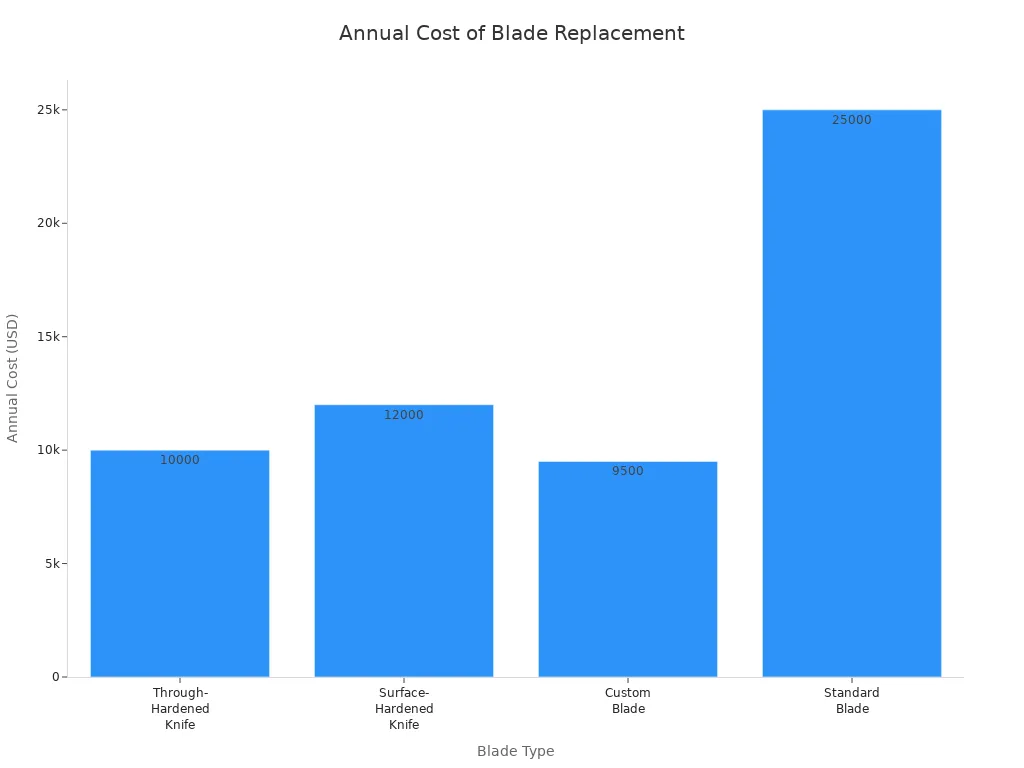

그만큼 cost of plastic crusher blades replacement involves more than just the initial price. Companies incur annual expenses to replace these blades, which can range from $9,500 for custom blades to $25,000 for standard blades. The table below outlines the costs:

| 블레이드 유형 | 평균 수명 | 연간 교체 비용(100개 블레이드 기준) |

|---|---|---|

| 관통 강화 칼 | 12개월 | $10,000 |

| 표면 강화 칼 | 6개월 | $12,000 |

| 커스텀 블레이드 | 40일 이상 | $9,500 |

| 표준 블레이드 | 10일 | $25,000 |

Additional expenses such as downtime and routine maintenance also contribute to the total cost of ownership. Innovative designs for plastic crusher blades, like those offered by Nanjing Metal, help reduce the cost of plastic crusher blades replacement by extending blade life and improving machine efficiency. Companies that manage both blade replacement costs and maintenance expenses achieve greater value over time.

주요 요점

- The cost of plastic crusher blades changes with blade type, material, size, and supplier.

- Picking strong blades like OEM ones saves money. They last longer and stop machines from breaking often.

- Taking care of blades by cleaning and sharpening helps them last. It also makes the machine work better.

- Changing blades when needed stops machines from breaking. This lowers repair bills and saves energy.

- Blade material changes how long blades last and how much they cost. Hard materials like tungsten carbide last longer but cost more at first.

