A pointed tip blade is a tool with a sharp, narrow end. It is made for detailed and careful cutting tasks. Its special shape helps make clean and exact cuts, even in small or tricky areas. These blades are made for delicate work and are useful in many industries.

Pointed tip blades are used in things like factories and medical work. They are also helpful for crafts and daily chores, showing how flexible they are. Companies like Nanjing Metal make custom blades to fit specific needs, giving the best results. You can contact them for questions or special orders.

Key Takeaways

- Pointed tip blades are made for precise cutting. Their sharp, thin tips make clean cuts in small spaces. They are great for crafts, medical work, and industrial jobs.

- Using strong materials makes blades last longer. Tungsten carbide and stainless steel are common because they stay sharp and don’t break easily.

- Safety is very important with pointed tip blades. Always wear gloves, store blades safely, and don’t use too much force to avoid accidents.

- Taking care of your blades helps them last. Clean them after using to stop rust and sharpen them when needed to keep them working well.

- Custom blades can work better for certain jobs. They are made for specific tasks, helping you cut faster, waste less, and save money over time.

What Is a Pointed Tip Blade?

Alternate Names and Terminology

Pointed tip blades have different names in various fields. Some call them precision blades, fine-tip blades, or needle-point blades. These names show their use for detailed work. In crafts, they are often called hobby blades. In medicine, they might be known as surgical blades. No matter the name, they all have a sharp, narrow tip for accuracy.

