Start by cleaning your 천공 칼날 after each use to maintain a sharp edge and ensure smooth, safe cuts. Proper use and regular maintenance can extend the blade’s lifespan by up to 200% and reduce blade changes by 70%. The table below highlights how best practices improve performance with a perforated knife, delivering greater precision and safety in industrial applications:

| 성과 지표 | Scissor-type Knife | Conventional Knife |

|---|---|---|

| Submucosal dissection time (minutes) | 6.2 | 15.6 |

| Circumferential incision time (minutes) | 8.4 | 13.8 |

| En bloc resection (%) | 90 | 70 |

| Adverse events: Perforation or muscle injury (%) | 10 | 70 |

Perforated knives are widely used in packaging, textiles, and food processing industries. For optimal results, consider a 커스텀 블레이드 tailored to your specific needs.

주요 요점

- Always clean and dry your perforated knife after you use it. This helps keep it sharp and stops rust from forming.

- Pick the right blade material and shape for your job. This makes the knife work better and last longer.

- Hold the knife at a 15 to 30 degree angle. Use steady pressure to make smooth and easy cuts.

- Change the blade if it gets dull, chipped, or cuts rough. This keeps you safe and helps your work stay good.

- Think about getting custom blades from trusted makers like Nanjing Metal. This helps you get the best fit and knives that last longer.