- Using the right blade type and material for the plastic helps cut better and makes less waste.

- Good suppliers give help, warranties, and quick delivery. This keeps machines working well.

- Watching total cost of ownership (TCO) helps companies choose better blades and plan maintenance.

Cost of Plastic Crusher Blades Replacement

Price Factors

The cost to replace plastic crusher blades depends on a few things. Companies need to think about blade type, material, and size when looking at the total price.

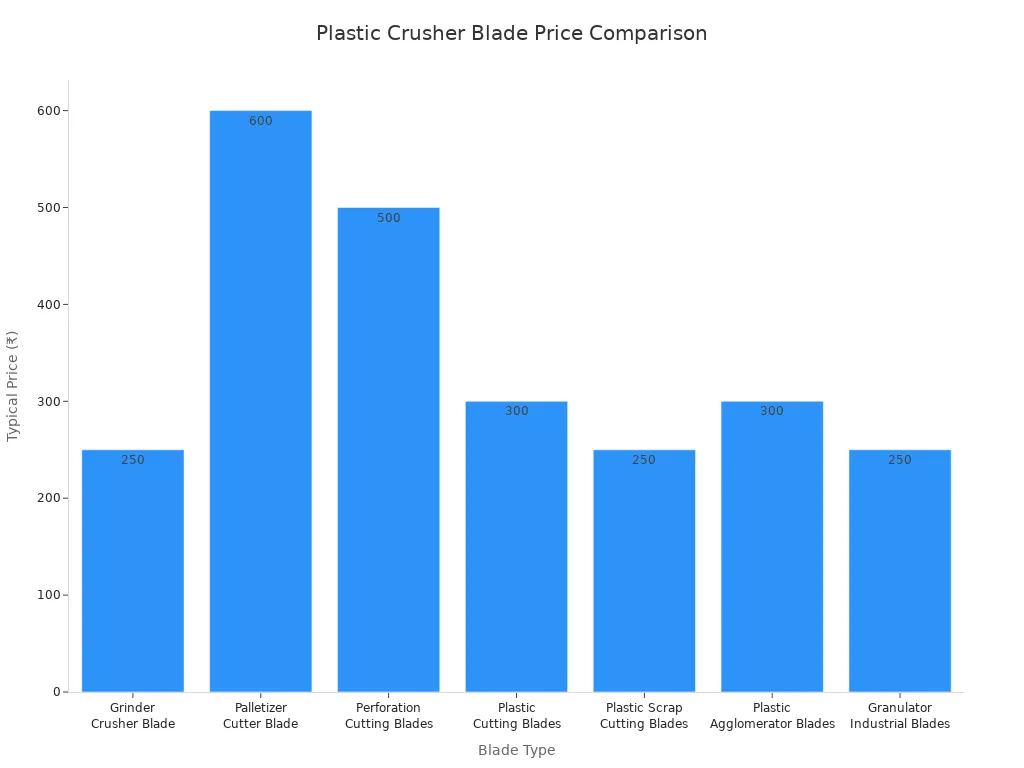

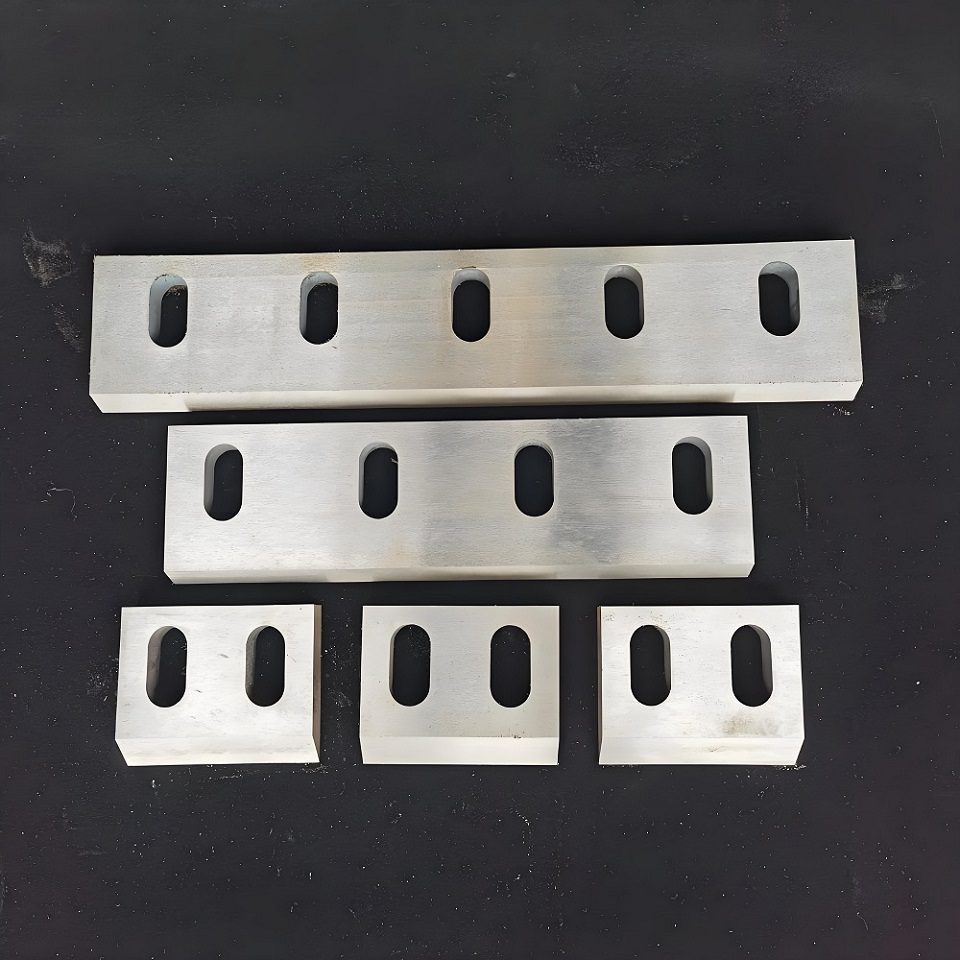

블레이드 유형

Plastic crusher blades come in different shapes. Some are rotor blades, stator blades, tubular blades, claw blades, or multi-edge blades. Each blade type does a special job in the crusher. This changes how well the crusher works and how much the blade costs. Rotor blades spin, while stator blades stay still. These are used in most plastic granulators. Tubular and claw blades are good for tough or odd-shaped materials. Multi-edge blades have more cutting sides. This means they last longer before needing to be replaced.

| 블레이드 유형 | Typical Price Range (₹) | Size Details | 재료 |

|---|---|---|---|

| Grinder Crusher Blade | 250 | As per requirement | 합금강 |

