You want your shop to work well, right? Good Хранение инструментальной оснастки пресс-тормоза helps a lot. Shops that use smart storage can change tools up to 70% faster. They also get more work done. Storing tools the right way keeps them safe from damage.

| Выгода | Подробности |

|---|---|

| Prevents 90% of accidental damage | Use foam-lined racks, rust inhibitors, and organize tools for quick identification |

Being organized saves you time, money, and stress.

Ключевые выводы

- Storing press brake tooling well can make tool changes much faster. You can change tools up to 70% quicker. This means your shop can get more work done.

- Use cabinets that you can change and foam inserts to keep tools safe. These help stop tools from getting damaged. They also keep tools neat and easy to find.

- Shadow boards show you where each tool should go. You can see if a tool is missing right away. This helps you find tools faster and not lose them.

- Mobile tool carts let you move tools to your work area. You do not have to walk far to get tools. This saves time and makes work easier.

- Storing tools upright can give you back most of your floor space. You can get up to 90% more room. This keeps your shop neat and helps you work better.

- Check and clean your tools often so they do not get ruined. Make a plan to do this on a regular basis. This helps your tools last longer and work well.

- Teach your team how to lift things safely and store tools the right way. This helps stop injuries and keeps everyone safe at work.

- Use digital systems to keep track of your tools. You will always know where each tool is. This stops tools from getting lost.

Press Brake Tooling Storage Solutions

When you want to keep your press brake tooling storage efficient, you need the right systems in place. Let’s look at some of the best practices for organizing your shop and making every press brake setup faster and safer.

Cabinets and Shelving

Modular Cabinets

Modular cabinets give you a flexible way to store press brake tooling. You can adjust the layout as your needs change. These cabinets keep your tools safe and organized. Many shops use tooling cabinets with foam inserts or dividers. This setup protects your tools from damage and makes it easy to spot missing items.

- Automated storage and retrieval systems help you track tools and reduce retrieval time.

- In some facilities, automated cabinets deliver each tool to a set spot, so you never waste time searching.

- You can even track tool usage and life expectancy with these systems.

If you use Nanjing Metal’s press brake tooling, you know how important it is to protect your investment. Modular cabinets work well for both standard and custom blades. If you need custom solutions, check out Лезвия на Заказ for more ideas.

Adjustable Shelves

Adjustable shelves let you change the height and spacing to fit different types of press brake tooling. This makes it easy to store long punches, dies, or even special shapes. You can move shelves up or down as your collection grows. Adjustable shelving is one of the best practices for shops that handle a variety of tools.

You can also use shelves to separate tools by type or size. This helps you speed up every press brake setup. When you know exactly where each tool sits, you save time and avoid mistakes.

Tip: Label each shelf with the tool type or size. This simple step keeps your press brake tooling storage organized and easy to use.

Shadow Boards

Visual Identification

Shadow boards use outlines or shapes to show where each tool belongs. You can see at a glance if something is missing. This visual system helps you keep track of your press brake tooling and makes it easy for everyone to follow best practices.

Shadow boards work well for busy shops. You can hang them near your press brake machines for quick access. This setup cuts down on tool retrieval time and keeps your workflow smooth.

Labeling Systems

Adding clear labels to your shadow boards takes organization to the next level. Each spot gets a label with the tool name or number. This makes it easy for anyone to find the right tool fast. Labeling also helps new team members learn the system quickly.

Shadow boards help you reduce errors and boost accountability. When every tool has a home, you know right away if something is out of place. This keeps your press brake tooling storage neat and safe.

| Исследование случая | Описание |

|---|---|

| Visual Press Brake Storage | This system lets you spot punch and die locations without opening drawers. You save time and keep your shop organized. |

| Magnetic iTool Press Brake Tool Identification System | This system works with any tooling cabinet. Operators can see tool locations right away, which improves efficiency and organization. |

Tool Carts

Mobile Storage

Tool carts give you a way to move press brake tooling right where you need it. You can roll a cart to the press brake setup area, load it with the tools for the next job, and keep everything within reach. Mobile storage is one of the best practices for busy shops with frequent tool changes.

You can set up carts with foam inserts or dividers. This keeps your press brake tooling safe during transport. Some shops use carts with locking wheels for extra safety.

Stationary Options

Stationary tool carts stay in one spot, often near the press brake machines. You can use them as mini storage stations for your most-used tools. This setup helps you cut down on walking and keeps your press brake tooling storage close at hand.

If you want more ideas for organizing your press brake tooling, visit Nanjing Metal for solutions that fit your shop. Remember, the right storage system protects your tools and makes every press brake setup smoother.

