You need to set the blade gap carefully on your blade gap setting perforating machine to achieve excellent results and high product quality. Studies show that even small changes in the gap can bend the die and cause perforation errors, so precision is crucial. With Nanjing Metal’s perforating blade knives, you create neat and consistent holes while extending the life of your machine. Proper blade gap setting on your perforating machine reduces damage, improves product quality, and prevents issues like tearing or uneven cuts. For micro-perforating tasks, the correct blade gap setting keeps you in control and ensures outstanding results. Choosing durable perforating blade knives helps your 칼날 간극 설정, 타공기 perform optimally and maintain superior perforation quality.

주요 요점

- Set the blade gap carefully. This helps stop tearing and uneven cuts. It also keeps the machine safe from damage.

- Use the right tools like feeler gauges and torque wrenches. These tools help you measure and adjust the blade gap safely.

- Always turn off the machine before you make changes. Lock the machine so you stay safe.

- Check the blade gap all along the blade. This makes sure the perforation quality stays the same everywhere.

- Look at the blades often. Clean, oil, and sharpen them. Change blades when they get worn out.

- Watch for vibration in the machine. Fix it fast to stop blade damage and bad perforation.

- Teach operators how to use the machine well. Good training helps them make fewer mistakes and improves product quality.

- Write down all maintenance, blade changes, and settings. Keeping records helps you find problems early and make the machine work better.

