You need your 과립기 칼날 to make clean, sharp cuts to ensure your granulator operates at peak performance. Proper maintenance and regular sharpening of your granulating blade can extend the life of your equipment, reduce downtime, and save you money. Neglecting blade care may result in inconsistent pellet sizes and faster wear on your granulator. Many choose a 커스텀 블레이드 for specialized applications to achieve optimal results.

주요 요점

- Keep granulating blades sharp and clean. This helps them cut better and last longer.

- Check blades often. Sharpen them after 40 to 50 hours of use. This stops uneven wear and keeps pellets good.

- Store blades in dry, clean places. Use edge guards to stop rust and damage.

- Sharpen blades with the right tools and angles. Use coolant to help blades stay strong and last longer.

- Change blades if you see cracks, chips, or warping. Replace them if sharpening does not make them sharp again. This keeps your machine safe and working well.

Why Granulating Blade Maintenance Matters

절단 효율성

Granulators help make pellets that are the same size. You need to keep the blades sharp for this to happen. If you take care of your blades, they work better. Sharp blades cut easier and faster. This means your machine does not have to work as hard. It also makes the process smoother.

| 미터법 | 개선 |

|---|---|

| 처리 효율성 | 30% improvement |

| 장비 수명 | 40% 더 길다 |

| 비용 절감 | 중요한 |

Check your blades every 40 to 50 hours. This helps you find dull blades early. Sharpen and clean them on time to stop uneven wear. Good care keeps your blades working well. You get even pellets and fast work.

블레이드 수명 연장

You want your blades to last a long time. Use sharpening, set the right gap, and feed materials carefully. These steps help your blades last longer. Good care stops heat damage and keeps blades strong. Coolant helps blades stay hard during sharpening.

Keep the blade width and straightness correct. This lets you set the best gap. It helps your machine work better and makes blades last longer. You will have less downtime and safer work. Over time, you will need fewer new blades and get steady results.

Cost and Energy Savings

Taking care of blades saves money and energy. Blades in good shape use less power. For example, a plant in Germany made 22% more pellets and used 14% less energy per ton. Another company moved materials 60% better and saved 40% on storage.

Tip: Watch how much power your granulator uses. If it goes up fast, your blades may be worn or broken.

Regular care can get you discounts on sharpening and spare parts. You also get faster service. If you skip maintenance, your machine works harder and breaks down more. This costs more money. Good care makes your equipment last longer and helps your business earn more.

Granulating Blades Maintenance Steps

Cleaning and Inspection

Step 1: Initial Rinse and Debris Removal

First, take the granulator blades out of the machine. Rinse each blade with water to remove loose plastic and dust. Use a soft brush to scrub off any stuck-on dirt.

Tip: Wear cut-resistant gloves to keep your hands safe from sharp edges.

Step 2: Vibratory Cleaning for Deep Contaminant Removal

Put the blades in a vibratory cleaning machine. This machine shakes the blades and removes dirt stuck deep in the metal. It also makes the blade surface shiny and smooth. Vibratory cleaning helps clean every small space on the blade. This keeps the blade working well for a long time.

Note: Shiny blades can help cut better and cause less damage, as shown in studies.

Step 3: Visual and Tactile Inspection for Wear or Damage

After cleaning, look at each blade carefully. Check for chips, cracks, or uneven spots on the edge. Gently run your finger along the blade to feel for rough places.

Caution: If you see cracks or big damage, replace the blade to stay safe.

Step 4: Measurement of Blade Dimensions Before Sharpening

Use a micrometer or caliper to check the blade’s thickness, width, and straightness. Write down these numbers before sharpening. Mark the spot that needs sharpening so you only remove what is needed.

Tip: Measuring helps you keep the right gap and makes your granulator blades last longer.

Step 5: Documentation of Condition and Maintenance Actions

Write down all your inspection results and measurements in a maintenance record. Include the date, blade condition, and any repairs or sharpening you did.

Keeping good records helps you follow a strong maintenance plan and see how blades wear over time.

Storage and Handling

Proper Storage Environment

Keep granulating blades in a dry, clean place away from water and chemicals. Use racks or holders to keep blade edges apart and stop them from touching.