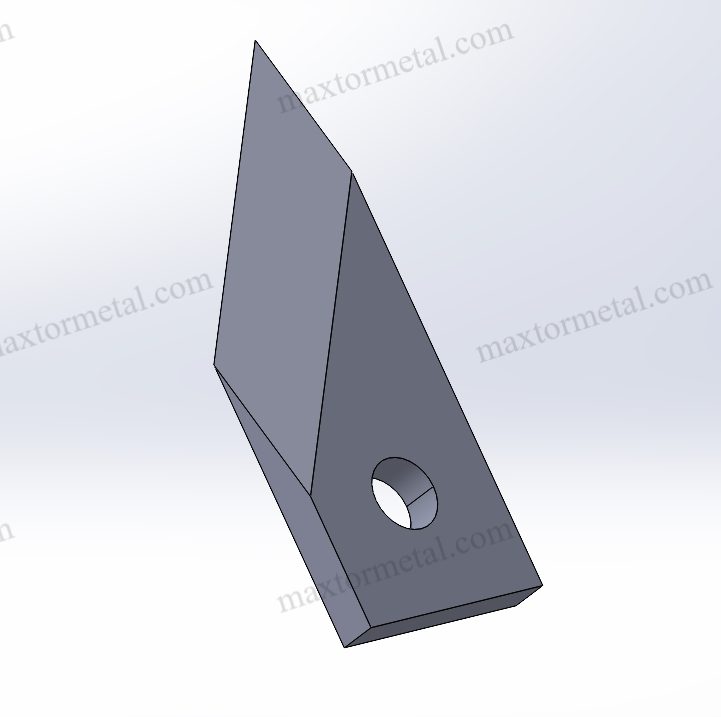

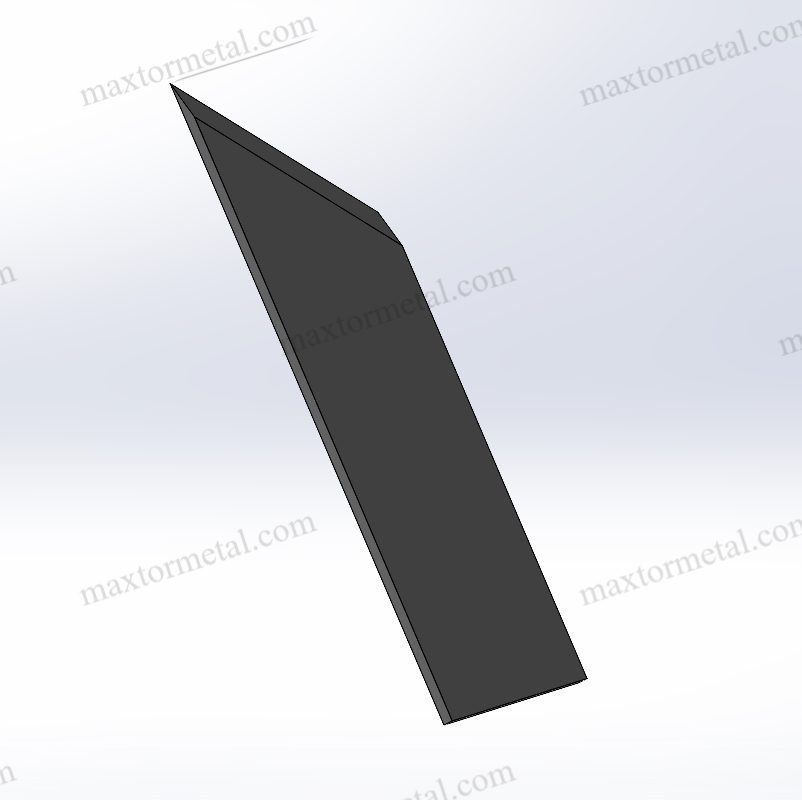

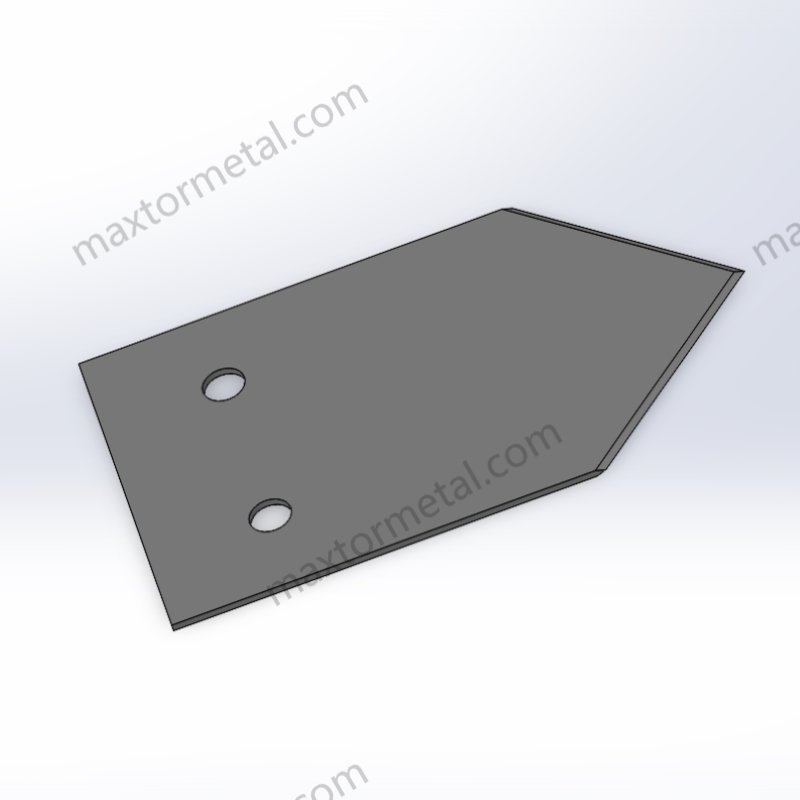

Design and Key Features

Pointed tip blades are made for precision and strength. They have a thin, sharp end for tight spaces or small details. Strong materials like stainless steel and tungsten carbide make them last longer.

Main features include:

- A sharp tip for detailed cutting work.

- Durable materials that resist damage and rust.

- Can fit with many tools for different uses.

This design makes them great for cutting, piercing, or opening items. They give clean cuts, even on hard materials.

How It Works

Pointed tip blades focus force on their sharp end. When pressed, the tip cuts into the material precisely. This is helpful for tasks needing careful cuts, like slicing thin layers or making patterns.