칼날 간극 설정, 타공기

Blade Gap Basics

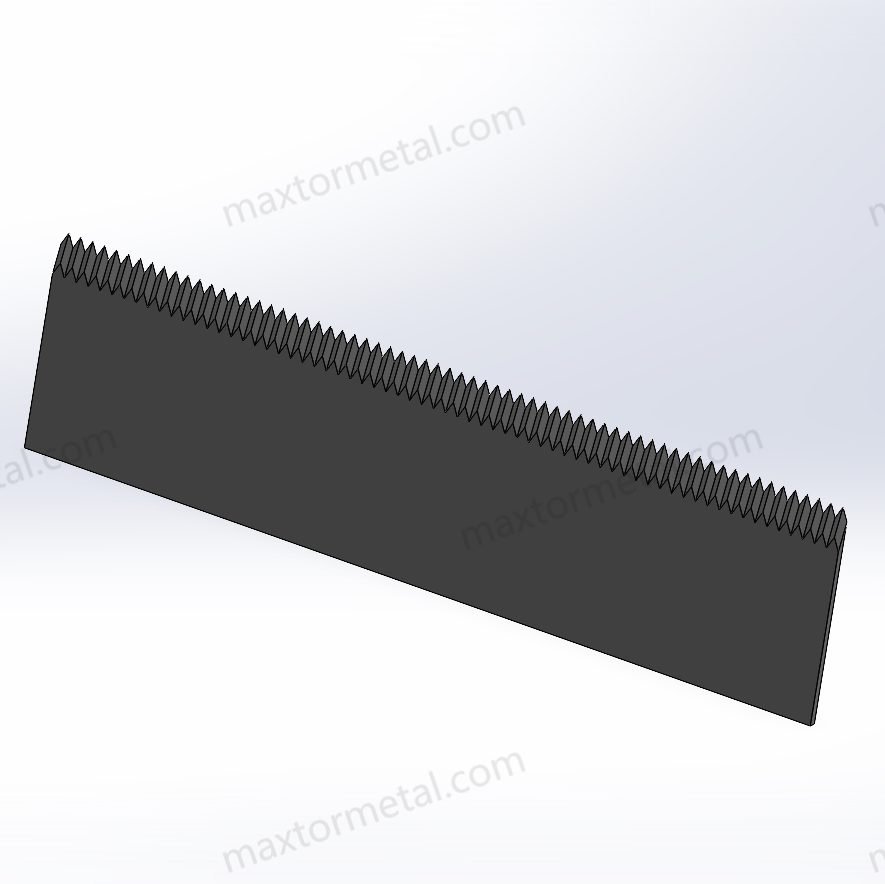

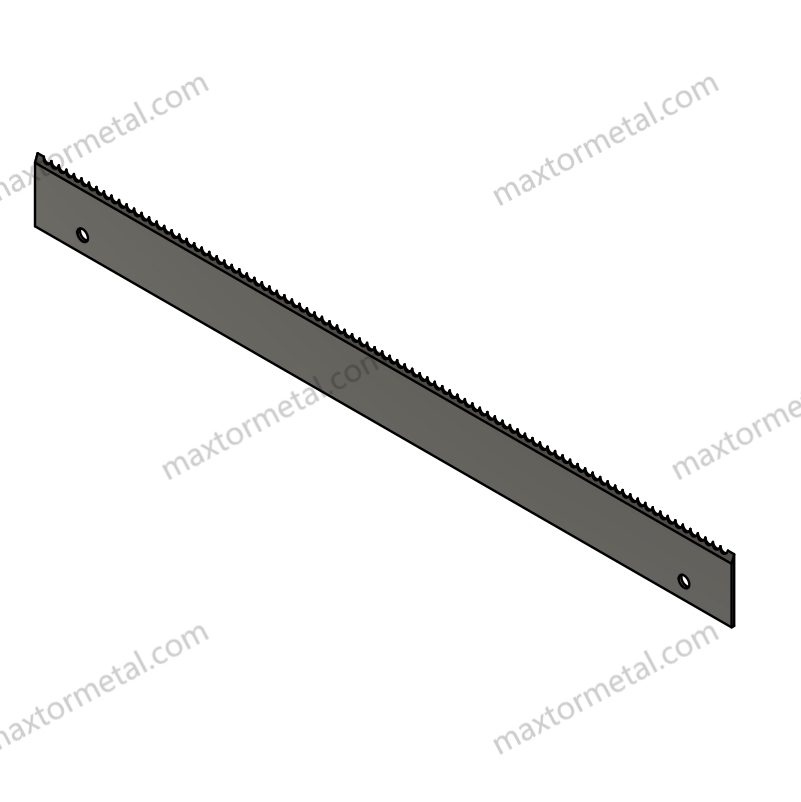

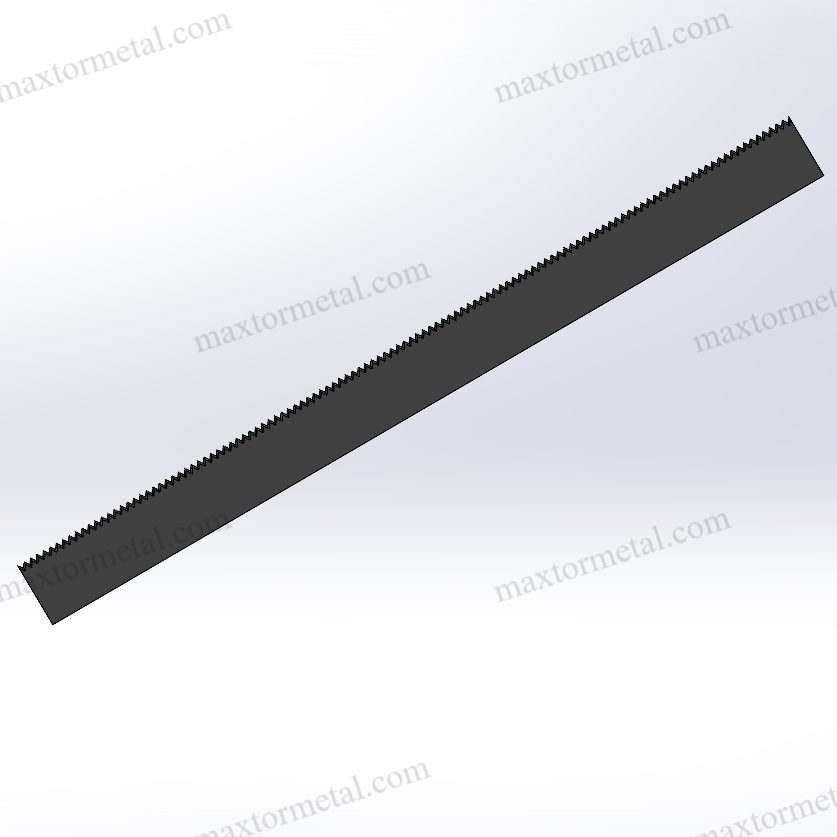

To get good results, you must know about blade gap. The blade gap is the space between the perforating blade and the anvil. This small space is very important for each perforation. If the gap is too big, the holes may look messy or not finished. If the gap is too small, the material might tear or the machine could wear out faster.