Vertical Storage

Triangle Trolleys

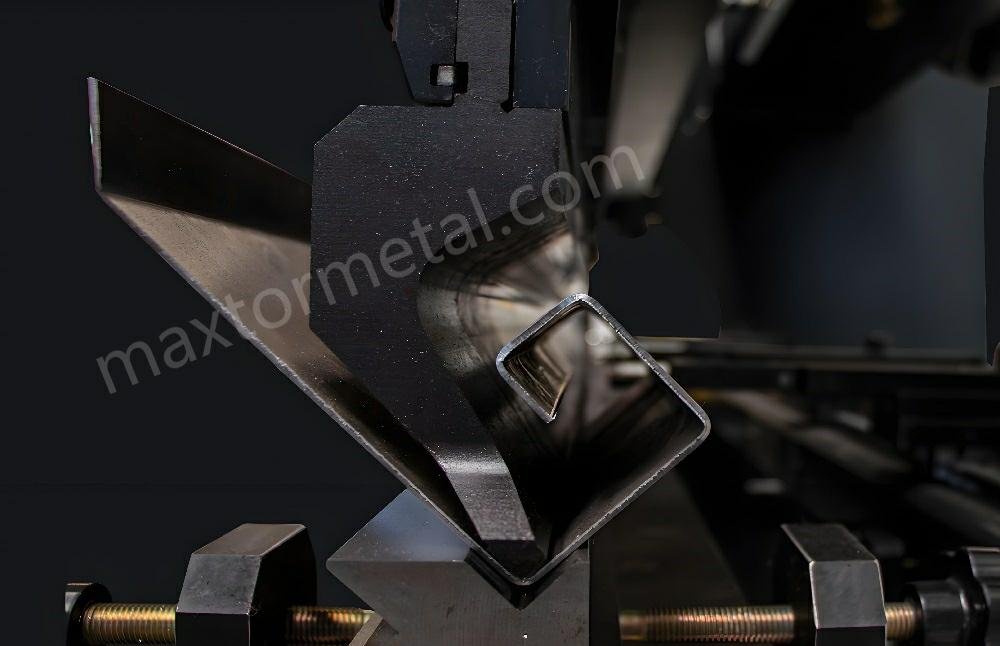

Triangle trolleys give you a smart way to store press brake tooling. These trolleys stand upright and use a triangular frame. You can hang punches and dies on each side. This design lets you see all your tools at once. You do not need to dig through drawers or shelves. You just roll the trolley to your press brake and pick the tool you need.

Many shops use triangle trolleys because they save time. You can load them with the exact press brake tooling for your next job. When you finish, you roll the trolley back to its spot. This keeps your workspace clear and organized. Triangle trolleys also help protect your tools. Each tool has its own spot, so you avoid scratches and dents.

Tip: Use triangle trolleys for heavy or long press brake tooling. You will move tools safely and reduce the risk of dropping them.

Space Optimization

Vertical storage changes the way you use your shop floor. Instead of spreading tools out on shelves, you stack them up. This method works well for shops with limited space. You can fit more press brake tooling in a smaller area. Vertical racks, trolleys, and cabinets all help you get the most out of your floor space.

Let’s compare vertical storage to traditional horizontal storage:

| Storage Method | Floor Space Recovery | Storage Capacity Increase |

|---|---|---|

| Traditional Horizontal Storage | Up to 0% | 0% |

| Vertical Storage Solutions | Up to 90% | 40% or more |

With vertical storage, you can recover up to 90% of your floor space. You also boost your storage capacity by at least 40%. This means you can keep more press brake tooling close to your machines. You spend less time walking and searching for tools. Your shop stays neat, and you work faster.

Vertical storage also makes it easy to spot missing or damaged press brake tooling. You see every tool at a glance. This helps you keep your tools in good shape and ready for the next job.

Note: If you use custom or oversized press brake tooling, look for vertical racks with adjustable hooks or shelves. This way, you can store every tool safely and within reach.

Lean Press Brake Operations

Lean press brake operations help you get more done with less effort. When you organize tools and set up your workspace the right way, you save time and reduce mistakes. Let’s break down how you can make your shop run smoother and safer.

Эффективность рабочего процесса

Minimizing Tool Changeover Time

You know how much time you lose when you hunt for the right press brake tools. If you keep your tool storage location close to the machine, you cut down on wasted steps. You can grab what you need and get back to work fast. Shops that focus on lean press brake operations often see setup time drop by half. That means you spend more time bending metal and less time searching for tools.

Tip: Use color-coded labels and shadow boards to spot missing tools right away. This simple step can shave minutes off every setup time.

Streamlined Tool Retrieval Processes

A good system for tool organization makes every job easier. When you sort and label your press brake tools, you know exactly where each one belongs. Visual management tools, like outlined shapes or color tags, help you find what you need at a glance. You don’t waste time guessing or digging through drawers. This approach keeps your setup times short and your workflow steady.

- 5S organization helps you sort, set in order, shine, standardize, and sustain your workspace.

- Visual cues and clear labels make it easy for anyone to follow your system.