Put rust blockers and edge guards on blades after sharpening to protect them.

Safe Handling Procedures

Always be careful when you handle granulator blades. Use both hands and wear gloves. Carry blades in a safe box or with covers on the edges.

Never stack blades right on top of each other because this can make them chip or get dull.

Common Mistakes and How to Avoid Them

- Mistake 1: Storing blades in wet or dirty places.

Correction: Use storage with good air and clean racks to stop rust and dirt. - Mistake 2: Handling blades without safety gear.

Correction: Always wear gloves and use edge guards to stop injuries and blade damage.

Maintenance Scheduling

Creating a Maintenance Calendar

Make a calendar for cleaning, checking, and sharpening your granulator blades. Plan these tasks based on how much you use the machine or how much material you process.

Schedules that fit your work help blades last longer and keep your machine running.

Sample Annual Maintenance Schedule Table

| Month | 일 | Details/Notes | Responsible Person | Date Completed |

|---|---|---|---|---|

| January | Full inspection & cleaning | Check for chips, cracks | Maintenance Lead | |

| February | Sharpening & measurement | Record dimensions | Operator | |

| March | Storage check | Inspect racks, apply inhibitor | Maintenance Lead | |

| April | Clearance adjustment | Adjust blade gap | Technician | |

| May | Vibration monitoring | Use sensors, log results | Operator | |

| June | Full inspection & cleaning | Repeat January tasks | Maintenance Lead | |

| July | Blade rotation | Swap blade positions | Operator | |

| August | Sharpening & measurement | Record dimensions | Operator | |

| September | Storage check | Inspect racks, apply inhibitor | Maintenance Lead | |

| October | Clearance adjustment | Adjust blade gap | Technician | |

| November | Vibration monitoring | Use sensors, log results | Operator | |

| December | Full inspection & cleaning | End-of-year review | Maintenance Lead |

Suggestion: Change the position of your granulator blades often. Doing this before they get too worn can make them last up to 30% longer. Keep checklists and digital logs near the machines so you can always update records.

A good maintenance plan, with trained workers and clear steps, helps your granulator work its best. Regular care not only makes blades last longer but also gives you more material and saves energy.

Sharpening Granulator Blades

유지하려면 과립화기 블레이드 working well, you must sharpen them carefully. Each step is important for safety and blade performance. Sharpening the right way helps your equipment last longer. It also makes the cutting edge sharp again. This helps your granulator work better.

Safe Removal and Preparation

You need to be safe and ready before sharpening. Here are the steps to get your blades out and ready:

- Turn off the granulator and unplug it. This stops it from turning on by accident.

- Put on gloves, goggles, and a face mask. These protect you from sharp edges and metal bits.

- Take out the blade assembly by following the instructions. You may need to unscrew or unlock the blade holder.

- Clean each blade well. Use a solvent and a soft brush to get rid of dirt. Make sure the blade is dry before you go on.

- Look at the blade for chips, cracks, or too much wear. If you see big damage, get a new blade instead of sharpening.

- Measure the blade’s thickness, width, and straightness. Write down these numbers for later.

Tip: Checking and measuring helps you know if you should sharpen or replace your granulator blades.

Precision Sharpening Methods

You need the right tools and ways to sharpen well. This helps your blades get sharp and stay the right shape.

Step 1: Secure Blade Using Magnetic Chuck

Put the blade on a magnetic chuck. This keeps the blade still while you sharpen it.

Step 2: Set Correct Sharpening Angle

Set the sharpener to match the blade’s original angle. The right angle helps the blade cut well and last longer.

Step 3: Use Coolant to Prevent Overheating

Use coolant while sharpening. Coolant keeps the blade cool and strong.

Step 4: Grind Off Minimal Material

Take off only a little bit of material each time. This keeps the blade strong and lets you sharpen it many times.

Step 5: Check for Burrs and Remove Them

After grinding, look for burrs. Use a fine stone or tool to smooth out rough spots.