| Palletizer Cutter Blade | 600 | As per requirement | 합금강 |

| Perforation Cutting Blades | 500 | As per requirement | 합금강 |

| Plastic Cutting Blades | 300 | 8 Inch | 합금강 |

| Plastic Scrap Cutting Blades | 250 | As per requirement | 합금강 |

| Plastic Agglomerator Blades | 300 | As per requirement | 합금강 |

| Granulator Industrial Blades | 250 | As per requirement | 합금강 |

Blade prices change based on how they are made and what they do. Companies can order custom blades for their machines and materials. If you want special blades, check the 커스텀 블레이드 페이지 더 많은 선택을 위해.

재료

The material of the blade is very important. It changes both the price and how long the blade lasts. Different materials have their own features:

- 탄소공구강: This is cheap and tough. It is easy to sharpen. But it wears out fast, so you need to replace it often. It usually lasts 3 to 6 months.

- 고속도강(HSS): This is harder and lasts longer. It stays sharp for 6 to 12 months. It costs more than carbon tool steel, but you save money because it lasts longer.

- 합금 도구 강철: This is a good mix of price and strength. It often lasts 6 to 12 months. Many companies like this choice.

- 텅스텐 카바이드: This is very hard and strong. It costs the most but can last 12 to 24 months. It is best for companies that want to save money over time.

