Lựa chọn tốt nhất meat slicer blades depends on your specific needs. Consider what type of meat you want to slice and how much slicing you will be doing. Whether you need a lưỡi dao tùy chỉnh for deli meats or serrated blades for frozen foods, Nam Kinh Metal offers high-quality options to ensure each slice meets your standards. The right commercial meat slicer blades not only improve safety but also make your work faster and more efficient. For more information or to request a custom blade, please contact Nanjing Metal directly. Below is a table highlighting current trends in industrial meat slicer blades, showing their applications and market insights:

| Segment | Subcategories | Market Insights |

|---|---|---|

| Slicer Type | Manual, Automatic, Semi-automatic | Automated slicers are becoming increasingly popular in businesses. |

| Loại lưỡi dao | Serrated, Smooth, Frozen Meat Blades | Each blade type is optimized for specific tasks in meat processing plants. |

| Ứng dụng | Meat Processing, Foodservice, Home | Most meat slicer blades are utilized in large-scale commercial operations. |

| Market Size (2024) | USD 1,254.62 million globally | Growing demand as more companies invest in advanced slicing solutions. |

Những điểm chính

- Pick the right blade type for your food. Use a smooth blade for boneless meats and cheese. Use a serrated blade for frozen or tough meats. Use specialty blades for special jobs. This helps you get the best slices.

- Choose blade materials that fit your needs. Carbon steel is sharp and good for tough cuts. Stainless steel is easy to clean and safe for food. Hardened steel lasts a long time.

- Match the blade size and features to your work. Think about how much you need to slice and what kind of meat you have. This helps you work faster and keep the quality high.

- Clean and take care of your slicer often. This keeps blades sharp and stops rust. It also keeps your food safe.

- Think about custom blades from trusted brands like Nanjing Metal. These can help you cut faster, waste less, and meet special factory needs.

Meat Slicer Blades Overview

Industrial meat slicer blades are important in big food factories. These blades are not the same as the ones used at home or in small kitchens. Industrial meat slicers are made for fast and accurate slicing. They often have automatic blade movement and settings you can program. This helps workers do less and get more done.

Types of Meat Slicer Blades

When picking a meat slicer, you should know the main blade types:

- Smooth blades: These blades have a straight, sharp edge. You use them to slice boneless meats, cooked foods, and cheese. Smooth blades make clean and even slices. They are best when you want thin, even pieces.

- Lưỡi răng cưa: These blades have a toothed edge. You use them for tough meats, frozen foods, or things with a hard crust. The serrated blade grabs and cuts through thick or frozen items without slipping.

- Specialty blades: These blades are made for special jobs. Some cut cooked poultry, fish, or even things that are not food, like packaging. Specialty blades can have different shapes or coatings for certain jobs.

Tip: In big factories, circular blades are common because they slice lots of meat fast. Straight and curved blades are used for special jobs, like dicing or skinning.

Most commercial meat slicer blades are made from stainless steel or high-speed steel. These materials keep the blades strong and clean, which is very important in food factories.

Common Blade Sizes

Industrial meat slicer blades come in many sizes for different machines. The most common sizes you will see are:

- 10-inch (250 mm)

- 12-inch (300 mm)

- 14-inch (350 mm)

- 16-inch (400 mm)

Big blades help you cut larger pieces of meat and work faster. Small blades are good for careful slicing or when you do not have much space. Always pick a blade size that matches your work and the type of meat slicer you have.

Remember: Automatic and programmable features help you keep slices the same thickness and save work. That is why industrial meat slicer blades are made to last, cut well, and stay clean.

Blade Materials for Industrial Meat Slicer Blades

Picking the right blade material is very important in big factories. Each material has its own good points for slicing different foods and following food safety rules. Here are the main choices you will see in the industry.

Thép Cacbon

Carbon steel blades are common in places that slice a lot of meat. Carbon steel gives a sharp edge that cuts red meats and frozen foods easily. This material is good if you change blades often and want to save money.

Thuận lợi:

- Carbon steel blades stay sharp for a long time, so slicing is easy.

- They cut tough and frozen meats fast.

- You can sharpen these blades again, so they last longer.

Cân nhắc:

- Carbon steel blades can rust if you do not dry and clean them.

- You must clean them well to keep food safe.

Typical Uses:

- High-volume meat processing

- Slicing red meats and frozen foods

Tip: If you clean your meat slicer blade after every shift, it can last about 30% longer. Taking care of your blade helps it work better and last longer.