Using good perforating blade knives gives you neat lines and helps your machine last longer. If you need something specific, you can look at 맞춤형 블레이드 for your needs.

Importance of Accurate Setting

Setting the blade gap right is very important for good work. When the gap is set well, you get even lines and avoid problems like bad holes or damage. Keeping the gap the same also stops the machine from shaking and keeps the blades from wearing out fast. Reports say a steady blade gap can cut machine shaking by 70%. This is because a steady gap stops uneven pressure and shaking inside the machine.

You also help your perforating blade knives last longer. Studies show that a small gap difference keeps blades from bending and makes the surface better. This means your blades stay sharp and last longer. By being careful, you keep your work going and stop long breaks for fixing things.

팁: Always check the whole blade for the same gap. Even a small change can hurt the final product.

Tools for Adjustment

You need the right tools to set the blade gap setting perforating machine safely. Here are the main tools:

- Feeler gauges: These tools measure the gap between the perforating blade and the anvil.

- Torque wrenches: Use these to tighten bolts just right, not too much or too little.

- Safety equipment: Wear safety glasses to keep your eyes safe from flying bits. Use cut-proof gloves to protect your hands from sharp edges. Wear steel-toed boots to keep your feet safe. Wear tight clothes and do not wear loose things, jewelry, or let your hair hang loose so nothing gets caught.

- Lockout/tagout devices: Before you start any ajuste or adjustment, turn off and lock the machine. Never skip safety steps or remove guards during the ajuste de máquina.

- Specialized adjustment tools: Some machines need special tools from the maker for the best setting. Always read your machine’s manual for help.

Using these tools and being safe keeps you safe and makes your perforation work better. The right tools also help you keep the same results and make your perforating blade knives and machine last longer.

Adjustment Steps

Measuring the Gap

You need to measure the blade gap very carefully. This helps you get good perforation quality every time. First, turn off the machine and lock it. This keeps you safe from accidents. Clean the perforating blade knives and the anvil. Dirt or dust can mess up your measurements and the holes you make.

Use a feeler gauge to check the gap in different spots. Check the front, middle, and back of the blade. The gauge should move with a little bit of resistance. Write down your numbers so you can see if something is off. For better accuracy, use feeler gauges that measure as small as 0.01 mm. If you want to be extra sure, use dial indicators or straightedges. These tools help you see if the blade gap is the same everywhere.

팁: Always check the gap again after you adjust it. When your measurements are steady, your perforation quality gets better.

After measuring, run the machine with no material inside. This lets you see if the blade moves smoothly and the pressure is right. Try cutting scrap material that is like what you use for real jobs. Look at the cuts and make small changes if you need to. These steps help your blade gap setting perforating machine work well every time.

Setting and Securing

After you measure, you must set and lock the perforating blade knives. Use the machine’s screws or bolts to move the blade. Adjust it until the gap is the same all the way across. Use a torque wrench to tighten everything to the right level. Tightening things right stops the blade from moving or shaking. This keeps your perforation quality high.

Check the gap again with your feeler gauge after you lock the blade. This makes sure the gap did not change. Take away all tools and clean up before you start the machine again. Being careful and safe helps you keep your perforation process steady and good.

메모: Using the right tools and following each step helps your perforating blade knives last longer. It also keeps your machine working well.

일반적인 실수

If you make mistakes while setting the blade gap, you can get bad perforation or machine problems. Try not to make these common mistakes:

- Not turning off or locking the machine before you start. This can be dangerous.

- Using the wrong or old measuring tools. If you use dirty feeler gauges or stack them wrong, your gap will not be right. This can make rough edges, burrs, or torn material. These problems lower cut quality and wear out the blade faster.

- Tightening screws too much or too little. If you do not use the right screwdriver, the blade might not lock. The gap could stay the same. This makes the blade loose and hurts the quality of the perforation.

- Not checking the gap along the whole blade. If you skip spots, you get uneven holes and less consistency.

- Not using the right cannulated hexagonal screwdriver. Only this tool fits the screw nut inside and locks the blade tight. This keeps the blade fixed and gives you the best perforation quality.

| 실수 | 결과 |

|---|---|

| Incorrect measuring tools | Poor gap accuracy, bad perforation |

| Improper screwdriver | Unlocked blade, unstable fixation |

| Skipping safety steps | Injury risk, machine damage |

| Incomplete gap checks | Uneven perforation, low consistency |

알리다: You must learn how to use measuring tools and adjustment equipment the right way. If you make mistakes, your blade gap setting perforating machine will not work well. This can also hurt the quality of your perforating blade knives.