For example, in crafts, you can carve fine designs in paper or fabric. In factories, they cut tough materials like rubber or plastic. The sharp tip reduces effort and avoids damaging nearby areas.

Characteristics of Pointed Tip Blades

Materials Used

The materials in pointed tip blades affect how strong they are. Makers often use metals like tungsten carbide, stainless steel, and bi-metal alloys. Tungsten carbide stays sharp longer, making it great for precise work in fields like aerospace. Carbide-tipped blades are very strong and cut hard materials well. Bi-metal blades mix flexible steel with high-speed steel, making them tough and useful for many jobs.

| Material Type | Durability Features | Uses |

|---|---|---|

| Tungsten Carbide | Stays sharp longer, perfect for detailed tasks. | Aerospace and car part manufacturing. |

| Carbide-tipped | Very strong and cuts hard materials easily. | Heavy-duty jobs in cars and planes. |

| Bi-metal | Combines strong steel with flexible steel for many uses. | Common in factories for precise cutting. |

These materials help pointed tip blades work well for crafting or factory tasks.

Safety Considerations

Pointed tip blades need careful use to avoid accidents. Studies show the risks of sharp tips. For example, Nichols-Drew et al. (2019) studied injuries from pointed-tip knives, showing their dangers. Later, Nichols-Drew (2023) suggested rounded-tip knives for cooking to prevent accidents.

| Study Reference | Key Findings |

|---|---|

| Nichols-Drew et al. (2019) | Studied injuries caused by sharp knives, showing their risks. |

| Nichols-Drew et al. (2020) | Looked at clothing damage with rounded knives, supporting safer designs. |

| Nichols-Drew (2023) | Suggested rounded knives to save lives and reduce accidents. |

To stay safe, wear gloves and store blades safely. Don’t use too much force, as it can cause slips or breaks.

Maintenance and Durability

Taking care of your blade makes it last longer. Clean it often to stop rust and sharpen it to keep it working well. Tests show blades like the D40 can last through 152,500 uses, equal to 20 years. The D63 blade also stayed strong during tests, proving it works well under pressure.

- The D40 blade lasted 152,500 uses, equal to 20 years, with a load of ±6.9 kN.

- The D63 blade was tested 16,250 times and stayed strong.

- Both blades passed tests for strength and long-term use.

Good blades, like those from BAUCOR®, are trusted for precise work. Follow care tips to keep your blade working for a long time.

Applications of Pointed Tip Blades

Pointed tip blades are useful in many areas because they are precise and flexible. Their special shape helps with tasks needing careful control. Below are some ways they are used in different industries.

Industrial Uses

Cutting Materials

In factories, pointed tip blades are great for cutting many materials. They can easily slice rubber, plastic, or thin metal sheets. The sharp tip focuses the force on a small spot, making clean cuts. For example, in car-making, these blades cut detailed shapes from tough materials so parts fit perfectly.

Precision Work

When exactness is needed, pointed tip blades are the best choice. They are often used for engraving, trimming, or shaping items. Workers in factories use them to make detailed designs or remove extra material without harming nearby areas. Their ability to handle delicate jobs makes them important in electronics, where accuracy is key.

Medical Uses

Surgery

Doctors use pointed tip blades for surgeries because they make precise cuts. These blades help surgeons work carefully, especially in sensitive areas. Their sharp tips cause less tissue damage, helping patients heal faster. For example, during eye surgeries, the fine tip ensures careful cutting, lowering the chance of problems.