Reducing Unnecessary Movements

Every extra step you take adds up. If you walk back and forth across the shop to get tools, you lose valuable time. By placing tool storage near your press brake, you cut down on walking and reduce setup time. You also feel less tired at the end of the day. This kind of waste reduction is a key part of lean manufacturing.

| Выгода | How It Helps You |

|---|---|

| Less walking | Faster setups, less fatigue |

| Tools close by | Fewer mistakes, smoother workflow |

| Organized workspace | Higher press brake productivity |

Ergonomic Placement

Height-Appropriate Storage

You want to avoid bending or reaching too much. Store your press brake tools at a height that feels natural. This keeps your back and shoulders safe. When you set up shelves or racks at the right level, you make tool changes quick and easy.

Easy Access to Frequently Used Tools

Keep your most-used tools front and center. Place them where you can grab them without moving other items. This setup saves you time during every setup time. You also lower the risk of dropping or damaging tools.

Reducing Physical Strain for Operators

A smart tool storage location helps you work safely. When you keep tools close to the machine, you don’t have to carry heavy items far. This reduces strain on your body and helps prevent injuries. Studies show that storing tools near the press brake leads to quicker, easier, and safer tool changeovers.

Note: Ergonomic storage isn’t just about comfort. It also boosts your press brake productivity by making every movement count.

Proximity to Machines

Dedicated Storage Adjacent to Press Brakes

Set up dedicated storage right next to your press brake. This way, you always have the right tools within arm’s reach. You don’t waste time walking across the shop. You also keep your workspace tidy and safe.

Quick Access During Production Runs

When you run a big job, you need to switch tools fast. If your tool storage location is close by, you can change tools in seconds. This keeps your production line moving and helps you hit your deadlines. Organizing tool storage close to the press brake is crucial for minimizing setup times, which directly enhances operational efficiency.

Reducing Walking Distance

Shorter walking distances mean faster setup time and less fatigue. Storing tool cabinets near the press brake reduces setup times and decreases worker frustration. You feel more focused and ready for the next job.

Callout: Lean press brake operations rely on classified storage systems. These systems help you organize tools, cut down on wasted movement, and keep your shop running at its best.

Key Lean Manufacturing Principles for Tool Storage:

- 5S organization transforms your workspace and reduces time spent searching for tools.

- Visual management, like color-coded labels, helps you identify and access tools quickly.

Top Benefits of Lean Tool Storage:

- Increased productivity

- Improved quality

- Reduced setup times

When you follow these steps, you see real results. You save time, protect your tools, and make your shop a safer place to work.

Press Brake Productivity Challenges

Disorganization

Misplaced Tools

It is annoying when you cannot find the tool you need. Many shops have this problem. If you do not have a clear storage system, tools get lost. This slows you down and can stop your work. You might spend minutes looking for a punch or die. These minutes add up quickly.

A messy storage area causes problems like these:

- You lose tools often.

- You waste time searching for the right tool.

- You might use the wrong tool by accident.

Tip: Give every tool its own spot. Use labels or shadow boards so you always know where things go.

Inefficient Tool Retrieval

If your press brake tooling storage is messy, you waste time getting tools. You may need to open many drawers or walk across the shop. This makes your work slower and setups take longer.

Here is how being disorganized hurts your work:

| Испытание | Impact on Production Output |

|---|---|

| Increased setup times | Makes the bending process take longer |

| Potential damage to tools | Causes problems and can stop production |

| Safety risks for operators | Makes accidents more likely and slows down work |

You want your shop to run well. When you organize your press brake tooling storage, you save time and help your team focus.

Increased Setup Time

Every minute spent looking for tools is lost work time. Messy press brake tooling storage makes setups take longer. If you cannot find the right punch or die fast, your schedule falls behind. This hurts your work and costs you money.

- Messy storage makes setups slow and causes delays.

- Bad storage can damage tools and cause problems.

- Poor organization can make your shop unsafe.

You can stop these problems by keeping your press brake tooling storage neat and simple to use.