Step 6: Clean and Dry Blade After Sharpening

Wipe the blade clean and dry it. This stops rust and keeps the edge sharp.

| Measurable Improvement | 설명 |

|---|---|

| Increased blade life | Taking off little material and keeping blades cool helps them last longer. |

| 향상된 절단 효율성 | Keeping the right angles helps blades cut better and wear less. |

| Enhanced material utilization | Good blade care gives you 3-5% more product by making less dust. |

| Reduced energy consumption | Sharp blades and good gaps use less energy, especially when running all the time. |

| Extended component life | Less shaking and stress helps blades and machine parts last longer. |

| Multiple re-sharpenings possible | You can sharpen blades up to ten times before needing new ones. |

| Consistent machine output | Keeping the right gap between blades helps your machine work the same every time. |

Note: Sharpening blades the right way costs less than buying new ones and gives you better results.

Maintaining Angles and Tolerances

You must keep the right angles and sizes every time you sharpen. This helps your blades work well and last longer.

Step 1: Use Precision Measuring Tools (Micrometers, Calipers)

Use micrometers or calipers to check the blade’s thickness, width, and edge angle. Good measurements help you keep the blade the right shape.

Step 2: Verify Angle Consistency Across Blade Edge

Check that the angle is the same along the whole edge. If the angle changes, the blade will wear out faster and not cut as well.

Step 3: Check Tolerances Against Manufacturer Specifications

Compare your numbers to what the manufacturer says. Staying in these limits helps the blade fit and work right.

Step 4: Document All Measurements for Future Reference

Write down all your measurements and sharpening steps in a log. Good notes help you see how blades wear and plan future care.

Step 5: Repeat Sharpening Up to 10+ Times if Within Tolerance

If your blades are still in the right range, you can sharpen them up to ten times. This saves money and makes blades last longer.

Callout: Using a professional sharpener or automatic machine can make sharpening more accurate and faster. Good sharpening keeps your granulator working well and helps your equipment last longer.

You can sharpen granulator blades many times if you follow these steps. Careful sharpening keeps blades sharp, saves energy, and helps your machine work better. Regular sharpening helps your production stay smooth and your business run well.

When to Replace Granulating Blades

마모의 징후

It is important to know when to replace your granulating blades. If you wait too long, your machine can get damaged. Your pellets may also turn out bad. Look for these signs that show you need new blades:

Excessive Edge Wear

Sometimes, the blade edge looks round or not even. This happens after sharpening many times. When the edge is too thin, it cannot cut well. You will see more dust and small bits in your pellets. If you notice this, plan to get a new blade soon.

Chipping or Cracking Along the Blade

Check the blade surface closely. Small chips or cracks can show up after heavy use. Hard things in the granulator can also cause this. Even tiny cracks can get bigger fast. If you see any, stop using the blade right away. A damaged blade can be unsafe and hurt your machine.

Inability to Maintain Sharpness After Sharpening

Sometimes, you sharpen the blade but it still does not cut well. If the edge gets dull fast or will not stay sharp, the steel may be worn out. Using this blade will make your machine work worse and stop more often.

Visible Deformation or Warping

Look at the blade for bends or warps. A straight blade is needed for good cutting. If you see any bending, the blade will not fit or work right. Replace any blade that does not stay flat.

Increased Power Consumption or Poor Pellet Quality

Watch how much power your machine uses. If it goes up, your blades may be dull or broken. You might also see pellets with rough sides or different sizes. These are signs your granulating blades are not working well. Getting new blades will help your system work better.

Tip: Write down when you change blades and how your machine works. This helps you see problems early and plan for new blades before things get worse.

Replacement vs. Sharpening

You must choose if you should sharpen your blades again or buy new ones. Picking the right option saves money and keeps your work safe.

Cost-Benefit Analysis of Replacement vs. Continued Sharpening

Sharpening costs less than buying new blades. But each sharpening takes away some blade material. This makes the blade last a shorter time. When sharpening does not make the blade cut well, it is better to get a new one. Use this table to compare:

| 요인 | 날카롭게하다 | Replacement |

|---|---|---|

| Cost per cycle | 낮은 | 더 높은 |

| Blade lifespan | Extends, but limited | Resets to maximum |

| 중단 시간 | 짧은 | May be longer |

| 성능 | Restored if within tolerance | Fully restored |

Note: If you sharpen a blade more than ten times, check if it still matches the maker’s rules. If it does not, get a new blade.