- Specialty Materials: Some blades use stainless steel or have special coatings. These help stop rust or lower friction. They are used for special jobs and have different prices and lifespans.

| 재료 | 초기 비용 | 장기 비용 | 수명 |

|---|---|---|---|

| 탄소공구강 | 낮은 | 높은 | 짧은 |

| 고속도강 | 보통의 | 보통의 | 중간 |

| 합금 도구 강철 | 보통의 | 낮은 | 긴 |

| 텅스텐 카바이드 | 높은 | 매우 낮음 | 매우 긴 |

Many companies switch from carbon tool steel to alloy tool steel or carbide. This helps them save time and money on blade replacement. If you need special materials, visit the 커스텀 블레이드 페이지 더 많은 옵션을 보려면.

크기

Blade size also matters for price and how well it works. Bigger blades need more material and careful making, so they cost more. Custom sizes for special crushers or plastics can also be more expensive. Companies should pick the right size for their machines. This helps them cut well and not waste money.

OEM vs Aftermarket

When buying new blades, companies pick between OEM and aftermarket blades. This choice changes both the first price and how much you spend later.

- OEM blades cost about twice as much as aftermarket blades. They use better materials, fit well, and have good warranties.

- OEM blades last longer and keep machines running. This means you spend less on replacing blades over time.

- Aftermarket blades are cheaper and arrive faster. But their quality can change, so you may need to replace them more often.

- OEM suppliers check quality, track orders, and give support. This helps companies fix machines faster.

- Aftermarket suppliers focus on low prices and quick shipping. Some have good warranties, but OEMs usually check quality more closely.

Tip: Companies should think about both the first price and long-term savings. Buying good OEM blades can lower the cost of replacement blades and make machines work better.

교체 빈도

How often you replace blades depends on the material, plastic type, and care. Companies that recycle a lot change blades more often because they wear out faster.

| 블레이드 재질 | Typical Lifespan Under High-Volume Use |

|---|---|

| 고속도강(HSS) | 3~6개월 |

| Tungsten Carbide-Coated | 6~12개월 |

| Usage Type | 재료 유형 | 교체 빈도 |

|---|---|---|

| Light Usage | Soft plastics or part-time | Every 6–12 months |

| Heavy-Duty Usage | Hard or abrasive plastics | Every 3–6 months |

| Heavy-Duty Usage | Fiberglass-filled plastics | Every 2 months |

Taking care of blades helps them last longer. Cleaning, oiling, and sharpening can make blades last up to 50% longer. Training workers and not overloading machines also helps.

Companies that check blade wear and replace them on time have less downtime and spend less money. Picking the right blade and taking care of it helps companies save on the cost of plastic crusher blades replacement and keeps crushers working well.

총 소유 비용

Knowing the total cost of ownership (TCO) for plastic crusher blades helps companies make smart choices and save money. TCO means all the costs, both direct and indirect, during the blade’s life. Companies need to think about more than just the first price. They should also look at costs for running the machine, fixing it, downtime, and how much energy it uses.

TCO 구성 요소

Initial Purchase

The first cost includes buying the blades, shipping, taxes, and putting them in. Blade prices go from $50 to $200, depending on size and material. Blades made from special alloys or with V-shaped designs cost more at first but last longer. Companies should remember the cost of new blades and how good blades last longer.

유지

Regular care means cleaning blades to get rid of plastic, oiling moving parts, and sharpening or balancing blades. It also means checking bearings and electrical parts. Companies need to plan for new parts and paying workers. Getting spare parts easily and using modular blade designs helps fix machines faster and costs less. Doing regular care makes blades last longer and saves money.

중단 시간

Downtime happens when blades are changed, during planned care, or if something breaks. When machines stop, companies lose time and pay more for workers. If orders are late, customers may not be happy. Keeping extra blades and parts in many places helps machines start working again quickly. Using smart systems to watch machines can stop surprise repairs and keep machines running.