Diagnostic Tools

Pointed tip blades are also part of tools used for medical tests. Tools like biopsy punches or scalpels often have sharp tips to take tissue samples accurately. A study showed the success of a tool called the “Scissor-Tip-Separator,” which has a pointed tip. Over four months, no damage was reported, and 86.4% of users rated it highly. This shows how these blades improve medical tools, leading to better patient care.

| Evidence Description | Result |

|---|---|

| Damaged scissors needing repair yearly | 36 pieces |

| Scissors needing replacement yearly | 10 pieces |

| Time using ‘Scissor-Tip-Separator’ | 4 months |

| Reports of blade damage after use | 0 reports |

| Percentage of users rating it highly | 86.4% (38 users gave 5 stars) |

| Nurse feedback on scissor performance | No surgeon complaints during surgery |

Crafting Uses

Art Projects

Artists and crafters love pointed tip blades for their detailed work. These blades are great for carving designs, cutting stencils, or shaping paper, foam, or fabric. Their sharp tips make it easy to create fine patterns or delicate cuts. Whether for school projects or professional art, these blades offer the precision needed.

DIY Projects

For DIY fans, pointed tip blades are must-have tools. They help with tasks like cutting wallpaper or trimming extra material during home projects. Their flexibility makes them useful for both small and big jobs. For instance, in woodworking, a pointed tip blade helps carve detailed designs or adjust pieces to fit perfectly.

Everyday Uses

Kitchen Tasks

A pointed tip blade is handy for kitchen jobs. Its sharp end helps with precise tasks like peeling fruits or removing seeds. You can also carve designs into vegetables for decoration. Unlike big knives, this blade handles delicate work without harming nearby areas.

When cutting meat, it trims fat and separates small pieces easily. It’s also great for filleting fish, where careful cuts are needed. Many chefs choose this blade for jobs requiring control and skill.

Tip: Wash your blade right after using it. This stops food from dulling the edge. Dry it well to keep it sharp for next time.

Packaging Solutions

Pointed tip blades are great for opening packages and cutting tough materials. They quickly slice through boxes, shrink wrap, or tape without damaging what’s inside.

In warehouses, workers use these blades to open bulk packaging fast. At home, they’re useful for opening mail or cutting labels. Their sharp tips make clean cuts, perfect for tasks needing accuracy.

Note: Keep your blade stored safely after use to avoid accidents. Use a cover or a safe spot for storage.