Troubleshooting Perforating Blade Knives

Uneven Perforation

Uneven perforation is a problem in many factories. Sometimes, the holes or cuts do not line up. The perforation can look rough or messy. Knowing why uneven perforation happens helps you fix it fast and keep your work looking good.

The main reasons for uneven perforation are:

- Folds that are not straight, which can happen if the material is fed wrong.

- The side lay distance is not set right, or the side guide marble weight is wrong.

- Static electricity, rollers that are not set well, or curled paper.

- The fold rollers move at different speeds, or the pull-out wheels on the slitter shaft are used wrong.

- The perforation blade is not put on right or is facing the wrong way.

Before you try to fix things, check how the folding setup and machine are adjusted. Small changes to the fold plates can help the rollers move at the same speed. This stops uneven perforation. Always make sure the perforating blade is put on the right way and goes in the correct direction. This helps stop the perforation from getting worse.

When you use Nanjing Metal perforating blade knives, follow these steps to fix problems:

- Look at the cutter protection strip. If it has cuts or holes, change it.

- Check how far the blade sticks out. It should not be more than a credit card below the holder.

- Change the cutting force and speed for your material. Use the maker’s rules and test before you start working.

- Look at the blade’s shape. If the edges are rough or torn, use a blade that fits your material.

- Clean the blade and machine often to get rid of dirt or glue.

- Make sure the material goes in smoothly and does not stop.

- Change the pressure and tension to fit the material and blade.

You should change blades when they get dull or broken. Check if the blade lines up with the anvil often to stop uneven perforation. If you need something special, try 맞춤형 블레이드 made for your job.

팁: Keep a log of cleaning, blade changes, and fixes. This helps you find problems early and keep your perforation quality steady.

Inconsistent Line Length

If the line length is not the same, your product may not look or work right. Some lines may be longer or shorter, which can cause trouble when using or packing the product.

Many things can make line length different:

| 요인 | 설명 |

|---|---|

| 블레이드 재질 | How hard, rust-proof, and heat-proof the blade is changes how well it cuts and how even the lines are. |

| Tooth Profile | The shape of the teeth changes how the blade cuts and lasts, which affects how neat the perforation is. |

| 절단 속도 | The speed changes heat and blade wear. If the speed is wrong, the lines can be uneven. |

| 유지 | Sharpening and cleaning the blade keeps it sharp and helps the line length stay the same. |

| 재료 호환성 | Using the right blade for your material (paper, plastic, metal) is important for even perforation. |

| 사용자 정의 | Special blade shapes for your material or package help make the perforation better and more even. |

Other reasons are bad design or wrong settings for the perforation process, tools with bad shapes or surfaces, and problems with the tube material or heating.

If the blade is not lined up right, the line length can change. You can see this if the cuts are uneven, have rough edges, burrs, or chips. To fix these problems:

- Check the blades for damage or rough spots.

- Change the blade clearance to fit the thickness of the material.

- Set up the machine again and check if the blade is lined up.

- Change or sharpen blades if needed.

- Clean and oil blades often.

- Make sure the material is held down and supported during cutting.

Check and fix things often to stop problems later. Use good measuring tools to set up and watch the blade closely.

재료 찢어짐

Material tearing, sometimes called breakaway on holes, happens when the punch goes too deep. This can make the back of the plate tear in ways you did not expect. You might also see burrs, wavy edges, or bent edges. If the space between the punch and die is wrong or the material is brittle, it can also cause tearing or slitting.

Blade wear is a big reason for material tearing. Old blades make rough cuts and can tear the material. To stop this, do these things:

- Pick the right blade for your material and job.

- Check blades before you use them for cracks, chips, or uneven wear.

- Follow the maker’s rules for speed and equipment.

- Keep blades in dry, airy places so they do not get damaged.

- Put blades on the right way and make sure they are tight.

- Use even pressure when cutting to stop overheating and wearing out the blade too soon.

- Watch the blade while you work and change it if it gets worn.

- Do not use the blade for jobs it cannot handle.

- Wear safety gear to stay safe.

