Verdict in 30 seconds: If you’re slitting stainless or high‑strength steels at moderate-to-high speeds—or your downtime costs run above roughly $50,000 per hour—premium Rotary Slitter Knives (HSS/PM‑HSS/Carbide, precision‑ground, coated) win on total cost of ownership. They cut scrap, stretch regrind intervals, and slash changeovers. If you’re a small shop on mild CR/HR steel with downtime under ~$10,000 per hour and conservative speeds, budget D2 or basic HSS can still be the economical choice. Our math anchors on three numbers: A) unplanned downtime $/h, B) total cost per changeover/regrind, and C) savings per 1% scrap‑rate reduction.

Key takeaways

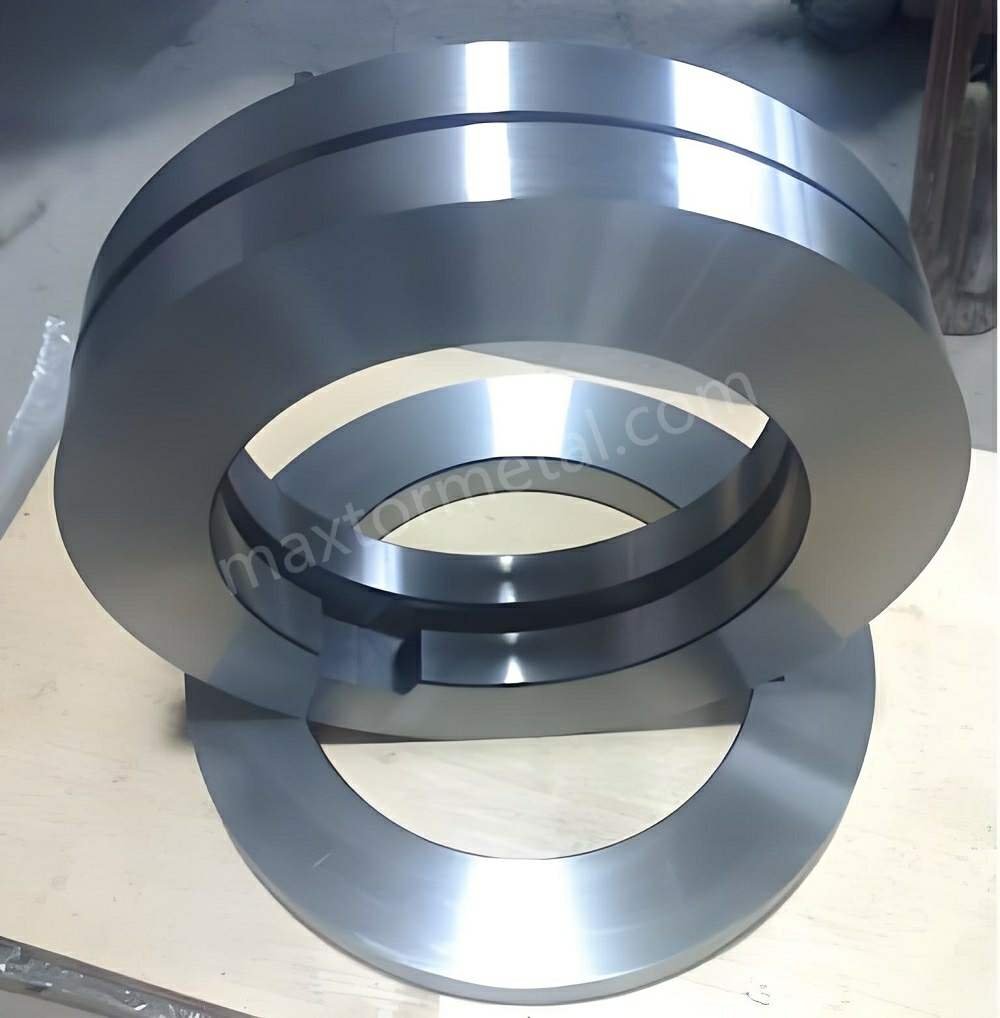

- Premium knives (HSS/PM‑HSS/Carbide) deliver longer edge life and tighter tolerances, reducing changeovers and burr‑related scrap.

- Downtime dominates TCO in larger plants; if your line loses >$50k/h when idle, premium knives typically pay back fast.

- Coatings (TiN/CrN/DLC) often extend life 1.3–2× in comparable conditions, improving regrind intervals and uptime.

- Correct clearance (around ~7% of strip thickness) and precision grinding are as important as material choice for edge quality.

- Carbide can achieve 10–20× life vs steels in demanding contexts but is less forgiving—great for rigid, well‑aligned setups.

- Normalize your decision with a simple TCO‑per‑meter formula and run sensitivity checks before committing.