When to Prioritize Replacement (e.g., Safety, Performance, Downtime)

You should always get a new blade if:

- The blade has cracks, chips, or is bent.

- The blade cannot stay sharp after sharpening.

- The machine still works badly after you fix it.

- There is damage that could cause harm.

If you see any of these, do not wait. New blades keep your machine and workers safe.

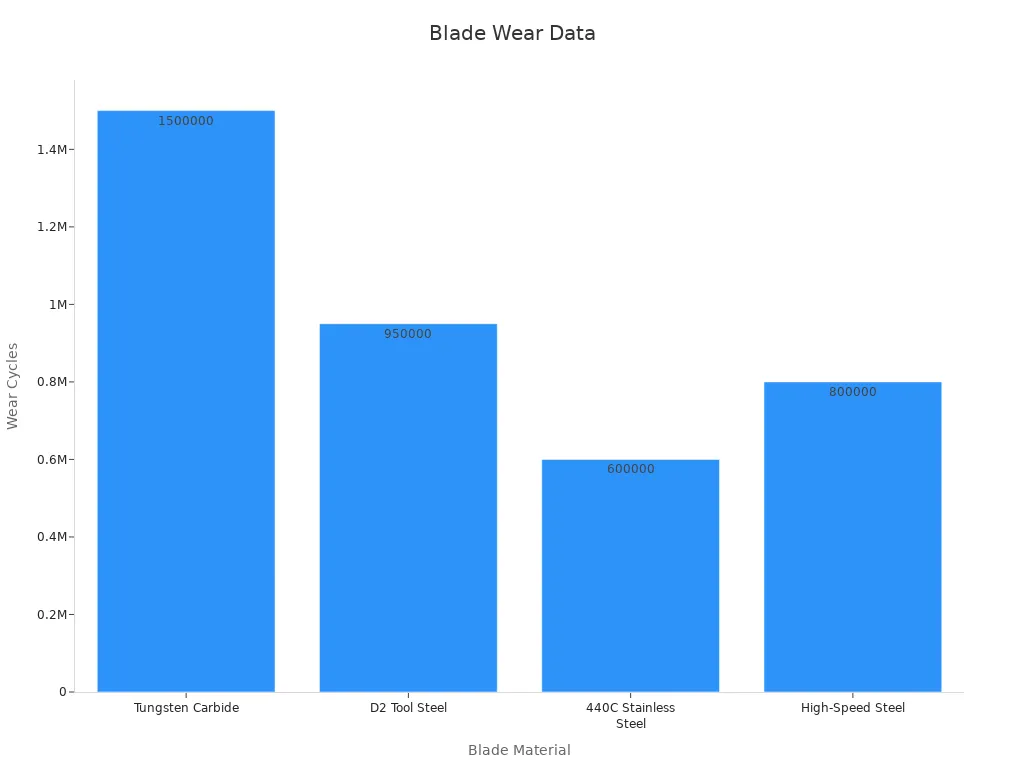

Factors Affecting Decision (Blade Material, Application, Maintenance History)

Some things help you pick between sharpening and getting new blades:

- 블레이드 재질: Harder steels and carbide-tipped blades last longer but cost more to replace.

- 적용 분야: Cutting tough or filled plastics wears blades out faster.

- Maintenance History: Blades that are cared for can be sharpened more times. Bad records or missed care make blades wear out sooner.

Look at your notes and think about how often you cut hard materials. This helps you know when to get new blades.

Example Scenarios for Replacement and Sharpening Choices

- Scenario 1: You cut soft, clean plastics and always do maintenance. Your blades stay sharp after each sharpening. You can keep sharpening until the blade is too thin.

- Scenario 2: You see chips and cracks after running a batch with metal in it. Get a new blade right away to stop machine damage.

- Scenario 3: Your worker says the blade gets dull fast, even after sharpening. The blade is worn out. Buy a new one to make your machine work well again.

- Scenario 4: You notice more power use and bad pellet quality. You check and see the blade edge is very worn. Replace the blade to help your system work its best.