- Teach workers how to use blades safely and spot dangers.

- Take care of cutting machines and change old parts.

- Use oil or coolant to lower friction and heat.

- Watch the room conditions that could change how the blade works.

- Buy blades from trusted makers.

알리다: Clean and check your perforating blade knives often. Oil them and store them right to make them last longer and stop material tearing.

If you see tearing a lot, check for blade wear, bad alignment, or wrong clearance. Change your machine settings and blades if you need to. For special jobs or materials, custom blades can help stop tearing and make your perforation better.

Blade Wear and Damage

Blade wear and damage can cause big problems for your perforating process. You need to check your perforating blade knives often to keep your machine working well. If you do not check for blade wear, your cuts will look rough or uneven. Dull blades make more friction and make the machine work harder. You might hear strange noises or feel more shaking when you cut. These are signs that your blades need help.

Watch for these signs of blade wear and damage: Dull edges can leave rough or jagged cuts. More friction during cutting can slow down the machine. You might hear odd sounds or feel extra shaking when the machine runs. Look for cracks, chips, rust spots, or bends on the blade. Edges that are uneven or chipped are also a problem.

Check your blades under bright light. Use a magnifier to find small cracks or chips early. Clean your blades after every use. Put oil on them to stop rust and keep them sharp. Change the blade depth and pressure as the blades get worn. This helps keep your perforation quality high.

Checking and caring for your blades helps you avoid costly machine stops. Most people check blades every day or week, depending on how much they use the machine. Sharpen your blades every 40 to 80 hours if you use them a lot. Change them between 200 and 500 hours, or sooner if you see damage. Watch for signs like slower cutting, uneven cuts, or more noise. These mean you need to sharpen or change your blades.

A simple maintenance schedule can help you:

| 일 | 빈도 | What to Check |

|---|---|---|

| 시각 검사 | Daily/Weekly | Cracks, chips, rust, dullness |

| 날카롭게하다 | 40-80 hours | Edge sharpness, cutting quality |

| 대사 | 200-500 hours | Severe wear, damage, or lost quality |

| Cleaning/Oiling | 매번 사용 후 | Remove debris, prevent rust |

팁: Keep a log of all blade changes and care. This helps you see patterns and plan new blades before problems start.

If you use Nanjing Metal perforating blade knives, you get blades made from strong materials. These blades last longer and resist damage better. Still, you need to check your blades often to keep your machine and blades in good shape. If you see any damage, change the blade right away. This keeps your perforation lines neat and your machine safe.