에너지 사용

Energy use is a big part of the cost to run machines. Sharp blades and good machines use less power. Dull or broken blades need more energy to cut plastic. For example, a 10 kW crusher running for one hour uses 10 kWh, which costs about $1.30. Machines with energy-saving features, like frequency converters and smart feeding, use less power. Better cutting chambers and drives also help save energy and lower care needs.

TCO Calculation

Companies find TCO by adding up all costs, both direct and indirect, over a set time, like a year or the blade’s life. Direct costs are the first price and regular care. Indirect costs are downtime, energy use, and lost work from slow machines. The table below shows a sample TCO for different blade materials and uses:

| 요소 | 합금 도구 강철 | 텅스텐 카바이드 | 탄소공구강 |

|---|---|---|---|

| Initial Purchase | $120/blade | $200/blade | $50/blade |

| Maintenance (Annual) | $2,000 | $1,200 | $3,000 |

| Downtime (Annual) | $1,500 | $800 | $2,500 |

| Energy Use (Annual) | $1,000 | $900 | $1,300 |

| 교체용 블레이드 | 2/year | 1/year | 4/year |

| Total Annual Cost | $6,740 | $4,900 | $8,200 |

Note: Companies that buy better blades and do regular care spend less on repairs, downtime, and energy. Changing blades on time stops lost work and keeps machines safe.

Checking blade condition often, like looking at edge wear and how well it cuts, helps workers change blades before they get too dull. Inspections cost $500 to $750 each month but stop big problems and save time. Changing blades on time can save over $12,000 each year by using less fuel and keeping work going. Not checking blades leads to more broken parts and higher repair bills.

- Watching chip quality and how much energy is used helps find worn blades early.

- Changing feed rate, speed, and blade tension when needed keeps machines working well.

- Replacing dull blades right away helps machines cut better and makes blades last longer.

Companies that track TCO and improve care plans spend less and get more work done. Buying strong blades and using good systems means fewer repairs and replacements, which saves money in the long run.

Impact on Plastic Granulator Performance

블레이드 품질

Blade quality is very important for how well a plastic granulator works. Good blades are made with strong steel and special heat treatment. This makes the blades hard and tough against wearing out. Because of this, the blades stay sharp even when used a lot. Sharp blades cut plastic cleanly, so the pieces are all the same size. This helps make better products. Companies check blade hardness and sharpness to make sure they work well. When companies use strong blades, they do not need to change them as often. This means the machine does not stop working as much. The table below shows how good blades help the granulator:

| 측면 | Impact of High-Quality Blades |

|---|---|

| 재료 경도 | Increases wear resistance and durability |

| 절단 정밀도 | Ensures consistent granule size and product quality |

| 내마모성 | Reduces downtime for replacement, boosting production capacity |

| 에너지 소비 | Lowers motor load, saving electricity |

| Output Rates | Enhances throughput and reduces maintenance frequency |

Machine Downtime

Machines stop working when blades get dull or break. Dull blades do not cut well, so there is more dust and less plastic gets cut. If too much plastic is put in, it can sit on top of the blades. This can jam the machine or make the motor work too hard. These problems make the machine stop and cost more to fix. Newer machines have blades that are easy to adjust and fix. This helps the machine start working again faster. Changing blades quickly and putting them in the right way keeps the crusher running well. Machines with automatic feeding do not let too much plastic go in at once. This keeps the blades safe and stops the machine from breaking.

Tip: Having extra blades and using blades that are easy to change helps companies fix the crusher fast after it stops.

생산력

How much plastic a granulator can process depends on blade care. When blades get dull, the machine uses more power and works harder. The inside of the machine gets hotter, which can be dangerous. Old blades and screens make plastic pieces uneven and create more dust. If blades or screens get blocked, the machine slows down. Cleaning and sharpening blades often keeps cuts smooth and plastic pieces even. Checking and changing old blades and screens stops clogs and keeps the crusher working its best. Good care saves energy, lowers noise, and keeps the machine cool. It also means less time fixing the machine and spending money on repairs. Picking the right kind of blade, like staggered or paddle blades, helps the machine work faster and use less energy.

