| 다른 이름들 | 젤리 톱니 모양의 칼날, 밀크티 톱니 모양의 칼날 |

|---|---|

| 원산지 | 중국 |

| 애플리케이션 | 식품 포장 |

| 재료 | 스테인레스 스틸 |

| 모델 번호 | GP-JP |

| OEM 서비스 | 사용 가능 |

| 지불 조건 | L/C, T/T, 웨스턴 유니온 |

| 패키지 | 판지 상자, 나무로 되는 케이스에서 |

| 배달 시간 | 7~20일 |

공유 대상:

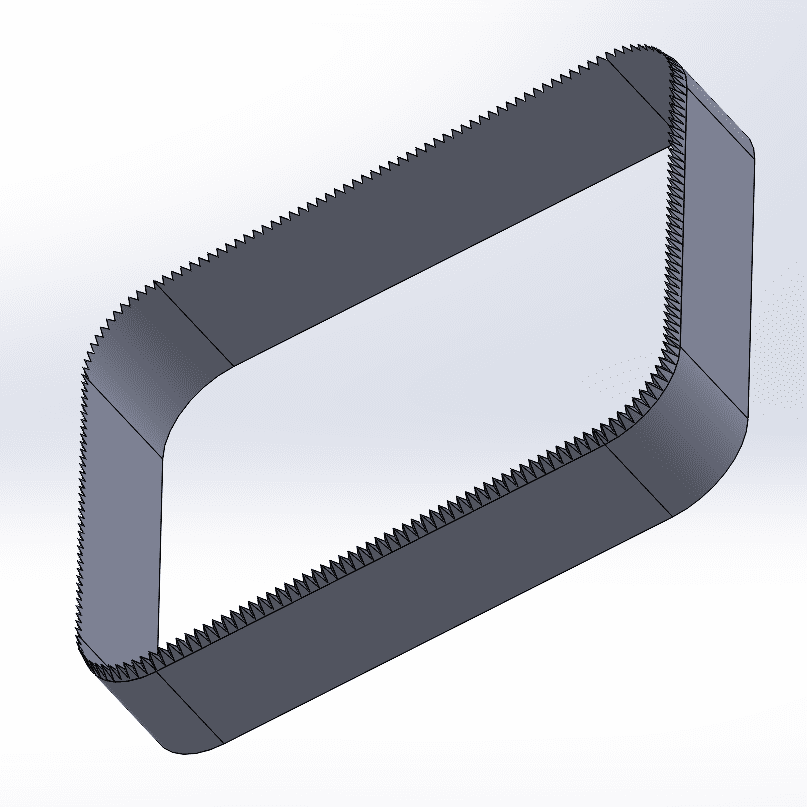

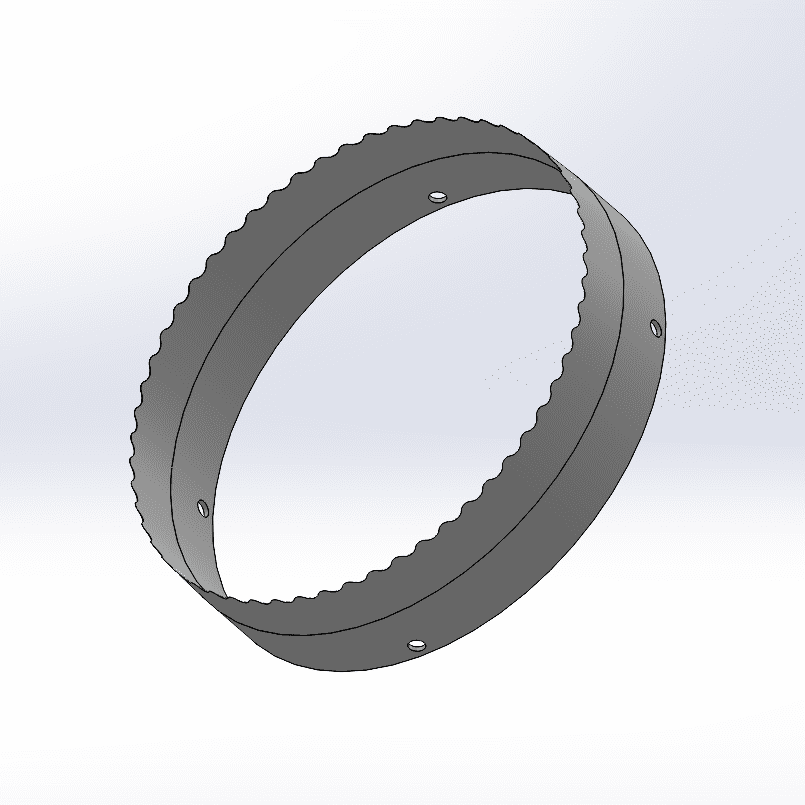

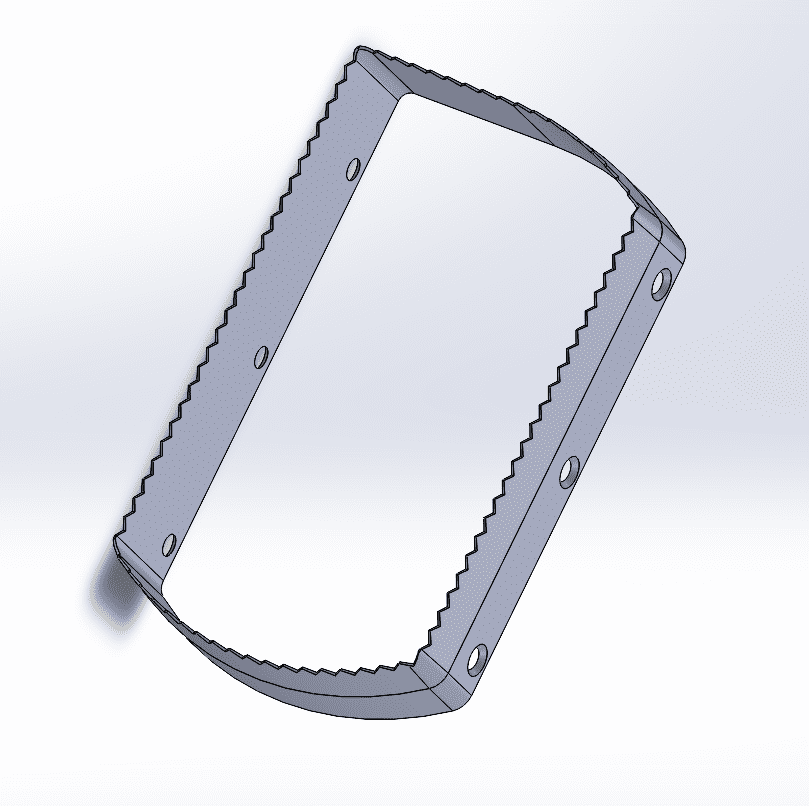

The term “Tooth Punch Blades” refers to a specific type of punch blade characterized by a cutting edge that features a series of teeth or serrations. Unlike punch blades with a continuous, smooth cutting edge, Tooth Punch Blades are designed to create holes or perforations with a specific edge profile or to facilitate tearing or separation of the material being punched. The teeth can vary in size, shape, and spacing depending on the intended application and the desired effect. Tooth Punch Blades are particularly useful for processing materials where a clean, shear-like cut is not always desired, or where a specific texture or tear initiation point is needed around the punched feature. These blades operate in punching machines or presses, similar to other punch blades. Tooth Punch Blades are also sometimes referred to as “serrated punch blades,” “perforating punch blades” (if the teeth are small and closely spaced), “notching punch blades” (if used to create edge notches), or “tear-off punch blades,” depending on the specific application and the resulting hole or cut.

Tooth Punch Blades are used in various industrial and craft applications where a toothed or perforated edge is required in the punched material. Key uses and application scenarios include:

The specific size, shape, and spacing of the teeth on the Tooth Punch Blade are critical to achieving the desired perforation or tear characteristics in the punched material.