Thép không gỉ

Stainless steel is the best choice when you need to keep food safe. These blades are used in poultry and seafood plants, where cleaning happens a lot. Stainless steel blades do not rust, so they are great for wet places.

Thuận lợi:

- Stainless steel blades do not rust, even in wet air.

- They are easy to clean, which helps keep food safe.

- These blades last longer in places with lots of water.

Cân nhắc:

- Stainless steel blades may wear out faster if you use them a lot.

- You might need to get new blades more often for hard or frozen foods.

Typical Uses:

- Poultry and seafood processing

- Places with strict cleaning rules

Ghi chú: Cleaning stainless steel with special chemicals makes it easier to remove sticky food. This helps you keep your meat slicer blade clean and working well.

Hardened Steel

Hardened steel blades are best for tough jobs and long work hours. These blades are made stronger with heat, so they last longer and stay sharp. Use them when you need a blade for hard or frozen meats and do not want to change blades often.

Thuận lợi:

- Hardened steel blades last a long time, even with hard work.

- They do not wear out fast and stay sharp for many hours.

- Special coatings can make these blades last up to 50% longer.

Cân nhắc:

- Hardened steel blades need a pro to sharpen them.

- You must follow a care plan to keep them working well.

Typical Uses:

- Long production lines

- Slicing hard or frozen meats

- Jobs where you cannot stop to change blades

Table: Performance Comparison of Blade Materials

| Vật liệu lưỡi | Average Blade Life (Cutting Hours) | Failure Rate Under Overload | Rust Formation Time (High Humidity) |

|---|---|---|---|

| Thép không gỉ | 100–150 | 4× faster failure | > 48 hours |

| Thép tốc độ cao (HSS) | 50–100 | 3× faster failure | Không có |

| Carbon Steel (High-Carbon) | Không có | Không có | Rust starts within 48 hours |

You should pick the blade material that fits your job. Use carbon steel for lots of red meat, stainless steel for places where food safety is most important, and hardened steel for long, tough jobs.

Remember: Cleaning, oiling, and checking your blade can help it last up to 30% longer. Special coatings and sharpening also help your blade work its best.

Uses of Meat Slicer Blades in Industry

Industrial meat slicer blades are very important in food factories. You see these blades in places that slice meat, cheese, and other foods. Each job needs a different blade type and material for the best results. Picking the right blade helps you work faster, stay safe, and make good products.

Meat Processing

Meat slicer blades are used most in meat processing plants. These places handle lots of beef, pork, poultry, and frozen meats. The main blade types here are smooth and serrated. Smooth blades cut deli meats and boneless cuts into even slices. Serrated blades are better for tough or frozen meats because they grip and cut easily.

Blade material is very important in meat processing. Stainless steel and carbon steel are common choices. Stainless steel does not rust and is easy to clean, so it helps with hygiene. Carbon steel blades stay sharp longer and are good for slicing lots of meat. Good blades can help you waste up to 15% less meat. This saves money and helps you make more products. Keeping blades in good shape also helps stop food safety problems. Bad blade care can cause about 30% of food safety issues in the industry.

Tip: Always pick the blade type and material that matches the meat you slice. This helps you get the best cuts and quality.

Cheese and Other Food Products

Meat slicer blades are also used for cheese, vegetables, and other foods. Cheese factories often use smooth blades made from stainless steel or ceramic. These materials help you get even slices and keep blades clean. Some blades have a titanium coating to last longer and stay sharp.

People want very thin slices of cheese and deli foods. Thin and ultra-thin slicers are popular now. These blades can make slices as thin as 0.5 mm, which is good for sandwiches and ready-to-eat meals. The table below shows how slicing thickness and use affect the market:

| Slicing Thickness Category | Thickness Range | 2023 Revenue Share | Growth Rate | Notes |

|---|---|---|---|---|

| Ultra-Thin Slicers | 0.5 mm | Không có | 6.2% CAGR | High demand for precise slicing |

| Thin Slicers | 0.5-1 mm | ~40% | Không có | Most popular for cheese and deli meat |

| Medium Slicers | 1-2 mm | Không có | Không có | Used for vegetables and fruits |

| Thick Slicers | >2 mm | Không có | Không có | For specialty and bulk products |

Cheese makes up over 32% of the food slicer market. Food factories are the biggest users, showing how important good slicing is. Automatic slicers and controls help you get the same thickness every time and waste less food. These tools make work faster and help you make better products.