Machine Vibration Issues

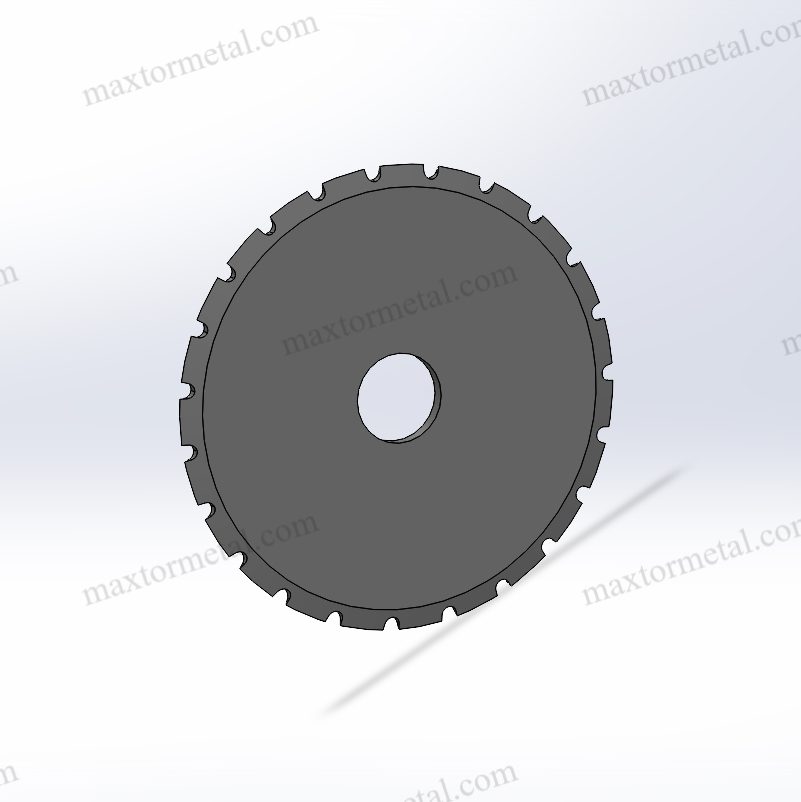

Machine vibration can ruin your perforation quality and hurt your equipment. You might see uneven perforation, hear loud noises, or even get blade damage if your machine shakes too much. The main reason for vibration is resonance. This happens when the blades hit the anvil cylinder at a speed that matches the cylinder’s own shaking speed. When this happens, the anvil cylinder shakes more, and the blades can bend or get dull.

You may see more vibration if you use many blades at once. For example, machines with six or eight blades on the cylinder can have more trouble. Making the anvil cylinder stronger or changing the bearings does not always fix the problem. Instead, you need to change the shape of the anvil or the knife blade cylinder. Some people use cylinders that are partly hollow or filled with special stuff. This changes how the cylinder shakes and helps stop resonance.

To fix vibration problems: First, check for loose bolts or parts. Tighten everything to the right level. Next, check if the blades are lined up right. Blades that are not lined up can cause uneven perforation and more shaking. Look for worn or damaged blades and change them if needed. Make sure the anvil and blade cylinders are in good shape. If the machine still shakes, ask your machine supplier about changing the structure.

알리다: Never ignore machine vibration. It can cause blade damage, bad perforation, and even break your machine.

You should always check for vibration as part of your troubleshooting. Regular care, good alignment, and using high-quality perforating blade knives help lower vibration. This keeps your machine running well and your perforation lines even.

Troubleshooting Micro-Perforating Machine

Micro-Perforation Challenges

Micro-perforating machines have special problems that regular perforating does not. These machines make very tiny, exact holes. This job is harder for both the machine and the person using it. Here are some main problems you might see:

- Getting the right hole depth and accuracy is tough. Old punch and laser ways can make holes too shallow or messy.

- Punching can crush soft things like wood veneer. This can break the holes and stop air from moving well. It also makes sound work worse.

- Lasers cut better, but they can burn the material. The heat can change how the product looks and how long it lasts.

- Regular perforation cores can block tiny holes. This stops sound from being absorbed. Newer core designs help keep almost all holes open.

- Micro-perforating machines cost more to buy and fix. Small companies may find these costs hard to pay.

- You need trained workers to use these machines. This means you spend more on training and pay.

- Laser machines do not like too much heat, wetness, or dust. These things can make the machine work worse.

- Some materials do not work with micro-perforating. You also have to follow strict rules, which makes things harder.

You need to watch out for these micro-perforating machine problems. Fixing micro-perforating machine issues often means looking for these special problems.

Pressure and Speed Adjustments

Pressure and speed are very important in micro-perforating. If the pressure is too high, the material can tear or get crushed. If the pressure is too low, the holes might not go all the way through. You must find the best setting for each job.

Start by setting the pressure for your material’s thickness and type. Do test runs to see what happens. Change the speed of your micro-perforating machine to match the pressure. Going too fast can make heat, especially with lasers, and this can burn or bend the material. Going slower gives you more control but takes longer.

Always check the holes after you change something. Look for clean, even holes with no burns or rips. If you see a problem, make a small change and test again. Fixing micro-perforating machine problems is often about getting these two settings just right.

팁: Write down your pressure and speed settings for each material. This helps you fix problems faster next time.

Material Thickness Considerations

How thick your material is changes how your micro-perforating machine works. Most micro-perforating machines work best with thin or medium-thick materials. Laser micro-perforating can handle more thicknesses, like metals, ceramics, plastics, and mixed materials. You can use lasers for thicker plates than other machines.

Cold needle micro-perforators are best for thin materials. They do not use heat, so the material stays the same. You can use them for rubber, fake leather, wood veneer, plastics, paper, and non-woven stuff. The holes can be about 50 microns to 1.8 millimeters wide. Laser micro-perforators make even smaller holes, from 40 to 200 microns, and are good for thin films and tricky patterns.

When fixing micro-perforating machine problems, always check if your material is the right thickness. Using the wrong thickness can make holes not go through or hurt the material. You should also think about how bendy or heat-sensitive your material is before you start.