The materials used to manufacture Tooth Punch Blades are chosen for their ability to maintain the sharp edges of the teeth under repeated impact and to resist wear. Common materials include:

The selection of the appropriate material depends on the material being punched, the required precision and durability of the teeth, and the production volume. Proper heat treatment is essential to ensure the teeth have the necessary hardness and toughness to perform effectively.

The defining characteristic is the toothed cutting edge. Beyond this, Tooth Punch Blades can have various overall shapes and tooth configurations:

The design of the teeth (size, shape, pitch, angle) is critical and is tailored to the specific material being punched and the desired outcome of the perforation or tear. Precision manufacturing is essential to ensure the teeth function correctly and consistently.

If you don’t find the blade you are looking for, we can also customize it. See our “맞춤형 블레이드” to learn how! Welcome to 묻다!

수입의 편리함을 누리기 쉽고, 운송에서 통관까지 전체 과정을 우리가 처리해 드립니다. 귀하는 VAT만 지불하고 상품이 회사에 도착할 때까지 기다리시면 됩니다.

우리는 수많은 응용 분야에서 블레이드가 사용되는 것을 보아 왔으며 정확성, 내구성 및 타의 추종을 불허하는 경쟁력 있는 가격을 제공하여 귀하가 진행하는 모든 프로젝트를 처리할 준비가 되어 있습니다.

도면, 스케치 또는 샘플을 제공하든, 우리는 귀하를 위해 도면을 그리고 제조할 수 있습니다. 또한 거의 모든 산업용 툴링 애플리케이션을 개선하기 위해 기존 설계 및 사양을 수정하는 데 도움을 줄 수 있습니다. 귀하의 특정 요구 사항에 대해 논의하려면 전담 영업 팀에 문의하십시오.

품질을 관리하기 위해 첫 번째 제품 검사, 입고 자재 검사, 인증된 자재, 진행 중 품질 검사, 최종 품질 검사를 포함한 일련의 테스트와 검사를 수행합니다.

귀하가 수입업체, 유통업체, 도매업체 또는 최종 사용자이든, 우리는 최소 MOQ, 번거로운 문의 없음, 더 큰 구매의 자유를 통해 귀하의 참여를 환영합니다.

당신의 전담 모니터가 되어, 생산 라인의 모든 중요 노드를 정기적으로 전송하세요. 아무리 멀리 떨어져 있어도 제품의 진행 상황을 최대한 파악하세요!

난징 Metal 산업 CO., 제한

Mingjue 산업 단지, Lishui, 난징, 장쑤성, 중국