| Outros nomes | craft hot knife, electric hot knives, foam cutter, hot knife blades, hot knife cutter, hot knives, industrial hot knife, plastic hot knife, rope cutter hot knife, thermal cutters, types of hot knives, webbing hot knife |

|---|---|

| Aplicativo | Automotive Industry, Carpet Installation, Construction, Crafts and Hobbies, Electrical Work, Foam Cutting, Gasket Manufacturing, Marine Industry, Packaging, Plastic Fabrication, Rubber Processing, Textile Industry, Webbing and Rope Cutting |

| Número do modelo | CB-HKB |

| Serviço OEM | Disponível |

| Termos de pagamento | L/C, T/T, Western Union, XTransfer |

| Pacote | Caixa de papelão, em caixas de madeira |

| Prazo de entrega | Based on Quantity |

Compartilhar com:

A hot knife, also known as a thermal cutter or electric hot knife, is a tool with an electrically heated blade used to cut through and sometimes seal synthetic materials by melting them. Unlike traditional cold cutting methods that can leave frayed edges on fabrics and other materials, a hot knife melts the material as it cuts, resulting in a clean, sealed edge that prevents fraying or unraveling. The term “hot knife” directly refers to the heated blade that performs the cutting action.

Hot knives are versatile tools with a wide array of applications across various industries and crafts due to their ability to cleanly cut and seal synthetic materials. Some common uses include:

The blades of hot knives are typically made from materials that can efficiently conduct and retain heat. Common materials include:

The blade may also be coated with materials like Teflon to reduce friction and prevent melted material from sticking to the blade, ensuring a smoother cut.

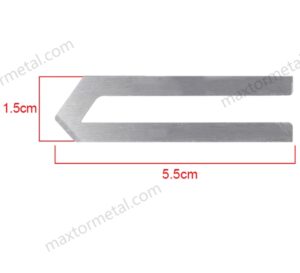

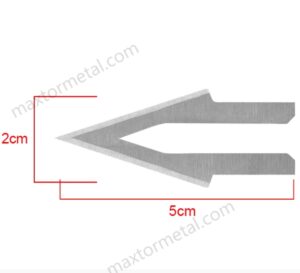

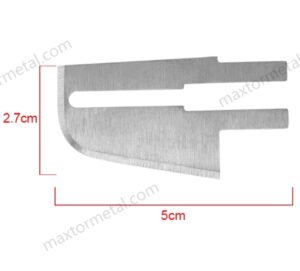

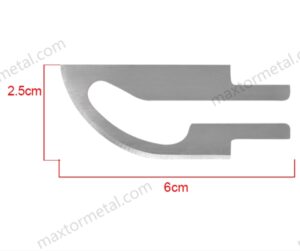

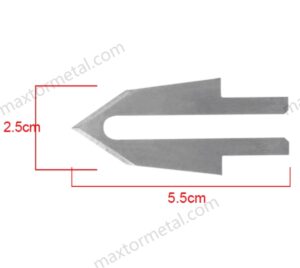

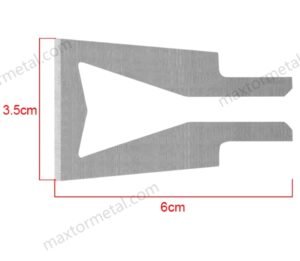

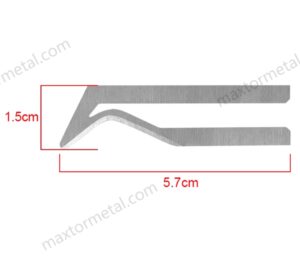

Hot knives come with a variety of interchangeable blade shapes to suit different cutting tasks and materials. Some common shapes include:

The working principle of a hot knife involves the electrically heated blade melting the synthetic material upon contact. The heat softens the material, allowing the blade to pass through with minimal resistance. For sealing, the melted edges resolidify quickly after the blade passes, creating a fused, clean finish. The temperature of the blade is often adjustable to suit different materials and cutting speeds.

Não oferecemos apenas tamanhos padrão de facas para canais superiores, mas também facas especiais projetadas para melhorar sua produtividade. Tudo que você precisa fazer é fornecer desenhos ou amostras.

Contact our friendly sales team today and they’ll help assess your specific needs and provide you with proven upgrade options. Alternatively, submit a quote request.

1. Serviço de importação completo e sem complicações

Fácil de aproveitar a conveniência da importação, do transporte ao desembaraço aduaneiro, nós cuidamos de todo o processo, você só precisa pagar o IVA e aguardar a chegada da mercadoria na empresa.

2. Preços competitivos

Vimos suas lâminas serem usadas em inúmeras aplicações e estamos prontos para lidar com qualquer projeto que você lançar em nosso caminho - oferecendo precisão, durabilidade e preços competitivos incomparáveis.

3. ODM e OEM disponíveis

Quer você forneça desenhos, esboços ou amostras, somos capazes de desenhar e fabricar para você. Também temos a capacidade de auxiliar na modificação de designs e especificações existentes para melhorar quase qualquer aplicação de ferramental industrial. Entre em contato com nossa equipe de vendas dedicada para discutir seus requisitos específicos.

4. Controle de qualidade

Uma série de testes e inspeções são realizados para controlar a qualidade, incluindo inspeção do primeiro artigo, inspeção do material recebido e materiais certificados, inspeção de qualidade em processo e inspeção de qualidade final.

5. Aquisição flexível, cooperação ilimitada

Seja você um importador, distribuidor, atacadista ou usuário final, convidamos você a se juntar a nós com o mínimo de quantidade mínima, sem complicações para consultas e mais liberdade para compras.

6. Monitor no exterior, relatório em tempo real do progresso da produção

Torne-se seu monitor exclusivo, transmita regularmente cada nó importante na linha de produção, não importa a distância, e acompanhe o progresso do produto o máximo possível!

Nanjing Metal Industrial CO., limitada

Parque Industrial Mingjue, Lishui, Nanjing, Jiangsu, China

Mantenha-se atualizado com nossas últimas notícias.