Perforated Knife Basics

What Is a Perforated Knife

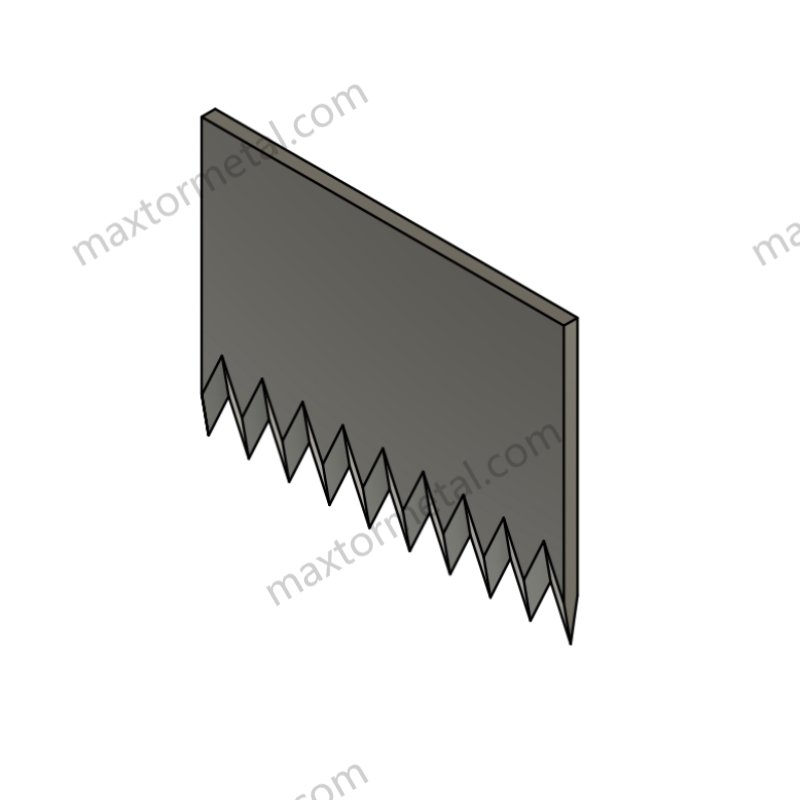

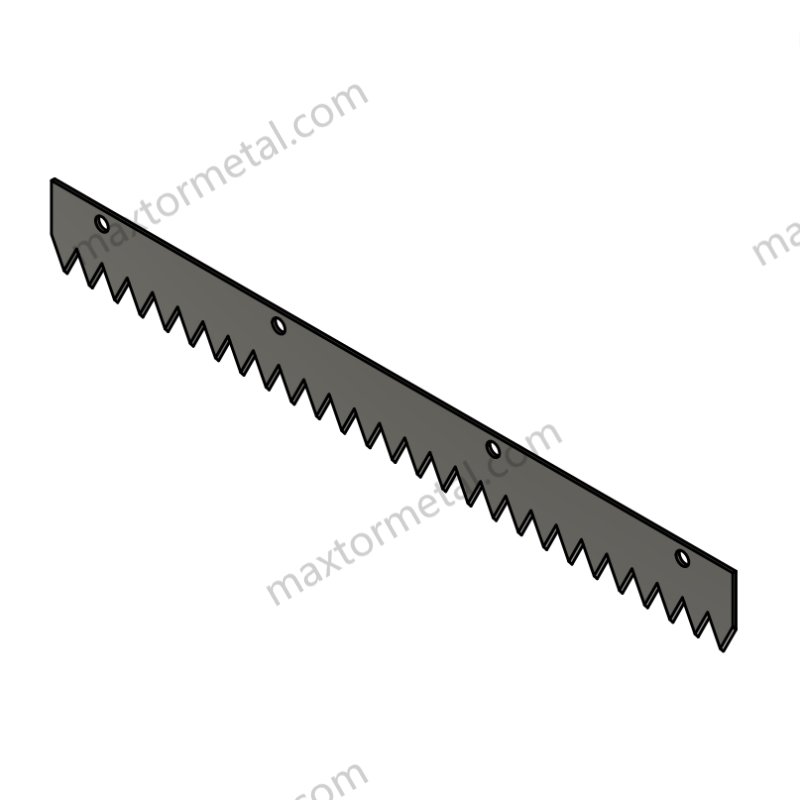

A perforated knife is a special tool for cutting. It makes small cuts or holes in things. This helps make weak lines so you can tear or split things easily. The blade has sharp parts and spaces with no edge. This pattern is called the “cut and tie” ratio. You see perforated knives when you open packages or tear notebook paper. They also help remove labels.

The table below lists the main technical details and uses for a perforated knife:

| 측면 | 세부 |

|---|---|

| 재료 | High-Speed Steel (HSS), Tool Steel, Stainless Steel, Tungsten Carbide, Powder Metallurgy Steels |

| Blade Shapes | Straight, Rotary, Toothed, Circular, Custom shapes |

| 작동 원리 | Applies pressure to create intermittent cuts; cut and tie ratio controls tearability and strength |

| 일반적인 응용 프로그램 | Packaging, Paper products, Food processing, Textile and leather, Manufacturing, Office supplies, Labels |

Key Features and Benefits

Perforated knives have many good points for cutting jobs. Here are some main features and benefits:

- There are many blade types, so you can pick what works best. You can use straight, rotary, toothed, or circular blades.

- The knife is made from strong metals like solid carbide steel. This means it stays sharp and lasts longer.

- The cut and tie ratio lets you control how easy it is to tear. You get neat and exact cuts every time.

- Perforated knives are used for packaging, food wrap, bubble wrap, tape, cardboard, and medicine packs. They are also used in notebooks, labels, and textiles.

- These knives make it easier to open boxes and packages.

Tip: Always pick the right blade shape and metal for your job. This helps your knife work better and last longer.

Using Your Perforated Knife Effectively

Best Materials and Tasks

A perforated knife works best when you use it on the right materials. Different materials react in their own way to the serrated edge. The table below shows how each material and coating can help your knife last longer and work better:

| 재료 | 주요 특징 | 일반적인 응용 프로그램 |

|---|---|---|

| 고탄소강 | 단단하고 오래 지속되는 | Paper cutting, light-duty tasks |

| 스테인레스 스틸 | Rust-resistant, durable | Food and medical packaging |

| 텅스텐 카바이드 | Extremely hard, long-lasting | Plastics, textiles, high-speed machinery |

| 세라믹 | Lightweight, rust-free | 전자제품, 공예품 |

| 공구강 | 튼튼하고 열처리 가능 | Custom blades, heavy-duty cutting |

Tungsten carbide and stainless steel are very strong. These materials help the knife stay sharp for a long time. You will not need to change blades as often, so you can keep working.