Tool Damage

Improper Storage Methods

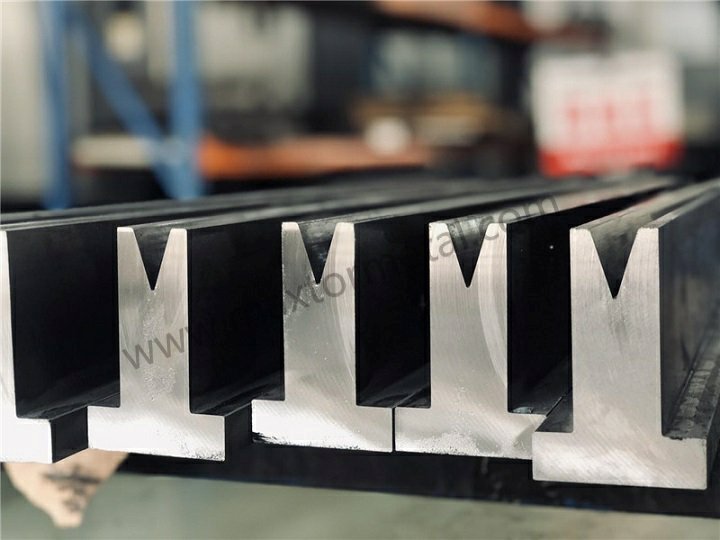

Bad storage is a big reason tools get damaged. If you stack tools or leave them out, they can get scratched or bent. Press brake tooling storage should keep your tools safe. Racks, foam inserts, or special cabinets protect your tools from harm.

Storing press brake tools the wrong way can wear them out. Tools can get damaged from rubbing or bumping into each other. You want your tools to last, so take care of them.

Lack of Protective Measures

Without protection, your tools are in danger. Rust is a big problem in many shops. Humidity and bad air can make tools wear out faster. Rust problems can cost a lot of money. You can stop this from happening.

Note: Use rust blockers, keep your storage dry, and check your tools often. These easy steps can save you money on repairs.

Frequent Handling Errors

If you do not have a good storage system, you move tools too much. Every time you move a tool, you might drop it or hit it. Handling tools too often can chip, crack, or break them. Try to touch each tool as little as possible. Store them so you can grab them safely and easily.

Space Constraints

Overcrowded Work Areas

Crowded work areas make everything harder. Too many tools and not enough space means you stack things or block paths. This is not safe and slows you down. You might trip or have trouble moving heavy tools.

| Доказательство точки | Описание |

|---|---|

| Tool Handling | Bad storage and moving heavy tools can cause problems and safety risks. |

| Physical Demands | Heavy tools may need more people to move, which can cause injuries and slow work. |

You want your workspace to be clear. Use vertical storage or special cabinets to save floor space and make your shop safer.

Limited Storage Capacity

Not enough storage means you cannot keep tools organized. You might have to pile tools or store them far away. This wastes time and can damage tools. A good tooling library helps you find tools fast and keeps your work smooth.

- Shorter tooling pieces are easier to load and unload, making work safer and faster.

Try adding more shelves or using carts to grow your press brake tooling storage. This keeps tools close and ready to use.

Poor Layout Planning

A bad layout can ruin your press brake tooling storage. If storage is far from machines, you waste time walking. If you block exits or crowd your space, it is not safe.

Callout: Plan your storage so tools are near where you use them. Keep walkways open and easy to use.

When you fix these problems, your shop becomes safer, faster, and better. Good press brake tooling storage helps everything run smoothly.

Safety Hazards

When you set up your shop, safety should always come first. Poor tool storage can create real dangers for you and your team. Let’s look at the main risks and how you can avoid them.

Tripping and Slipping Risks

Messy tool storage often leads to tools left on the floor or in walkways. You might step on a punch or trip over a die. Slipping on oil or metal shavings near scattered tools can send you to the hospital. You want to keep your shop floor clear and safe.

Here’s what you can do:

- Place all tools back in their tool storage after each use.

- Use shadow boards or racks to keep tools off the ground.

- Clean up spills and debris right away.

Tip: Walk your shop at the end of each shift. Check for tools or clutter in walkways. A quick sweep can prevent accidents.

Heavy Lifting Injuries

Press brake tooling can be heavy. If you lift tools from awkward spots or high shelves, you risk hurting your back or shoulders. Bad tool storage makes lifting even harder. You want to avoid injuries that can keep you off the job.

Try these steps to stay safe:

- Store heavy tools at waist height in your tool storage.

- Use carts or trolleys to move large tools instead of carrying them.

- Ask for help with oversized or awkward items.

A smart tool storage setup lets you grab what you need without straining. You protect your body and keep your team healthy.

Obstructed Emergency Exits

Blocked exits are a big safety hazard. If tool storage blocks a door or pathway, you could get trapped in an emergency. You need clear routes to get out fast if something goes wrong.

Keep these rules in mind:

- Never place tool storage in front of emergency exits.

- Mark exit paths with bright tape or signs.

- Check that all storage units leave enough space for quick escape.

| Hazard | Как это предотвратить |

|---|---|

| Tripping on tools | Store all tools in proper tool storage |

| Lifting injuries | Use carts and store tools at safe heights |

| Blocked exits | Keep tool storage away from doors and aisles |

Safety is everyone’s job. When you organize your tool storage, you make your shop safer for everyone.

Comparing Storage Systems

When you set up your shop, you want the best press brake tooling storage system. Each option has strengths and weaknesses. Let’s break down racks, cabinets, and carts so you can pick what works for you.