메모: Always use the right micro-perforating machine and method for your material’s thickness and type to get the best results.

Monitoring and Fine-Tuning

You have to watch your micro-perforating machine closely for good results. Checking the machine often helps you find micro-perforating machine issues early. Watch the machine every time it runs. Listen for new sounds or changes in speed or shaking. These things can mean the micro-perforating process needs a fix.

Make a simple checklist to help you check things. This keeps you organized and helps you find problems fast. Here is an example:

| Monitoring Task | What to Check | How Often |

|---|---|---|

| 시각 검사 | Blade alignment, wear, debris | Every shift |

| Sound Check | Unusual noises, vibration | Every run |

| Hole Quality | Clean, even micro-perforating | Every batch |

| Speed/Pressure Review | Consistent settings | 주간 |

Use a magnifier to look at the micro-perforating holes. Make sure the holes are clean and even. If you see rough edges or blocked holes, change the machine settings. Fine-tuning means making small changes to pressure, speed, or blade spot. Change one thing at a time and test after each change. This helps you learn what works best for your material.

팁: Write down every change and fix you make. This helps you remember which settings give the best micro-perforating results.

You can use sensors or cameras to watch the micro-perforating process as it happens. These tools tell you about micro-perforating machine issues right away. If you see the quality drop, stop the machine and check your list. Troubleshooting means checking if the blade is sharp, lined up, and if the material feeds right.

Teach your team to spot signs of trouble. Show them how to use the checklist and write down changes. Working together keeps your micro-perforating machine running well. When you fine-tune, always test on scrap material first. This saves good material and keeps your machine safe.

Checking and fine-tuning often helps you stop costly stops. You make your product better and help your micro-perforating blades last longer. By doing these steps, you get good at fixing micro-perforating machine problems and keep your line working well.

Optimization for Perforation Performance

정기 유지 관리

You keep your perforating machine working well by doing regular maintenance. Cleaning, checking, and oiling your equipment stops breakdowns and helps it last longer. You should look at the perforating blade knives every day for damage or wear. After each shift, take away dust and dirt from the machine. Put oil on moving parts to lower friction and stop them from getting too hot.

A regular maintenance plan helps you find problems early. You can use a simple checklist to keep track of cleaning, blade changes, and oiling. This habit helps with optimization and keeps your machine reliable. Teaching your team good maintenance steps makes things safer and cuts down on machine stops. ACME Industries saw faster work and fewer accidents after training their workers.

Maintenance tips: Clean blades and machine parts every day. Look for cracks or chips. Oil gears and shafts once a week. Change old perforating blade knives before they hurt quality.

Routine maintenance is the base for making your machine work better. You protect your money and keep your production line moving.

운영자 교육

Operator training is very important for good perforation and machine reliability. You need to know how to set up, care for, and fix your equipment. Makers often give training at your site and user guides to help you learn. Hands-on training teaches you how to use perforating blade knives and change the machine for different materials.

Training programs show you how to set the shaft gap, care for bushings and bearings, and keep counter knives sharp. You learn to clean tools and use good parts. Testing perforation in its final use helps you see if it works well. Keeping logs of setups helps you avoid making the same mistakes and supports optimization.

A study found that operators with training made fewer mistakes and did more steps right. You get better results and fewer machine problems by using these training methods. Operator training makes things safer, faster, and improves product quality.

Upgrading Components

Upgrading machine parts gives you better results and longer blade life. You can pick perforating blade knives made from strong materials like high-speed steel (HSS) or tungsten carbide. These blades stay sharp longer and do not wear out fast, so you change them less and have less downtime.

| 블레이드 재질 | 주요 특징 | Benefits for Perforating Machines |

|---|---|---|

| 고속도강(HSS) | Strong, sharp, and tough | Stays sharp longer, cuts better |

| 텅스텐 카바이드 | Very hard, heat resistant | Lasts a long time, does not wear out quickly |

| Coatings (PVD, CVD) | Makes the surface harder and smoother | Blades last longer and cut better |

Custom blades made from these materials fit your machine and job needs. You get better accuracy and can use them for different materials. Upgrading to good perforating blade knives lowers waste and saves on repairs. You also make your products better and keep your machine working well.

You should think about upgrading parts as part of your optimization plan. This step helps you control quality and reach your production goals.