종이와 판지

You can use a serrated knife to cut paper and cardboard. This is good for packaging, labels, and crafts. The perforated edge lets you tear along the line easily. It does not ruin the rest of the sheet. This way, you waste less paper and get straight edges.

플라스틱 필름

Plastic films like shrink wrap need a sharp, serrated blade. A perforated knife with a strong edge cuts these films fast. You will see less sticking and tearing. This helps you finish your work up to 20% faster.

Thin Metal Sheets

In factories, people use a serrated knife to cut thin metal sheets. The knife makes small holes or lines in the metal. This makes it easier to shape or split the metal. If you change the blade shape, you can lower stress on the knife by 27%. This helps the knife last longer.

Textiles and Fabrics

People who make clothes or furniture use a perforated knife for fabric. The serrated edge lets you cut straight lines or shapes. The fabric does not fray. This keeps your cuts neat and helps you work quickly.

식품 가공 응용 분야

In food factories, a serrated knife slices bread and other foods. The perforated edge gives you even slices and less crumbling. Stainless steel blades are best for food. They do not rust and stay sharp.

Tip: Pick the right blade material and edge shape for your job. This will help you work better and keep your knife sharp longer.

Proper Cutting Technique

You get the best results by using the right cutting method. Studies show that holding the knife at a 15-30 degree angle works well. Use even pressure to cut your work time in half. You also get smoother cuts and your blade lasts longer.

Secure the Material Firmly

Put your material on a flat, steady surface. Hold it tight so it does not move. This keeps your hands safe and helps the knife cut well.

Hold the Knife at the Correct Angle

Hold the knife at a 15-30 degree angle to the material. This lets the serrated edge cut into the surface. A 30-degree angle helps you cut faster and better.

Apply Even Pressure

Push down with steady, even force. Do not press too hard or too soft. Even pressure helps the knife last longer and gives you smooth cuts.

Use Smooth, Controlled Motions

Move the knife in a slow, steady way. Do not jerk or force the knife. This keeps the edge sharp and protects your material.

Inspect the Blade Regularly

Check the knife’s edge often for dull spots or dirt. A clean, sharp edge works best. Change the blade if it gets chipped or does not cut well.

Note: Using the right angle and pressure helps you get better results. It also keeps your knife sharp for a longer time.

안전 팁

Always follow safety rules when you use a serrated knife. These tips help you stay safe and keep your knife in good shape.

Always Wear Cut-Resistant Gloves

Wear cut-resistant gloves to protect your hands. Even a small slip can cause a bad cut with a sharp knife.

Keep Fingers Away from the Cutting Path

Keep your fingers and hands away from the knife’s path. Plan your cuts so your hands do not get close to the edge.

Store the Knife with a Blade Guard

After you finish, put a blade guard on your knife or store it safely. This stops accidents and keeps the edge sharp.

Clean the Knife After Each Use

Clean your knife every time you use it. Wipe the serrated edge with a soft cloth to remove dirt. This stops rust and keeps your knife ready.

Replace Damaged or Dull Blades Promptly

If you see chips or the blade is dull, change it right away. A sharp, undamaged blade is safer and works better.

Safety Reminder: Never hurry when using a serrated knife. Take your time to stay safe and keep your knife working well.

Perforated Knife Maintenance

Taking care of your serrated knife helps you get the best results every time you use it. Good knife care keeps your blade sharp, safe, and ready for any job. You can follow these steps to make sure your serrated knife lasts longer and works better.

Cleaning and Drying

Keeping your serrated knife clean is the first step in knife care. A clean knife cuts better and stays sharp longer. You should always clean your knife after each use.

Disconnect Power and Remove Blade Safely

If you use a machine knife, turn off the power before you touch the blade. Always wait for the machine to stop moving. Remove the serrated knife carefully. Hold the handle, not the edge. This step keeps you safe and protects the knife.

Use Mild, Non-Corrosive Cleaners

Choose a gentle cleaner for your serrated knife. Strong chemicals can damage the blade. Mild soap and warm water work best. This keeps the knife free from rust and stains.

