穿孔刃(パーフォレーションブレード、パーフォレイテッドブレード、ホールソーとも呼ばれる)は、材料に連続した小さな切り込みや穴を開け、切断されていない部分を残して切断するための特殊な切断工具です。これにより、材料はミシン目に沿って簡単に引き裂いたり、分離したりすることができます。「穿孔」という用語自体は、物体に連続した穴や裂け目を開けて簡単に切り離せるようにする行為を意味します。工業用途において、穿孔刃は、包装から紙製品まで、様々な用途で材料に制御された弱点を作るために不可欠です。

切り取り線を簡単に作成できるため、ミシン目カッターは幅広い業界で広く使用されています。一般的な用途としては、以下のようなものがあります。

材料の選択 穿孔刃 切断する材料と用途の要件によって異なります。一般的な材料には以下のものがあります。

適切な素材を選択することで、穿孔刃は鋭い切れ味を維持し、寿命を通して安定した性能を発揮します。黒色酸化物などのコーティングを施すことで耐摩耗性を向上させ、摩耗箇所の識別を容易にすることもできます。

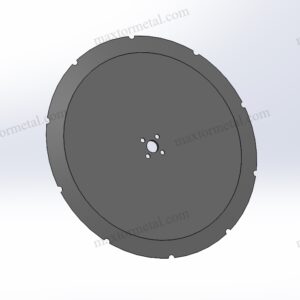

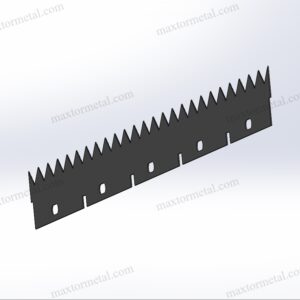

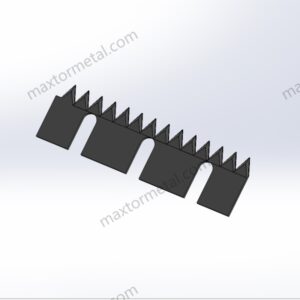

穿孔刃 様々な形状や構成があり、異なる穿孔パターンと切断動作を実現します。一般的な形状には以下が含まれます。

穿孔刃の動作原理は、材料の特定の点または線に沿って圧力をかけることで、1つまたは複数の切り込みを入れます。刃の形状、特に歯と刃先によって、穿孔の長さと間隔が決まります。回転刃の場合、連続回転により、材料の経路に沿って均一な穿孔が保証されます。「カットアンドタイ」比は重要なパラメータであり、切断長さと残りの切断されない材料の長さを決定し、引き裂きやすさと、分離前の穿孔された材料の強度を左右します。

シームレスな輸入の利便性をお楽しみください。輸送から通関まで、私たちが全プロセスを処理します。お客様はVATを支払い、商品が会社に到着するのを待つだけです。

当社のブレードは数え切れないほどの用途でその性能を発揮しており、お客様からどのようなプロジェクトをご依頼いただいても対応可能です。精度、耐久性、そして比類のない競争力のある価格をご提供します。

図面、スケッチ、サンプルをご提供いただければ、当社で設計・製造いたします。既存の設計や仕様の変更を支援し、あらゆる産業用工具の用途を改善する能力も備えています。具体的なご要望については、当社の専門営業チームまでお問い合わせください。

品質管理のために一連のテストと検査が実施され、これには初回品検査、入荷材料検査と材料証明書確認、工程内品質検査、最終品質検査が含まれます。

お客様が輸入業者、販売業者、卸売業者、最終ユーザーのいずれであっても、最小限のMOQ、お問い合わせの手間なし、より自由な購入で、お客様の参加を歓迎します。

お客様専属のモニターとして、生産ラインのあらゆる重要な進捗を定期的にご報告いたします。どんなに遠く離れていても、製品の進捗状況を可能な限り正確に把握いただけます。

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China