Specialty Industrial Applications

Some factories use meat slicer blades for special jobs. They might use custom blades to cut packaging, portion seafood, or slice plant-based foods. Specialty blades can have different shapes or coatings for certain tasks. For example, a curved blade can skin fish, and a coated blade can cut sticky foods.

It is important to match the blade to your product and job. Special jobs often need very exact cuts and special blades. Using the right blade helps you keep quality high and meet what customers want. New technology, like smart sensors and laser markings, helps blades work better and last longer.

Note: Always check what your factory needs before picking a blade. The right blade helps you work faster, stop delays, and make the best products.

How to Choose a Meat Slicer Blade

Picking the right meat slicer blade helps your factory work better. It also keeps workers safe and makes your food look good. You should think about a few things before you buy a blade. Follow these steps to get the best results for your business.

Matching Blade to Product

First, think about what food you want to slice. Different foods need different blades for the best results. Smooth blades are good for boneless meats and cheese. Serrated blades are better for frozen meats or foods with hard outsides. Specialty blades help with tricky foods like fish or sticky items.

You also need to think about how thick you want each slice. If you want thin, even slices for deli meats or cheese, pick a blade made for that job. For thick cuts or big batches, choose a blade that can handle it without losing quality.

Tip: Always use the right blade for your food. This helps you get the best slices and keeps your work easy.

Considering Production Volume

How much food you slice matters when picking a blade. Factories that slice a lot need blades that stay sharp and work well for a long time. The size of your machine and the type of meat also matter.

Here is a table to help you see which blade works for different jobs:

| Belt Width (mm) | Blade Diameter (mm) | Max Meat Thickness (cm) | Production Capacity (kg/hr) | Meat Type Impact |

|---|---|---|---|---|

| 200 | 150 | 4.5 | 200-250 | Lower density meat (e.g., chicken breast) |

| 600 | 350 | 12 | 1000-1100 | Higher density meat (e.g., beef) |

Bigger blades and wider belts help you slice more meat faster. If you cut beef or other tough meats, you can move more food each hour. You can also switch blade sets to change how thick you cut and work faster.

Tip: Check how much food you slice each day. Pick a blade that matches your needs so you can keep up and do a good job.

Maintenance and Cleaning

Taking care of your meat slicer keeps it safe and working well. You need to clean it often so food does not build up and make people sick. Good care also helps your blade last longer and cut better.

Follow these steps to keep your slicer in good shape:

- Clean and sanitize the blade every 4 hours if you use it all day. This stops food from sticking and keeps the blade safe.

- Clean the whole machine at the end of each day. Take it apart, wash all the pieces, and put it back together after drying.

- Check the blade after cleaning for any damage or loose parts. This helps you find problems early and stop accidents.

- When cleaning, unplug the machine, take out food bits, wipe with sanitizer, rinse, and let it air-dry.

- For deep cleaning, take the slicer apart, wash with cleaner, scrub hard spots, rinse, and dry before putting it back together.

Note: Cleaning your slicer often stops rust, germs, and sickness. It also keeps your blade sharp and safe to use.

Budget and Longevity

You want a blade that lasts a long time and does not cost too much to keep. Look for blades that are strong and do not rust easily. Chromium-plated carbon steel blades stay sharp and do not rust, so you do not need new ones as often. Some slicers have sharpeners built in, which helps your blade last longer and saves money.

Here are some tips to help you pick a good blade:

- Pick blades that are strong and easy to use. This means less time fixing them and less tired workers.

- Slicers that use less energy save you money and last longer.

- New features like smart alerts can tell you when to fix your slicer and help you avoid big repairs.

- Even if a blade costs more at first, you save money later by wasting less food and making better cuts.

- A good blade means better food, less waste, and faster work.

Tip: Spending more on a good blade saves you money over time. You get better cuts, need fewer new blades, and keep your team safe.

If you need a new blade, always follow the maker’s directions. This keeps your slicer working well and your workers safe.