Wipe with a Soft Cloth or Sponge

Use a soft cloth or sponge to clean your knife. Scrub along the serrated edge. Do not use rough pads. A soft touch keeps the knife in good shape.

Avoid Abrasive Tools Like Steel Wool

Never use steel wool or hard brushes on your serrated knife. These tools scratch the blade and make it dull. Stick to soft materials for knife care.

Dry Thoroughly to Prevent Rust

After you clean your knife, dry it right away. Use a dry towel to wipe the serrated edge and handle. Water left on the knife can cause rust. Store your knife only when it is completely dry.

Tip: Always clean your knife after every use. This simple step keeps your serrated knife sharp and ready.

Sharpening and Honing

A sharp serrated knife makes every cut easier. You need to sharpen your knife to keep it working well. Many people ask how to sharpen your knives, especially serrated ones. You can follow these steps to properly sharpen a serrated knife.

Use a Whetstone or Professional Sharpener

You can sharpen a serrated knife with a whetstone or a tool made for serrated blades. Some people use a round file for the grooves. A professional sharpener can also help you get the best edge.

Maintain the Original Blade Angle

When you sharpen, keep the same angle as the original edge. Most serrated knives have a special angle. This angle helps the knife cut better. If you change the angle, the knife may not work as well.

Apply Even Pressure During Sharpening

Push gently and evenly when you sharpen. Too much force can damage the serrated edge. Move the sharpener along each groove. This keeps the knife sharp and safe.

Inspect for Chips or Damage Before Use

Look at your serrated knife before you use it. Check for chips, cracks, or dull spots. If you see damage, sharpen the knife or replace it. Good knife care means checking your blade often.

Seek Professional Maintenance for Industrial Knives

If you use your serrated knife in a factory or for heavy work, ask a professional to sharpen it. Industrial knives need special care. A professional can properly sharpen a serrated knife and fix any problems.

Note: You should sharpen a serrated knife only when needed. Too much sharpening can wear down the blade.

Storage Tips

Storing your serrated knife the right way is part of good knife care. Safe storage keeps your knife sharp and protects you from cuts.

Store with a Blade Guard or in a Case

Always put a blade guard on your serrated knife before you store it. You can also use a case. This keeps the edge safe and stops accidents.

Keep in a Dry, Cool Environment

Store your knife in a place that is dry and cool. Heat and moisture can damage the serrated edge. A dry spot helps prevent rust.

Avoid Stacking or Overlapping with Other Tools

Do not stack your serrated knife with other tools. The edge can get dull or chipped. Give each knife its own space.

Label and Organize for Easy Access

Keep your knives organized. Use labels or a special holder. This makes it easy to find the right serrated knife when you need it.

Safety Reminder: Safe storage is a big part of knife care. It keeps your serrated knife sharp and ready for every job.

What to Avoid

Some things can harm your serrated knife. Avoid these mistakes to keep your knife in top shape.

Do Not Use Acidic or Alkaline Solutions

Never clean your serrated knife with strong acids or bases. These can eat away at the blade. Stick to mild cleaners for knife care.

Avoid Prolonged Exposure to Air or Moisture

Do not leave your knife out in the open or in water. Air and moisture can cause rust. Always dry and store your serrated knife right away.

Never Store Without Proper Protection

Do not put your serrated knife in a drawer without a guard. The edge can get damaged. Use a blade guard or case every time.

Do Not Use Excessive Force During Cleaning or Sharpening

Do not press too hard when you clean or sharpen your knife. Too much force can bend or break the serrated edge. Gentle care works best.

Avoid Improper Storage That May Cause Damage

Do not store your serrated knife with heavy tools or in a crowded space. The blade can get chipped or dull. Give your knife its own spot.

Callout: Good knife care means cleaning, sharpening, and storing your serrated knife the right way. These steps help your knife last longer and work better.

Blade Replacement and Signs

When to Replace the Blade

Knowing when to replace your knife blade helps you keep every cut clean and safe. You should watch for certain signs that show your knife needs a new blade. If you notice any of these, it is time to act.