Racks

Плюсы

Racks give you a simple way to store press brake tooling. You see all your tools at once. You can grab what you need quickly. Racks work well for shops with lots of space. You can organize punches and dies by size or type.

- Easy to access tools

- Good for visual inventory checks

- Simple to install and expand

Минусы

Racks do not protect tools from dust or moisture. You might see more wear and tear if you leave tools exposed. Racks can get crowded if you have many tools. You may need extra space for safety.

Note: Racks work best when you keep your shop clean and dry. If you want more protection, you might look at cabinets or carts.

Cabinets

Security

Cabinets offer strong security for your press brake tooling storage. You can lock drawers and keep tools safe from unauthorized use. Cabinets protect tools from rust and corrosion. They keep dust and moisture away. You can use foam inserts or pads to prevent damage.

| Особенность | Выгода |

|---|---|

| Lockable drawers | Prevents tool loss and theft |

| Foam inserts | Stops scratches and dents |

| Organized layout | Speeds up tool retrieval |

Cabinets help you keep your tools in top shape. When you store tools in cabinets and clean them often, they can last over 10 years. You keep accuracy and save money on replacements.

Расходы

Cabinets cost more than racks or carts. You pay for security and protection. Some cabinets come with automated tracking or digital locks. These features add value but also raise the price. If you want to protect your investment, cabinets make sense.

Tip: If you use custom blades or special press brake tooling, cabinets with adjustable shelves give you the flexibility you need. You can find more options at Nanjing Metal.

Carts

Гибкость

Carts give you the most flexibility for press brake tooling storage. You can move them anywhere on the shop floor. You set up carts for each job and roll them to the press brake. Carts work well in busy shops with frequent tool changes.

- Mobility lets you reposition carts easily

- Customization options fit different tools

- Adaptable to changing workflows

Fixed storage solutions do not offer this level of flexibility. You might waste time walking back and forth. Carts help you stay efficient and organized.

Техническое обслуживание

You need to keep carts clean and organized. Proper maintenance prevents tool loss and damage. You should protect tools from rust and corrosion. Safe handling keeps your tools working longer.

- Organize tools to avoid damage

- Clean carts and tools often

- Store tools in dry, protected spaces

Vertical storage systems with pads give extra protection. Cabinets with lockable drawers keep tools secure. When you follow good cleaning and storage practices, your press brake tooling can last for years.

Callout: Choose the storage system that fits your workflow, space, and budget. Each option helps you keep your press brake tooling storage efficient and safe.

Техническое обслуживание инструмента листогибочного пресса

Taking care of your press brake tooling storage helps you get better results. It also means less stress. You want your tools to last a long time. They should be safe and ready for every job. Here are some ways to make that happen.

Регулярные проверки

You need to check your press brake tooling storage often. Inspections help you find problems before they get worse. Here is a simple chart to help you remember what to do:

| Частота | Что проверять |

|---|---|

| Перед каждым использованием | Протрите начисто; проверьте состояние; нанесите антикоррозийное масло |

| Ежедневно | Проверьте наличие трещин, несоосности и видимых повреждений. |

| Еженедельно | Clean tools and machine parts; oil moving components |

| Ежемесячно | Повторно осмотрите все инструменты; смажьте маслом пуансоны и матрицы. |

| Ежегодно | Perform full calibration and replace worn components |

If you follow this plan, you will catch problems early. Your press brake tooling storage will stay neat and safe. You will also save money and avoid stopping work.

Tip: Set reminders for each inspection. Use a calendar or checklist to help you remember.

Cleaning Practices

Clean tools work better and last longer. You want your press brake tooling storage to stay free from dirt and rust. Here are some easy cleaning steps:

- Look at punches and dies every day for damage.

- Wipe tools with a soft cloth after each use.

- Clean surfaces and check alignment every day.

- Remove dirt and old oil after every job.

- Clean hydraulic and electrical parts every week.

- Add new oil to moving parts and the hydraulic system.

- Deep clean important areas once a month.

- Clean and oil gibs to stop friction and wear.

Doing these things keeps your press brake tooling storage in good shape. You also stop mistakes and tool problems.

Note: Clean tools are safer and help you avoid accidents in your shop.

Управление запасами

You need to know where every tool is all the time. Good inventory management keeps your press brake tooling storage working well. Many shops use special software to help with this. Here is how it helps you:

| Особенность | Выгода |

|---|---|

| Real-time tracking | You always know how many tools you have. |

| Modular configurations | You can change storage as you get more tools. |

| FIFO strategy | You use tools in the order you got them, so work goes faster. |

With software, you can track every punch and die. You know when to buy new tools and when to throw out old ones. You also do not lose tools or run out during busy times.

Callout: Smart inventory management means you spend less time looking for tools and more time working.

When you do regular checks, keep things clean, and use good inventory management, your press brake tooling storage stays neat and ready. You get better work, safer days, and tools that last longer.

