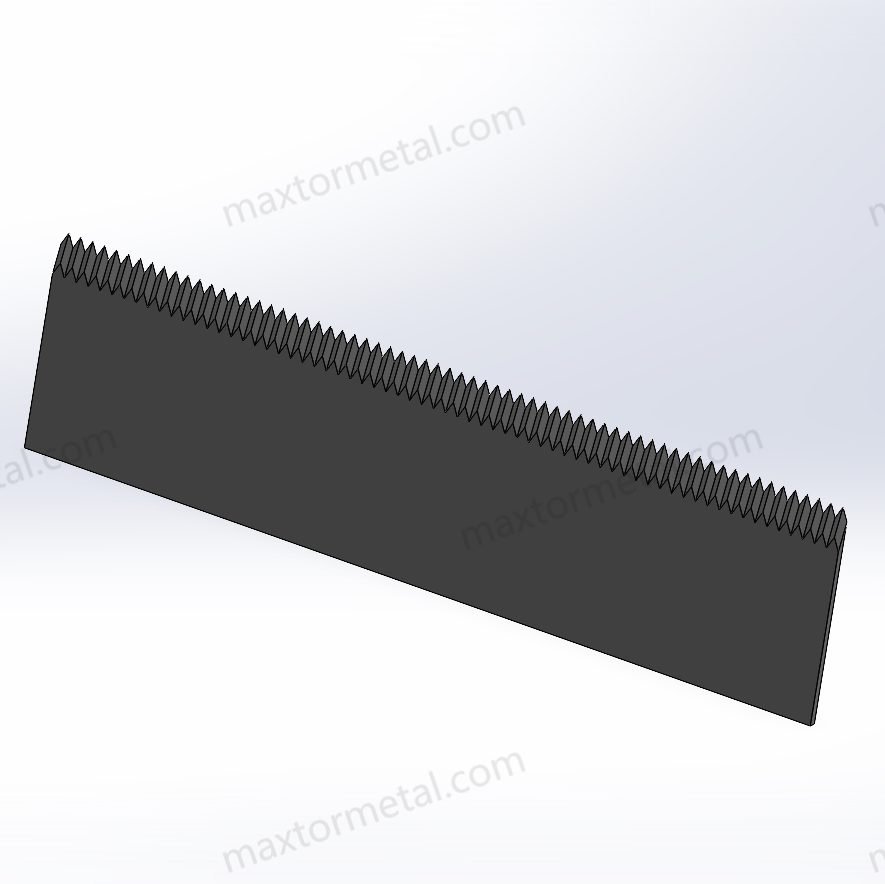

Perforating blade maintenance tips for maximizing lifespan & sharpening

You can make your perforating blades last longer by doing a few easy things. Clean the blades often. Use the correct lubricant. Keep them in a safe spot. Check your tools a lot to find damage early. Sharpen the blades when they get dull. Tip: Use these perforating blade maintenance tips to get great results every day. Key Takeaways Why Maintenance Matters Benefits Taking care of your perforating blades helps them work better. Doing things like cleaning, oiling, and checking your blades is important. You can find small problems before they get worse. If you see nicks or cracks early, you can fix them fast. Cleaning after each use gets rid of dirt that […]

食品業界におけるミシン目ブレード:安全と衛生の基準

Perforating blades are very important in the food industry. They help keep food safe and clean. These strong blades make packaging that shows if it has been opened. They also help control who can get medicine and stop food from getting dirty. Perforated machine knives let air move in packages. This helps stop mold and keeps food fresh longer. In food processing, stainless steel blades do not rust. They can be cleaned often. This keeps things clean and meets safety rules. Good blades with a clean design stop germs and help keep food safe. It is important to take care of blades and pick the right materials. This helps stop […]