After Noticeable Decrease in Cutting Performance

You may see your knife does not cut as well as before. The material might tear instead of slicing smoothly. If you need to push harder or the cut looks rough, your knife blade has lost its sharp edge. This is a clear sign you need to replace it.

When the Blade Shows Visible Damage or Chips

Look closely at your knife. If you see chips, cracks, or missing pieces on the edge, you should stop using it. Damaged blades can break during use. This puts you and your work at risk.

Following Manufacturer’s Recommended Replacement Schedule

Manufacturers often give a schedule for changing your knife blade. You should follow this advice. Regular replacement keeps your knife working at its best. It also helps you avoid sudden problems.

If the Blade Fails to Cut Cleanly or Leaves Jagged Edges

A good knife makes smooth, straight cuts. If your knife leaves jagged or rough edges, the blade has become dull. You should replace it right away to keep your work neat and safe.

When Switching to a New Material That Requires a Sharper Edge

Some materials need a sharper edge for a clean cut. If you plan to cut a new type of material, check your knife first. If the edge is not sharp enough, put in a new blade. This helps you get the best results.

Tip: Always check your knife before starting a new job. A fresh blade saves time and gives you better cuts.

Warning Signs of Wear

You can spot blade wear by looking and listening. These warning signs help you know when to replace your knife blade.

Dull or Rounded Cutting Edge

A sharp edge feels smooth and even. If you run your finger (carefully) along the edge and it feels dull or rounded, the knife will not cut well. Dull blades make your work harder and less safe.

Increased Effort Required to Cut

If you notice you need to use more force to cut, your knife blade has worn down. This extra effort can lead to mistakes or even injury.

작동 중 비정상적인 소음

Listen for strange sounds when you use your knife. Squeaking, grinding, or rattling noises can mean the blade is damaged or out of alignment.

Visible Nicks, Chips, or Cracks on the Blade

Check your knife for small nicks, chips, or cracks. Even tiny flaws can grow worse with use. Replace the blade if you see any damage.

Inconsistent or Uneven Cuts

A worn knife blade may leave uneven or wavy cuts. If your cuts do not look straight or clean, the edge may be too dull or damaged.

Accumulation of Debris or Rust on the Blade Surface

If you see rust or debris building up on your knife, it can affect how well the blade works. Clean your knife often, but if the edge still looks bad, replace the blade.

Note: You can use a caliper or micrometer to check if your blade has become too thin. If the blade cannot hold a sharp edge after you sharpen it, it is time for a new one.

교체 지연의 위험

Waiting too long to replace your knife blade can cause many problems. You should know the risks so you can avoid them.

Reduced Cutting Quality and Efficiency

A dull or damaged knife blade makes poor cuts. Your work will take longer, and the results will not look as good.

Higher Risk of Material Damage or Waste

A worn blade can tear or crush the material instead of slicing it. This leads to waste and extra costs.

Increased Likelihood of Operator Injury

Using a dull knife means you need to push harder. This raises the chance of slips and cuts. Keeping a sharp edge helps you stay safe.

Potential Damage to the Knife Holder or Machine

A blade that is too dull or damaged can strain the knife holder or machine. This may cause costly repairs or downtime.

Greater Downtime Due to Unexpected Blade Failure

If your knife blade breaks during use, you must stop work to fix it. Replacing blades on schedule helps you avoid these delays.

Callout: Watch for signs of wear and replace your knife blade before problems start. This keeps your work safe, fast, and high quality.