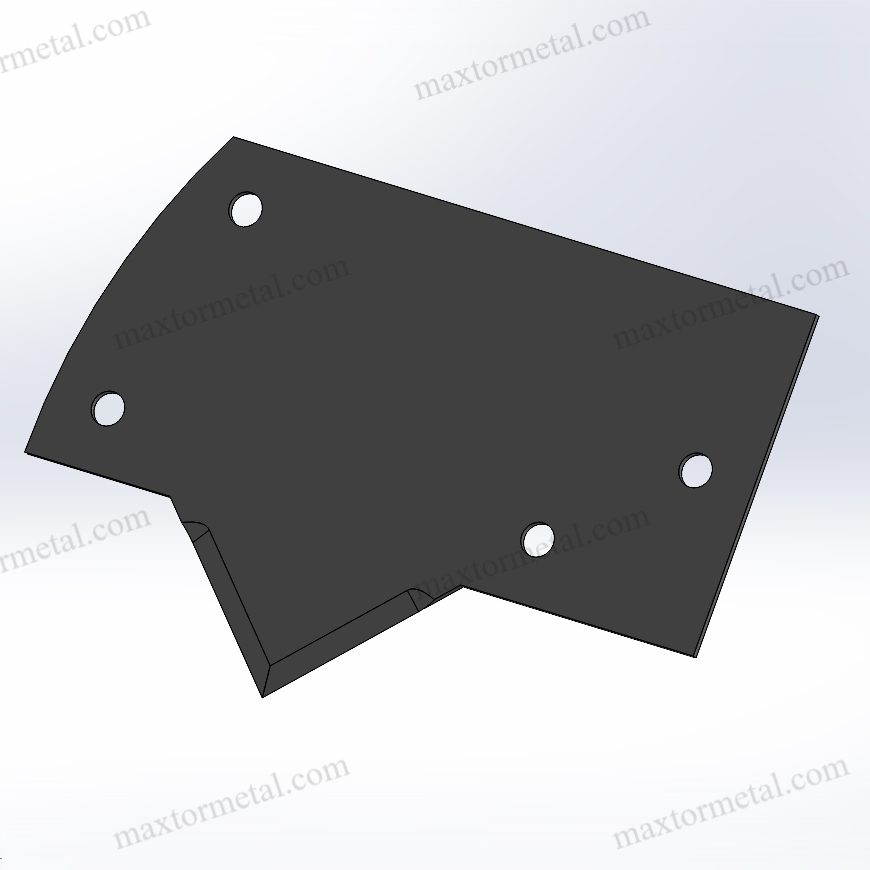

Customization and Manufacturing

Benefits of Customization

Making a pointed tip blade custom has many perks. One big benefit is precision. Custom blades are made to cut faster and cleaner. Another advantage is durability. Strong materials help the blade last longer, so you replace it less often. Custom blades also save money over time. While they may cost more at first, they reduce repair costs and material waste later. Plus, customization cuts down on waste. Tailored designs use fewer resources and avoid extra production.

| Benefit | Description |

|---|---|

| Precision | Custom blades cut faster and cleaner due to high accuracy. |

| Durability | Strong materials make them last longer, needing fewer replacements. |

| Cost Efficiency | Higher upfront costs save money on repairs and materials over time. |

| Waste Reduction | Tailored designs reduce waste and use resources wisely. |

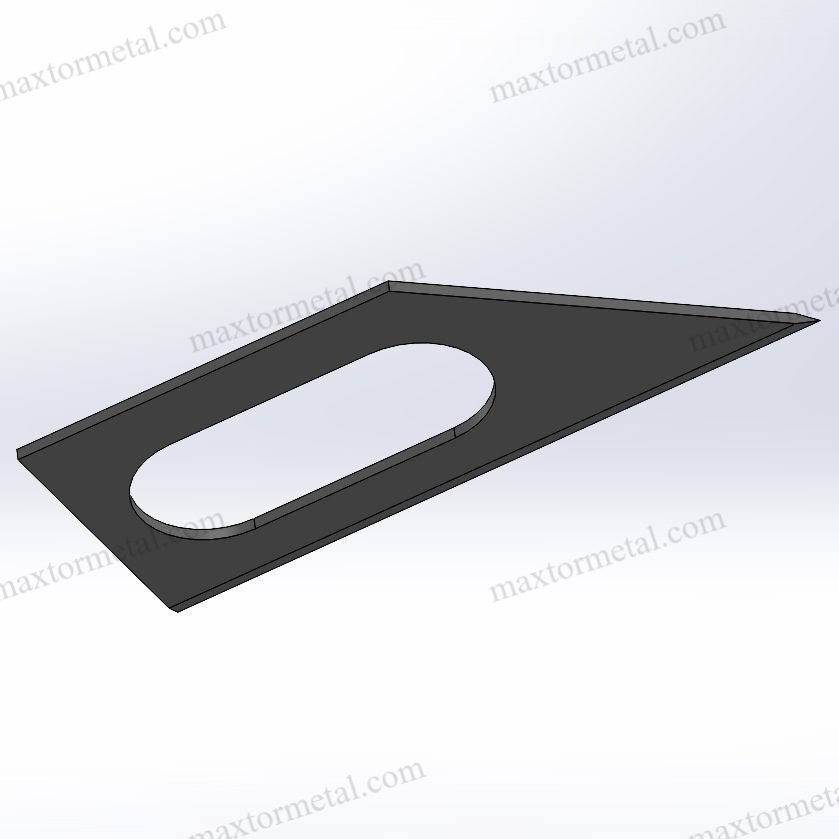

Manufacturing Process Overview

Making custom pointed tip blades uses advanced methods for better results. Point milling is a key step. It controls how the blade varies across its length. This makes the blade work better overall. Modified point milling improves performance under high pressure. It also boosts important metrics like choke margin and throat area.

- Point milling helps control blade variation for better performance.

- Even blade distribution improves how well the blade works.