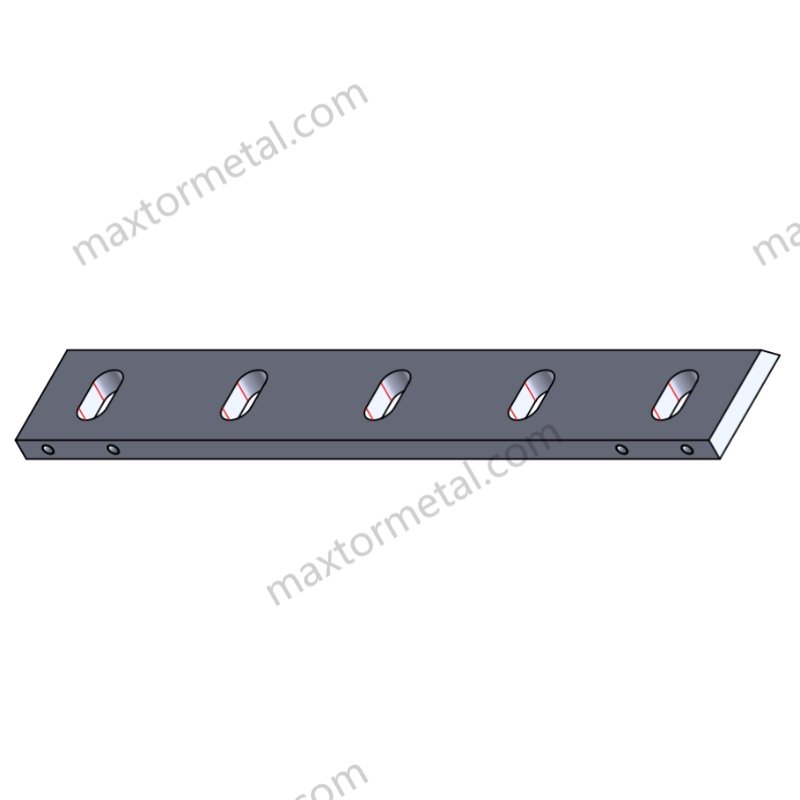

ブレードギャップ設定:ミシン目機のトラブルシューティングと性能最適化

You need to set the blade gap carefully on your blade gap setting perforating machine to achieve excellent results and high product quality. Studies show that even small changes in the gap can bend the die and cause perforation errors, so precision is crucial. With Nanjing Metal’s perforating blade knives, you create neat and consistent holes while extending the life of your machine. Proper blade gap setting on your perforating machine reduces damage, improves product quality, and prevents issues like tearing or uneven cuts. For micro-perforating tasks, the correct blade gap setting keeps you in control and ensures outstanding results. Choosing durable perforating blade knives helps your blade gap setting perforating machine perform optimally and […]

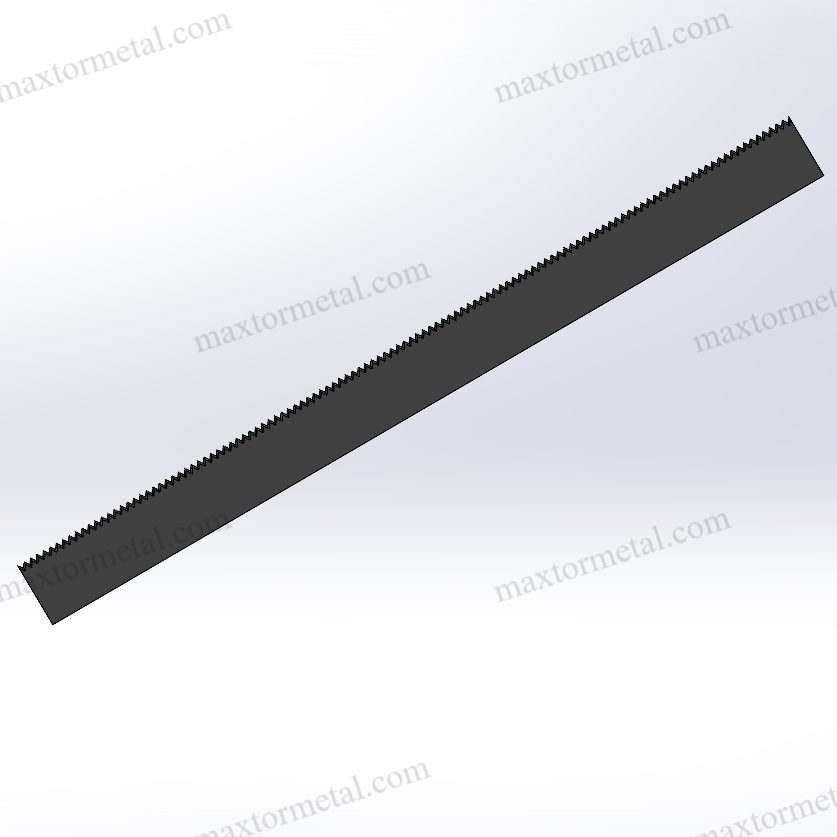

不織布用ミシン目ブレードのテキスタイルおよび複合材料における革新的な用途

Perforating blades for non-woven fabric have changed the textile and composite industries. They make very exact and clean cuts. This helps work go faster and makes products better. In hygiene, automotive, and aerospace fields, these blades shape fabric and composite materials for each job. Picking the right blade stops fraying and tearing. New blade types help keep the size and shape correct for every textile and composite product. Makers use these new ideas to work faster, make fewer mistakes, and create fabrics that pass tough tests. Aspect Impact on Efficiency and Quality Blade Selection Clean cuts, less waste, higher product quality Tool Head Configuration Faster cutting, improved accuracy, supports complex textile […]