Custom Meat Slicer Blades

Benefits of Lưỡi Dao Tùy Chỉnh

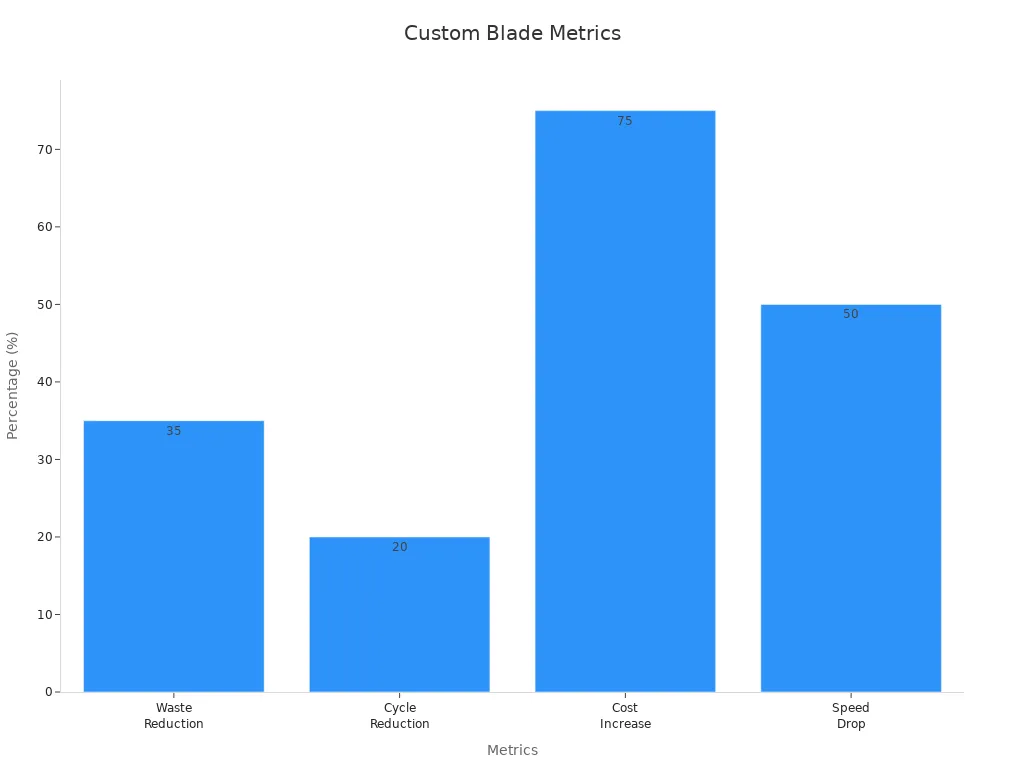

Custom meat slicer blades help your factory work better. You can pick a blade that fits your needs. This makes your work faster and easier. When you use a blade made for your job, you waste less material. You also get better results. For example, if you change the blade tolerance from ±0.005mm to ±0.02mm, you can waste 35% less material. Your production time can also be 20% shorter. You save money because you do not need new blades as often. Custom blades help you follow safety and hygiene rules, which is very important in food factories.

| Tolerance (mm) | Material Waste (%) | Production Cycle Time | Cost Increase (%) |

|---|---|---|---|

| ±0.01 | 5-10 | Chậm | +75 |

| ±0.02 | 2 | 20% shorter | Standard |

| ±0.05 | <2 | Fast | Thấp hơn |

Custom blades help your factory run smoother. You throw away less scrap and spend less time fixing machines. These blades also help you keep up with new machines and new ways of working.

Nanjing Metal Custom Solutions

Nanjing Metal is a trusted company that makes custom industrial blades. They have been making blades for 20 years. Their team knows how to design blades for many jobs. Nanjing Metal uses strong materials and modern machines to make blades that fit your needs. Their custom blades last longer and cut faster. You will have less downtime at work.

| Performance Metric | Lưỡi dao tiêu chuẩn | Lưỡi dao tùy chỉnh | Sự cải tiến |

|---|---|---|---|

| Cắt nhanh | 100 units/hour | 140 units/hour | +40% |

| Tuổi thọ của lưỡi dao | 1.000 chu kỳ | 2.000 chu kỳ | +100% (2x longer) |

| Thời gian ngừng hoạt động bảo trì | 10 giờ/tháng | 5 giờ/tháng | -50% |

Custom blades from Nanjing Metal are also better for the environment. You use fewer blades, so there is less waste and less CO2. Many customers say they waste 25% less and use 15% less energy. The company has ISO9001 quality checks and puts customers first. This makes them a good choice for reliable and efficient blades.