- Modified designs handle high pressure and improve key metrics.

Nanjing Metal’s Custom Blade Solutions

Nanjing Metal is a trusted name in making industrial blades. With 18 years of experience, they create high-quality custom blades. Their skilled team designs blades to fit client needs. For example, a food company switched to Nanjing Metal’s custom serrated blade. They saw big improvements. Cutting speed went up by 22%. Blade life grew from two weeks to six weeks. Precision improved, with variance dropping to less than 0.5 mm.

| Metric | Before Customization | After Nanjing Metal Custom Blade | Improvement |

|---|---|---|---|

| Blade changes per week | 10 | 3 | –70% |

| Average cut scrap rate | 6.5% | 2.2% | –66% |

| Downtime due to blade wear | 4 hours/week | 1 hour/week | –75% |

Nanjing Metal ensures clients get blades that work better and last longer. Want to learn more? Contact their sales team for help.

Technological Advancements in Blade Design

New technology has changed how pointed tip blades are made. These changes make blades sharper, stronger, and more useful. Now, blades are designed to fit the needs of fields like medicine, crafting, and factories.

Enhanced Materials

Better materials now make blades last longer and stay sharp. Makers use special metals like titanium and ceramic mixes. These materials stop blades from rusting or wearing out quickly. This means you won’t need to replace them as often.

Tip: Choose blades with advanced materials for tough and precise jobs.

Laser Cutting Technology

Laser cutting has improved how blades are shaped. This method creates sharp edges and exact designs. It helps make cleaner cuts and wastes less material. Lasers also allow for detailed designs, perfect for surgery or crafts.

Smart Blade Integration

Some blades now have sensors to track their performance. These “smart blades” can tell when they need sharpening. In factories, they help workers avoid delays by giving alerts.

Eco-Friendly Manufacturing

Blade-making is becoming more eco-friendly. Companies now use less energy and recyclable materials. This helps the planet while still making high-quality blades.

| Advancement | Benefit |

|---|---|

| Advanced Alloys | Stronger, rust-resistant blades. |

| Laser Cutting Technology | Cleaner cuts, less waste. |

| Smart Blade Integration | Tracks wear and boosts efficiency. |

| Eco-Friendly Processes | Helps the environment. |

These updates make pointed tip blades better, meeting your needs with ease and reliability.

Knowing what a pointed tip blade does helps you pick the best tool. These blades are strong, safe, and useful in fields like medicine, crafts, and factories. Custom designs make them work better for your needs.

Nanjing Metal makes custom blades that save time and money. Their skilled team creates top-quality blades for your specific tasks. Check out their products to find the right blade for your job.

Tip: Contact Nanjing Metal’s experts for help with custom blade choices.

FAQ

1. What makes pointed tip blades unique?

Pointed tip blades have a sharp, thin end for accuracy. Unlike rounded or flat blades, they focus on small areas. This helps make precise cuts or pierce materials without harming nearby parts.

2. How should you store pointed tip blades safely?

Keep pointed tip blades in a case or sheath for safety. This stops accidents and keeps the blade sharp. Don’t leave them open in drawers or on desks where they could hurt someone.

3. Can you sharpen a pointed tip blade yourself?

Yes, use a fine sharpening stone or honing tool carefully. Slide the blade gently at the right angle on the stone. If unsure, ask an expert to avoid ruining the blade.

4. Are pointed tip blades good for beginners?

Yes, but beginners must be cautious. Follow safety rules like wearing gloves and practicing on easy materials first. Start with simple tasks to gain skill before trying detailed work.

5. How do you pick the right pointed tip blade?

Think about what you’ll cut and how precise it needs to be. For hard materials, pick tungsten carbide blades. For crafts or medical work, choose a fine, sharp blade for better accuracy.

Tip: Always pair the blade with the right tool and job for the best outcome.

See Also

How Blade Geometry Impacts Cutting Efficiency – A Guide to Smarter, Faster Industrial Cutting