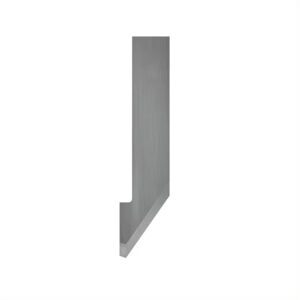

| Другие имена | Микро Лезвие |

|---|---|

| Место происхождения | Китай |

| Приложение | Metalworking, Производственное предприятие, Строительные работы |

| Номер модели | КБ-ПК |

| OEM-сервис | Доступный |

| Условия оплаты | Л/К, Т/Т, западное соединение |

| Упаковка | Картонная коробка, В деревянных ящиках |

| Срок поставки | 7-20 дней |

Поделиться с:

The term “Oscillating Knife” refers to a type of cutting tool that utilizes a rapid back-and-forth motion (oscillation) of the blade to achieve a precise and efficient cut through a variety of materials. Unlike rotary or static knives that rely on a continuous shearing action, Oscillating Knives use a high-frequency, short-stroke vibration to slice through materials with less friction and drag. This cutting method is particularly effective on soft, flexible, or fibrous materials that can be difficult to cut cleanly with traditional blades. Oscillating Knives are commonly used in automated cutting machines in industries such as textiles, leather, foam, rubber, packaging, and composites. The specific design of the blade and the frequency of oscillation are tailored to the material being cut and the desired cutting speed and precision. Oscillating Knives are also sometimes referred to as “vibrating knives,” “reciprocating knives (though the motion is typically short and high-frequency),” “high-frequency cutting blades,” or “servo-driven oscillating blades,” depending on the machine and the specific motion mechanism.

Oscillating Knives are versatile cutting tools with a wide range of applications across various industries due to their ability to handle diverse materials:

The specific type of Oscillating Knife blade (shape, material, edge) and the parameters of the oscillating motion (frequency, amplitude) are selected based on the material properties, thickness, and the complexity of the cut required.

The materials used to manufacture Oscillating Knives are chosen for their sharpness, wear resistance to withstand the vibrations and contact with various materials, and flexibility to endure the oscillating motion without fracturing. Common materials include:

Coatings are frequently applied to Oscillating Knives to enhance their performance and longevity. Common coatings include:

The selection of the blade material and coating depends on the specific materials being cut, the cutting speed, and the desired blade lifespan and cut quality.

Oscillating Knives come in a variety of shapes and edge configurations tailored to specific cutting tasks and materials:

The mounting mechanism of the Oscillating Knife is also crucial, ensuring secure attachment to the oscillating cutting head of the machine and allowing for quick blade changes. Different machines may use different mounting systems (e.g., screw-on, quick-release).

Если вы не нашли нужный вам клинок, мы также можем изготовить его по индивидуальному заказу. Посмотрите наш «Пользовательские лезвия» чтобы узнать как! Добро пожаловать в спрашивайте!

.webp)

Легко оценить удобство импорта: от транспортировки до таможенного оформления мы берем на себя весь процесс, вам нужно только заплатить НДС и дождаться прибытия товара в компанию.

Мы видели, как его лезвия используются в бесчисленном количестве применений, и готовы реализовать любой проект, который вы нам предложите, обеспечивая точность, долговечность и непревзойденную конкурентоспособную цену.

Если вы предоставите чертежи, эскизы или образцы, мы можем нарисовать и изготовить для вас. Мы также можем помочь в изменении существующих конструкций и спецификаций для улучшения практически любого промышленного применения инструмента. Пожалуйста, свяжитесь с нашей специализированной группой продаж, чтобы обсудить ваши особые требования.

Для контроля качества проводится ряд испытаний и проверок, включая проверку первого изделия, входной контроль материалов и сертификацию материалов, контроль качества в процессе производства, окончательный контроль качества.

Независимо от того, являетесь ли вы импортером, дистрибьютором, оптовиком или конечным потребителем, мы приглашаем вас присоединиться к нам с минимальным минимальным объемом заказа, отсутствием хлопот с запросами и большей свободой при покупке.

Станьте вашим эксклюзивным монитором, регулярно транслирующим каждый важный узел на производственной линии, независимо от того, как далеко он находится, чтобы как можно дальше отслеживать прогресс продукта!

Нанкин Metal Industrial CO., Limited

Промышленный парк Минджуэ, Лишуй, Нанкин, Цзянсу, Китай

Будьте в курсе наших последних новостей.