Callout: Checking your blades often and keeping good notes helps you make smart choices. This keeps your granulating blades working well and protects your equipment.

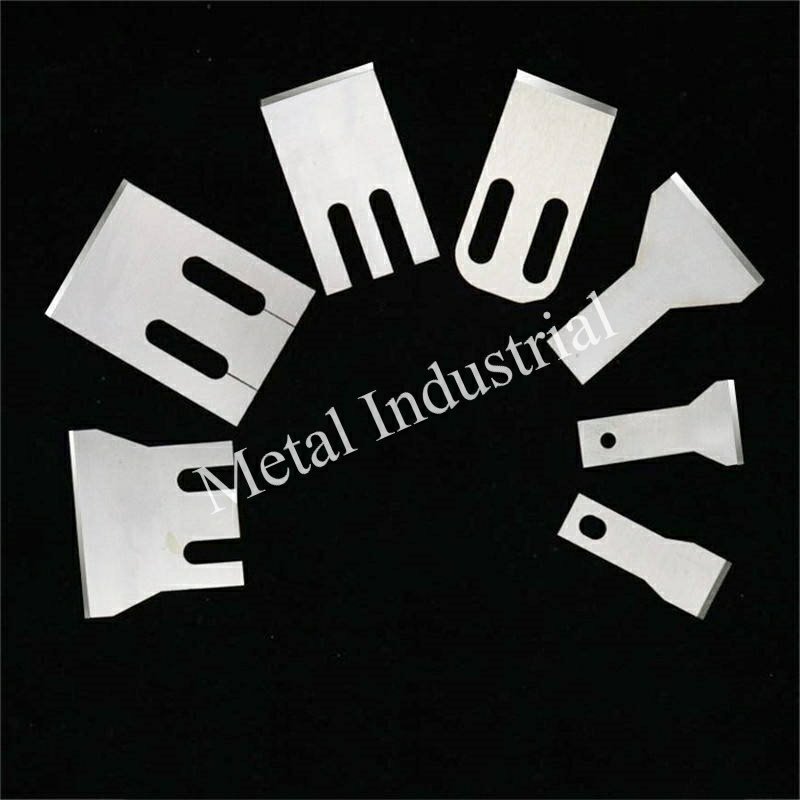

Custom Granulating Blades

맞춤화의 이점

Making plastic pellets can be hard. Each job needs a special way to do it. Custom granulating blades help you get the right results. You can pick the best material, shape, and coating for your work. This helps your granulator knife make clean cuts every time.

- You can pick tool steels like D2, A8, or M2. You can also choose high-speed steel or carbide-tipped blades. These materials last longer and do not wear out fast, even with rough plastics.

- Heat treatments and coatings like titanium nitride or chromium plating make blades stronger. They also help stop rust and damage.

- 커스텀 블레이드 shapes and sizes fit your pelletizing machine. This works for underwater, strand, or hot die face systems.

- You can match the blade’s shape and gap to your process. This stops smearing and makes pellets the right size and shape.

- OEM and ODM services let you change details like blade thickness and edge angle.

맞춤형 블레이드는 여러 가지 장점을 제공합니다.

- You can sharpen a custom granulator knife up to ten times. This saves up to 85% compared to buying new blades often.

- You get more pellets and steady quality because the blades are made to fit well.

- You waste less because the blades cut pellets to the right length. This helps you use your raw materials better.

- New blade designs and machines help you use less labor and keep pellet quality the same.

Note: Custom blades help you fix special problems and make your equipment last longer. You spend less on repairs and get better results you can trust.

Nanjing Metal Industrial CO., Limited

If you need a good granulator knife maker, Nanjing Metal Industrial CO., Limited is a top choice. They have over 20 years of experience making custom blades for many uses. Their skilled teams make sure every blade meets high standards.

| Metric / Example | 표준 블레이드 | Custom Blade (Nanjing Metal) |

|---|---|---|

| Sharpness loss after 4,000 cuts | 35% | 11% (ceramic-coated) |

| Blade lifespan in recycling | 7–10 days | 42 days (CPM10V alloy, TiCN) |

| Downtime reduction (plastic plant) | 기준선 | 65% 미만 |

| Monthly blade changes | 12 | 3 |

| Total monthly cost (incl. labor) | $800+ | $450 |

Nanjing Metal has many blade materials, like SK2, HSS, M2, SKD11, D2, A8, and carbide-tipped blades. They check quality at every step and watch production in real time. Their blades work in recycling, compounding, and labs. As a top granulator knife maker, Nanjing Metal (visit homepage) helps you get longer blade life, less downtime, and lower costs.