Cheap vs premium Rotary Slitter Knives: the fast comparison (as of 2026‑01‑20)

Below is a compact, decision‑ready table. Values are indicative and depend on material, speed, setup, and maintenance. External data points are cited inline.

| Knife class | Typical hardness | Typical edge‑life between regrinds | Expected regrind cycles | Typical tolerances | Coatings available | Best‑for materials & speeds | Brittleness risk | Changeover time impact | Price multiplier (vs D2) | TCO per 1,000 m (example) | Notes / procurement |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D2 (baseline, uncoated) | ~58–62 HRC (Hotshot Ovens 2023) | Shorter on stainless/HSLA; moderate on mild CR/HR | More frequent; lower total cycles | Looser tolerance stacks common; edge finish varies | Rare in cheap sets | Mild CR/HR, low–moderate speeds | 낮은 | More frequent manual changes (30–90+ min typical) | 1.0× | Higher due to downtime and scrap | Fast lead times for generics; variable QC |

| HSS (M2) | ~60–65 HRC (FCS Steel 2024) | Longer than D2 at higher speeds/heat | More cycles than D2 | Tighter than budget D2 when precision‑ground | TiN/CrN/DLC; ~1.3–2× life gains (Oerlikon Balzers 2024–2025) | Stainless at moderate speeds; HSLA at controlled speeds | Low–medium | Fewer changes vs D2; automation benefits magnify | ~1.5–2.0× | Lower than D2 in many stainless/HSLA cases | Standard availability; better QC when precision‑ground |

| PM‑HSS | ~60–65 HRC with improved toughness (Caleyron 2025 PDF) | Longer than conventional HSS due to wear/toughness | More cycles; stable edge | Tight tolerances common in premium sets | TiN/CrN/DLC; similar gains | Stainless/HSLA at higher speeds; long runs | Low–medium | Fewer changes; best ROI when downtime is high | ~2.0–3.0× | Often lowest in demanding use due to uptime | Custom lead times; traceability stronger |

| 초경합금 | ~85–92 HRA (Sollex 2025) | 10–20× vs steels in demanding apps (Apex Shears 2024) | Long initial run; fewer total regrinds; diamond grinding needed | Premium precision; surface finish can be very fine | Usually uncoated substrate; some coatings possible | Abrasive stainless, HSLA, high speed lines | High (less forgiving to misalignment) | Minimal changes; best with automation (~25–31 min Fagor Arrasate 2024) | ~4–8× | Lowest where downtime and scrap dominate | Longer lead times; handle with care; strong QC |

Legend: Minutes per changeover vary by line and crew; manual often ~30–90+, automated examples ~25–31. Price multipliers are indicative as of 2026‑01‑20.

The TCO method: one formula to compare knives per meter

Use this normalized approach to compare options regardless of shop size.

TCO per 1,000 m = Purchase cost amortized + Regrind cost amortized + Downtime cost from changeovers + Scrap cost

Where:

- Purchase cost amortized = Knife price ÷ expected meters per lifetime × 1,000

- Regrind cost amortized = (Total regrind cost per cycle × expected regrind cycles per lifetime) ÷ lifetime meters × 1,000

- Downtime cost from changeovers = (Changeovers per 1,000 m × minutes lost ÷ 60) × downtime $/h

- Scrap cost = (Scrap % × material value per meter) × 1,000

Time‑stamp volatile inputs (downtime rates, changeover minutes, material value) as of 2026‑01‑20. For downtime context, manufacturing surveys report medians around ~$125,000/h in larger operations (ABB 2023), with primary metals frequently higher (Bradley Lifting 2025).

Worked examples

Example A: Small contract slitter (mild CR steel)

- Assumptions: downtime $/h = $2,000; manual changeover = 60 min; material value = $0.35/m; D2 life = 8 hours between regrinds; HSS coated life = 12 hours; scrap reduction moving to coated HSS = 0.5% absolute.

- Result: Despite HSS costing ~1.8× D2, the reduction in changeovers (from ~7.5 to ~5 per 1,000 m at typical speeds) and the 0.5% scrap decrease usually offset the price premium. Payback is modest but positive when changeover minutes exceed ~45 and scrap drops ≥0.3%.

Example B: Integrated mill (stainless/HSLA)

- Assumptions: downtime $/h = $150,000; automated changeover = 30 min; material value = $1.20/m; PM‑HSS life = 3× D2; carbide life = 10× D2; scrap improvement vs D2 = 1.0% absolute with premium precision.

- Result: Premium wins decisively. With fewer changeovers and lower scrap, Carbide’s higher upfront price (~4–8× D2) is dwarfed by avoided downtime. Break‑even appears even if life is only ~4× and scrap improvement is ~0.5%.