TCO Optimization Strategies

블레이드 선택

Picking the right blades is important to save money. Companies should choose blades that match the plastic they cut. Hard plastics need strong blades. Soft films need softer blades. The table below shows what to think about when picking blades:

| Criteria/Factor | 설명 |

|---|---|

| Plastic Type and Hardness | Hard plastics need tough blades; soft plastics need softer blades. |

| 블레이드 모양 | Straight for standard use, claw for thick plastics, flat for thin plastics, V-type for uniform size. |

| 블레이드 소재 | D2 (SKD-11) for wear resistance, 9CrSi for cost savings, HSS for high-volume and long life. |

| 기계 호환성 | Blade size and mounting must fit the crusher; custom blades may be needed. |

| 생산량 | High output favors efficient blades like V-type or claw blades. |

| Desired Output Size | Uniform granule size achieved with V-type blades and tight clearances. |

| 유지 관리 요구 사항 | Choose blades that match plant maintenance skills; some blades are easier to sharpen and replace. |

Blades that fit the machine and plastic work better. Custom blades can help cut plastic faster and break less. Companies can look at Nanjing Metal’s custom blades page 더 많은 선택을 위해.

유지보수 모범 사례

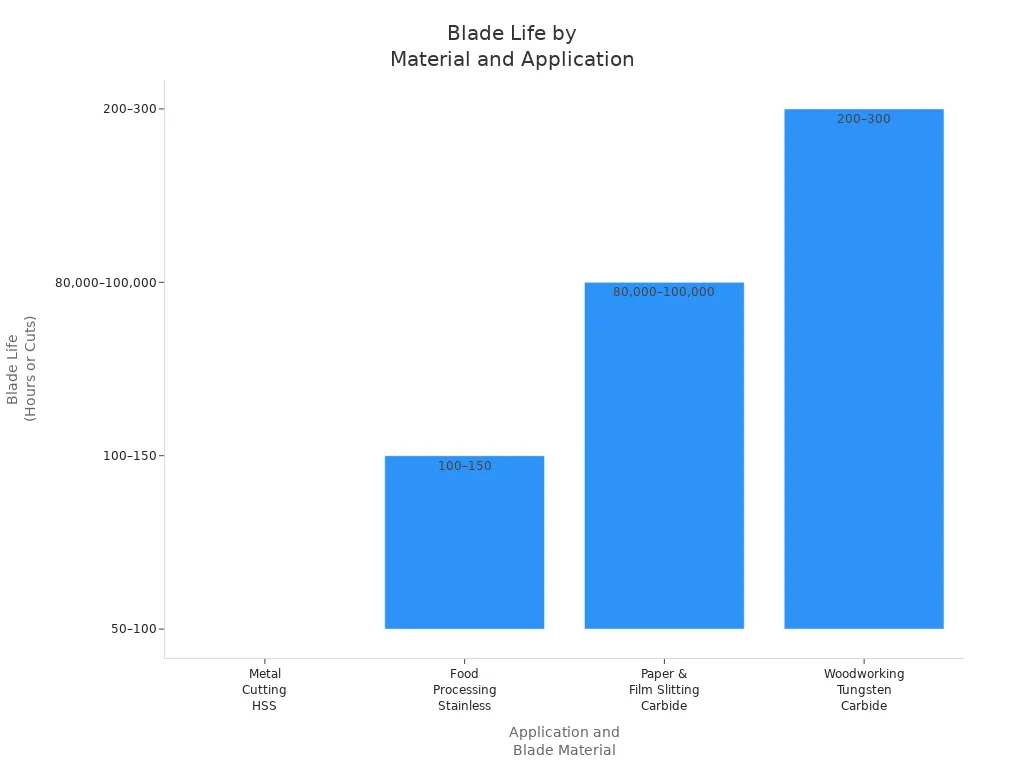

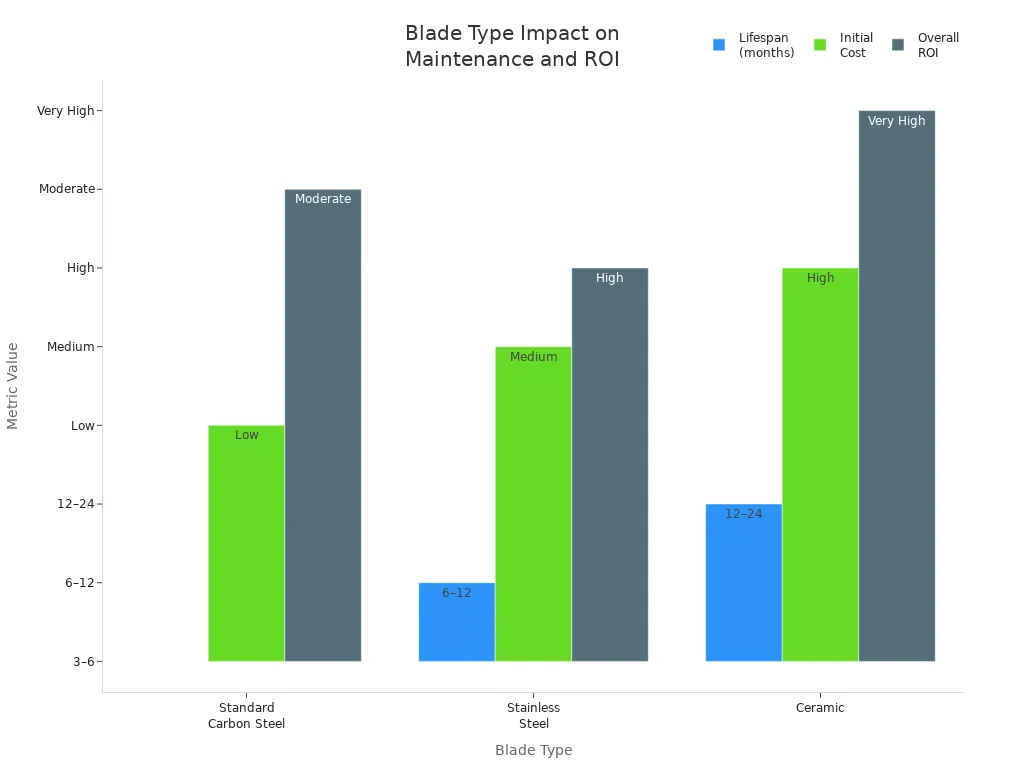

Taking care of blades helps them last longer. Using strong materials like tungsten carbide makes blades tougher. Good care means cleaning blades and the crusher every day. Bolts should be checked each week. Wires should be checked too. Oiling moving parts stops them from getting too hot. Workers should watch how much plastic goes in and change the speed for different plastics. The chart below shows how long blades last and how much they cost:

Blades that are cared for do not break as much. Factories that do regular care spend less on new blades. Cleaning, sharpening, and changing old parts stops big problems and saves money.

Tip: Training workers is very important. Trained workers know how to care for blades and keep them sharp. They also follow safety rules. This makes blades last longer and keeps machines working.

공급업체 지원

Good supplier support helps companies save money and time. OEM services, like Nanjing Metal, make sure blades fit and work well. Some suppliers offer help with sharpening, warranties, and fast shipping for new or special blades. Custom blades made for certain plastics work better and last longer.

Nanjing Metal helps companies fix machines faster and spend less on care. Their help includes design, buying materials, making blades, checking quality, and giving advice. These services make machines last longer and work better. Companies have fewer repairs, spend less, and get more value.

Warranty and Availability

보증 범위

Warranty coverage is important for the total cost of ownership. Most top suppliers give a one-year warranty for plastic crusher blades. This covers problems with materials or how the blades are made. Some suppliers let you pay more for extra protection. This helps buyers feel safe about their purchase.