Safety in Tooling Storage

Keeping your shop safe starts with smart press brake tooling storage. You want to protect yourself and your team from injuries. Let’s look at three key areas: lifting procedures, weight distribution, and emergency access.

Lifting Procedures

Press brake tooling can get heavy. If you lift tools the wrong way, you might hurt your back or drop a tool. You need to use safe lifting steps every time.

Here’s what you should do:

- Plan your lift: Check the weight of the tool before you pick it up. If it feels too heavy, ask for help or use a cart.

- Bend your knees: Keep your back straight. Use your legs to lift, not your back.

- Hold tools close: Keep the tool close to your body. This gives you better control and balance.

- Move slowly: Don’t rush. Take your time to avoid accidents.

Tip: Use lifting aids like carts or trolleys for large or awkward press brake tooling. This keeps you safe and protects your tools.

Weight Distribution

You want your press brake tooling storage to stay stable. Uneven weight can tip over racks or carts. This can cause injuries or damage your tools.

- Store heavy tools on lower shelves or racks.

- Spread out the weight evenly on carts and shelves.

- Don’t overload one side of a storage unit.

Here’s a quick table to help you remember:

| Storage Type | Лучшая практика |

|---|---|

| Shelves | Heavy tools on the bottom |

| Carts | Balance weight on both sides |

| Racks | Evenly space out heavy and light tools |

Note: Check your storage units often. Make sure nothing leans or wobbles.

Emergency Access

You need clear paths in your shop. In an emergency, you want to get out fast. Press brake tooling storage should never block exits or walkways.

- Keep all exits clear of carts, racks, and cabinets.

- Mark emergency routes with bright tape or signs.

- Store tools so nothing sticks out into walkways.

If you see a blocked exit, fix it right away. Remind your team to keep paths open. Safety comes first in every shop.

Callout: Safe press brake tooling storage helps you work faster and keeps everyone protected. Make safety checks part of your daily routine. 🦺

Handling Large Press Brake Tooling

Lifting Equipment

Handling large press brake tooling can feel like a big job. You want to move heavy tools safely and quickly. The right lifting equipment makes all the difference. Here are some options you can use in your shop:

- Cranes: These work well when you need to lift heavy press brake tooling. Cranes give you flexibility and strength. Make sure the crane’s rope is strong and has safety devices. Always check the crane before you use it.

- Forklifts: If you have smaller press brake tooling, a forklift can help. Pick a forklift with the right load capacity. Only let trained operators use forklifts. This keeps everyone safe.

- Lifting Slings: Slings help you move press brake tooling with care. Use slings that meet safety standards. Check the weight limit before you lift anything.

Tip: Always inspect your lifting equipment before you start. Look for signs of wear or damage. If you see a problem, fix it right away.

Oversized Tool Storage

Large press brake tooling needs special storage. You cannot just put these tools on a regular shelf. Oversized tools take up more space and need extra support. You want to keep them safe and easy to reach.

Try these ideas for better press brake tooling storage:

- Use heavy-duty racks with wide shelves. These racks hold more weight and keep tools steady.

- Store long punches and dies horizontally to stop them from bending.

- Add padding or foam to shelves. This protects the surface of your press brake tooling.

- Label each spot so you know where every tool belongs.

Here’s a quick table to help you plan your storage:

| Тип инструмента | Best Storage Method | Extra Protection |

|---|---|---|

| Long Punches | Horizontal racks | Foam padding |

| Large Dies | Heavy-duty shelves | Anti-rust coating |

| Custom Shapes | Adjustable shelving | Labeled sections |

Note: Keep your oversized press brake tooling close to the machine. This saves time and reduces the risk of dropping heavy tools.

Обучение персонала

You want your team to handle large press brake tooling safely. Training is key. When everyone knows the right way to lift and store tools, accidents go down and productivity goes up.

Focus on these training points:

- Show your team how to use cranes, forklifts, and slings.

- Teach safe lifting techniques. Remind everyone to bend their knees and keep their back straight.

- Explain the importance of checking press brake tooling storage for hazards.

- Encourage questions. Make sure everyone feels comfortable asking for help.

Callout: A well-trained team keeps your shop safe and your press brake tooling in top shape. Regular training sessions help everyone stay sharp and confident. 🛠️

Advanced Storage Options

If you want better press brake tooling storage, try advanced options. These choices help you save time and make fewer mistakes. They also help your shop run better.

Automatic Tool Change

Think about changing all your press brake tools in under a minute. Automatic tool change systems can do this for you. You do not have to spend 15 to 30 minutes swapping tools by hand. The system lifts and moves the tools for you. It checks if tools are lined up right and if they are worn out. This helps you avoid big mistakes.