프로세스 개선

You can make your machine work better by improving your process. Start by using quality management systems that people trust around the world. ISO 9001:2015 certification helps you write down and check every step in your work. This system makes you do careful checks and follow the same rules each time. Your team gets better at making the same good product and following rules.

Standard operating procedures, or SOPs, are very important for quality. Write easy steps for every job, like putting in blades or cleaning the machine. Check and change these SOPs often to keep them up to date. When everyone does the same thing, you make fewer mistakes and get better perforation. SOPs also help new workers learn faster.

You should also make sure your press is lined up right. When the press is lined up, you get even holes and smooth edges. For steel, you can pick all-across punch presses or section punch presses. All-across punch presses are good for thin sheets and fast jobs. Section punch presses are better for thick materials and can make many patterns with CNC programming. Choose the right press for your material and job to keep your machine working well.

New stamping methods can help your process too. Hydraulic stamping gives steady force for even holes. Mechanical stamping is good for fast, nonstop work. Mechanical servo stamping lets you set the stroke for tricky patterns and fast work. Each way helps your machine work better and makes your product good.

Laser perforation is another way to make your process better. Laser beam splitting makes sure every hole is the same size by spreading energy evenly. Closed-loop laser pulse monitoring checks that you get the right number of tiny holes. If a pulse is missed, the machine stops so you do not get bad products. Closed-loop laser power control keeps the laser strong and steady, so your holes stay the same. These controls help you keep your product good every time.

You should also check your work often. Look at your perforation lines and machine settings on a schedule. Use checklists to remember to clean, change blades, and do maintenance. This helps you find problems early and keep your machine working its best.

팁: Always try to get better. Look at your process, ask workers for ideas, and find ways to make your line safer and faster.

When you work on process improvements, your machine works better, your product is higher quality, and you have fewer problems. You also make your workplace safer and more dependable for everyone.

예방 조치

유지 관리 일정

You need a clear plan to keep your machine working well. Regular checks help you find problems early. Make a daily, weekly, and monthly schedule for your perforating machine. Each day, clean the blade area and check for loose bolts. Every week, look at the blade gap and check for wear on the perforating blade knives. Each month, check the whole system for alignment and lubrication.

A simple table helps you organize your maintenance tasks:

| 일 | 빈도 | Responsible Person |

|---|---|---|

| Clean blade area | 일일 | Operator |

| Check blade gap | 주간 | Technician |

| Lubricate moving parts | 월간 간행물 | Maintenance Team |

Maintenance tips: Always follow the manufacturer’s rules for each job. Use only approved tools and wear safety gear.

If you stick to your schedule, your machine lasts longer and works better. You also lower the chance of sudden breakdowns.

Documentation

Good records help with optimization and maintenance. Keep a logbook for every machine. Write down each maintenance job, blade change, and adjustment. Note the date, the task, and who did it. This helps you see patterns and find problems that happen again.

You can use a computer or a notebook. Make sure everyone knows how to fill out the log. Look at the records during team meetings. This habit helps you decide when to change parts or update your maintenance plan.

Keeping good records makes troubleshooting faster and easier. You save time and do not repeat mistakes.

성능 모니터링

You should watch your machine’s performance to find issues early. Listen for new noises, more vibration, or changes in cutting quality. Use checklists to help with inspections. If you see a drop in performance, fix the problem quickly.

Use sensors or manual checks to measure blade gap and alignment. Compare your results with old records. If you see a pattern, change your maintenance schedule or process. This helps you keep your blade gap setting perforating machine troubleshooting and performance optimization working well.

Regular maintenance tips: Set reminders for checks and reviews. Ask your team to help watch and report problems.

By following these steps, you keep your machine reliable and your production line running smoothly. You also help with long-term optimization and maintenance for your business.

You get the best results when you follow every step for blade gap setting, troubleshooting, and optimización de cuchillas perforadoras. Good blades from Nanjing Metal help you make clean cuts and keep your machine working well, even for micro-perforating jobs. Doing regular maintenance and always working on optimización helps your machine run without problems. You can share your stories or ask our sales engineers for help 여기. When you give feedback, it helps everyone get better.

또한 참조

종이 타공 칼날의 일일 유지보수 팁: 청소, 윤활, 연마 및 칼날 끝 보호 규칙

플라스틱 필름 타공 칼날 최적화: 속도, 압력 및 톱니 모양 매칭