A good warranty lowers risk for companies. If a blade breaks because of a factory mistake, the supplier will replace it for free. This helps companies save money and keeps machines working. In places like Europe and America, a 12-month warranty with CE certification is normal. This shows that the supplier cares about quality and trust.

When companies pick a supplier with a strong warranty, they worry less. They know help is there if something goes wrong. This means less downtime and better control over costs for plastic crusher blades replacement.

리드 타임

How fast blades arrive affects how well companies work. Quick delivery lets companies change old blades fast. This means machines do not stop for long. The table below shows how long it takes to get blades from big suppliers:

| 공급업체 | Condition | Lead Time (days) |

|---|---|---|

| Nanjing Metal | In stock | 3–4 |

| Nanjing Metal | Not in stock | 15 (negotiable by order qty and schedule) |

| Another Supplier | 1 set order | 15 |

| Another Supplier | Larger orders | Negotiable |

Nanjing Metal delivers fast when blades are in stock. They also work with buyers for bigger or special orders. Getting blades quickly helps companies avoid long stops in production. Suppliers with good stock and import services help companies plan repairs easily.

Blade supply also changes the total cost of ownership. Having more than one supplier and flexible orders helps companies avoid problems if supplies slow down. Companies working with Nanjing Metal get steady blade supply, even when demand is high or tariffs change. This means less downtime, fewer surprise costs, and smooth production.

Good warranty coverage and quick delivery from trusted suppliers help companies save money and keep machines running. These things help companies work better for a long time.

A plastic granulator works best when companies think about more than blade replacement cost. Good blades help machines run longer and use less energy. They also keep the regrind quality high. Companies should:

- Pick blade material that fits the granulator’s job.

- Keep blades sharp by cleaning and checking them often.

- Watch when blades need replacing to keep machines working.

- Train workers and do regular care for the granulator.

If companies want to save money and get the most value, they should talk to a sales engineer who knows a lot. 난징 Metal 팀에 문의하세요 for expert help with plastic granulator blades.

자주 묻는 질문

What factors affect the cost of plastic crusher blades replacement?

The price changes based on blade material, size, and type. The supplier you pick also matters. Blades made from tungsten carbide cost more but last longer. OEM suppliers make blades that fit better and last longer. This can help companies save money over time.

How often should companies replace plastic crusher blades?

How often blades need changing depends on how much they are used. It also depends on what kind of plastic is being cut and how well the blades are cared for. Heavy-duty work may need new blades every 3 to 6 months. Checking blades often helps companies know when to replace them.

Do OEM blades offer better value than aftermarket blades?

OEM blades fit machines well and use strong materials. They last longer and help machines run with less stopping. This makes them a better choice for saving money in the long run than many aftermarket blades.

How does blade quality impact machine performance?

Good blades stay sharp and do not wear out fast. This helps machines cut plastic well and use less energy. Machines with good blades stop less and can make more plastic pieces.

What maintenance practices extend blade life?

Cleaning blades, sharpening them, and oiling moving parts help blades last longer. Workers should not put too much plastic in the machine at once. Following the maker’s rules also helps. Doing these things means blades do not need to be replaced as often.

Can companies use the same blades for all plastics?

No, not all plastics use the same blades. Hard plastics need stronger blades. Softer plastics can use regular blades. Picking the right blade for the plastic helps machines work better and saves money.

How do warranty and lead times affect total cost of ownership?

A good warranty and fast shipping help companies fix machines quickly. This means less time waiting and fewer surprise costs. Suppliers give good support and quick blade delivery.

What are signs that blades need replacement?

If blades are dull, make uneven cuts, or create more dust, they may need changing. If the machine uses more energy, it can also mean blades are worn out. Workers should watch for these signs and change blades soon to keep machines working well.

또한 참조

산업용 기계의 OEM 및 애프터마켓 플라스틱 분쇄기 교체 칼날 선택

플라스틱 분쇄기 블레이드 교체 가이드: 언제, 어떻게 올바르게 교체하는가

플라스틱 분쇄기 vs. 펠릿화기: 플라스틱 재활용 효율성 향상을 위한 올바른 장비 선택 방법