Here is a quick chart:

| Особенность | Manual Change Time | Automatic Change Time | Time Saved |

|---|---|---|---|

| Tool Change Duration | 15-30 minutes | Under 60 seconds | Up to 29 minutes |

With automatic tool loading, you can start new jobs fast. These systems can hold up to 40 tools at once. You do not need to make as many changes by hand. This means you make fewer mistakes and stay safer.

- You can switch jobs quickly.

- You are less likely to make mistakes.

- You have more tools ready for any job.

Tip: Automatic tool changers help you finish jobs on time and handle many different projects.

Digital Tracking

It can be hard to keep track of every tool in your shop. Digital tracking makes this simple. You use one system to see where each tool is. You do not have to search through drawers or shelves.

- You see all your tools in one place.

- You know who used each tool and when.

- You find missing or worn tools fast.

Digital tracking helps you make good choices. You can plan jobs faster and stop delays. Your team works better because they always know where tools are.

Note: Digital tracking helps everyone stay responsible and keeps your press brake tooling storage neat.

Software Integration

Software integration connects everything together. You link your tool storage with your shop’s main software. This lets you plan jobs, track tool use, and order new tools automatically.

- You do not waste time looking for tools.

- You use your tools and people better.

- You get real-time data to help you decide what to do.

Software integration helps you see problems and fix them before they slow you down. You get more done with less work. Your shop stays busy, and your press brake tooling storage always helps you work well.

Callout: Advanced storage options like automatic tool changers, digital tracking, and software integration help you do better in a busy shop. They make your work easier, safer, and more efficient. 🚀

Implementation Steps

Assess Needs

Evaluate Current Storage Systems

Start by looking at your current press brake storage. Walk around your shop and ask yourself a few questions. Do you keep your tools in organized tool storage stations? Are your cabinets close to the press brake where you use them? If not, you might waste time walking back and forth.

Here’s a simple checklist to help you:

- Check if you use cabinets designed for press brake tooling.

- See if your cabinets have lockable drawers for security.

- Look for vertical storage with protective pads to keep tools safe.

- Make sure you have safety features, like interlocks, to stop more than one drawer from opening at once.

- Notice if you store tools at the point of use, right by the press brake.

If you find gaps, write them down. This helps you see where your tooling storage system needs improvement.

Identify Tooling Types and Quantities

Next, make a list of every tool you use. Count your punches, dies, and any custom pieces. Group them by type and size. This step helps you figure out what kind of tool storage stations you need.

You might have some tools you use every day and others you only need for special jobs. Keep the most-used tools in easy-to-reach spots. Store less-used tools in cabinets or on shelves further away. This way, your tooling storage system stays neat and you always know where to find what you need.

Tip: Use clear labels for every tool. Visual press brake storage makes it easy to spot missing items and keeps your shop organized.

Analyze Workflow and Bottlenecks

Watch how you and your team move around the shop. Do you walk too far to get tools? Do you spend time searching for the right die? These are signs of bottlenecks.

Try to keep your shop layout focused on minimizing movement. Store tools at the point of use. Mobile carts can help if you work on different jobs in different areas. Shadow boards also make it easy to grab peripheral tools fast.

Ask your team for feedback. They might spot problems you miss. Fixing these small issues can make your press brake storage much more efficient.

Layout Planning

Design Efficient Storage Zones

Plan your shop so every tool has a home. Create zones for different types of press brake tooling. Place tool storage stations near each press brake. This setup saves time and keeps your workspace tidy.

Use visual press brake storage, like shadow boards or labeled racks, to help everyone find tools quickly. When you design clear zones, you cut down on confusion and speed up every job.

Ensure Safe and Clear Pathways

Safety comes first. Make sure your pathways stay clear. Don’t let carts or cabinets block walkways or emergency exits. Store heavy tools on lower shelves to prevent accidents.

Here’s a quick table to help you remember:

| Safety Step | Почему это важно |

|---|---|

| Clear walkways | Prevents trips and falls |

| No storage in front of exits | Keeps emergency routes open |

| Heavy tools at waist height | Reduces lifting injuries |

Check your shop at the end of each day. A quick sweep keeps your tooling storage system safe for everyone.

Optimize Proximity to Press Brakes

Keep your tool storage stations as close to the press brake as possible. This setup cuts down on wasted steps and speeds up tool changes. You want to grab what you need without walking across the shop.

Mobile carts can help if you need to move tools between machines. Cabinets with wheels give you flexibility. The closer your tooling storage system is to the action, the faster you work.

Обучение персонала

Train on New Storage Procedures

When you set up a new press brake storage system, show your team how to use it. Walk them through each storage zone. Explain where to find and return every tool.

Use hands-on practice. Let everyone try the new system. This helps them remember the steps and builds good habits.

Emphasize Safety Protocols

Remind your team about safety every day. Show them how to lift heavy tools the right way. Point out safe pathways and emergency exits. Make sure everyone knows how to use cabinets and carts safely.

