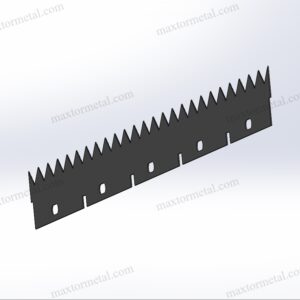

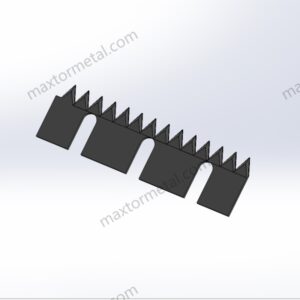

| Outros nomes | Lâminas para fazer sacos, facas para cortar sacos, lâminas para perfurar sacos, lâminas em forma de T, facas serrilhadas, lâmina serrilhada para máquina de embalagem vertical, faca dentada para máquina de embalagem vertical, lâmina serrilhada para embalagem vertical, faca dentada para embalagem vertical, lâmina serrilhada para máquina de embalagem vertical |

|---|---|

| Lugar de origem | China |

| Aplicativo | Plástico, embalagens, sacos, rolos |

| Material | Aço carbono |

| Número do modelo | CV-BM |

| Serviço OEM | Disponível |

| Termos de pagamento | L/C, T/T, Western Union |

| Pacote | Caixa de papelão, em caixas de madeira |

| Prazo de entrega | 7 a 20 dias |

Compartilhar com:

Packaging blades, also referred to as packaging machine knives, are specialized cutting tools designed for integration into packaging machinery. These blades perform a variety of cutting, slitting, perforating, and sealing tasks essential for preparing and processing packaging materials like films, foils, paper, cardboard, and various other flexible or rigid materials used to contain and protect goods. The term “packaging blades” is a broad descriptor encompassing a wide array of blade types tailored to the specific demands of different packaging equipment and processes.

Packaging blades are fundamental components in a multitude of automated packaging processes across diverse industries. Their applications are extensive and include:

The selection of materials for packaging blades is crucial to ensure food safety (where applicable), resist corrosion from various product and packaging material interactions, and maintain a sharp, durable cutting edge for consistent, high-speed operation. Common materials include:

Surface treatments and coatings like Titanium Nitride (TiN) or Chromium plating are often applied to enhance surface hardness, reduce friction, and improve resistance to wear and corrosion, thereby extending the lifespan of packaging blades.

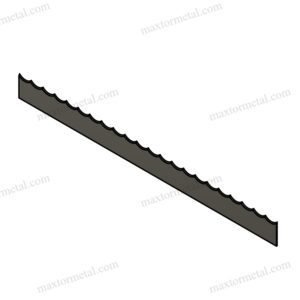

Packaging blades are manufactured in a wide variety of shapes and edge configurations to match the specific cutting or sealing mechanisms of different packaging machines:

The working principle of packaging blades varies depending on their function and the machine they are integrated into. Cut-off blades typically employ a shearing action against a fixed anvil or another moving blade. Sealing knives use heat and pressure to fuse and cut films. Rotary blades provide continuous cutting as they rotate against the material. The precision of the blade’s geometry, the sharpness of its edge, the applied force, and the synchronization with the machine’s operation are all critical factors in achieving clean, accurate cuts and reliable seals in packaging processes.

Bem-vindo ao investigar!

Caso não encontre a lâmina que procura, também podemos personalizá-la. Veja nosso “Lâminas Personalizadas"para aprender como!

Fácil de aproveitar a conveniência da importação, do transporte ao desembaraço aduaneiro, nós cuidamos de todo o processo, você só precisa pagar o IVA e aguardar a chegada da mercadoria na empresa.

Vimos suas lâminas serem usadas em inúmeras aplicações e estamos prontos para lidar com qualquer projeto que você lançar em nosso caminho - oferecendo precisão, durabilidade e preços competitivos incomparáveis.

Quer você forneça desenhos, esboços ou amostras, somos capazes de desenhar e fabricar para você. Também temos a capacidade de auxiliar na modificação de designs e especificações existentes para melhorar quase qualquer aplicação de ferramental industrial. Entre em contato com nossa equipe de vendas dedicada para discutir seus requisitos específicos.

Uma série de testes e inspeções são realizados para controlar a qualidade, incluindo inspeção do primeiro artigo, inspeção do material recebido e materiais certificados, inspeção de qualidade em processo e inspeção de qualidade final.

Seja você um importador, distribuidor, atacadista ou usuário final, convidamos você a se juntar a nós com o mínimo de quantidade mínima, sem complicações para consultas e mais liberdade para compras.

Torne-se seu monitor exclusivo, transmita regularmente cada nó importante na linha de produção, não importa a distância, e acompanhe o progresso do produto o máximo possível!

Nanjing Metal Industrial CO., limitada

Parque Industrial Mingjue, Lishui, Nanjing, Jiangsu, China

Mantenha-se atualizado com nossas últimas notícias.