Special Considerations

Material-Specific Needs

Different plastics and fillers can make blade care tricky. Each type of plastic changes how you look after and sharpen your granulator knives. Hard plastics like PET or glass-filled nylon can wear blades out fast. For these, you should use tungsten carbide or titanium-coated steel blades. These blades last longer and stay sharp, even with tough jobs.

Soft plastics like PP and PE can stick to the blade and cause clogs. Stainless steel blades with a straight edge work best for these. Brittle plastics, such as rigid PVC, can chip easily. You should use D2 tool steel with a serrated edge to stop chipping. Heat-sensitive plastics like polycarbonate need high-speed steel blades with sharp angles. This helps stop the plastic from melting.

| 플라스틱 타입 | 도전 | Best Blade Material | 엣지 타입 |

|---|---|---|---|

| 애완 동물 | High wear | 텅스텐 카바이드 | 파인 에지 |

| PVC(강성) | Brittle, chips easily | D2 공구강 | 톱니 모양의 |

| PP & PE | Smearing, clogging | 440C 스테인리스 스틸 | Straight |

| Polycarbonate | 열에 민감하다 | 고속도강(HSS) | 날카로운 각도 |

| 나일론(PA6, PA66) | High friction | 티타늄 코팅 강철 | Polished |

Tip: Always check the blade gap. Keep it between 0.2 and 0.3 mm for the best cuts. If the gap is wrong, you get bad regrind and more dust.

Environmental Factors

Where you keep your blades matters for blade care. Humid places can make steel blades rust. Store blades in a dry, cool place to stop rust. Use ultrasonic cleaning to get rid of plastic stuck on blades and to keep them cool. Coatings like titanium nitride make blades smoother and help them last longer.

Some plastics are made of many layers or mixed materials. These can need specific

blade shapes, like spiral or serrated edges. Some granulators have smart sensors that watch blade wear all the time. These sensors help you know when to do maintenance before things break, so you have less downtime.

For lab, recycling, and compounding work, you should:

- Switch out spare blades so you do not stop for long.

- Check blades often and use hour meters to see how much they are used.

- Pick the right blade material and shape for the plastic you are cutting.

Note: Picking the right blade and care plan for your material and workplace keeps your granulator working well and your pellets looking good.

If you want your granulator to work well, make a good maintenance plan. Clean your blades often. Check them for problems and sharpen them when needed. Doing these things on time helps you find issues early. This keeps your machine safe and working longer. Taking care of your blades saves money and helps your granulator do its job better. If you need special blades, pick a company you trust.

자주 묻는 질문

How often should you sharpen granulating blades?

Sharpen your blades after 40 to 50 hours of use. If cuts look dull or your machine uses more power, sharpen sooner.

Tip: Write down each time you sharpen in a log.

What is the best way to store granulator knives?

Keep your knives in a dry and clean place. Put them on racks or in holders so the edges do not touch.

- Add something to stop rust

- Use guards to cover the edges

This helps stop rust and keeps blades from getting damaged.

Can you use the same blade for different plastics?

You can use one blade for many plastics, but results change. Hard or filled plastics need stronger blades.

| 플라스틱 타입 | 추천 블레이드 |

|---|---|

| Soft | 스테인레스 스틸 |

| Hard/Filled | 카바이드 팁 |

How do you know when to replace a blade instead of sharpening?

Change your blade if you see cracks, chips, or if it is bent. If sharpening does not make it sharp again, get a new blade.

Safety first: Broken blades can hurt your machine.

Where can you get custom granulator blades?

Order custom blades from a company you trust.

또한 참조

귀하의 기계에 가장 적합한 펠릿나이프 선택을 위한 종합 가이드