Safety tip: Always store heavy tools at waist height and keep walkways clear.

Encourage Feedback and Questions

Ask your team what works and what doesn’t. Encourage them to share ideas for making the press brake storage better. When you listen to feedback, you find new ways to improve your tooling storage system.

Let your team know it’s okay to ask questions. The more they understand, the safer and more efficient your shop will be.

Постоянное совершенствование

Collect and Review Staff Feedback

You want your press brake tooling storage system to work for everyone. The best way to know if it does? Ask your team. Your operators use the storage every day. They see what works and what slows them down. Make it a habit to check in with them.

- Hold short meetings at the end of each week.

- Ask questions like, “Did you have trouble finding any tools?” or “What would make storage easier?”

- Use a suggestion box for anonymous feedback.

Tip: Listen to all feedback, even if it sounds small. Sometimes, a tiny change can save hours over time.

When you collect feedback, write down the main points. Look for patterns. If several people mention the same problem, you know it needs fixing.

Monitor Storage System Performance

You need to know if your press brake tooling storage system is helping or hurting your workflow. Keep track of how long it takes to find and return tools. Watch for signs of clutter or misplaced items.

Try these steps:

- Time how long it takes to set up for a new job.

- Count how often tools go missing or get damaged.

- Check if walkways stay clear and safe.

Here’s a simple table to help you track performance:

| What to Monitor | Как часто | Почему это важно |

|---|---|---|

| Tool retrieval time | Еженедельно | Shows if storage is efficient |

| Tool loss or damage | Ежемесячно | Protects your investment |

| Workspace organization | Еженедельно | Keeps shop safe and tidy |

If you see problems, talk to your team. Find out what slows them down. Use this information to make your press brake tooling storage better.

Implement Incremental Upgrades

You do not need to overhaul your whole system at once. Small changes can make a big difference. Start with the easiest fixes. Maybe you add more labels, move a cart closer to the press brake, or install new shelves.

- Upgrade one part of your storage at a time.

- Test each change before moving on.

- Ask your team if the upgrade helped.

Note: Continuous improvement means you never stop looking for ways to get better. Even small upgrades keep your press brake tooling storage system efficient and safe.

Stay flexible. Your shop will change as you take on new jobs or add new tools. Keep improving your press brake tooling storage, and you will see better productivity, safer workdays, and happier operators. 🚀

When you use a smart press brake tooling storage system, you get more work done and keep your tools safe. An organized tool cabinet helps you find tools quickly. Cabinets placed in the right spots keep tools in good condition. Here are some tips for tool management: look at how you store tools now, buy better storage if needed, and teach your team how to use it. Check your storage often and make small changes to improve it. Want to make your shop better? Свяжитесь с нами сегодня для получения экспертной помощи.

Часто задаваемые вопросы

What is the best way to organize press brake tooling storage?

You should group tools by type and size. Use labeled shelves, cabinets, or shadow boards. This setup helps you find tools fast and keeps your workspace tidy.

How often should I inspect my press brake tooling storage?

Check your storage every day for damage or missing tools. Do a deeper inspection each week. Regular checks help you spot problems early and keep your tools safe.

Can I use regular shelves for press brake tooling storage?

Regular shelves work for light tools. For heavy or custom press brake tooling, use reinforced shelves or cabinets. This prevents bending, damage, or accidents.

How do I prevent rust on my press brake tooling storage?

Keep your storage area dry. Wipe tools after use. Use rust inhibitors or oil. Store tools in cabinets with moisture control if possible.

What safety tips should I follow for press brake tooling storage?

Store heavy tools at waist height. Keep walkways clear. Use carts or lifting aids for large tools. Always check that storage units are stable.

Why does proximity to the press brake matter for tooling storage?

When you keep storage close to your press brake, you save time and energy. You can change tools faster and reduce walking, which boosts productivity.

How can I track my press brake tooling inventory?

Try using a simple spreadsheet or inventory software. Label each tool and update your list after every use. This helps you avoid losing tools and keeps your shop organized.

What should I do if my press brake tooling storage gets crowded?

Add more shelves or use vertical storage racks. Move less-used tools to another area. Keep only the tools you need close to your press brake for easy access.

Смотрите также

Выбор Лучшей Инструментальной Оснастки для Пресс-Тормоза для Нержавеющей Стали

Инструментальная Оснастка Пресс-Тормоза Европейского против Американского Стиля: Что Подходит для Вашего Цеха?

Гибка в Воздухе против Гибки в Матрицу: Выбор Правильной Инструментальной Оснастки для Пресс-Тормоза для Вашего Проекта

Полное Руководство по Матрицам Пресс-Тормоза: Выбор Лучшего Материала для Предотвращения Износа

Руководство по Инструментальной Оснастке Пресс-Тормоза для Начинающих: Выбор Правильного V-образного Отверстия Матрицы