| その他の名称 | craft hot knife, electric hot knives, foam cutter, hot knife blades, hot knife cutter, hot knives, industrial hot knife, plastic hot knife, rope cutter hot knife, thermal cutters, types of hot knives, webbing hot knife |

|---|---|

| 用途 | Automotive Industry, Carpet Installation, Construction, Crafts and Hobbies, Electrical Work, Foam Cutting, Gasket Manufacturing, Marine Industry, Packaging, Plastic Fabrication, Rubber Processing, Textile Industry, Webbing and Rope Cutting |

| モデル番号 | CB-HKB |

| OEMサービス | 利用可能 |

| 支払い条件 | L/C、T/T、ウェスタンユニオン、XTransfer |

| 包装 | 段ボール箱, 木製ケース |

| 納期 | Based on Quantity |

シェア先:

ホットナイフは、サーマルカッターや電動ホットナイフとも呼ばれ、電気で加熱された刃を持つ工具です。合成素材を溶かして切断したり、場合によっては溶かすことで接着したりします。従来の冷間切断方法では布地などの端がほつれてしまうことがありますが、ホットナイフは素材を溶かしながら切断するため、ほつれや解けを防ぎ、きれいな切れ味の刃先が得られます。「ホットナイフ」という用語は、切断動作を行う加熱された刃を直接的に指します。

ホットナイフは、合成素材をきれいに切断・密封できるため、様々な産業や工芸品に幅広く応用できる万能ツールです。一般的な用途としては、以下のようなものがあります。

の刃 熱いナイフ 通常、熱を効率的に伝導・保持できる素材で作られています。一般的な素材には以下のようなものがあります。

刃はテフロンなどの素材でコーティングされていることもあり、摩擦を減らして溶けた材料が刃に付着するのを防ぎ、より滑らかな切断を実現します。

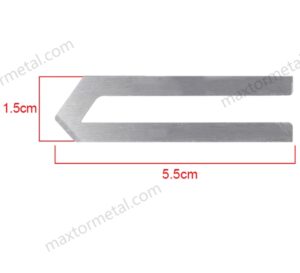

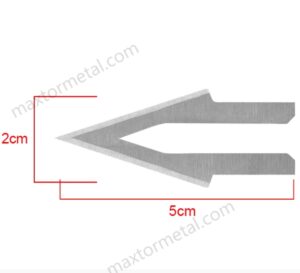

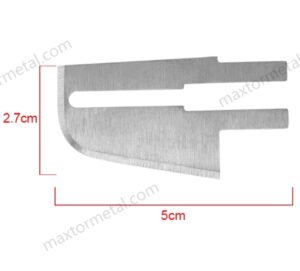

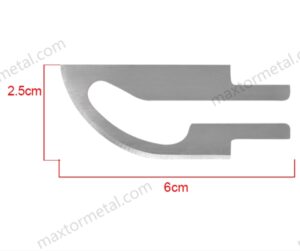

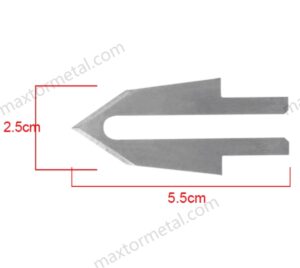

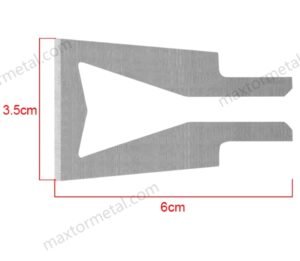

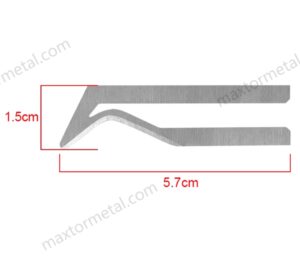

熱いナイフ 様々な切断作業や材料に合わせて、交換可能な様々な刃の形状が付属しています。一般的な形状には以下が含まれます。

の動作原理 熱いナイフ 電気加熱された刃が合成素材に接触すると、その素材が溶けて切断されます。熱によって素材が柔らかくなり、刃が最小限の抵抗で通過できるようになります。シーリング加工では、刃が通過した後、溶けた刃先がすぐに再固化し、融合したきれいな仕上がりになります。刃の温度は、様々な素材や切断速度に合わせて調整できる場合が多くあります。

当社では、標準サイズのトップグルービングナイフだけでなく、お客様の生産性を向上させるために設計された特殊ナイフも提供しています。図面やサンプルをご提供いただくだけです。

今すぐ当社のフレンドリーな営業チームにご連絡ください。お客様の具体的なニーズを的確に把握し、実績のあるアップグレードオプションをご提案いたします。または、お見積り依頼を送信してください。

1. 手間のかからないワンストップ輸入サービス

シームレスな輸入の利便性をお楽しみください。輸送から通関まで、私たちが全プロセスを処理します。お客様はVATを支払い、商品が会社に到着するのを待つだけです。

2. 競争力のある価格

当社のブレードは数え切れないほどの用途でその性能を発揮しており、お客様からどのようなプロジェクトをご依頼いただいても対応可能です。精度、耐久性、そして比類のない競争力のある価格をご提供します。

3. ODMとOEMも利用可能

図面、スケッチ、サンプルをご提供いただければ、当社で設計・製造いたします。既存の設計や仕様の変更を支援し、あらゆる産業用工具の用途を改善する能力も備えています。具体的なご要望については、当社の専門営業チームまでお問い合わせください。

4. 品質管理

品質管理のために一連のテストと検査が実施され、これには初回品検査、入荷材料検査と材料証明書確認、工程内品質検査、最終品質検査が含まれます。

5. 柔軟な調達、無制限の協力

お客様が輸入業者、販売業者、卸売業者、最終ユーザーのいずれであっても、最小限のMOQ、お問い合わせの手間なし、より自由な購入で、お客様の参加を歓迎します。

6.海外モニター、生産進捗リアルタイムレポート

お客様専属のモニターとして、生産ラインのあらゆる重要な進捗を定期的にご報告いたします。どんなに遠く離れていても、製品の進捗状況を可能な限り正確に把握いただけます。

Nanjing Metal Industrial CO., Limited

Mingjue Industrial Park, Lishui, Nanjing, Jiangsu, China