When to Choose Customization

Pick custom blades if your factory has specific needs. If you slice unique foods, need a certain thickness, or want to work faster, custom blades are best. Custom blades are also good if you must follow strict hygiene rules or want special coatings. As more factories use meat slicers, more people need blades that fit their machines.

Custom blades help you stop downtime, make better slices, and use new technology. Some factories saw 70% fewer blade changes each week after switching. Scrap rates also dropped by 66%. These changes show that custom blades help every part of your work.

Tip: Custom blades help you follow rules, save money, and keep your factory running well.

If you want to know more or need a custom blade, you can Liên Hệ a Nanjing Metal sales engineer today.

How to Use a Meat Slicer Safely

Industrial meat slicers help you work faster, but safety is very important. You need to know how to use a meat slicer the right way. This keeps you and your team safe. Follow these steps to set up, use, and take care of your slicer for the best results.

Installation and Setup

Put your slicer on a flat, steady table. Make sure it does not move when you use it. Check that all safety parts, like blade guards and stop switches, are there. Before putting in the blade, wear cut-resistant gloves. Always follow the maker’s steps for putting in the blade. Tighten the blade well and make sure it spins easily. Plug in the slicer and test the safety switches. If your slicer has sensors or auto shut-off, check that they work before you start.

Tip: Always check all safety parts before turning on the slicer. This easy step can stop many accidents.

Operation Tips

Use both hands when you use the slicer. Keep your fingers away from the blade at all times. Set the thickness before you start slicing. Never reach over the blade. Use the food pusher or carriage to move meat to the blade. If you need to change the blade or clean the slicer, turn off the power and unplug it first. Regular care, like sharpening and oiling the blade, helps your slicer work well. Some slicers can clean and sharpen themselves, which saves time and helps you work more.

- Always make sure the blade is sharp. A dull blade can slip and hurt you.

- Clean the slicer after every use. This helps stop food from making people sick.

- Check safety parts like blade guards and switches before each shift.

Note: Cleaning and caring for your slicer lowers the chance of accidents and keeps it working well.

Safety Precautions

You must follow strict safety rules when using industrial slicers. Wear safety gear, like gloves and aprons. Never skip safety parts. Training is very important for safe use. Studies show that using both written steps and live demos gives the best cleaning and safety results.

| Training Method | Cleaning Time | Hygiene (ATP-B) | Perceived Effectiveness |

|---|---|---|---|

| No Instruction | Fastest | Highest fail | Least effective |

| Written Instruction | Slower | Lower pass rate | Often not followed |

| Demonstration | Improved | Better hygiene | More effective |

| Written + Demonstration | Best | Best hygiene | Most effective |

If you use the blade wrong or do not clean it well, you can spread germs like Salmonella and Staphylococcus. Always clean your slicer every four hours and after each shift. Use the right cleaning products and follow all safety steps. If you want to sharpen a meat slicer blade, use the built-in sharpener or follow the maker’s guide.

Tip: Good training and regular cleaning keep your team and your food safe.

Picking the best slicing blade for your factory depends on what you slice, how much you make, and the quality you want. You need to choose a blade style and material that fits your product. Custom blades can help you work faster and reach your goals. If you want expert help or a custom blade, you can contact a Nanjing Metal sales engineer. Make your slicing better for the best results.

Câu hỏi thường gặp

What is the best blade type for slicing frozen meat?

You should use a serrated or toothed blade for frozen meat. This type grips and cuts through hard surfaces easily. Serrated blades help you get clean slices without slipping.

How often should you replace industrial slicer blades?

You need to check your blade’s sharpness daily. Replace it when you see dull edges or uneven cuts. High-volume factories may need new blades every few weeks.

Can you use the same blade for meat and cheese?

You can use one blade for both, but you should clean it well between uses. For best results, use a smooth blade for cheese and boneless meats. This helps you get even slices.

Where can you get custom industrial slicer blades?

You can order custom blades from a trusted manufacturer like Nanjing Metal. This company has 20 years of experience making industrial machine blades for many industries.

How do you contact a sales engineer for more help?

You can contact a Nanjing Metal sales engineer for expert advice or to request a custom blade. They will help you choose the right solution for your needs.

Xem thêm

Cách chọn vật liệu và hình dạng lưỡi cắt của lưỡi máy cắt thịt

Microserrated Circular Meat Cutting Bladvà

How to Choose the Right Circular Slitter Blades for Long-Lasting Performance