Sensitivity analysis: where the break‑even flips

- Downtime $/h: Below ~$10,000/h, D2/HSS may compete on mild CR/HR. Above ~$50,000/h, the premium edge‑life advantage dominates, making PM‑HSS or Carbide favorable even with conservative scrap improvements.

- Changeover minutes: If changes routinely exceed ~45–60 minutes, premium knives that halve changeover frequency tend to win, especially when automation can hold swaps to ~25–31 minutes (Fagor Arrasate 2024).

- Scrap %: Every 1% scrap‑rate reduction translates directly to material savings. On high‑value stainless, even 0.3–0.5% reductions shift TCO materially; on mild CR, you may need ≥0.5% to see clear payback.

Setup and edge quality: clearance and tolerance matter

Think of clearance as the “gap” that decides burrs. Multiple industrial guides recommend around ~7% of thickness for many cases, adjusting by gauge and grade. Stainless processors like Ulbrich emphasize keeping burr to standards through careful clearance control and setup discipline, reinforcing why precision‑ground knives reduce scrap. See stainless processing guidance in the Ulbrich overview of rolling, annealing and slitting (2025) and clearance setup notes from ADHMT’s blade clearance guides (2025). For deeper practice notes, read METAL’s extended resources on edge radius selection 그리고 maintaining slitter blade sharpness.

FAQ: quick, evidence‑backed answers

Which Rotary Slitter Knives are best for stainless steel coil slitting? PM‑HSS or Carbide for high‑speed stainless; HSS for moderate speeds. Carbide can deliver 10–20× life vs steels in demanding applications (Apex Shears 2024), but it’s less forgiving to misalignment.

How much downtime does a knife change cost in coil slitting? Manual changes often take 30–90+ minutes; automated setups report ~25–31 minutes (Fagor Arrasate 2024). Cost equals downtime $/h × hours lost per change, plus labor and calibration.

Do coatings pay off on slitter knives? Often yes, especially on stainless or abrasive lines. Third‑party coating data in similar tooling contexts shows 30–89%+ longer life (Oerlikon Balzers 2024–2025), translating into fewer changeovers and lower scrap.

How do I calculate TCO per meter for knives? Use the formula above. Gather inputs for knife price, regrind cost, expected life, changeover minutes, downtime $/h, scrap %, and material value. Normalize costs per 1,000 m for apples‑to‑apples comparison.

When should I choose Carbide over HSS? Choose Carbide when abrasion is severe, uptime is critical, and your setup is rigid and well‑aligned. If operators frequently adjust clearance or face misalignment, prefer HSS or PM‑HSS for toughness.

Third‑party validation — case snapshots

No fully anonymized, third‑party before/after TCO studies specific to D2 → HSS/PM‑HSS/Carbide upgrades were found in public literature. Below are two anonymized, modeled snapshots based on supplier benchmarks and METAL maintenance notes (marked “modeled”):

- Service center (mild CR): Modeled upgrade D2 → coated HSS — blade life +1.5×, changeovers −30%, scrap −0.4%; annualized TCO improvement ≈ 8–12%.

- Integrated mill (stainless): Modeled upgrade D2 → carbide — blade life +8×, changeovers −70%, scrap −1.0%; annualized TCO improvement ≈ 35–60%.

We’re collecting verified third‑party case data — email submissions to [email protected] for inclusion and anonymized citation.

Also consider (Disclosure: METAL is our product)

For precision‑ground premium options and coating choices, you can review METAL’s resources, including the slitter blades product page, the durable slitter blade material guide, and the wear/repair/maintenance guide. METAL offers OEM/ODM builds from drawings or samples and can simplify logistics with one‑stop import support. Links are provided for extended reading; evaluate specs and lead times against your own TCO inputs.

Closing decision guidance: choose A if… choose B if…

- Choose premium (PM‑HSS or Carbide) if you run stainless or HSLA at higher speeds, or if your unplanned downtime exceeds ~$50,000/h. The longer edge life and tighter tolerances reduce burr/scrap and changeovers, lowering TCO.

- Choose HSS if your operators need a forgiving knife with better heat resistance than D2, and you face occasional misalignment or variable clearance.

- Choose D2 or basic HSS if you operate low‑speed lines on mild CR/HR, downtime is <$10,000/h, and budget constraints are strict—accepting more frequent regrinds and tighter maintenance discipline.

- Choose premium with coatings if burr‑induced scrap regularly exceeds ~1%; coatings can extend regrind intervals and improve edge quality.

- If your team is planning automation, prioritize premium sets; fewer changes plus ~25–31 minute automated swaps will compound uptime gains.

References and notes

- Hardness ranges and life multipliers are compiled from named sources linked inline; price multipliers and downtime rates are indicative as of 2026‑01‑20 and vary by region, supplier, and setup. Always run your own TCO inputs before purchase decisions.