Perforated Industrial Machine Knives & Custom Solutions

맞춤형 혜택

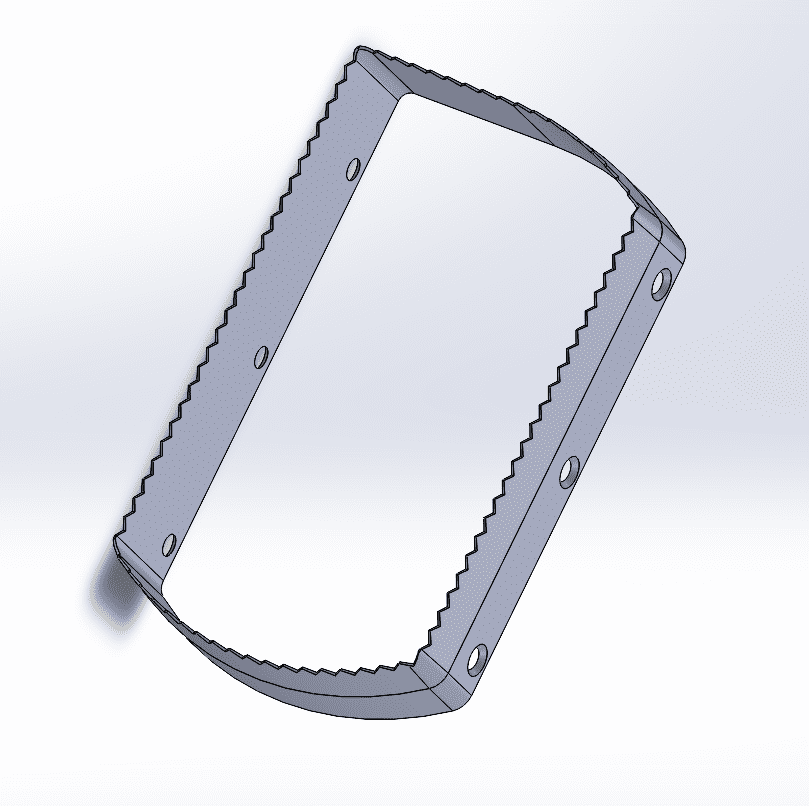

You get better results with perforated industrial machine knives made for you. Custom perforated industrial blades help fix special cutting problems at work. You can pick the blade’s shape, size, and what it’s made of. This way, your knife fits your job perfectly.

Custom knives let you:

- Match the blade to what you cut, like paper, plastic, or metal.

- Choose the best “cut and tie” ratio for easy tearing and strong edges.

- Make cuts cleaner and safer, so you waste less material.

- Save money because the knife lasts longer and needs fewer changes.

Using perforated industrial blades made for your work gives you more control. You can cut faster and use less effort. Your products look nicer, and your team stays safer. Many businesses, like packaging, textiles, and food processing, use these custom blades to keep things running well.

난징 Metal 개요

Nanjing Metal is a top company that makes perforated industrial machine knives. Nanjing Metal has made these blades for over 20 years for many jobs. Their skilled engineers and modern machines make sure you get the right knife.

You get good quality from them:

- They have ISO certification and check quality at every step.

- Laser machines measure each knife to make sure it’s the right size.

- Heat treatments make the blades strong and tough.

- They test each knife to last up to 10,000 uses.

- Both experienced and new engineers work together to make better blades.

- You get updates so you can see where your order is.

They gives both OEM and ODM services. You can send your own design or ask them to help make a new blade. Their team helps you pick the best material and design for your job. They also have good prices and make importing easy.

Note: The right knife from a trusted maker helps you do your best work every day.

You get the best results from your knife when you follow simple steps. Clean and dry your blade after each use. Give special care to your tool, especially when you cut bread. Replace the blade when you notice it struggles to slice bread or leaves rough edges. Choose custom solutions if you often cut bread in large amounts. Good care keeps your work safe and your slices perfect.

자주 묻는 질문

How often should you clean your perforated knife?

You should clean your knife after every use. This keeps the blade sharp and prevents rust. Use a soft cloth and mild soap. Dry the knife well before storing it.

What materials can you cut with a perforated knife?

You can cut paper, cardboard, plastic films, textiles, and thin metal sheets. Some blades also work for food processing. Always choose the right blade for your material.

How do you know when to replace the blade?

Look for dull edges, chips, or rough cuts. If you need more force to cut, it is time to change the blade. Regular checks help you spot problems early.

Can you get a custom perforated knife for your business?

Yes! Many manufacturers offer custom blades. You can choose the shape, size, and material.

또한 참조

천공 산업용 블레이드: 포장 및 그 외 분야에서 정밀 절단의 핵심